文章编号:1004-0609(2011)12-3100-08

Al掺杂TiO2介孔材料的合成、表征和光催化性能

刘国聪1, 2,董 辉1,刘少友3

(1. 玉林师范学院 新材料研发与化学生物传感技术所,玉林 537000;

2. 中南大学 化学化工学院,长沙 410083;

3. 贵州凯里学院 应用化学研究所,凯里 556000)

摘 要:以钛酸四丁酯为钛源、十八水硫酸铝为铝源、三乙醇胺为模板剂, 采用研磨-溶胶技术合成了Al掺杂的TiO2介孔材料, 并利用XRD、EDS、TEM、BET、UV-vis和IR等手段表征了材料的结构、形貌、比表面积、孔径分布及光学性能。结果表明:Al掺杂能够减小TiO2光催化剂的粒径, 提高介孔TiO2的热稳定性;Al掺杂TiO2介孔材料的平均孔径为4.5 nm, 比表面积达到110.2 m2/g;相比商用P25和介孔TiO2,Al掺杂介孔TiO2的吸收边发生红移,对初始浓度为20 mg/L 的甲基橙进行催化降解1 h 后,其降解率达到92.5%。

关键词:TiO2;Al掺杂;介孔材料;光催化剂

中图分类号:O614. 33 文献标志码:A

Synthesis, charaterization and photocatalytic activities of

Al-doped TiO2 mesoporous materials

LIU Guo-cong1, 2, DONG Hui1, LIU Shao-you3

(1. Institute of Advanced Materials and Chembiosensing Technology, Yulin Normal University, Yulin 537000, China;

2. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

3. Institute of Applied Chemistry, Kaili University, Kaili 556000, China)

Abstract: Using tetrabutyl orthotitanate (TBOT) as Ti source, Al2(SO4)2·18H2O as Al source and triethanolamine as a template, Al-doped TiO2 mesoporous materials were synthesized via grinding-sol-gel method. The structure, morphology, crystalline size, specific surface area, pore size and photocatalytic activity of the as-prepared samples were characterized by X-ray diffractometry, high-resolution transmission electron microscopy (HRTEM), N2 adsorption desorption and UV-vis spectrometer (UV-vis) techniques. The results show that Al-doped TiO2 has the wormhole-like mesoporous structure, and the Al doping can not only decrease the particle size of nanoparticles, but also improve the stability of the mesoporous TiO2. The specific surface areas and the average pore diameter of Al-doped TiO2 is about 110.2 m2/g and 4.5 nm, respectively. Compared with P25 and mesoporous TiO2, the gap adsorption edge of Al-doped TiO2 mesoporous materials exhibit a little red shift, the degradation ratio of which can be up to 92.5% during the photodegradation of methyl orange with the initial concentration of 20 mg/L for 1 h.

Key words: TiO2; Al-doping; mesoporous material; photocatalyst

硅基和非硅基介孔材料因具有较大比表面、规则有序孔道结构以及广泛的应用前景一直深受科研者的青睐并取得了很大的进展[1-5],其中,一些介孔金属氧化物功能材料如介孔氧化钛因具有合适的孔隙率、尺寸和较大的比表面积而广泛应用于膜工业、催化反应、太阳能转化以及化学生物传感器等领域[6-13]。

目前,TiO2介孔材料的合成颇受关注,如溶胶-凝胶法、模板法、水热法、溶剂热法、超声诱导法、离子液体法、热分解法以及超临界组装法等均用于合成介孔TiO2[14-21],其中水热和溶剂热法虽然能够获得较好的介孔材料,但难以实现大规模的工业化生产,而超声、超临界以及热解法等的制备成本过高、工艺较复杂,并且后续高温处理时容易出现介孔塌陷,致使其光催化应用受到了一定的局限。溶胶-凝胶法是较为简单而实用的一种方法,然而,该方法制备的纳米颗粒极易团聚,并在沉积和后热处理过程中导致介孔材料结构的不规整性。为控制孔径、孔容和介孔结构的规整性,一些结构导向剂如CTAB、PEG、P123和F127等有机物常用于导向形成长程有序的三维纳米结构,进而获得孔径小于10 nm的TiO2介孔材 料[22-24]。由于TiO2是一种宽禁带(3.4 eV)半导体,只能被波长较短的紫外光激发,其光量子效率较低,为提高光利用率和催化效率,许多过渡金属离子和非金属掺杂、金属氧化物的包覆、贵金属担载的TiO2的研究成为热点[22, 25-28],并且具有大比表面积的金属掺杂的介孔TiO2具有优良的介孔结构,可有效改善光的穿透效率,致使更多的有机污染物分子吸附于其表面,从而提高其光催化活性。然而,相关Al掺杂TiO2的介孔材料的合成与催化性能的研究却鲜见报道。

