文章编号: 1004-0609(2005)02-0270-07

6000系铝合金汽车板预时效及组织性能

刘 宏1, 2, 宋文举1, 赵 刚1, 刘春明1, 左 良1

(1. 东北大学 材料与冶金学院, 沈阳 110004; 2. 山东轻工业学院 机电工程学院, 济南 250100)

摘 要: 通过硬度、 拉伸和成形性实验及透射电镜、 扫描电镜、 能谱和金相分析, 研究了Mg、 Si和Mn含量的变化对6000系汽车板铝合金的显微组织、 力学性能及成形性的影响, 并探讨适宜的预时效处理工艺。 研究结果表明: 提高合金中的Mn含量, 可增加合金中不可溶结晶相及弥散相粒子的数量, 前者对合金的延伸率不利, 后者阻碍了合金固溶处理过程中的再结晶。 对于Si过剩的合金, 提高合金中Mg和Si的质量比和Mn含量会使其强度升高, 延伸率、 应变硬化指数、 塑性应变比和埃利克森值被降低。 合金板材固溶处理水淬后立即预时效, 较为适宜的预时效(固溶处理后立即在170℃下进行5~10min的短时预时效) 不仅能降低其自然时效的硬度, 而且能提高人工时效的硬化效果, 有利于车身构件的冲压成形和烤漆硬化能力的提高。

关键词: 6000系铝合金; 汽车板; 预时效; 硬度; 烤漆硬化 中图分类号: TG146.2

文献标识码: A

Pre-aging and microstructures properties on 6000 series aluminium alloys for automotive body sheets

LIU Hong1, 2, SONG Wen-ju1, ZHAO Gang, LIU Chun-ming1, ZUO-Liang1

(1. School of Materials and Metallurgy,

Northeastern University, Shenyang 110004, China;

2. School of Mechanical and Electrical Engineering,

Shandong Institute of Light Industry, Jinan 250100, China)

Abstract: Through transmission electron microscope, scan electron microscope, energy spectrum, metallograph analysis and hardness, tensile and formability tests, the effects of Mg, Si and Mn contents variation on the microstructures, tensile properties and formability of a few 6000 series aluminium alloys for automobile body sheets were investigated, the suitable pre-aging treatment technology was also researched. The results show that the number of insoluble constituents and dispersoid particles in alloys increase with increase of Mn content, the former is detrimental for the specific elongation of alloys, and the latter impedes recrystallization during solution treatment. For Si alloys excess, the strength is enhanced, and the specific elongation, strain hardening exponent, plastic strain ratio and Erichsen value, are decreased with Mg and Si mass ratio and Mn content increasing. Pre-aging of alloy sheets immediately after solution treatment and quenching can not only reduce the hardness of subsequently natural aging, but also enhance the hardening effect of following artificial aging, which is advantage to stampping formation and hardenability increasing during paint bake cycle. The suitable pre-aging treatment system is the short-time pre-aging at 170℃ for 5-10min immediately after solution treatment.

Key words: 6000 series aluminium alloys; automotive body sheets; pre-aging; hardness; paint bake hardenability

铝合金作为汽车板材料不断地应用于新车设计中以减轻其质量。 为利用汽车车身涂装烤漆加热工艺, 使合金时效强化, 并考虑合金的优点, 目前的研究主要集中在可时效硬化的6000系铝合金上[1-4]。 但T4状态的6000系铝合金板材冲压成车身构件后, 在170℃烤漆时, 由于烤漆时间较短(一般小于30min), 不仅不能发挥合金的时效硬化潜力, 而且还可能发生回归现象, 造成铝合金车身板经烤漆加热后不能获得时效强化[5-7]。 研究表明, Al-Mg-Si合金的预时效不仅能改变其析出特性, 而且对随后人工时效具有较大的影响[8-12]。 另外, 不同的合金组成对其时效析出以及组织和性能也会产生重要影响[13-15]。

本文作者通过研究几种6000系铝合金的显微组织、 力学性能及成形性, 探索预时效处理工艺, 为获得性能更好的汽车板铝合金材料以及为汽车厂供应合适状态的6000系铝合金车身板材提供依据。

