DOI:10.11817/j.ysxb.1004.0609.2020-39437

原位自生TiB2/Al复合材料的组织与力学性能

李永飞,黄礼新,王立生,刘春海

(中信戴卡股份有限公司, 秦皇岛 066011)

摘 要:采用钛盐与硼盐反应法成功制备原位自生TiB2/纯Al复合材料。利用扫描电子显微镜、透射电子显微镜和拉伸试验机研究不同粒子含量(质量分数为1%、2%和3%)对复合材料组织和力学性能的影响。结果表明:原位生成的TiB2粒子有矩形、近圆形和六边形三种形貌,尺寸为200~500 nm;粒子与Al基体界面洁净无反应层。随着粒子含量的增加,复合材料的强度随之升高,而伸长率则随之降低;当TiB2含量为3%时,屈服强度和抗拉强度分别达到78.1 MPa和102 MPa,相比于纯Al分别提高58%和43%,而伸长率降至32.5%,下降了24%。断口分析表明:随着TiB2粒子含量的增加,粒子团聚机率增加,在拉伸过程中,裂纹在粒子团聚处萌生并扩展,导致材料的塑性降低。

关键词:复合材料;TiB2颗粒;力学性能;组织

文章编号:1004-0609(2020)-01-0033-07 中图分类号:TG146.21 文献标志码:A

颗粒增强铝基复合材料具有低密度、高比刚度、高比强度、低膨胀、高导热、高可靠性以及抗冲击等特点,在航空航天、武器装备、交通运输、精密仪器等领域具有非常广泛的应用需求[1-8]。与外加法相比,原位自生法具有增强粒子尺寸细小、分布均匀、界面洁净、粒子与基体的结合强度高等优势,且基体合金的韧塑性牺牲较小[9-10]。在现有的原位合成工艺中,熔盐反应法[11]制备铝基复合材料由于工艺简单、成本低、易于批量化生产,得到广泛关注和研究。同时,与TiC、Al2O3、SiC等增强粒子相比,TiB2具有高熔点、高硬度、高弹性模量,优良的耐腐蚀和耐磨性能,与基体润湿良好且不发生反应等特点[12-13],使得原位自生TiB2增强铝基复合材料成为研究的热点。

目前,国内外针对熔盐反应法制备TiB2颗粒增强铝基复合材料的研究主要集中在颗粒形成的反应过程、制备工艺改进及TiB2增强不同体系铝合金的组织和性能。例如,CHEN等[14-15]报道了重熔稀释法制备TiB2增强铝基复合材料的工艺;HAN等[16]采用超声辅助工艺制备TiB2增强铝基复合材料,在降低反应温度的同时改善了粒子的团聚状态;WANG等[17]详细研究了TiB2粒子含量对TiB2/A356复合材料组织、性能的影响。然而,对于TiB2/纯Al(表示为TiB2/Al,下同)复合材料的组织、性能及界面等缺乏系统研究。TiB2/Al复合材料的系统研究对于TiB2增强不同体系铝合金的研究具有借鉴意义。为此,本文以熔盐反应法制备的TiB2/Al复合材料为对象,利用扫描电子显微镜(SEM)和透射电子显微镜(TEM)系统地研究了增强粒子的形貌、分布及与基体的界面结合状况。同时研究了复合材料组织和力学性能随粒子含量的变化 规律。

1 实验

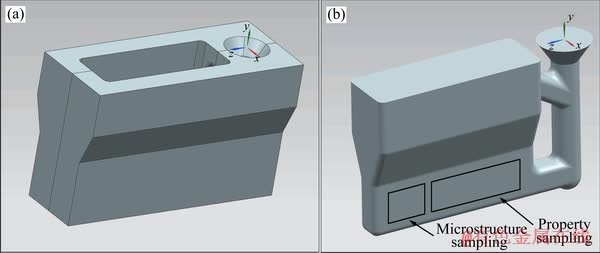

实验采用原材料纯度为99.7%(质量分数)的工业纯铝锭,纯度均为99.0%的颗粒状氟硼酸钾和氟钛酸钾。将纯铝锭在电阻炉中熔化并过热至850 ℃后,加入按TiB2化学计量比混合均匀并烘干处理的氟硼酸钾和氟钛酸钾,混合盐与铝液反应1.5 h后去除表面残盐,待熔体温度降至740 ℃后加入精炼剂,并用石墨搅拌器搅拌除气5 min,扒除表面残渣后,将合金熔液浇入事先预热的金属型模具中(见图1(a)),浇注温度为710 ℃。由此制得TiB2质量分数分别为1%、2%和3%的TiB2/Al复合材料。同时,在相同实验条件下制备纯Al试样作为对比。

