文章编号: 1004-0609(2004)10-1723-06

(Al2O3+TiB2)/ZL202复合材料的制备和力学性能

赵德刚1, 刘相法1, 边秀房1, 刘相俊1, 张永昌2

(1. 山东大学 材料液态结构及其遗传性教育部重点实验室, 济南 250061; 2. 临沂恒源热电有限公司, 临沂 276000 )

摘 要: 采用原位熔体反应合成法制备了(Al2O3+TiB2)/ZL202复合材料。 用电子探针对复合材料的微观组织进行观察。 结果表明: 增强相TiB2颗粒主要分布于晶界上, 与CuAl2相交织在一起, 尺寸在1μm左右, 呈现圆球形, Al2O3颗粒约在3μm左右, 呈现规则的颗粒或圆球状, 且彼此分离, 界面干净。 对铸态复合材料室温抗拉强度和硬度的测试发现, 两相颗粒增强的复合材料都较单一颗粒增强复合材料要高。 经过T6处理后, (Al2O3+TiB2)/ZL202复合材料的抗拉强度由221.0MPa提高至339.6MPa, 提高幅度达53.67%, 其延伸率降低至2.60%。

关键词: 原位合成; 金属基复合材料; 力学性能; TiB2; Al2O3; 颗粒 中图分类号: TB331

文献标识码: A

Fabrication and mechanical properties of (Al2O3+TiB2)/ZL202 composites

ZHAO De-gang1, LIU Xiang-fa1, BIAN Xiu-fang1, LIU Xiang-jun1, ZHANG Yong-chang2

(1. The Key Laboratory of Materials Liquid Structure and Heredity, Ministry of Education, Shandong University, Jinan 250061, China;

2. Linyi Hengyuan Thermoelectricity Co. LTD, Linyi 276000, China)

Abstract: Fabrication technology of (Al2O3+TiB2)/ZL202 composites by in-situ reaction synthesis process was fabricated. The electron probe microanalyses of the composites reveal that TiB2 particles distribute along the grain boundaries, which interweave with CuAl2 phases. TiB2 particle is about 1μm in size, with nearly spherical form. Al2O3 particles are about 3μm in size, which are separated and its interfaces are clean. From the results of hardness tests and tensile experiments at room temperature, it is found that the hardness of the composites reinforced cooperatively by both TiB2 and Al2O3 is obviously higher than that of composites reinforced by one kind of particle. After T6 treatment, the tensile strength of (Al2O3+TiB2)/ZL202 composite increases from 221.0MPa to 339.6MPa, which is raised by 53.67%. The ductility of composites is 2.60%.

Key words: in-situ reaction; metal matrix composites; mechanical properties; TiB2; Al2O3; particles

近年来, 对以Al2O3、 TiC、 SiC等颗粒为增强相的金属基复合材料的研究逐渐增多, 但大部分是单一增强相[1-3], 制备方法多采用液-气反应[4]、 液-固反应[5]、 液-液反应[6]、 混合盐反应[7]、 直接氧化法[8]、 自蔓延高温合成法[9]、 离子反应合成法[10]等, 而对于两相或多相颗粒增强[11, 12]的金属基复合材料国内外研究尚不多。 本文作者主要研究通过熔体原位反应的方法制备Al2O3、 TiB2两相颗粒协同增强的Al-Cu基复合材料, 并对其微观组织和力学性能作了探讨性研究。

1 实验

1.1 制备工艺

首先制备基体Al-Cu合金, 为便于设计复合材料的成分, 采用含铜量在9%~11%的二元合金ZL202为基体合金。 在中频感应炉中, 将基体合金ZL202熔化并过热至870℃左右, 将按 TiB2的化学计量比(x(Ti)∶x(B)=1∶2)配好的KFB4, K2TiF6混合盐混合均匀, 用铝箔包好加入到铝合金基体熔体中, 用石墨棒充分搅拌, 待反应完毕后将熔渣倒出, 然后降低熔体温度至730℃左右, 再将一定量混合均匀的CuO粉、 Al粉用铝箔包好加入到熔体中, 待完全反应后保温15min左右, 加入DSG-3精炼剂进行精炼和除气, 在700℃左右将合金液浇入抗拉试样模具中, 即制备出Al2O3、 TiB2两相颗粒增强Al-Cu基复合材料, 同时对部分试样进行T6处理。