1 实验

实验材料是以99.9%高纯铝、 电解铜、 工业纯镁、 高纯铁箔、 工业纯锌以及Al-9.5Si、 Al-9Mn、 Al-4Cr、 Al-3Ti(质量分数, %)等中间合金为原料, 在电阻坩埚炉中熔化, 并于水冷铜模中浇铸成尺寸为220mm 120mm 20mm的铸锭, 将铸锭切头铣面, 经470℃、 5h和540℃、 16h的双级均匀化处理后, 加热至430℃热轧成厚度为4.5mm的板料, 再经410℃、 1h中间退火, 最终冷轧成1.2mm厚的薄板。

按照GB/T5027-1999和GB/T5028-1999标准, 测应变硬化指数值n、 塑性应变比值r的试样分别从合金板材上与轧向成0°、 45°、 90°的三个方向截取, 其标距宽度和长度分别为12.5mm和50mm。 常规力学性能测定按板材纵向取样, 标距宽度和长度分别为10和45mm。 硬度和埃利克森值(IE)的测定分别采用20mm 20mm以及60mm 60mm的片状样品。 透射电镜试样是以1.2mm厚的薄板机械减薄至0.07mm后冲剪成d3mm的圆片, 再进行双喷电解减薄。 电解液为30%(体积分数)硝酸+70%(体积分数)甲醇混合液, 温度控制为-25~-20℃。

所有性能测试样品均进行540℃、 30min固溶水淬处理。 对其中用于测试力学性能、 n、 r和IE值的试样作T4(即固溶水淬后室温停留两周)处理, 硬度试样的处理分为3种情况: 1) 在T4条件下, 进行80℃、 30min模拟烤漆前的酸碱洗, 然后在170℃进行不同时间的时效处理; 2) 作T4P处理(即固溶处理水淬后立即在170℃预时效不同时间(5, 10, 20, 30min), 再在室温停放2周); 3) T4P处理后进行80℃、 30min模拟烤漆前的酸碱洗, 然后作170℃、 30min的模拟烤漆处理, 透射电镜及晶粒组织观察试样经固溶处理水淬后, 分别作170℃、 6h和170℃、 30min的时效处理, 并对铸锭双级均匀化处理的组织进行扫描电镜能谱分析。

拉伸实验在CMT5105-SANS微型控制电子万能实验机进行。 埃利克森实验采用直径d8mm的球形凸膜。 硬度测量使用HVA-10A型小负荷维氏硬度计, 加载49N。 采用LEICA MPS30型金相显微镜、 Philips EM-400T型透射电镜、 SSX-550扫描电镜(SEM)及附带的DX-4型能谱仪进行显微组织观察和相成分的能谱(EDS)分析。

2 分析与讨论

2.1 合金成分

合金的化学成分如表1所列。 11~13号合金的Mg和Si, Mg和Cu质量比以及Mn含量依次增大, 其中11和12号合金为Si过剩合金, 13号合金为Mg过剩合金。

表1 合金的化学成分

Table 1 Chemical compositions of alloys (mass fraction, %)

2.2 力学性能和成形性

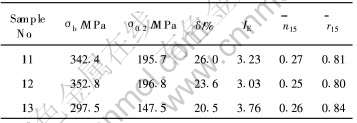

合金薄板在T4状态下的 、

、 和IE值及力学性能结果如表2所列。 由表可见, 11和12号合金板材具有较高的抗拉强度σb、 屈服强度σ0.2和延伸率δ, 但n[TX-]15和IE值并不高。 对于Si过剩合金(如11和12号合金), 增大Mg和Si质量比及Mn含量有利于提高合金的强度, 但影响合金的塑性和冲压成形性。 对于Mg过剩的合金(13号合金), 板材的σb、 σ0.2和δ均较低, 而n[TX-]15、 r[TX-]15和IE 值却较高。

