文章编号:1004-0609(2012)02-0585-07

采用Na2SO3溶液从硒渣中选择性浸出Se及其动力学

郑雅杰,陈昆昆

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:采用SO2还原沉金后液制得硒渣,再用Na2SO3选择性浸出硒渣,使Se得到有效分离;通过研究浸出过程中Se浸出率随时间的变化,建立该反应的动力学方程,确定Na2SO3溶液浓度、液固比、搅拌速度及反应温度对Se浸出率的影响,并计算相应的表观活化能。结果表明:增加Na2SO3溶液浓度和升高反应温度可以较大幅度提高Se的浸出率,液固比和搅拌速度对浸出Se的影响较小;Na2SO3浸出Se过程为Avrami模型混合控制,其特征参数n和表观活化能E分别为0.235和20.847 kJ/mol,Se的浸出率受反应温度的影响较大。

关键词:硒;硒渣;亚硫酸钠;选择性浸出;动力学

中图分类号:TF843.5; TF803.21 文献标志码:A

Selective leaching Se from selenium residue by

Na2SO3 solutions and leaching kinetics

ZHENG Ya-jie, CHEN Kun-kun

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Selenium was effectively separated from selenium residue. The selenium residue was prepared from the solution after precipitating gold by SO2 reduction, followed by Na2SO3 selective leaching. The effects of Na2SO3 concentration, liquid and solid ratio, stirring speed and reaction temperature on Se extraction were confirmed with the change of Se leaching ratio during the leaching process of Se by Na2SO3. The kinetics equation was established and the corresponding apparent activation energy was calculated. The results indicate that Se leaching ratio increases greatly with increasing Na2SO3 concentration and reaction temperature. The liquid and solid rate and stirring speed have little influence on Se extraction. The kinetics of leaching Se from selenium residue follows the Avrami model and the leaching process is hybrid controlled. The apparent activation energy of leaching Se and the feature parameter of Avrami equation are determined to be 20.847 kJ/mol and 0.235, respectively. The reaction temperature has great influence on Se leaching rate.

Key words: selenium; selenium residue; sodium sulfite; selective leaching; kinetics

硒是稀散金属,不仅广泛应用于电子、玻璃、陶瓷、化工、冶金、农业、食品、卫生和环保等行业,而且具有重要的药用价值,是一种强抗氧化剂,为人类和动物生存必需的微量元素。硒主要共生于铜矿、铜铁矿、铜镍矿、铜铅锌矿、铅锌矿、黄铁矿、硫磺矿和部分含硒金矿等,在这些矿物的火法和湿法冶金过程中,硒主要富集于烟尘、电解过程产生的阳极泥和制硫酸过程产生的酸泥中[1]。提取硒的主要原料是铜电解的阳极泥,目前冶炼厂主要采用硫酸化焙烧-蒸馏-还原工艺回收硒[2-4],该工艺流程短、成本低、硒回收率高,充分利用了烟气中的SO2,有利于废气综合利用,但对系统密封性要求高。对于湿法回收硒,在酸性溶液或碱性溶液中,采用MnO2作为添加剂或使用超声强化浸出含硒物料,其硒浸出率都较高[5-11]。此外,有报道采用氯酸钠在酸性溶液中氧化浸出烟尘中的硒[12],该方法简单且硒回收效果好,但该方法用于含硒碲物料时,使硒碲一起浸出,需增加硒碲分离工艺,延长了工艺流程。采用CS2和Na2SO3溶液提取含硒沉积物中的硒,Na2SO3溶液能完全溶解各种晶态的单质态硒和水溶性氧化硒,而CS2只能溶解无定形的单质态硒但具有更好的选择性[13]。在回收阳极泥中贵金属过程中,产生的沉金后液含有大量稀贵金属,沉金后液经过SO2或锌粉还原得到硒渣[14-16],其含有高品位硒,可以作为提取硒的原料。本文作者采用SO2还原沉金后液得到硒渣,再用Na2SO3溶液从硒渣中选择性浸出硒,使硒渣中的硒得到有效回收,并对浸出动力学进行研究,为改善浸出条件和提高浸出率提供理论依据。

