DOI:10.19476/j.ysxb.1004.0609.2018.09.19

低品位铅铋物料熔池熔炼中元素的分配行为

杨天足1,肖 辉1,陈 霖1, 2,陈 威1,刘伟锋1,张杜超1

(1. 中南大学 冶金与环境学院,长沙 410083

2. 湖南金旺铋业股份有限公司 博士后科研流动站协作研发中心,郴州 423000)

摘 要:低品位复杂物料中杂质元素含量高,其分配行为对熔炼工艺条件及产品质量具有很大影响。针对低品位铅铋物料氧化熔炼及其氧化渣还原熔炼两段工艺开展研究,考察了各因素对元素分配行为的影响。结果表明:氧化熔炼最佳工艺条件为:通氧量200 L/kg,铁硅质量比1.3,钙硅比0.4。在此工艺条件下,铅、铋、铜、锌、砷和锑在渣中分配比例分别为47.05%、7.37%、10.93%、55.12%、55.86%和47.59%。还原熔炼最佳工艺条件为:铁硅质量比1.2,钙硅质量比0.8,还原剂用量为理论量的1.3倍,还原时间60 min。在此工艺条件下,铅、铋、铜、锌、砷和锑直收率分别为93.34%、99.60%、49.58%、84.38%、49.31%和87.26%。

关键词:铅;铋;低品位复杂物料;熔池熔炼;元素分配

文章编号:1004-0609(2018)-09-1883-10 中图分类号:TF812;TF817 文献标志码:A

铋被广泛应用于冶金、医药、化工、核能、半导体等领域。中国的铋储量居世界第一位,占世界总储量的75%[1]。我国铋储量虽然十分丰富,但70%以上以铋含量低于15%的低品位精矿或铅、铜、锡等金属冶炼的副产品和中间产品形式存在,成分复杂,品位高低不等,其清洁高效处理技术的开发是铋冶炼行业亟待解决的关键问题。

铋的冶炼方法可分为火法和湿法两类。其中传统火法工艺主要有沉淀熔炼、还原熔炼、混合熔炼等[2-3],沉淀熔炼是通过铁屑置换硫化铋精矿中的铋,还原熔炼主要通过碳质还原剂还原含铋的氧化物,混合熔炼则是将硫化铋矿和氧化铋矿混合后在熔炼炉中发生硫化铋沉淀反应、氧化铋还原反应以及硫化铋与氧化铋的交互反应。传统铋火法粗炼技术对原料适应能力较差,主要用于处理高品位的含铋物料;在熔炼过程中同时产生大量冰铜,降低铋回收率;且易产生低浓度SO2烟气,难以经济的进行环保处理。

湿法工艺主要用于处理低品位精矿和复杂物料以提高铋提取的选择性。国内已工业生产并具有代表性的湿法工艺包括硫酸-工业食盐浸出法、三氯化铁-盐酸浸出法等[4-6]。湿法工艺多采用氯盐体系浸出,原料为硫化矿时需要加入氯气、三氯化铁等氧化剂。铋浸出至溶液后可采用铁屑还原得海绵铋或通过水解沉淀制得氯氧铋。湿法粗炼技术虽然能够提高铋提取的选择性,但存在试剂消耗量大,设备腐蚀严重,废水处理困难等问题。

富氧熔池熔炼工艺属于强化冶炼技术,具有原料适应性强,炉床能力高、劳动环境好以及高效节能等优点[7],近年来已被广泛应用于铜、铅、镍等有色金属冶炼行业[8-10]。针对含铋物料的高效清洁处理问题,杨天足等提出了富氧熔池熔炼处理工艺[11-12]。该工艺将含铋精矿进行氧化熔炼脱硫后,对氧化渣进行还原熔炼得到铋合金,再根据铋合金成分进一步精炼。目前该技术已在低品位铅铋物料处理方面进行了工业化应用[13]。相比于传统的铋冶炼工艺,该工艺原料适应性大大提高,处理能力达到反射炉的50倍以上,铋回收率达到98%以上,且通过富氧技术避免了低浓度SO2烟气污染,取得了良好的经济和环保效应。但该项技术目前仅针对物料中的主要金属铋和铅在富氧熔池熔炼过程中的行为进行了考察,而对铜、锌、砷和锑等元素的分配行为则尚未进行研究。随着近年来铋冶炼原料成分的进一步复杂化,考察这些元素分配行为对于优化工艺技术指标,产品质量和环保措施具有重要的意义。