本文作者以三乙醇胺为模板剂,采用简单的研 磨-溶胶-凝胶技术制备了具有蚯蚓状孔道结构的Al掺杂TiO2 介孔分子筛, 并对样品的物相结构、元素形态组成、比表面积、能带隙以及光催化性能进行了分析。

1 实验

1.1 化学试剂

钛酸四丁酯(Tetrabutyl orthotitanate, TBOT),三乙醇胺(Triethanolamine, TEA),十八水合硫酸铝(Al2(SO4)3·18H2O,AR),无水乙醇(AR),甲基橙(Methyl orange, MO),上述试剂均为分析纯;实验用水为去离子水。

1.2 Al掺杂TiO2介孔材料的合成

实验所用TBOT和Al2(SO4)3·18H2O的摩尔比控制为1 000 : 25(即 ),而三

),而三

乙醇胺的质量是前两者的20%,具体步骤如下:称取一定量的Al2(SO4)3·18H2O和量取一定体积的三乙醇胺混合于一个研钵中,并连续研磨20 min形成一个糊状液体, 然后向其中逐滴滴入一定量的钛酸丁酯,并持续研磨25 min后得到一个粘胶液体,再将粘胶液体全部转移到一个大烧杯中陈化12 h,然后在140 ℃下加热2 h后自然冷却至室温获得固体样品。再将固体样品用研钵研磨成细粉,反复用去离子水冲洗直到不再检验出 为止,再于100 ℃干燥3 h获得样品。为除去模板剂,将样品在连续通N2且以5 ℃/min速度程控升温至550 ℃的管式炉中焙烧4 h获得Al-TiO2介孔材料。此外,按照同样步骤制备介孔TiO2以备 比较。

为止,再于100 ℃干燥3 h获得样品。为除去模板剂,将样品在连续通N2且以5 ℃/min速度程控升温至550 ℃的管式炉中焙烧4 h获得Al-TiO2介孔材料。此外,按照同样步骤制备介孔TiO2以备 比较。

1.3 样品的表征

样品的物相采用BRAKER D8型X射线粉末衍射测定,辐射源Cu Kα,电压40 kV,电流40 mA,扫描速度4 (°)/min, 扫描范围 10°~70°,低角扫描范围2θ = 0.5°~5°,步长0.02°。样品的元素存在形态采用美国 Thermo ESCALAB 250X光电子能谱仪(XPS)分析,工作条件如下:单色Al Ka (hn =1 486.6 eV),功率150 W,500 μm束斑能量分析器固定透过能为 20 eV;样品的尺寸及形貌采用美国FEI公司生产的透射电子显微镜(TEM,Philips Tecnai 20G2 S-TWIN)进行表征;样品的紫外-可见漫反射光谱采用德国耶拿公司产的紫外-可见光谱仪(UV-vis, Specord 200)测试,以BaSO4为参比;BET比表面积由Tristar 3000物理吸附仪测定,测定前经350 ℃、1.0×104 Pa处理15 h。

1.4 样品的催化活性评价

介孔Al-TiO2的光催化活性通过降解甲基橙溶液来评价。将0.2 g Al-TiO2介孔材料分散至100 mL浓度为20 mg/L甲基橙水溶液(pH=2)中,经15 min的超声分散后,得到悬浊液。在光催化反应之前,将悬浊液置于暗箱中磁力搅拌30 min,使体系达到吸附/解吸平衡。光催化反应在实验室自制的光催化器中进行。使用光源为100 W紫外灯,波长主峰值为365 nm。使用紫外灯照射的同时对悬浊液进行磁力搅拌。每隔一段时间即停止光照和搅拌,取出一部分悬浊液离心分离,使用TU-1901双光束紫外可见分光光度计,测量波长508 nm,检测分离所得澄清溶液的吸光度。其他光催化剂的活性评价在相同条件下完成。