1.2 实验原理

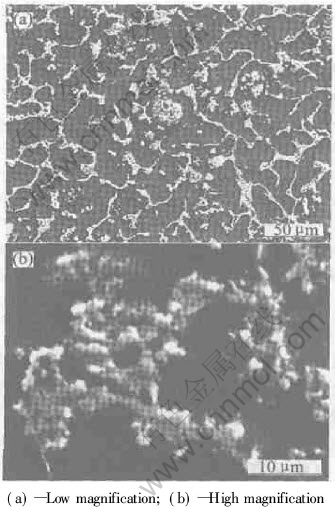

加入的KFB4、 K2TiF6混合盐之间发生原位反应生成TiB2颗粒, 反应如下:

反应(2)还形成了TiAl3颗粒, 但是TiB2颗粒比TiAl3稳定, 只有在适当的动力学条件下, TiAl3 相才会出现在最终的复合材料凝固组织中, 否则TiAl3会发生分解, 与熔体中的B反应形成更稳定的TiB2颗粒。 本实验严格控制Ti与B的比例, 抑制了TiAl3的生成[13]。

另外, 第2次加入的CuO粉与Al粉发生反应:

反应(3)的标准吉布斯能为: ΔG0=-1186970+38.33T, 在730℃时, 该反应的吉布斯能为-1148371.7kJ/mol, 故反应能够自发进行, 同时反应生成的Cu也正好熔于基体中作为合金的一种元素。 但该反应非常剧烈, 故加入过量Al粉以起到稀释剂的作用, 且并不引入其他杂质。

2 结果与分析

2.1 复合材料的相分析

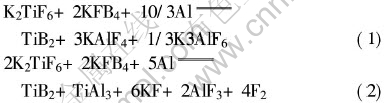

图1所示为(Al2O3+TiB2)/Al-Cu复合材料的X射线衍射谱。 对XRD谱的物相分析结果表明: 图中存在Al、 CuAl2、 TiB2、 Al2O34种相, 没有TiAl3的衍射峰, 也没有出现其他可分辨的衍射峰, 说明通过原位反应法制备了TiB2、 Al2O3两相颗粒协同增强的Al-Cu基复合材料。

图1 Al-Cu基复合材料的X射线衍射谱

Fig.1 XRD pattern of Al-Cu matrix composites

2.2 复合材料的微观结构

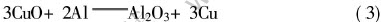

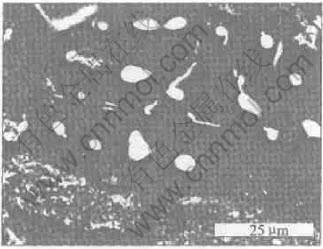

图2所示为复合材料的微观组织。 可见, θ-CuAl2相呈现出间断的枝晶状, 不连续的θ相构成了较为明显的网状结构, 将基体分割为小块状, 原位生成的Al2O3颗粒多集中在θ相周围, 有些甚至在θ相上分布, 而增强颗粒大部分集中在晶粒的边界处, 并且多呈现聚集团簇状。 这主要是由于TiB2粒子的导热系数与合金的导热系数之比小于1, 根据颗粒增强金属基复合材料凝固时颗粒分布的热传导依据, 粒子将被固液界面所排斥, 这就导致TiB2颗粒多集中于晶粒的晶界处, 至于TiB2 颗粒存在聚集现象的原因应该与Al-Si合金基体的复合材料中发现的TiB2颗粒存在偏聚现象[14]的原因类似, 都是小部分TiB2颗粒在基体合金的凝固过程中被α-Al的结晶前沿推到边界处而造成的局部聚集现象。

图2 (Al2O3+TiB2)/Al-Cu复合材料的SEM像

Fig.2 SEM images of (Al2O3+TiB2)/Al-Cu composites

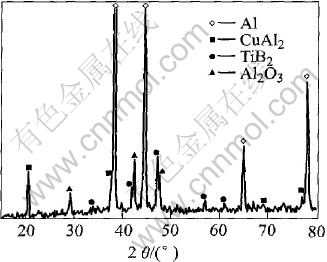

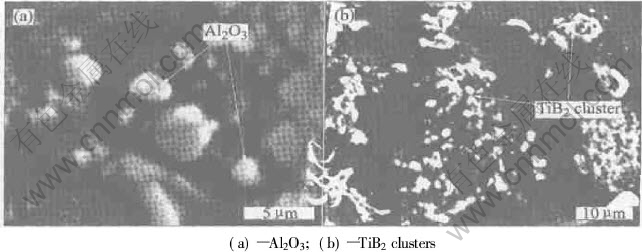

图3所示为Al2O3颗粒和TiB2团簇形貌的SEM形貌。 可以看出, 通过原位反应生成的Al2O3颗粒约在3μm左右, 呈规则颗粒或圆球状, 且彼此分离, 基本上没有出现粘连或者聚集现象, 其界面上较为干净, 没有其他夹杂物。 而单个的TiB2大都在1μm左右, TiB2团簇多与θ相交织在一起, 共同分布在α-Al晶界周围。