按图1(b)所示切取试样用于组织观察和力学性能测试。金相观测样品经打磨、抛光后用0.5%(体积分数)的HF水溶液腐蚀2 min。采用型号为Zeiss EVO MA15的SEM进行组织观察。用线切割在试样底部切取长、宽为10 mm,厚度为1 mm的薄片用于粒子萃取和TEM样品制备。将切取的薄片浸入盛有15%(体积分数)HCl水溶液的烧杯中放置48 h,期间补充HCl溶液,确保样片与HCl充分反应,最后将烧杯底部的沉淀物反复清洗后烘干。由于TiB2可以在HCl溶液中稳定存在,而其他化合物如Al3Ti则被HCl完全溶解,因此可以确保沉淀物均为TiB2粒子。TEM样品是将薄片打磨至40 μm后,冲样器冲取直径为3 mm的圆片,用Gatan PIPS691型离子减薄仪对其进行减薄处理。采用JEOL 2100F型TEM对TiB2粒子形貌和复合材料的显微组织进行观察。参照GB/T 228.1—2010标准制备直径为6 mm拉伸试样,采用Zwick/Roell Z100型电子万能试验机进行室温拉伸性能测试,每种成分取6组拉伸试样,然后取其平均值。

2 结果与分析

2.1 TiB2/Al复合材料中TiB2粒子的形貌

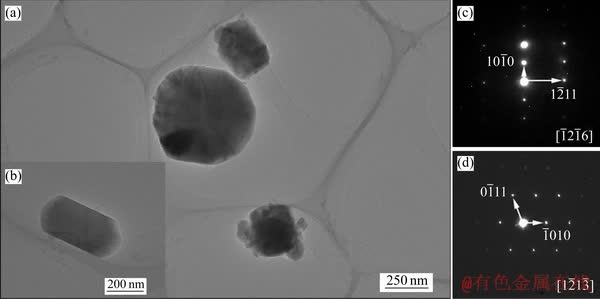

图2所示为萃取粒子的TEM像。由TEM明场像(见图2(a)和(b))可以看出,粒子具有矩形、近圆形和六边形三种形貌,粒子大小为200~500 nm。选区电子衍射(见图2(c)和(d))分析表明,萃取物为具有六方结构的TiB2粒子,晶格常数为a=0.301 nm、c=0.281 nm。在TEM明场像中可以清楚地看到矩形和六边形粒子的棱角圆钝,这对避免应力集中提高材料的力学性能有利。

图1 实验用金属型模具及浇注试样示意图

Fig. 1 Schematic diagram of experimental metallic mould(a) and corresponding casting sample(b)

图2 萃取颗粒的TEM明场像与选区电子衍射谱

Fig. 2 TEM bright field images of extraction particles((a), (b)) and corresponding selected area electron diffraction patterns((c), (d))

2.2 TiB2/Al复合材料的显微组织

图3所示为复合材料的SEM像。从图3可以看出,TiB2粒子的引入可以显著细化基体合金,且随着粒子含量的增加,细化效果愈加显著。由于凝固界面前沿对粒子的排斥作用,使得TiB2粒子倾向于沿着晶界弥散分布,只有极少部分的TiB2粒子被基体吞噬。原位生成的TiB2粒子由于尺寸较小、比表面积大,因此界面能高,沿晶界分布的TiB2粒子会彼此吸附。从图3(b)、(d)、(f)可以看出,晶界处TiB2粒子呈带状分布,机械搅拌处理未能对粒子的这种分布状态起到很好地改善作用。随着粒子含量的增加,晶界处粒子团聚及缺陷的数量增多。如图3(f)所示,当粒子含量为3%时,Al基体中出现了未反应完全的残盐,同时,粒子团聚的数量增多,尺寸增大,合金中的气孔等缺陷增多。这是由于随着混合盐加入量的增加,原位反应过程中界面反应层生成的粒子增多,粒子碰撞的机率增加,生成粒子的团聚和对气体的吸附倾向也随之增加。