1 实验

1.1 实验步骤

1.1.1 SO2还原沉金后液实验

准确量取一定量的沉金后液并倒入三颈瓶中,启动搅拌,使用硫酸调整原料酸度,使用氯化钠增加溶液Cl-浓度,并在电热套中加热至一定温度,通入恒定流量的SO2还原,反应一段时间后过滤、洗涤、烘干得到硒渣。

1.1.2 Na2SO3浸出硒渣实验

将Na2SO3溶液加入容积为500 mL的三颈瓶中,并固定于电热套中,启动搅拌,待溶液温度升至一定温度时,按液固比迅速加入硒渣,恒温下反应一定时间后过滤得到含硒浸出液。

1.1.3 浸出动力学实验

在容积为500 mL带刻度的圆柱型玻璃反应器中,加入2 mol/L Na2SO3溶液210 mL,用变频调速搅拌器(JBV-Ⅲ型)控制搅拌速度并用超级恒温水浴锅(JR-A型)加热至一定温度;准确称取30 g硒渣并将其迅速倒入Na2SO3溶液中,开始计时并在烧杯上做好溶液刻度线记号,用于监控溶液体积变化,通过补加蒸馏水来确保体积恒定;反应过程中用水银温度计准确测量温度并监控温度变化,通过调节水浴锅功率输出来确保温度恒定,其温度波动为±2 ℃;恒温恒容条件下反应一定时间,每隔一定时间间隔吸取溶液0.1 mL对溶液中Se质量浓度进行分析,同时补充相应体积的Na2SO3溶液。

1.2 分析与检测

采用美国热电元素公司的Intrepid II XSP型电感耦合等离子体发射光谱仪(ICP)分析溶液化学成分;X射线荧光光谱仪(XRF)分析固体物质成分;日本理学D/max-TTR III型X射线衍射仪(XRD)分析固体物质物相;日本电子株式会社JSM-6300型扫描电镜(SEM)观察固体物质微观形貌。

Se浸出率(η)的计算公式如下:

式中:m为硒渣质量,g;w为硒渣中硒的质量分数,%;V为浸出液体积,L; 为浸出液中硒的质量浓度,g/L。

为浸出液中硒的质量浓度,g/L。

2 结果与讨论

2.1 SO2还原沉金后液回收Se

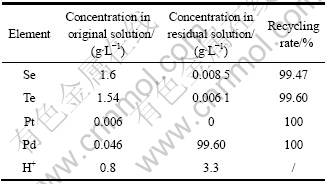

实验取6 L沉金后液,其化学成分如表1所列,在反应温度为85 ℃、反应时间4 h、H+浓度为3.3 mol/L、Cl-浓度为0.72 mol/L条件下通入SO2还原得到硒渣[15],反应后溶液(还原后液)成分及回收率和所得硒渣成份分别如表1和2所列,硒渣物组成和形貌相如图1所示。

表1 沉金后液和还原后液主要成分

Table 1 Main compositions of original solution and residual solution

表2 硒渣主要化学成分

Table 2 Main chemical compositions of selenium residue (mass fraction, %)

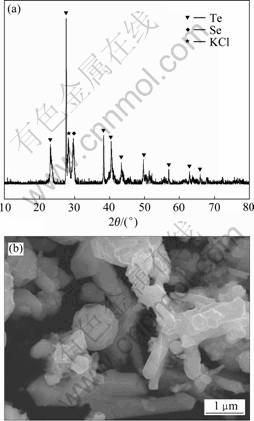

图1 硒渣XRD谱和SEM形貌

Fig. 1 XRD pattern(a) and SEM image(b) of selenium residue

由表1可知,Se和Te回收率分别达到99.47%和99.60%;由表2可知,硒渣主要成分为Se和Te,其

质量分数分别为41.73%和40.96%。由图1可知,在硒渣中,Se和Te以单质态形式存在;扫描电镜(SEM)分析表明,硒渣形貌主要是细小的球状颗粒和柱状颗粒。

2.2 Na2SO3浸出硒渣

2.2.1 Na2SO3溶液浓度对Se浸出率的影响

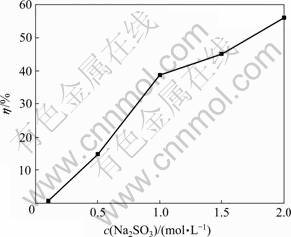

实验取30 g上述硒渣,迅速添加到Na2SO3溶液中,为确保固体颗粒能完全悬浮在溶液中,搅拌速度控制为300 r/min;硒在煮沸的Na2SO3溶液中能全部溶解[1],反应温度控制为85 ℃;当液固比为5:1时,恒温反应2 h,考察Na2SO3溶液浓度对Se浸出率的 影响,如图2所示。