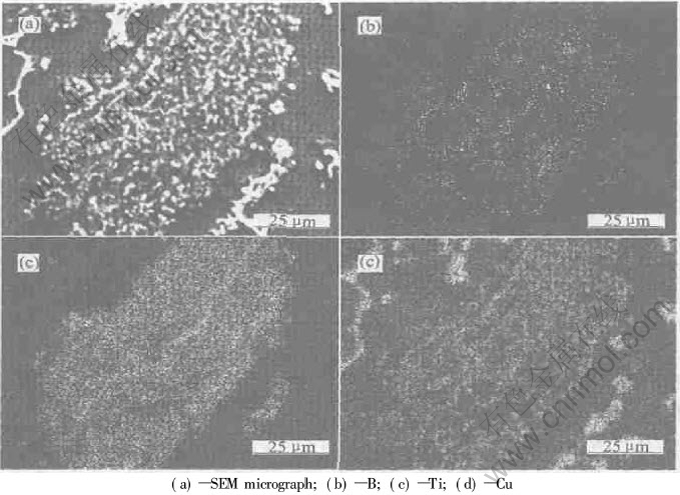

另外从图3中还发现在晶粒中间存在着尺寸大小从5~6μm到几十微米不等的不同于TiB2团簇的大型团簇, 大团簇元素面分布的电子探针结果如图4所示。 可以看出, 大型团簇由一些尺寸在1μm以下的小颗粒紧密排列组成, 占据整个晶粒的大半部分, 元素的面扫描显示大型团簇主要包含B、 Ti、 Cu3种元素, 并没有K、 F等杂质元素。 亚微米级的小颗粒可能为Al、 Ti、 Cu元素组成的三元过渡相。 作者认为这些过渡相的形成原因是铝热反应(3)中置换出来的活性铜原子迅速与熔体中的Ti、 Al结合而成, 如果制备时保温时间继续延长, 这些过渡相会逐步分解(由团簇尺寸的大小不一可以看出), 并最终会聚集在α-Al晶界处形成θ相和TiAl3相。 当然不排除是两相CuAl2和TiB2混合, 关于这一点, 还有待于实验的进一步证实。

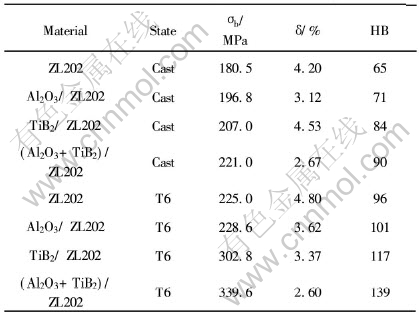

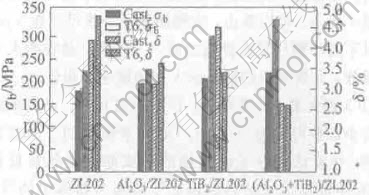

2.3 复合材料的力学性能

为对比所制备的(TiB2+Al2O3)/ZL202复合材料(颗粒含量的质量分数分别为2%Al2O3、 2%TiB2)的力学性能, 同时制备了基体相同的单一Al2O3颗粒及单一TiB2颗粒增强的复合材料, 其中各种增强相含量与(TiB2+Al2O3)/ZL202复合材料中颗粒含量是相同的, 然后测试了室温和T6处理后其硬度以及拉伸性能, 测试结果如表1和图5所示。 由表中数据可看见, 单一Al2O3 和TiB2颗粒增强的ZL202复合材料铸态下其抗拉强度和硬度值都得到不同程度的提高, 其最大抗拉强度分别提高9.03%和14.68%, 而两相颗粒协同增强的ZL202复合材料铸态下其最大抗拉强度达到220MPa, 比基体的180.5 MPa提高了22.44%, 其布氏硬度值则提高了38.46%, 也远远超过单一颗粒增强的复合材料, 另外, (TiB2+Al2O3)/ZL202复合材料的塑性较低, 延伸率只有2.67%。