图4所示为3%TiB2/Al复合材料的TEM像。从TEM明场像(见图4(a))和EDS结果(见图4(b)、(c))可以看出,尺寸为200~300 nm,具有矩形和六边形形貌的TiB2粒子分布在铝基体中,在其周围团聚分布着尺寸更小的TiB2粒子。TiB2粒子与Al基体界面的高分辨图像如图4(d)和(e)所示。从快速傅立叶逆变换(IFFT)(见图4(d)和(e)中插图)结果可以更清晰地看出Al基体与TiB2结合良好,界面洁净没有反应层。

2.3 TiB2/Al复合材料的力学性能

图5所示为纯Al与TiB2/Al复合材料的力学性能。从图5可以看出,复合材料的屈服和抗拉强度随着TiB2粒子含量的增加而增加,材料的伸长率则随着粒子含量的增加而降低。当粒子含量为3%时,屈服强度和抗拉强度分别达到78.1 MPa和102 MPa,与纯Al相比分别提高58%和43%,而伸长率则降至32.5%,下降24%。

图3 不同TiB2含量TiB2/Al复合材料的SEM像

Fig. 3 SEM images of TiB2/Al composites with different TiB2 mass fractions

图4 3%TiB2/Al复合材料的TEM明场像、EDS能谱结果与高分辨图像

Fig. 4 TEM bright field images of 3%TiB2/Al composite (Inset images are inverse fast fourier transform images)

复合材料的强化效果主要取决于基体强度和粒子与基体界面结合强度的匹配关系[18]。在TiB2/Al复合材料中,TiB2粒子可以显著细化晶粒,弥散分布的TiB2粒子对基体具有细晶强化作用。晶粒尺寸与屈服强度增量的关系可用Hall-Petch公式[13, 19-20]表示为

(1)

(1)

式中:d和d0分别为复合材料和纯Al的晶粒直径;k为Hall-Petch斜率,与基体合金有关。

由式(1)可以看出,晶粒尺寸d越小,材料的强度提高越明显。根据Orowan强化[21-22]机制,拉伸过程中弥散分布的TiB2粒子可以有效地阻止基体中位错的运动。由于TiB2的弹性模量高达550 GPa[18],因此,位错倾向于绕过TiB2粒子,在粒子周围形成位错环,生成的位错环将使下一根位错线通过此处时变得困难,从而提高材料的强度。同时,TiB2粒子与基体合金热膨胀系数的差异导致TiB2粒子周围位错密度增殖[17],位错与粒子以及与Orowan强化引起的位错环交互作用,引起材料的形变强化。本研究中原位生成的TiB2粒子与基体结合良好,弥散分布的粒子可有效地承载外加载荷,对复合材料起到强化作用。综上可知,细晶强化、Orowan强化、热膨胀系数差异引起的强化以及载荷承载效应共同作用,使得TiB2/Al复合材料的强度得到显著提升。

图5 TiB2含量对TiB2/Al复合材料力学性能的影响

Fig. 5 Effect of TiB2 contents on mechanical properties of TiB2/Al composites

图6 纯Al及TiB2/Al复合材料的拉伸断口形貌

Fig. 6 Tensile fracture morphologies of pure Al and TiB2/Al composites

图6所示为纯Al及复合材料拉伸试样断口形貌的SEM像。从图6(a)可以看出,纯Al试样的断口中存在大量椭圆形的剪切韧窝,基体中可见大量的滑移带。在拉伸过程中,材料微区发生塑性变形并以夹杂物为质点形成显微孔洞,随着载荷的增加,显微孔洞逐渐聚集并长大,达到临界尺寸后孔洞将相互连接而导致材料的断裂。此时,Al基体的塑性变形程度取决于显微孔洞的生长范围。由图6(b)所示,Al基体中引入TiB2粒子后,韧窝变浅直径变大且数量增加,韧窝由椭圆形变为等轴状,表明材料的塑性变差。韧窝均匀地分布在基体中,在韧窝底部可见TiB2粒子,这表明粒子与Al基体具有较高的界面强度。如图6(b)、(c)、(d)所示,随着TiB2含量的增加,复合材料断口中韧窝变浅,TiB2粒子团聚现象严重,且缺陷增多。在外加载荷作用下,在粒子团聚处产生应力集中,由于粒子间的结合强度较低,裂纹将首先在此处萌生并扩展,导致材料的塑性降低。