图2 Na2SO3溶液浓度对Se浸出率的影响

Fig. 2 Effect of Na2SO3 concentration on leaching rate of selenium

由图2可知,Se浸出率随Na2SO3溶液浓度的增加而增加,当Na2SO3溶液浓度为2 mol/L时,Se浸出率达到56.15%。由于受Na2SO3溶解度的限制,85 ℃时,100 g水能溶解28 g Na2SO3,即Na2SO3溶液饱和浓度为2.22 mol/L[17];浓度为2 mol/L的Na2SO3溶液已接近饱和,当Na2SO3溶液达到饱和后,继续增加Na2SO3用量会导致Na2SO3过量,使溶液中残留Na2SO3固体。因此,Na2SO3溶液浓度选择为2 mol/L。

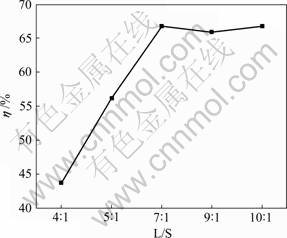

2.2.2 液固比对Se浸出率的影响

上述其它实验条件不变,当Na2SO3溶液浓度为2mol/L时,考察液固比对Se浸出率的影响,如图3所示。

由图3可知,当液固比小于7:1时,Se浸出率随液固比增加而增加,增加液固比使固体颗粒在液体中更分散,反应物混合更均匀,有利于反应物扩散,增加Se浸出率;当液固比为7:1时,Se浸出率达到66.78%;继续增加液固比,对Se浸出率没有影响。不同液固条件下滤渣的XRD谱如图4所示。由图4可知,硒渣经过Na2SO3浸出Se后,Se峰强度变弱;随液固比增大,Se峰强度逐渐变弱;当液固比大于7:1后,Se峰强度变化不明显,进一步说明液固比对Se浸出率的影响情况。因此,浸出过程液固比选择为7:1。

图3 液固比对Se浸出率的影响

Fig.3 Effect of liquid and solid ratio on leaching rate of selenium

图4 不同液固比条件下滤渣的XRD谱

Fig.4 XRD patterns of residue at different liquid and solid ratios

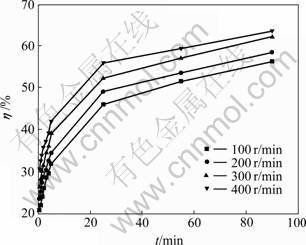

2.2.3 搅拌速度对Se浸出率的影响

上述其它实验条件不变,当液固比7:1时,搅拌速度对Se浸出率的影响如图5所示。

图5 搅拌速度对Se浸出率的影响

Fig.5 Effect of stirring speed on leaching rate of selenium

由图5可知,在不同搅拌速度下,Se浸出率随反应时间延长而迅速增加,当反应时间达到25 min后,Se浸出率缓慢增加;在同一时间点,Se浸出率随搅拌速度增加而增加,当搅拌速度从100 r/min增加到400 r/min时,Se浸出率增加幅度为7%~10%,可见搅拌速度对Se浸出影响不大。因此,浸出过程可能不受外扩散控制,搅拌速度选择为300 r/min。

2.2.4 反应温度对Se浸出率的影响

上述其它实验条件不变,当搅拌速度为300 r/min时反应温度对Se浸出率的影响如图6所示。

由图6可知,在不同反应温度下,初始浸出反应速度很快,Se浸出率随反应时间延长而增加,当反应时间延长到25 min后,Se浸出率缓慢增加;在同一时间点,Se浸出率随反应温度升高而迅速增加,当反应温度从23 ℃升高到95 ℃时,Se浸出率增加幅度为40%~50%,可见反应温度对Se浸出影响很大,因此浸出过程可能受表面化学反应控制;由于当反应温度高于85 ℃时,Se浸出率增加不大,且继续升高温度会导致消耗更多的能量,因此,浸出过程反应温度选择为85 ℃。