2 结果与讨论

2.1 样品的物相结构分析

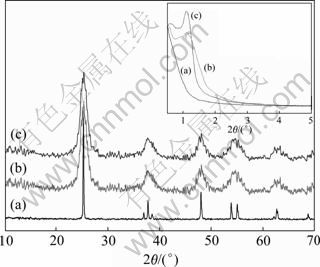

图1所示为样品的广角和小角(插图)XRD谱。由样品的小角衍射谱可知,研磨-溶胶法制备的TiO2(见图1中曲线(b))和Al掺杂的TiO2介孔材料(见图1中曲线(c))均在低角度(<2°)具有明显的(110)衍射峰, 这是介孔TiO2的特征衍射峰,而商业P25 TiO2并没有出现小角峰。图1的广角衍射结果显示,样品均在2θ=25.3°(101)、37.9°(004)、47.8°(200)、54.3°(211)、63.7°(204)等处出现锐钛矿相特征衍射峰,说明制备出的介孔TiO2材料的骨架结构为锐钛矿型,而且介孔样品的结晶度不如P25的,但衍射峰较宽,说明样品的晶粒尺寸变小。根据各个主要衍射峰的半峰宽数值和德拜-射乐公式可计算出Al-TiO2介孔、TiO2介孔和P25 TiO2的平均晶粒尺寸分别为11.7、26.5和49.8 nm。

图1 样品的广角和小角XRD谱

Fig.1 Wide-angle and low-angle (inset) XRD patterns of samples: (a) P25; (b) TiO2; (c) Al-TiO2

观察图1中曲线(b)和(c)可知,Al掺杂使介孔TiO2 结晶度下降并使(101)衍射峰位置略微偏移,这说明掺杂使介孔TiO2 的晶格发生了畸变,产生的晶体缺陷可成为催化反应的活性位,从而提高了介孔TiO2材料的催化性能及选择性。Al掺杂引起的晶格畸变使从锐钛矿晶型到金红石晶型的转变困难,锐钛矿TiO2晶体的热稳定性得到提高[5, 27]。但XRD谱中未出现氧化铝的特征峰,说明少量Al的掺杂实现了与Ti4+的同晶取代,降低了晶粒的尺寸,但并未引起TiO2晶型的变化。

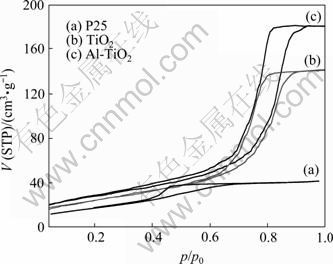

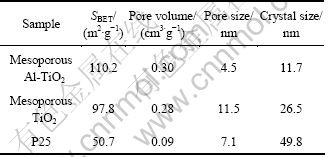

图2所示为样品的吸附-脱附等温线。由图2可知,研磨-溶胶法的样品均具有典型第Ⅳ类等温线, 且在0.6~1.0的相对压力下出现由毛细管凝聚现象引起的迟滞环, 这充分说明样品形成了介孔结构。根据N2吸附测试数据和BET公式分别得到3种样品的比表面积、孔容积、平均孔径和晶粒尺寸,其结果如表1所列。

图2 样品的N2吸附-脱附曲线

Fig.2 N2 adsorption-desorption isotherms and pore size distribution of samples

表1 样品的比表面积、孔容、孔径和晶粒尺寸

Table 1 BET surface, pore volume, and pore size distribution of samples

由表1可知,研磨-溶胶法制备的Al-TiO2和TiO2介孔的比表面积分别为110.2和97.8 m2/g,孔体积分别为0.30和0.28 cm3/g, 孔径分别为4.5和11.5 nm。Al掺杂TiO2的晶粒尺寸减小,晶粒堆积更加紧密,致使介孔的平均孔径变小。由此可知,Al掺杂后TiO2介孔材料具有较大的比表面积和较小的孔径,这也是提高其光催化效率的一个重要因素。