和IE值及力学性能结果如表2所列。 由表可见, 11和12号合金板材具有较高的抗拉强度σb、 屈服强度σ0.2和延伸率δ, 但n[TX-]15和IE值并不高。 对于Si过剩合金(如11和12号合金), 增大Mg和Si质量比及Mn含量有利于提高合金的强度, 但影响合金的塑性和冲压成形性。 对于Mg过剩的合金(13号合金), 板材的σb、 σ0.2和δ均较低, 而n[TX-]15、 r[TX-]15和IE 值却较高。

表2 T4状态下合金的力学性能和成形性

Table 2 Mechanical properties and formablity of alloys in T4 state

2.3 显微组织分析

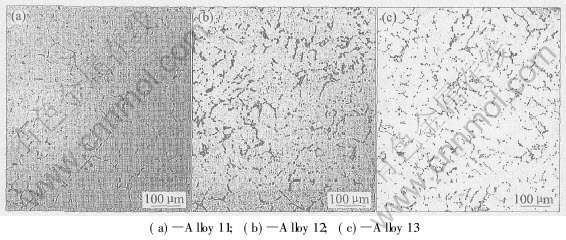

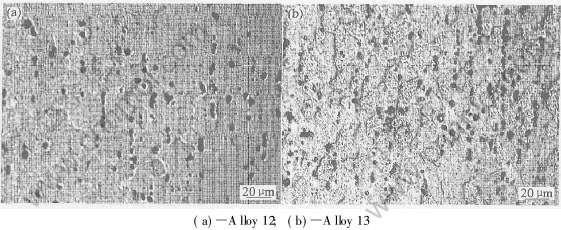

合金铸锭经均匀化处理后的显微组织如图1所示。 由图可见, 11~13合金未溶结晶相数量依次增多。 图2所示为合金11、 12和13的扫描电镜及能谱分析图, 这些结晶相主要为含Al(FeMnCr)Si的相及Mg2Si的相。 由于所形成的Al(FeMnCr)Si主

图1 合金均匀化处理后的显微组织

Fig.1 Microstructures of alloys after homogenizing treatment

图2 均匀化处理后未溶结晶相形貌

Fig.2 Morphologies and EDS patterns of non-solvent constituents

after homogenizing treatment

要是以AlFeSi为基[16], 且该相中的Mn含量随合金的平均Mn含量的升高而增大, 说明Mn参与了这些结晶相的形成, 而Mn和Fe有相互替代作用[16], 相当于提高了合金的平均含Fe量, 从而导致这类结晶相的数量随合金的Mn含量增加而增多。 合金元素Cr也具有和Mn类似的作用。 对于Si过剩的合金, 由于随Mg和Si质量比的增大, 形成Mg2Si相所消耗的Mg也随之增加, 因此12号合金的Mg2Si结晶相数量最多。

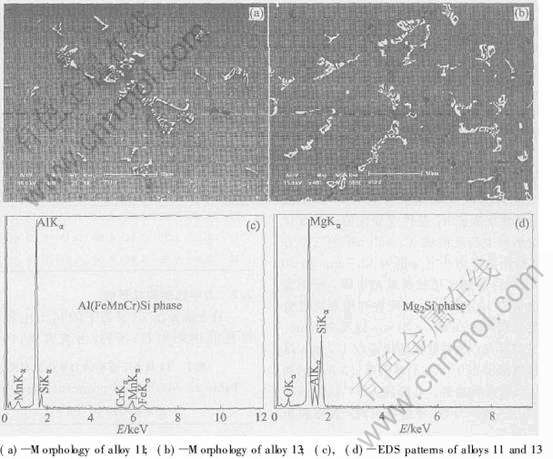

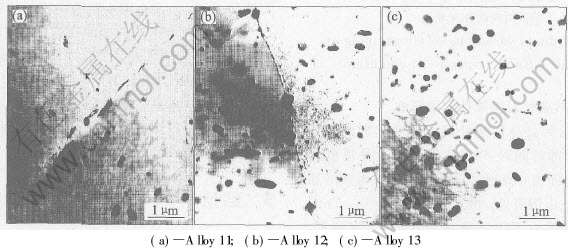

图3所示为合金薄板固溶水淬时效后的透射电镜组织。 增大合金的Mn含量, 合金中弥散相粒子的数量逐渐增多, 并钉扎在晶界上, 限制晶界移动, 阻碍再结晶。 图4所示为合金冷轧薄板经固溶水淬时效后纵断面的金相组织。 由图可看出, 合金在较高温度(540℃) 固溶处理时均未发生完全再结晶。 当合金中的未溶结晶相数量较多时, 它们在塑性加工过程中被轧碎并沿轧向分布, 使合金表现出纤维状组织特征(如Mn含量较高的13号合金)。