图6 反应温度对Se浸出率的影响

Fig.6 Effect of leaching temperature on Se extraction

2.3 浸出动力学

2.3.1 动力学模型选择

硒渣中的单质态Se与Na2SO3溶液反应,属于液固多相反应,反应发生在液固两相界面处,而且Se与Na2SO3反应无固体产物生成,其化学反应如下:

Na2SO3(l)+Se(s)= Na2SeSO3(l) (1)

对于大多数液固反应,其最常见的反应模型为收缩未反应核模型[18-19]。对于Na2SO3浸出Se过程一般包括下面3个步骤:1) 反应物Na2SO3(l)由主体溶液通过边界层液膜向固体Se表面扩散;2) 反应物Na2SO3(l)在反应界面上与固体Se发生化学反应;3) 生成物Na2SeSO3(l)通过边界层向主体溶液中扩散。Na2SO3浸出Se过程是由上述各步骤连续进行的,总的反应速度取决于最慢的环节,即控制步骤。

当浸出过程为液膜扩散控制时,其动力学方程为

1-(1-X)2/3=k1t (2)

当浸出过程为界面化学反应控制时,其动力学方程为

1-(1-X)1/3=k2t (3)

式中:X为反应物浸出率;t为反应时间;k1和k2均为表观反应速率常数。

根据图6数据,将反应温度、反应时间及1-X数据列表,如表3所列。

表3 不同反应温度下1-X随反应时间变化

Table 3 Change of 1-X with reaction time at different temperatures

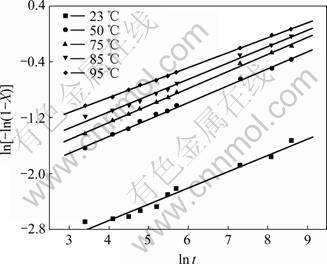

由表3验证,浸出动力学反应规律不符合上述两个方程,即该浸出过程不能用收缩未反应核模型来分析其动力学规律。由图5和6可知,Na2SO3浸出Se过程的初始反应速度极大,但随反应时间延长反应速率又逐渐减小,对于如此类型的液固多相反应,其动力学规律符合Avrami模型[20-23],其动力学方程如下:

-ln(1-X)=ktn (4)

式中:k为表观反应速率常数;特征参数n反映过程控制机理,仅与固体晶粒的性质和几何形状有关,不随反应条件而变;当n<1时,初始反应速率极大而反应速率随时间延长而不断减小;当n=1时,初始反应速率有限;当n>1时,初始反应速率接近0。

对式(3)两边同时取自然对数,得到

ln[-ln(1-X)]=lnk+nlnt (5)

将表3实验数据代入式(4),得到ln[-ln(1-X)]—lnt图,如图7所示。

图7 不同反应温度下ln[-ln(1-X)]与lnt关系图

Fig.7 ln[-ln(1-X)] vs lnt at different reaction temperatures

由图7可知,不同反应温度下ln[-ln(1-X)]与lnt具有很好的线性关系,从而证实Na2SO3浸出Se过程符合Avrami模型。图7中直线斜率和截距分别代表n和lnk,其对应值如表4所列。

表4 不同反应温度下的n和lnk

Table 4 Values of n and lnk at different reaction temperatures

由表4可知,不同反应温度下n值基本不变,其平均值和标准偏差分别为0.235和0.007 6,因此特征参数n为0.235。

2.3.2 活化能计算

在化学反应中,反应速率常数k是温度的函数,温度对反应速率常数的影响可用Arrhenius公式表 示[24]:

(6)

(6)

式中:k0为频率因子;E为活化能;T为热力学温度;R为气体常数。

对式(5)两边同时取自然对数得到

(7)

(7)