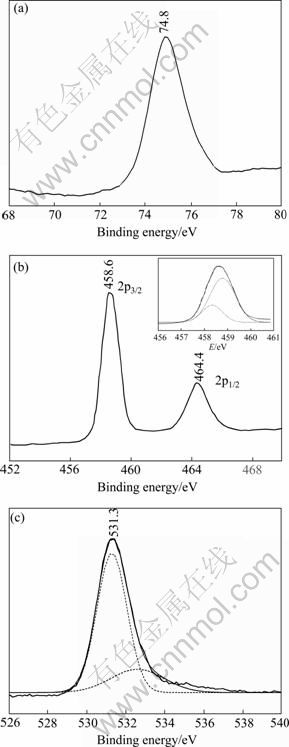

2.2 样品的元素形态分析

图3所示为Al-TiO2介孔材料的X射线光电子能谱,其中图3(a)、(b)、(c)所示分别为Al、Ti和O元素的单谱,说明样品由Al、Ti和O元素组成。图3(a)显示,Al 2p芯级能谱峰位于74.8 eV处,对应于Al的正三价氧化态。在Ti 2p的XPS高分辨谱(图3(b))中,结合能在458.6、464.4 eV处的芯级能谱峰分别归属于Ti 2p3/2和Ti 2p1/2,体现了Ti(Ⅳ)的特征XPS峰。相比纯TiO2,Al-TiO2介孔的两个峰移向较高结合能,说明介孔材料中Ti离子的化学环境受到了Al离子掺杂的影响。

图3 Al-TiO2介孔材料的XPS谱

Fig.3 XPS spectra of mesoporous Al-doped TiO2: (a) Al 2p (Inset shows high resolution spectra of Ti 2p3/2); (b) Ti 2p; (c) O 1s

图3(c)显示,样品中的O 1s芯级能谱峰位于531.3 eV处,不同于纯TiO2的O 1s的单峰(529.4 eV),通过拟合发现,Al-TiO2中O元素具有两个芯级峰,这充分说明介孔材料中存在两种不同化学位移的O2-。Al3+半径是0.061 nm,而Ti4+的半径为0.075 nm,两者比较接近,并容易在研磨-溶胶法制备过程中发生取代形成Al-O-Ti体系,造成介孔材料中的部分Ti4+处在一个电负性的环境中,使得Ti4+的正电荷适当分散而保持体系的电荷平衡,从而导致Ti 2p的结合能稍有增加,产生两个O 1s的芯级峰。根据Ti 2p和Al 2p的结合能数据,可以得到介孔材料中Ti与Al的摩尔比为41:5, 则Al在整个金属原子中含量为4.65%,接近添加值(4.76%)。由此可见,简单的研磨-溶胶法能够成功制备适量Al掺杂的TiO2介孔材料。

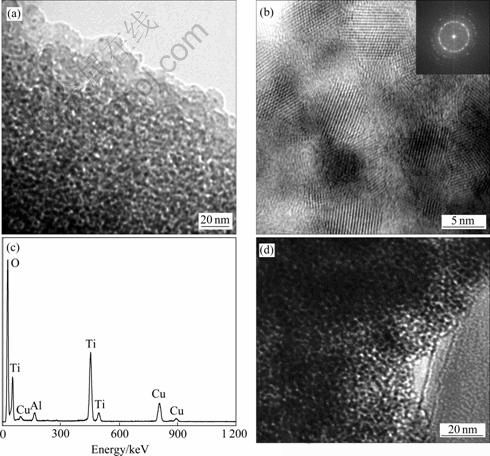

2.3 样品的TEM和HRTEM像

图4所示为Al掺杂TiO2和纯TiO2介孔材料的TEM像,其中图4(a)~(c)所示分别是Al-TiO2介孔材料的TEM、HRTEM和EDS谱,而图4(d)所示为TiO2介孔材料的TEM像。