3 结论

1) 采用熔盐反应法制备出粒子含量分别为1%、2%和3%的TiB2/Al复合材料。TEM分析结果显示,TiB2粒子具有矩形、近圆形和六边形这3种形貌,粒子大小为200~500 nm。粒子与基体结合良好,界面洁净无反应层。

2) TiB2粒子对基体具有细化作用,且细化效果随粒子含量的增加而愈加显著。

3) 原位生成的TiB2粒子强化效果显著,复合材料的强度随粒子含量的增加而升高,伸长率则随之降低。粒子含量为3%时,复合材料的屈服强度和抗拉强度分别达到78.1 MPa和102 MPa,与基体相比分别提高58%和43%。

4) TiB2/Al复合材料的断口呈韧性断裂特征,随着TiB2的增多,粒子团聚现象加剧,裂纹倾向于在团聚处萌生、扩展,材料的塑性降低。

REFERENCES

[1] ZHANG Yi-jie, MA Nai-heng, WANG Hao-wei, LE Yong-kang, LI Xian-feng. Damping capacity of in situ TiB2particulates reinforced aluminium composites with Ti addition[J]. Materials and Design, 2007, 28(2): 628-632.

[2] JAYALAKSHMI S, GUPTA S, SANKARANARAYANAN S, SAHU S, GUPTA M. Structural and mechanical properties of Ni60Nb40amorphous alloy particle reinforced Al-based composites produced by microwave-assisted rapid sintering[J]. Materials Science and Engineering: A, 2013, 581: 119-127.

[3] 潘利科, 韩建民, 张颖骁, 杨智勇, 李志强, 李卫京. 高含量SiCp/A356复合材料衍生材料的组织与性能[J]. 中国有色金属学报, 2016, 26(10): 2078-2085.

PAN Li-ke, HAN Jian-min, ZHANG Ying-xiao, YANG Zhi-yong, LI Zhi-qiang, LI Wei-jing. Microstructure and properties of derived material for high content SiCp/A356 composites[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2078-2085.

[4] TJONG S C, MA Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites[J]. Material Science and Engineering R, 2000(3/4): 49-113.

[5] 林雪冬, 刘昌明, 吕循佳, 郝旭红. 离心铸造初生Si及Si/MgSi2颗粒增强铝基复合材料的组织与性能[J]. 中国有色金属学报, 2013, 23(3): 695-698.

LIN Xue-dong, LIU Chang-ming, Lü Xun-jia, HAO Xu-hong. Structures and properties of aluminum matrix composite reinforced by primary Si and Si/Mg2Si particles fabricated by centrifugal casting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 695-698.

[6] KUMAR S, SARMA V S, MURY B S. Influence of in situ formed TiB2particles on the abrasive wear behaviour of Al-4Cu alloy[J]. Materials Science and Engineering A, 2007, 465: 160-164.

[7] YI Hong-zhan, MA Nai-heng, ZHANG Yi-jie, LI Xian-feng, WANG Hao-wei. Effective elastic moduli of Al-Si composites reinforced in situ with TiB2 particles[J]. Scripta Materialia, 2006, 54: 1093-1097.

[8] OZDEN S, EKICI R, NAIR F. Investigation of impact behavior of aluminium based SiC particle reinforced metal-matrix composites[J]. Composites A, 2007, 38: 484-494.

[9] EMAMY M, MAHTA M, RASIZADEH J. Formation of TiB2particles during dissolution of TiAl3in Al-TiB2metal matrix composite using an in situ technique[J]. Composites Science and Technology, 2006, 66(7/8): 1063-1066.

[10] LAKSHMI S, LU L, GUPTA M. In situ preparation of TiB2reinforced Al based composites[J]. Journal of Materials Processing Technology, 1998, 73(1/3): 160-166.

[11] DAVIES P, KELLIE J L F, WOOD J V. Development of cast aluminium MMC’S[J]. Key Engineering Materials, 1992, 77/78: 357-362.

[12] SURESH S, SHENBAGA VINAYAGA MOORTHI N. Aluminium-titanium diboride (Al-TiB2) metal matrix composites: Challenges and opportunities[J]. Procedia Engineering, 2012, 38: 89-97.

[13] CHEN Fei, CHEN Zong-ning, MAO Feng, WANG Tong-min, CAO Zhi-qiang. TiB2 reinforced aluminum based in situ composites fabricated by stir casting[J]. Materials Science and Engineering A, 2015, 625: 357-368.