根据表4相关数据可以绘制出lnk与1/T的关系图,如图8所示。

图8 Se浸出的Arrhenius图

Fig.8 Arrhenius plot for leaching of selenium

由图8可求斜率得到表观活化能E为20.847 kJ/mol,求截距得到频率因子k0为153.086,因此k=153.086exp[-20 847/(RT)]。一般冶金化学反应由扩散过程控制时,表观活化能小于约10 kJ/mol,化学反应控制时的活化能则在40 kJ/mol以上,混合控制的活化能则在10~40 kJ/mol之间[24]。因此,Na2SO3从硒渣中浸出Se过程为混合控制,由于反应物中Te等不溶物的包裹作用和生成物的扩散阻碍,使其反应速度减慢,导致Se浸出率不高。

3 结论

1) 当反应温度为85 ℃、反应时间4 h、H+浓度为3.3 mol/L、Cl-浓度为0.72 mol/L时,采用SO2还原沉金后液制得硒渣,Se回收率达到99.47%;硒渣含Se 41.73%,且Se以单质态形式存在;硒渣形貌主要是细小的球状颗粒和柱状颗粒。

2) 采用Na2SO3从硒渣中浸出Se,Se浸出率随Na2SO3溶液浓度增加而增加,随搅拌速度增加而缓慢增加,随反应温度升高而增加;当液固比小于7:1时,Se浸出率随液固比增加而增加;继续增加液固比对Se浸出率没有影响;当Na2SO3溶液浓度为2 mol/L、液固比为7:1、反应温度为85 ℃、反应时间2 h时,Se浸出率达到66.78%。

3) Na2SO3浸出Se过程符合Avrami模型,其反映过程控制机理的特征参数n为0.235,其表观活化能E为20.847 kJ/mol,浸出反应为混合控制,其动力学方程为

。

。

REFERENCES

[1] 翟秀静, 周亚光. 稀散金属[M]. 安徽: 中国科学技术大学出版社, 2009.

ZHAI Xiu-jing, ZHOU Ya-guang. Scattered metals[M]. Anhui: Press of University of Science and Technology of China, 2009.

[2] HOFFMANN J E. Recovering selenium and tellurium from copper refinery slimes[J]. The Journal of the Minerals Material Society, 1989, 41(7): 33-38.

[3] DUTTON W A, VAN DEN STEEN A J, THEMELIS N J. Recovery of selenium from copper anode slimes[J]. Metallurgical Transactions, 1971, 2: 3091-3097.

[4] 王吉坤, 张博亚. 铜阳极泥现代综合利用技术[M]. 北京: 冶金工业出版社, 2008.

WANG Ji-kun, ZHANG Bo-ya. Modern utilization technology of copper anode slime[M]. Beijing: Metallurgical Industry Press, 2008.

[5] CORNELIS G, POPPE S, GERVER T V, BROECK E V D, CEULEMANS M, VANDECASTEELE C. Geochemical modeling of arsenic and selenium leaching in alkaline water treatment sludge from the production of non-ferrous metals[J]. Journal of Hazardous Materials, 2008, 159: 271-279.

[6] JOSE R O R, MARIA J M F, JORGE M P, ELIA A R, SOLEDAD M L, PURIFICACION L M, DARIO P R. Influence of several experimental parameters on As and Se leaching from coal fly ash samples[J]. Analytica Chimica Acta, 2005, 531: 299-305.

[7] ABDOLLAHY M, SHAFAEI S Z. Optimized leaching conditions for selenium from Sar-Cheshmeh copper anode slimes[J]. Iran J Chem & Chem Eng, 2004, 23(2): 101-108.

[8] 李运刚. 湿法处理铜阳极泥工艺研究(Ⅰ)—铜、硒、碲的浸出[J]. 湿法冶金, 2000, 19(1): 41-45.

LI Yun-gang. Study on hydrometallurgical processing for copper-bearing anode mud(Ⅰ) —Selective leaching of Cu, Se and Te[J]. Hydrometallurgy of China, 2000, 19(1): 41-45.

[9] GU Heng. Study on selenium extraction from anode slime[J]. Journal of Guangdong Non-ferrous Metals, 2005, 15(2/3): 622-626.

[10] HAIT J, JANA R K, KUMAR V, SANYAL S K. Some studies on sulfuric acid leaching of anode slime with additives[J]. Ind Eng Chem Res, 2002, 41: 6593-6599.