T6处理后各种复合材料的强度都得到了不同程度的提高(图5), 其中 (TiB2+Al2O3)/ZL202复合材料的最大抗拉强度和硬度值在T6处理后分别增长了53.67%和54.44%, 远远高于基体ZL202和单一Al2O3和TiB2颗粒增强的ZL202复合材料在热处理后抗拉强度和硬度的增长率, 而其延伸率变化不明显。

Al2O3、 TiB2颗粒的加入提高了材料铸态的抗拉强度, 这应该从以下几个方面来考虑:

首先材料中引入了弥散分布的第二相TiB2和

Al2O3颗粒阻碍了位错的运动, 根据Orowan模型, 第二相粒子对位错产生钉扎力, 位错运动时需要克服的临界切应力为

式中 L为硬粒子间距; G为基体切变模量; b为柏氏矢量; R为粒子半径; *为位错脱离粒子时的临界角度。

由此可见, 第二相粒子越小, 分布越均匀, 间距越小, 复合材料的力学性能就越高。 本研究所制备的复合材料TiB2颗粒在尺寸1μm左右, Al2O3颗粒在尺寸3μm左右, 分布较为均匀, 故强化效果明显。

图3 复合材料中Al2O3颗粒和TiB2团簇的SEM形貌

Fig.3 SEM morphology of Al2O3 reinforcement and TiB2 clusters in composites

图4 (Al2O3+TiB2)/ZL202复合材料的电子探针分析

Fig.4 EPMA analysis of (Al2O3+TiB2)/ZL202 composites

表1 复合材料的力学性能

Table 1 Mechanical properties of composites

图5 T6处理前、 后复合材料的力学性能

Fig.5 Mechanical properties of composites before and after T6 heat treatment

其次是由于加入TiB2颗粒使得晶粒细化[15]。 根据Hall-Petch关系σy=σ0+kd-1/2, 其中σy为材料屈服强度; σ0等于单晶体金属的屈服强度; d为晶粒的平均直径; k为表征晶界对强度影响程度的常数, 由于晶粒变小而使得材料的屈服强度得到提高。 另外, 由于TiB2和Al2O3颗粒的热膨胀系数分别为6.39×10-6和6.8×10-6 K-1, 与Al基体的热膨胀系数差别较大, 由于热配错应力的原因, 颗粒周围形成高密度的位错区, 而根据Arsenault等的研究[16], 由粒子周围高密度位错引起的位错增强为

式中 ρ为位错密度; G为基体切变模量; α为小于1的常数。

而ρ与基体合金和增强相热膨胀系数之间存在的关系为

式中 φf为增强体的体积分数; d为增强颗粒直径; αmαf分别为基体合金与TiB2粒子的热膨胀系数; ΔT为温度变化。

由此可见, 在增强相周围由于高密度的位错会引起诱导屈服增强, 这也有利于强化基体合金。

经T6处理后, (TiB2+Al2O3)/ZL202复合材料强度和硬度提高的主要原因在于固溶处理引起的沉淀强化与增强相TiB2粒子和Al2O3颗粒起到的弥散强化共同作用。 经过热处理过程中的加热和保温阶段的时效处理后, 复合材料原先组织中呈现尖角状的CuAl2相在热处理加热保温阶段时固溶到基体组织中, 在随后的时效过程中又以弥散相的形式析出, 且会呈现出圆球状或者短杆状(如图6所示), 短杆状或圆球状的CuAl2相不再像热处理前呈现针尖状对基体还产生一定的不利影响, 而是对复合材料产生了一定的强化作用, 这样热处理后Cu元素的固溶析出强化机制与TiB2, Al2O3颗粒引起的弥散强化机制共同作用从而大大提高了复合材料材料的力学性能。

图6 T6处理后(Al2O3+TiB2)/ZL202复合材料的SEM像

Fig.6 SEM image of (Al2O3+TiB2)/ZL202 composites after T6 heat treatment

3 结论

1) 常压下, 采用原位反应与铸造工艺结合的方法制备了(TiB2+Al2O3)/ZL202复合材料, 增强相TiB2颗粒尺寸在1μm左右, 其团簇多与θ相交织在一起, Al2O3颗粒尺寸在3μm左右, 界面干净, 彼此分离。

2) Al2O3和TiB2颗粒的存在使材料的室温抗拉强度明显得到提高, 提高的幅度远远超过单一颗粒增强的复合材料。

3) 经T6处理后, (TiB2+Al2O3)/ZL202复合材料的抗拉强度由221.0MPa提高至339.6MPa, 提高幅度达53.67%, 其延伸率降低至2.60%。

REFERENCES

[1] 姜龙涛, 武高辉, 孙东立, 等. Al2O3p/Al复合材料中颗粒粒径与形态对组织和性能的影响[J]. 中国有色金属学报, 2002, 12(6): 516-520.