本文作者主要考察低品位铅铋物料熔池熔炼过程中主要工艺参数对铅、铋、铜、锌、砷、锑等元素分配行为的影响,计算其在熔炼过程中各物相中的分配比例,探索熔池熔炼工艺的最优工艺条件。

1 实验

1.1 实验原料

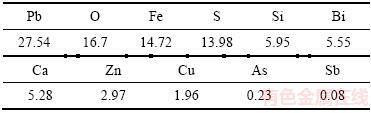

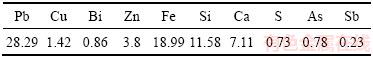

实验所采用的原料为湖南某企业的低品位铅铋物料,其主要元素含量(质量分数,%)如表1所列。该物料铅含量为27.54%,低于铅精矿(w(Pb)>45%);铋含量为5.55%,低于铋精矿(w(Bi)>15%),因此,该物料属于典型的低品位铅铋物料。

表1 低品位铅铋物料的主要成分

Table 1 Composition of low-grade lead and bismuth ore (mass fraction, %)

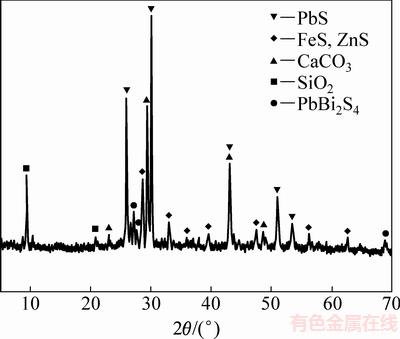

原料XRD谱如图1所示,物料中主要物相为PbS、FeS、ZnS、SiO2、CaCO3以及PbBi2S4等。

图1 低品位铅铋物料XRD谱

Fig. 1 XRD pattern of low-grade lead and bismuth ore

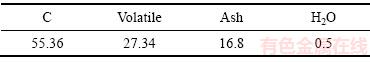

实验使用CaO,SiO2及Fe2O3化学纯试剂(西陇化学)配制熔剂,使用工业纯氧(湖南高科气体)作为氧化剂,以煤粉作为还原剂,煤粉成分如表2所列。

表2 还原煤粉成分

Table 2 Composition of coal (mass fraction, %)

1.2 实验设备

实验设备为高温井式炉(合肥科晶,VTF1600X),反应容器采用黏土坩埚(直径90 mm,高度70 mm)。对渣中成分半定量分析采用X射线荧光仪(XRF-1800,Shimadzu,日本岛津)。主要元素定量分析采用ICP-AES(IRIS,Interprid Ⅲ XRS,美国热电),物相分析使用X射线衍射仪(SmartLab,日本理学)。

1.3 实验方法

实验采用氧化熔炼-还原熔炼两段熔炼方式处理低品位铅铋物料。氧化熔炼实验方法为:称取200 g物料,根据渣型要求计算熔剂的配入量,充分混匀后移入坩埚中。在1250 ℃下通氧熔炼一定时间,取出氧枪,保温静置45 min。反应完成后坩埚取出冷却至室温、破碎,对渣和合金进行称量并分析成分。还原熔炼实验方法为:称取150 g氧化渣,根据渣型和还原煤理论用量计算熔剂和还原剂配入量,充分混匀后移入坩埚中,在1200 ℃下熔炼一定时间,保温静置45 min,对渣和合金进行称量并分析成分。元素分配率通过式(1)、(2)和(3)计算:

(1)

(1)

(2)

(2)

(3)

(3)

式中:wMeM为该元素在合金中的质量分数;mM为合金的总质量;mMeS为该元素在渣中的质量分数;mS为渣的总质量;mMe,tol为原物料中该元素的总质量。Dm、Ds和Dg分别表示元素分配至合金、渣和烟尘中的比例。