对于Si过剩合金(11和12号合金), Mg和Si质量比的增大有利于促进T4状态下Mg2Si序列初始物GP区的形成及密度的增大, 从而导致合金的强度升高。 但随着Mg和Si质量比的增大, 合金中除Al(FeMnCr)Si结晶相外, Mg2Si结晶相数量也逐渐增多。 当板材塑性变形时, 在这些粗大结晶相与基体间的界面处极易出现显微裂纹, 从而使合金的延伸率下降。 对于Mg过剩合金(13号合金), 固溶体中还溶有一定的Mg, 提高合金的加工硬化率, 在测定应变15%时的n、 r值时获得了较高值。 但当继续增大合金变形时, 合金中过量的结晶相促进裂纹的产生, 造成合金的最终延伸率下降, 因此13号合金虽然有较高的 、

、  和IE值, 但其延伸率较低。 只有Mg和Si的质量比及Mn含量适中时, 才能使6000系汽车板铝合金组织中的结晶相不过多, 使合金在得到强化的同时, 仍能保持较高的塑性。

和IE值, 但其延伸率较低。 只有Mg和Si的质量比及Mn含量适中时, 才能使6000系汽车板铝合金组织中的结晶相不过多, 使合金在得到强化的同时, 仍能保持较高的塑性。

2.4 预时效

图3 合金固溶处理后经170℃、 6h时效的TEM像

Fig.3 TEM images of alloys aging at 170℃ for 6h after solution treatment

图4 合金固溶处理后经170℃、 30min时效的显微组织

Fig.4 Microstructures of alloys aging at 170℃ for 30min after solution treatment

2.4.1 T4条件下模拟烤漆时效硬化速度曲线

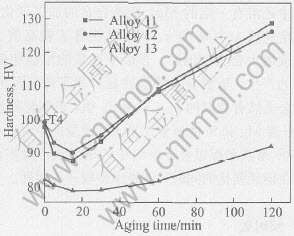

将T4状态下的样品, 进行80℃、 30min的处理, 然后再进行170℃不同时间的时效, 其硬度随170℃时效时间的变化趋势如图5所示。 由图可见, 所有合金在170℃时效(烤漆)30min内, 硬度较T4状态的均有降低, 说明T4条件下进行烤漆会使合金软化。

图5 合金在T4条件下于170℃时效不同时间的硬度变化

Fig.5 Hardness variations of alloys aging at 170℃ for different time in T4 condition