JIANG Long-tao, WU Gao-hui, SUN Dong-li, et al. Effect of particle size and morphology on microstructure and properties of Al2O3p/Al composites[J]. 2002, 12(6): 516-520.

[2] QIN Shu-yi, LIU Cheng, SUN Dong-li, et al. Micro-zone mechanical properties of SiCp/LD2 composites[J]. The Chinese Journal of Nonferrous Metal, 1999, 9(4): 748-751.

[3] Ibrahin I A. Particulate reinforced metal matrix composites: A review[J]. Mater Sci, 1991, 26(1): 1137-1156.

[4] Kiczak M J, Kumar K S. Formation of TiC in in-situ processed composites via liquid-gas reaction[P]. USA Patent 4880372, 1989-03-04.

[5] Odegard C, Bronson A. The reactive liquid processing of ceramic-metal composites[J]. 1997, 49 (6): 52-54.

[6] Subramanian R, Schneibel J H. Processing iron-aluminide composites containing carbides or borides[J]. JOM, 1997, 49(8): 50-55.

[7] Davies P, Shell J. Development of cast aluminum MMCs[J]. Key Engineering Materials, 1993, 77-78: 357-361.

[8] Rogers K A, Kumar P. The DCP method for fabricating dense oxide metal composites at modest temperatures with small dimensional changes[A]. Nagelberg A S. Processing Science and Advanced Ceramic[C]. Pittsburgh, USA: MRS, 1998. 275-282.

[9] Yang W C, Weatherly G C. A study of combusion synthesis of Ti-Al intermetallic compounds[J]. J Mater Sci, 1996, 31(14): 3707-3714.

[10]Koczak M J, Premkumark M K. Emerging technologies for the in-situ production of MMCs[J]. JOM, 1993, 162(1): 44-48.

[11] 吕维洁, 张小农, 张荻, 等. 原位合成TiC和TiB增强钛基复合材料的微观结构和力学性能[J]. 中国有色金属学报, 2000, 10(4): 163-168.

LU Wei-jie, ZHANG Xiao-nong, ZHANG Di, et al. Microstructure and mechanical properties of in situ synthesized (TiB+TiC)/Ti matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(4): 163-168.

[12] 王桂松, 耿林, 王德尊, 等. 反应热压(Al2O3+TiB2+TiAl3)/Al复合材料的组织形成机制[J]. 中国有色金属学报, 2004, 14(2): 228-232.

WANG Gui-song, GENG Lin, WANG De-zun, et al. Microstructure formation mechanism of (Al2O3 + TiB2 + Al3Ti) /Al composites fabricated by reaction hot pressing[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 228-232.

[13] HAN Yan-feng, LIU Xiang-fa. In situ TiB2 reinforced near eutectic Al-Si alloy composites[J]. Composite Part A, 2002, 33(8): 439-444.

[14] 方信贤, 孙国雄. 熔体直接反应生成TiB2/ZL101硅相形貌及变质剂效果的影响[J]. 铸造, 2000, 51(5): 272-275.

FANG Xin-xian, SUN Guo-xiong. Effect of TiB2 fabricated by direct reaction method on silicon morphology of ZL101 alloy and efficiency of modifier for ZL101 alloy[J]. Foundry, 2000, 51(5): 272-275.

[15] 赵芳欣, 张瑛洁, 尹绍奎, 等. 原位生成铸造TiB2/Al-Si复合材料的微观特征及弹性模量[J]. 铸造, 1998, 49(12): 13-16.

ZHAO Fang-xin, ZHANG Ying-jie, YIN Shao-kui, et al. Micro-feature and Youngs modulus of cast TiB2/Al-Si composite fabricated by in-situ reaction[J]. Foundry, 1998, 49(12): 13-16.

[16] Arsenault R J, Shi N. Dislocation generation due to differences between the coefficients of thermal expansion[J]. Mater Sci Eng A, 1986, 81(8): 175-187.

基金项目: 国家自然科学基金资助项目(50171037)

收稿日期: 2004-03-26; 修订日期: 2004-06-18

作者简介: 赵德刚(1981-), 男, 硕士研究生.

通讯作者: 刘相法, 教授, 博士; 电话:0531-8395414; 传真: 0531-8395414; E-mail: xfliu@sdu.edu.cn

(编辑 陈爱华)