从图4(a)和4(d)可以看出,两种样品都呈现出清晰的三维蚯蚓状孔道结构,具有典型的介孔结构。图4(b)显示,Al-TiO2介孔材料由晶化程度良好的纳米颗粒和无定形颗粒组成,尺寸约为7 nm、且晶化度高的纳米颗粒比较均匀地分散于无定形颗粒以及晶界内。Al-TiO2介孔材料的这种共存现象说明有序介孔来源于高温处理的无序介孔材料,而且样品中众多晶界可能阻碍了TiO2和Al掺杂TiO2晶体的进一步生长,甚至会出现介孔材料的塌陷现象[29]。Al-TiO2介孔材料的平均孔径约为4.5 nm,这与BET测试结果吻合。图4(b)中的插图所示为Al-TiO2样品的选区电子衍射花样,呈现出清晰的多晶衍射环,说明样品是掺杂有无定形结构的多晶,这与XRD谱基本一致。Al-TiO2介孔材料的EDS谱也显示,样品中含有Ti、O、Al和Cu 4种元素,其中,Cu来自于制样的铜网。上述结果进一步说明,简单的研磨-溶胶法可以成功合成晶体和非晶共存的Al掺杂的TiO2介孔材料。

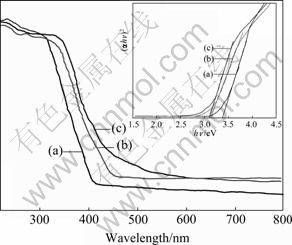

2.4 样品的紫外漫反射光谱分析

图5所示为TiO2、Al-TiO2介孔材料和商用TiO2光催化剂( P25)的紫外-可见漫反射光谱。

图4 Al-TiO2和TiO2介孔材料的TEM像及EDS谱

Fig.4 TEM image(a), HRTEM image(b) and EDS pattern(c) of mesoporous Al-TiO2 and TEM image(d) of TiO2

图5 样品的紫外-可见漫反射光谱图

Fig.5 UV-vis diffuse reflectance spectra of samples: (a) P25; (b) TiO2; (c) Al-TiO2

由图5可知, 商用P25光催化剂仅在小于400 nm的紫外光区具有吸光性能, 而TiO2介孔材料和Al掺杂的TiO2催化剂的吸光带边均发生少许红移。图5中的插图是3个样品的光吸收系数(αhv)2对能量(hv)的变化关系曲线。由此可知,P25、介孔TiO2和介孔Al-TiO2的直接禁带宽度分别是3.37、3.13和3.10 eV。一般而言,纳米尺寸效应引起样品的紫外吸收边的蓝移,但有序介孔结构的出现会使样品对光的吸收效率超越了尺寸效应,因而介孔TiO2的Eg略小于P25的能带隙。而在TiO2晶相中掺杂金属离子有利于吸收边的红移[31]。从图5(c)中并未发现与Al3+相关的电子转移吸收峰, 这说明吸光带边的红移在于掺杂Al3+进入TiO2的晶格结构导致TiO2的微观电子结构的改变。

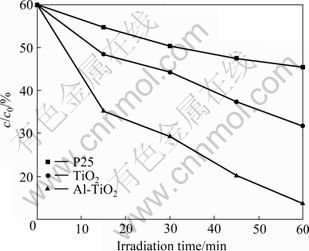

2.5 样品的光催化性能

TiO2、Al-TiO2介孔材料和以及商业P25 TiO2在紫外光(λ=365 nm,125 W)照射下进行光降解甲基橙溶液实验,其结果如图6所示。由图6可知,在紫外光照射1 h过程中,3种样品均对100 mL甲基橙溶液(20 mg/L, pH=2)具有一定程度的光降解能力,其中以Al-TiO2介孔材料的光催化效果最佳。

相对商业P25而言,TiO2和Al-TiO2介孔材料的光催化活性较强,其原因是介孔材料具有更大的比表面积,在同等条件下能够吸附更多的甲基橙分子。在光照30 min时,P25的光降解率仅为19.5%,介孔TiO2的光降解率为31.7%,而Al-TiO2介孔材料的光降解率已经达到 61.4%。当光照60 min后,后者的光降解率达92.5%,而前两者分别仅为29.3%和56.5%。可见,介孔TiO2经过Al掺杂后,其光催化活性得到了显著提高。Al-TiO2介孔材料的大比表面积和Al掺杂TiO2晶格引起的正电荷不平衡是光催化活性提高的两个重要因素,前者有利于大量吸附和分散甲基橙分子,在紫外光激发下,具有较高能量的电子容易从甲基橙分子激发状态下转移到Al-TiO2介孔材料的导带上,弥补Al-TiO2 介孔材料中的正电荷缺失,释放出更多的氧化性强的空穴,致使大量空穴能氧化分解甲基橙分子。