[14] CHEN Zong-ning, WANG Tong-min, ZHENG Yuan-ping, ZHAO Yu-fei, KANG Hui-jun, GAO Lei. Development of TiB2 reinforced aluminum foundry alloy based in situ composites—Part Ⅰ: An improved halide salt route to fabricate Al-5wt%TiB2 master composite[J]. Materials Science and Engineering A, 2014, 605: 301-309.

[15] WANG Tong-min, CHEN Zong-ning, ZHENG Yuan-ping, ZHAO Yu-fei, KANG Hui-jun, GAO Lei. Development of TiB2 reinforced aluminum foundry alloy based in situ composites—Part Ⅱ: Enhancing the practical aluminum foundry alloys using the improved Al-5wt%TiB2 master composite upon dilution[J]. Materials Science and Engineering A, 2014, 605: 22-32.

[16] LIU Zhi-wei, RAKITA M, XU W, WANG Xiao-ming, HAN Qing-you. Ultrasound assisted salts-metal reaction for synthesizing TiB2 particles at low temperature[J]. Chemical Engineering Journal, 2015, 263: 317-324.

[17] WANG Ming-liang, CHEN Dong, CHEN Zhe, WU Yi, WANG Fei-fei, MA Nai-heng, WANG Hao-wei. Mechanical properties of in-situ TiB2/A356 composites[J]. Materials Science and Engineering A, 2014, 590: 246-254.

[18] 乐康永, 张亦杰, 陈 东, 马乃恒, 王浩伟. 原位合成A356/TiB2复合材料的微观组织及力学行为[J]. 稀有金属材料与工程, 2006, 35(10): 1635-1638.

LE Kang-yong, ZHANG Yi-jie, CHEN Dong, MA Nai-heng, WANG Hao-wei. Microstructure and mechanical properties of in situ A356/TiB2 composites[J]. Rare Metal Materials and Engineering, 2006, 35(10): 1635-1638.

[19] PETCH N. The cleavage strength of polycrystals[J]. Journal of the Iron and Steel Institute, 1953, 174(1): 25-28.

[20] ZADEH A S. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect[J]. Materials Science and Engineering A, 2012, 531: 112-118.

[21] OROWAN E. Symposium on internal stresses in metals and alloys[M]. London: Institute of Metals, 1948: 451.

[22] ZHANG Z, CHEN D L. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength[J]. Scripta Materilia, 2006, 54(7): 1321-1326.

Microstructure and mechanical properties of in-situ TiB2/Al composites

LI Yong-fei, HUANG Li-xin, WANG Li-sheng, LIU Chun-hai

(CITIC Dicastal Co., Ltd., Qinhuangdao 066011, China)

Abstract: The in-situ TiB2/pure Al composites were fabricated successfully by titanium salt and boron salt reaction process. The influences of TiB2 contents (1%, 2% and 3%, mass fraction) on microstructure and mechanical properties were studied by scanning electronic microscopy, transmission electronic microscopy and tensile test machine. The results show that the morphologies of TiB2 particles present in rectangular, nearly rounded and hexagonal with the size of about 200-500 nm. And the interface between TiB2 particles and Al matrix is clean. Tensile test results indicate that the strength significantly increases while the elongation decreases with the increasing of TiB2 particles. The yield strength (YS) and ultimate tensile strength (UTS) of TiB2/pure Al composite at 3% TiB2 particles reach 78.1 MPa and 102 MPa, respectively, while the elongation reduces to 32.5%. The composite has achieved 58% and 43% improvement, respectively, in YS and UTS with respect to pure Al, while compromising 24% in ductility. The fractography reveals that agglomerations happen severely with increasing the TiB2 particles amounts, and the crack propagation tends to begin from the agglomerations, which leads to the decreasing of ductility.

Key words: composites; TiB2 particles; mechanical property; microstructure

Foundation item: Project(17211008D) supported by the Program of Science and Technology of Hebei Province, China

Received date: 2019-01-04; Accepted date: 2019-05-06

Corresponding author: LIU Chun-hai; Tel: +86-335-5358286; E-mail: liuchunhai@dicastal.com

(编辑 龙怀中)

基金项目:河北省省级科技计划项目(17211008D)

收稿日期:2019-01-04;修订日期:2019-05-06

通信作者:刘春海,正高级工程师;电话:0335-5358286;E-mail:liuchunhai@dicastal.com