[11] PUMURE I, RENTON J J, SMART R B. Accelerated aqueous leaching of selenium and arsenic from coal associated rock samples with selenium speciation using ultrasound extraction[J]. Environ Geol, 2009, 56: 985-991.

[12] HOU Xiao-chuan, XIAO Lian-sheng, GAO Cong-jie, ZHANG Qi-xiu, ZENG Li. Kinetics of leaching selenium from Ni-Mo ore smelter dust using sodium chlorate in a mixture of hydrochloric and sulfuric acids[J]. Hydrometallurgy, 2010, 104: 76-80.

[13] CHEN Y W, LI L, D’ULIVO A, BELZILE N. Extraction and determination of elemental selenium in sediments—A comparative study[J]. Analytica Chimica Acta, 2006 , 577: 126-133.

[14] 胡建辉. 从金还原后液中置换铂钯的工艺优化研究[J]. 湿法冶金, 2000, 19(2): 22-25.

HU Jian-hui. Study on optimum process for displacing Pt and Pd from the solution Au reduced[J]. Hydrometallurgy of China, 2000, 19(2): 22-25.

[15] 郑雅杰, 陈昆昆. 从溶液中回收稀贵金属的一种方法: 中国, 201010266679.0[P]. 2010-08-30.

ZHENG Ya-jie, CHEN Kun-kun. The method to recover rare and noble metals from the solution: China, 201010266679.0[P]. 2010-08-30.

[16] GEOFFROY N, DEMOPOULOS G P. The elimination of selenium(Ⅳ) from aqueous solution by precipitation with sodium sulfide[J]. Journal of Hazardous Materials, 2011, 185: 148-154.

[17] 顾庆超, 楼书聪, 戴庆平, 黄炳荣, 李乔均, 黄剑朎. 化学用表[M]. 南京: 江苏科学技术出版社, 1979.

GU Qing-chao, LOU Shu-cong, DAI Qing-ping, HUANG Bing-rong, LI Qiao-jun, HUANG Jian-ling. Metallurgical Principle[M]. Nanjing: Science and Technology of Jiangsu Press, 1979.

[18] 白 猛, 郑雅杰, 刘万宇, 张传福. 硫化砷渣的碱性浸出及浸出动力学[J]. 中南大学学报: 自然科学版, 2008, 39(2): 268-272.

BAI Meng, ZHENG Ya-jie, LIU Wan-yu, ZHANG Chuan-fu. Alkaline leaching and leaching kinetics of arsenic sulfide residue[J]. Journal Central South University: Science and Technology, 2008, 39(2): 268-272.

[19] LEVENSPIEL O. Chemical reaction engineering[M]. 3rd ed. New York: John Wiley & Sons, 1999.

[20] 畅永锋, 翟秀静, 符 岩, 李斌川, 张廷安. 还原焙烧红土矿的硫酸浸出动力学[J]. 分子科学学报, 2008, 24(4): 241-245.

CHANG Yong-feng, ZHAI Xiu-jing, FU Yan, LI Bin-chuan, ZHANG Ting-an. Sulphuric acid leaching kinetics of pre-reduced laterite ores[J]. Journal of Molecular Science, 2008, 24(4): 241-245.

[21] NIZAMETTIN D, ASIM K. Dissolution kinetics of ulexite in perchloric acid solutions[J]. Int J Miner Process, 2007, 83: 76-80.

[22] OKUR H, TEKIN T, KADIR OZER A, BAYRAMOGLU M. Effect of ultrasound on the dissolution of colemanite in H2SO4[J]. Hydrometallurgy, 2002, 67: 79-86.

[23] DICKINSON C F, HEAL G R. Solid-liquid diffusion controlled rate equations[J]. Thermochimica Acta, 1999, 340/341: 89-103.

[24] 李洪桂. 冶金原理[M]. 北京: 科学出版社, 2005.

LI Hong-gui. Metallurgical principle[M]. Beijing: Science Press, 2005.

(编辑 李艳红)

基金项目:广东省教育部产学研重大项目(2008A090300016)

收稿日期:2011-01-20;修订日期:2011-06-15

通信作者:郑雅杰,教授,博士;电话:0731-88836285;E-mail: zzyyjj01@yahoo.com.cn