图6 不同光催化剂的催化活性

Fig.6 Catalytic activities of various photocatalysts

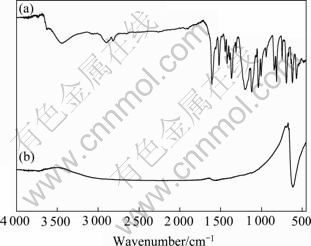

图7所示为用Al-TiO2介孔材料(4.65%)光降解甲基橙溶液(1 h)前后的IR谱。其中,图7(a)所示为甲基橙的标准红外吸收曲线,而图7(b)所示为Al-TiO2光催化降解1 h后所得溶液的红外吸收曲线。从标准谱看出,在1 541和1 562 cm-1处观察到硝基的不对称伸缩振动峰,经过光降解1 h后,该不对称伸缩振动峰基本消失,说明其偶氮键首先被氧化成硝基,然后硝基化合物进一步被降解。对于甲基橙分子,有效的降解反应部位也应是分子中的偶氮键,甲基橙光降解时偶氮键的红外信号的消失正好说明光降解过程已经完成。

图7 Al-TiO2光降解甲基橙前后的红外光谱

Fig.7 IR spectra of methyl orange (MO) before (a) and after (b) photodegradation by Al-TiO2

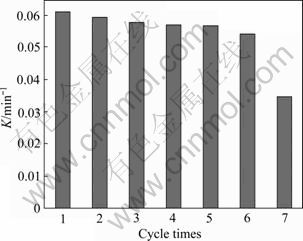

为考察Al-TiO2介孔材料的重复使用性,将完成光降解甲基橙实验的Al-TiO2催化剂回收干燥后继续用于光催化实验,如此反复7次,每次光催化均按2.3节实验进行。每次的光降解反应速率常数(K)如图8 所示。

图8 Al-TiO2 介孔材料的光降解反应速率常数

Fig.8 Degradation rate constant K of mesoporous Al-TiO2

由图8可知,Al-TiO2介孔材料重复使用6次时的光降解速率常数变化并不大,当连续使用7次时才有较大幅度的减小。这些结果说明Al-TiO2介孔具有良好的循环使用性能。

3 结论

1) 采用简单的研磨-溶胶技术制备的TiO2和Al-TiO2介孔材料均属于锐钛矿TiO2晶型,其平均晶粒尺寸分别为26.5和11.7 nm, 比表面积分别为110.2和97.8 m2/g。

2) Al3+进入TiO2晶格,致使Al-TiO2的直接禁带宽度为3.10 eV,小于TiO2介孔材料(3.13 eV)和商用P25 (3.37 eV)的能带隙。

3) P25、TiO2和Al-TiO2介孔材料对甲基橙具有紫外光催化降解甲基橙的能力,其光降解率由大至小的顺序是:Al-TiO2、TiO2、P25。其中,Al-TiO2介孔材料在紫外光(λ=365 nm,125 W)照射60 min后降解率可以达到92.5%,并且具有连续使用6次的循环寿命。

4) 这种简单易行的研磨-溶胶法具有较好的适用性,可推广至其他过渡金属元素(Cr、Co、Ni、Fe、Mo、W等)掺杂TiO2介孔材料的合成和光催化应用。

REFERENCES

[1] 张书翠, 姜 东, 唐 涛, 李君华, 徐 耀. 高分散TiO2/SBA-15的制备及光催化性能[J]. 物理化学学报, 2010, 26(5): 1330-1336.

ZHANG Shu-cui, JIANG Dong, TANG Tao, LI Jun-hua, XU Yao. Synthesis and photocatalytic activity of highly dispersed TiO2/SBA-15[J]. Acta Phys-Chim Sin, 2010, 26(5): 1330-1336.

[2] 刘克松, 张密林, 王 江, 付宏刚. 非硅基介孔材料和介孔复合体的合成与特性[J]. 应用化学, 2006, 23(1): 1-6.