2.4.2 预时效条件对烤漆性能的影响

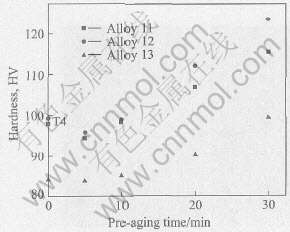

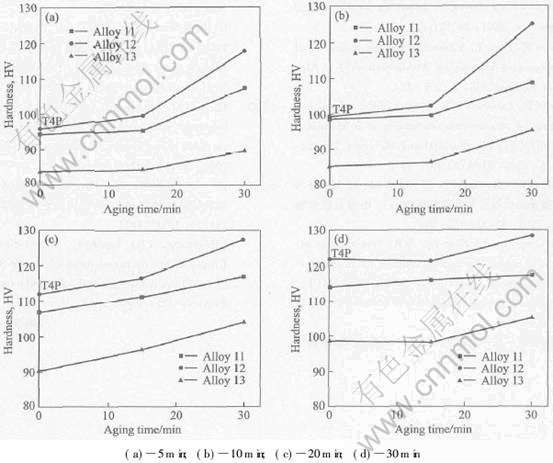

图6所示为合金固溶处理水淬后立即进行的170℃预时效的时间对T4P状态下合金硬度的影响, 图中横坐标的0点所对应的值为未预时效的原始T4态硬度。 由图可见, 所有合金经170℃、 5min的预时效所获得的T4P态硬度均低于T4态硬度, 且随预时效时间的延长, T4P态硬度也随之增大。当预时效为10min时, 合金的T4P态硬度与T4态硬度相近, 而当预时效超过10min时, T4P态硬度高于T4态硬度。 图7所示为预时效时间对合金烤漆硬化性的影响。 由图可见, 随着预时效时间的延长, 模拟烤漆的硬化能力也随之增强。

图6 预时效时间对T4P状态下合金硬度的影响

Fig.6 Effects of pre-aging time

on hardness of alloys by T4P treatment

由实验结果可以看出, 适当的T4P处理不仅能有效地消除合金T4状态下烤漆后性能降低的现象, 而且可使板材在烤漆前(即冲压前)具有相对低的硬度。 固溶处理后立即在170℃进行短时预时效, 基体中将形成大量的、 尺寸较大的β″核心, 从而造成过饱和固溶体中溶质的分布不均匀, 降低非β″核心处基体中溶质的过饱和度, 抑制了随后自然时效的硬化效果, 使得T4P状态下的硬度较低。 同时, 预时效过程形成的大量的β″核心, 在随后的170℃人工时效(即烤漆过程)时, 将促进β″相的均匀析出, 从而产生明显的烤漆硬化效应。

但如果预时效时间过长(为30min时), 在预时效期间有可能直接形成密度极高的β″相, 使T4P硬度显著增大。 尽管T4P状态在最终烤漆时会获得更好的强化效果, 但由于预时效过程中已产生了大量的β″相, 从而会影响后面烤漆时的硬化速度。

考虑到汽车板对合金冲压性能的要求, 所获得的T4P态硬度应不超过T4态硬度, 因而, 170℃的预时效处理不宜超过10min, 超过10min的预时效对板材的冲压性能不利。 但在保证合金冲压性能的前提下, 进行170℃、 10min的预时效能获得更好的强化效果。

3 结论

1) 随着合金中Mn含量的提高, Al-Mg-Si-Cu汽车板铝合金结晶相及弥散相粒子数量也随之增加。 结晶相在轧制过程被压碎, 并沿轧向分布, 从而使合金组织纤维化, 弥散相粒子钉扎晶界阻碍再结晶过程。

2) 对于Si过剩的合金, 增大Mg和Si的质量比及Mn的含量, Al-Mg-Si-Cu汽车板铝合金的强度也随之增加, 延伸率及 、 r15和IE值却随之下降。

、 r15和IE值却随之下降。

3) T4状态的6000系车身板铝合金经170℃、 30min短时间烤漆后, 其硬度均低于烤漆前的硬度。 而固溶处理后立即进行适当的预时效能消除合金T4状态下烤漆后性能降低的现象。

4) 随着预时效时间的延长, 合金的T4P态硬度和烤漆硬化能力也随之提高。 固溶处理后立即进行170℃、 5~10min的短时预时效处理更能满足汽车板对合金冲压性能及烤漆强化的要求。

图7 预时效时间对合金烤漆硬化性的影响

Fig.7 Effects of pre-aging time on paint bake hardenability of alloys

REFERENCES

[1]Burger G B, Gupta A K, Jeffrey P W, et al. Microstructural control of aluminum sheet used in automotive applications[J]. Material Characterization, 1995, 35: 23-39.

[2]Bottema J, Lahaye C, Baartman R, et al. Recent developments in AA6016 aluminium type body sheet product[J]. SAE Transaction J Mater and Manuf Sections, 1998, 107: 900-907.

[3]Kamat R G, Butler J F, Murtha Jr, et al. Alloy 6022-T429 for automotive sheet applications[J]. Materials Science Forum, 2002, 396-402: 1591-1596.