LIU Ke-song, ZHANG Mi-lin, WANG Jiang, FU Hong-gang. Synthesis and preparation of non-siliceous mesoporous materials and mesoporous composites[J]. Chinese Journal of Applied Chemistry, 2006, 23(1): 1-6.

[3] 薛韩玲, 葛岭梅, 李建伟. MCM-41介孔分子筛和纳米TiO2/MCM-41的合成与结构表征 [J]. 纳米科技, 2007, 4(5): 58-61.

XUE Han-ling, GE Ling-mei, LI Jian-wei. Synthesis and charaterization of mesoporous molecular sieve MCM-41 and TiO2/MCM-41[J]. Nanoscience & Nanotechnology, 2007, 4(5): 58-61.

[4] LI Hai-bing, LIU Guo-cong, CHEN Shu-guang, LIU Qi-cheng. Novel Fe doped mesoporous TiO2 microsphere: Ultrasonic- hydrothermal synthesis, characterization, and photocatalytic properties[J]. Physica E, 2010, 42: 1844-1849.

[5] LIU Shao-you, LIU Guo-cong, FENG Qi-gei. Al-doped TiO2 mesoporous materials: Synthesis and photodegradation properties[J]. Journal of Porous Materials, 2010, 17: 197-206.

[6] 田西林, 陶 杰, 陶海军, 包祖国, 汤育欣. 钛基材上制备TiO2纳米管阵列电极的电化学性能[J]. 中国有色金属学报, 2009, 19(5): 904-909.

TIAN Xi-lin, TAO Jie, TAO Hai-jun, BAO Zu-guo, TANG Yu-xin. Electrochemical properties of TiO2 nanotube arrays prepared by anodic oxidation on titanium substrate[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 904-909.

[7] TAGUCHI A, SCH?TH F. Ordered mesoporous materials in catalysis[J]. Microporous and Mesoporous Materials, 2005, 77: 1-45.

[8] ZHANG Bao-long, CHEN Bai-shun, SHI Ke-yu, HE Shang-jin, LIU Xiao-dong, DU Zong-jie, YANG Ke-lian. Preparation and characterization of nanocrystal grain TiO2 porous microspheres[J]. Applied Catalysis B: Environmental, 2003, 40: 253-258.

[9] AN Tai-cheng, LIU Ji-kai, LI Gui-ying, ZHANG Shan-qing, ZHAO Hui-jun, ZENG Xiang-ying, SHENG Guo-ying, FU Jia-mo. Structural and photocatalytic degradation characteristics of hydrothermally treated mesoporous TiO2[J]. Applied Catalysis A: General, 2008, 350: 237-243.

[10] MOHAMMADI M R, FRAY D J, CORDERO-CABRERA M C. Sensor performance of nanostructured TiO2 thin films derived from particulate sol-gel route and polymeric fugitive agents[J]. Sensors and Actuators B, 2007, 12: 74-83.

[11] MOHAMMADI M R, FRAY D J, CORDERO-CABRERA M C. Sensor performance of nanostructured TiO2 thin ?lms derived from particulate sol-gel route and polymeric fugitive agents[J]. Sensors and Actuators B, 2007, 124: 74-83.

[12] DENTANI T, NAGASAKA K I, FUNABIKI K, JIN Ji-ye, YOSHIDA T, MINOURA H, MATSUI M. Flexible zinc oxide solar cells sensitized by styryl dyes[J]. Dyes Pigments, 2008, 77: 59-69.

[13] 施晶莹, 冷文华, 程小芳, 张 昭, 张鉴清, 曹楚南. 钴氮共掺杂TiO2薄膜的制备及其光电化学性质[J]. 中国有色金属学报, 2007, 17(9): 1536-1542.

SHI Jing-ying, LENG Wen-hua, CHENG Xiao-fang, ZHANG Zhao, ZHANG Jian-qing, CAO Chu-nan. Preparation of cobalt and nitrogen codoped TiO2 thin films and their photoelctrochemical performance[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(9): 1536-1542.

[14] TAN Rui-qin, HE Yu, ZHU Yong-fa, XU Bo-qing, CAO Li-li. Hydrothermal preparation of mesoporous TiO2 powder from Ti(SO4)2 with poly(ethylene glycol) as template[J]. Journal of Materials Science, 2003, 38: 3973-3978.

[15] WANG Cheng, DENG Zhao-xiang, LI Ya-dong. The synthesis of nanocrystalline anatase and rutile titania in mixed organic media[J]. Inorg Chem, 2001, 40: 5210-5214.

[16] de Soler-ILLIA A A, LOUIS A, SANCHEZ C. Synthesis and characterization of mesostructured titania-based materials through evaporation-induced self-assembly[J]. Chem Mater, 2002, 14: 750-759.

[17] YU J C, ZHANG L Z, YU J G. Rapid synthesis of mesoporous TiO2 with high photocatalytic activity by ultrasound-induced agglomeration[J]. New J Chem, 2002, 74: 416-420.

[18] YOO K S, LEE T G, KIM J. Preparation and characterization of mesoporous TiO2 particles by modi?ed sol-gel method using ionic liquids[J]. Microporous and Mesoporous Materials, 2005, 84: 211-217.

[19] SU C, TSENG C M, CHEN L F, YOU B H, HSU B C, CHEN S S. Sol-hydrothermal preparation and photocatalysis of titanium dioxide[J]. Thin Solid Films, 2006, 498: 259-265.

[20] JIAO Jian-xia, XU Qun, LI Li-min. Porous TiO2/SiO2 composite prepared using PEG as template direction reagent with assistance of supercritical CO2[J]. Journal of Colloid and Interface Science, 2007, 316: 596-603.

[21] LI He-xing, BIAN Zhen-feng, ZHU Jian, ZHANG Die-qing, LI Gui-sheng, HUO Yu-ning, LI Hui, LU Yun-feng. Mesoporous titania spheres with tunable chamber structure and enhanced photocatalytic activity[J]. J Am Chem Soc, 2007, 129: 8406-8407.

[22] LI Jin-long, MA Xin-xin, SUN Ming-ren, LI Xiao-min, SONG Zhen-lun. Structure and visible photocatalytic activity of nitrogen-doped meso-porous TiO2 layer on Ti6Al4V substrate by plasma-based ion implantation[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(s2): s665-s668.

[23] SERTCHOOK H, ELIMELECH H, MAKAROV C, KHALFIN R, COHEN Y, SHUSTER M, BABONNEAU F, AVNIR D. Composite particles of polyethylene @ silica[J]. Journal of American Chemistry Society, 2007, 129: 98-108.

[24] FRINDELL K F, BARTL M H, ROBINSON M R. Visible and near-IR luminescence via energy transfer in rare earth doped mesoporous titania thin films with nanocrystalline walls[J]. Journal of Solid Chemistry, 2003, 172(1): 81-88.

[25] STATHATOS E, PETROV T, LIANOS P. Study of the efficiency of visible-light photocatalytic degradation of basic blue adsorbed on pure and doped mesoporous titania films[J]. Langmuir, 2001, 17(16): 5025-5030.

[26] YIN J S, WANG Z L. Temple-assisted self-assembly and cobalt doping of ordered mesoporous titania nanostructures[J]. Advanced Materials, 1999, 11(6): 469-472.

[27] WANG X C, YU J C, YIP H Y, et al. A mesoporous Pt/TiO2 nanoarchitecture with catalytic and photocatalytic function[J]. Chemistry: A Europen Journal, 2005, 11(10): 2997-004.

[28] YU J C, WANG X C, WU L. Sono- and photochemical routes for the formation of highly dispersed gold nanoclusters in mesoporous titania films[J]. Advanced Functional Materials, 2004, 14(12): 1178-1183.

[29] LI Hai-bin, LIU Guo-cong, DUAN Xue-chen, JIA Xiu-bo. Solvothermal synthesis and characterization of Fe (Ⅲ)-doped mesoporouse TiO2[J]. J Cent South Univ Technol, 2007(S2): 139-144.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(21061006,51162026);中南大学博士后基金资助项目(133274341015501);湖南省自然科学基金资助项目(08JJ3104);广西自然科学基金资助项目(2010GXNSFB013018,2011GXNSFA018049);中国博士后基金资助项目(20100480949);中国博士后特别资助项目(201104509)

收稿日期:2011-07-22;修订日期:2010-11-02

通信作者:刘国聪,教授,博士;电话:0775-2666917;E-mail: gcl_109@163.com