[4]Weatherly G C, Perovic A, Mukhopadhyay N K, et al. The precipitation of the Q phase in an AA6111 alloy[J]. Metallurgical and Materials Transactions A, 2001, 32A(4): 213-218.

[5]Kleiner S, Henkel C, Schulz P, et al. Paint bake response of aluminium alloy 6016[J]. Aluminium, 2001, 77 (3): 185-189.

[6]Miao W F, Laughlin D E. Precipitation hardening in aluminum alloy 6022[J]. Scrripta Materiala, 1999, 40(7): 873-878.

[7]林肇琦, 孙贵经. 铝合金显微组织的不均匀性与分级时效理论(上)[J]. 轻金属, 1978, 28(1): 47-56.

LIN Zhao-qi, SUN Gui-jing. Non-uniformity of microstructure and the step-aging theory of aluminium alloys (Upper portion)[J]. Light Metal, 1978, 28(1): 47-56.

[8]Zhen L, Kang S B. Effect of natural aging and preaging on subsequent precipitation process of an Al-Mg-Si alloys with high excess silicon[J]. Mater Sci & Tech, 1997, 13(11): 905-910.

[9]Zhuang L, de Haan R, Bottema J, et al. Improvement in bake hardening response of Al-Si-Mg alloys[J]. Materials Science Forum, 2000, 331-337: 1309-1314.

[10]关邵康, 姚波. 预时效及预应变对Al-Mg-Si 基汽车板材性能的影响[J]. 机械工程材料, 2001, 25(12): 17-19.

GUAN Shao-kang, YAO Bo. Effects of pre-aging and pre-strain on properties of Al-Mg-Si alloys for automotive body sheets[J]. Materials for Mechanical Engineering, 2001, 25(12): 17-19.

[11]Yamada K, Sato T, Kamio A. Pre-precipitation and two-step aging behavior of Al-Mg-Sialloys[J]. Aluminum Alloys, 1998, 2: 709-714.

[12]Miao W F, Laughlin D E. Effects of Cu content and preaging on precipitation characteristics in aluminum alloy 6022[J]. Metallurgical and Materials Transactions A, 2000, 31A(2): 361-371.

[13]潘青林, 李绍禄, 邹景霞, 等. 微量Mn对Al-Mg-Si合金微观组织与拉伸性能的影响[J]. 中国有色金属学报, 2002, 12(5): 972-976.

PAN Qing-lin, LI Shao-lu, ZOU Jing-xia, et al. Effects of minor manganese addition on microstructures and tensile properties of Al-Mg-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 972-976.

[14]关邵康, 姚波, 王迎新. Ti和Ce 对AlMgSi 基合金板材成形性能的影响[J]. 中国有色金属学报, 2002, 12 (4): 759-762.

GUAN Shao-kang, YAO Bo, WANG Ying-xin. Effect of Ti and Ce on forming properties of new type AlMgSi based alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2002, 12 (4): 759-762.

[15]Hirth S M, Marshall G J. Effects of Si on the aging behaviour and formability of aluminium alloys based on AA6016 materials[J]. Science and Engineering, 2001, A319-A321: 452-456.

[16]刘宏, 刘艳华, 赵刚, 等. Mn对Al-Mg-Si-Cu铝合结晶相的影响[J]. 中国有色金属学报, 2004, 14(11): 1096-1911.

LIU Hong, LIU Yan-hua, ZHAO Gang, et al. Effects of Mn on constituents of Al-Mg-Si-Cu alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(11): 1096-1911.

基金项目: 国家高技术研究发展计划资助项目(2002AA331050); 教育部科学技术研究重大资助项目(0208); 国家教育部高等学校优秀青年教师教学科研奖励计划资助项目

收稿日期: 2004-08-09; 修订日期: 2004-12-03

作者简介: 刘 宏(1959-), 女, 副教授, 博士研究生.

通讯作者: 赵 刚, 教授; 电话: 024-83681685; E-mail: zhaog@mail.neu.edu.cn

(编辑李艳红)