2 结果与讨论

2.1 氧化熔炼实验

2.1.1 通氧时间的影响

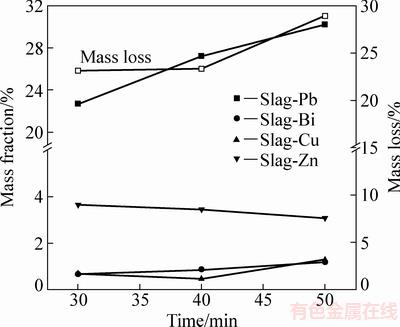

固定实验条件铁硅比(m(FeO)/m(SiO2))为1.3,钙硅比(m(CaO)/m(SiO2))为0.4,通氧速率为1.0 L/min,考察通氧时间对元素分配行为的影响,结果如图2所示。当通氧20 min左右时,炉渣未完全熔化,没有出现渣-金属分层现象。随着通氧时间从30 min增加至50 min,渣中铅、铋和铜含量分别由22.68%、0.67%和0.68%增加至30.21%、1.22%和1.29%。渣含锌则从3.64%降至3.08%。这说明随着通氧量增加,硫化物被氧化成氧化物进入渣相中的量增多,同时易挥发成分的挥发量增加,使得挥发率由23.13%增加至28.96%。当通氧时间为50 min时,物料被过氧化,熔炼产物只有渣相,而且质量损失率较高,说明该条件下不利于回收物料中的有价金属,因此选择通氧时间为40 min。

图2 通氧时间对渣中元素含量的影响

Fig. 2 Effect of oxygen injecting time on element contents in slag

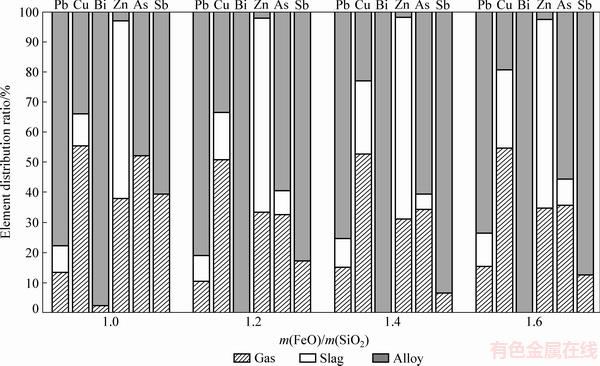

2.1.2 铁硅比的影响

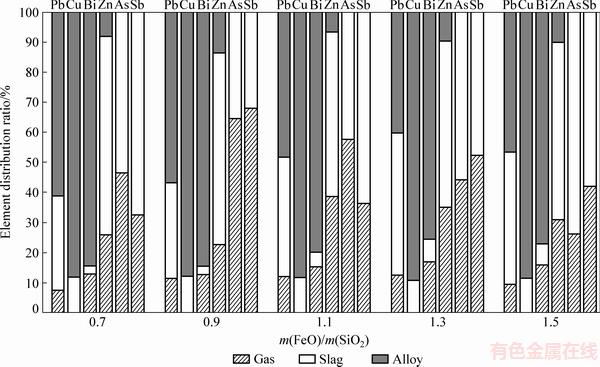

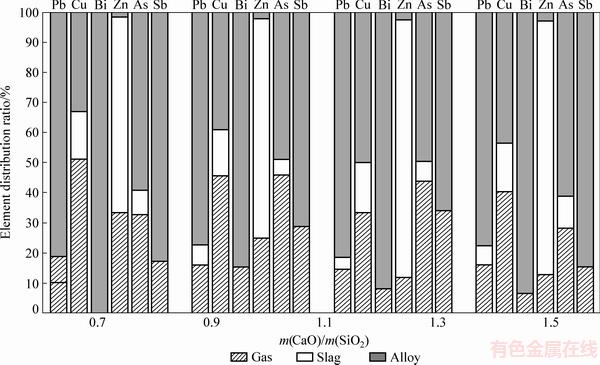

固定实验条件为通气速率1.0 L/min,通气时间40 min,钙硅比为0.4,控制铁硅比分别为0.7、0.9、1.1、1.3和1.5,探索铁硅比对元素分配的影响,结果如表3和图3所示。可以看出,当铁硅比从0.7增加到1.3时,渣中铅含量从16.19%增加到27.23%,铜在渣中的分配从31.49%增加到46.69%,继续增加铁硅比为1.5时,渣中铅含量降至23.43%,分配降至43.86%。因为随着铁硅比的增加,炉渣的碱度增加,同时其黏度降低,流动性增强,有利于生成的氧化铅与渣中SiO2结合进入渣中[15]。当铁硅比进一步增加时,过多的铁容易导致生成高熔点的Fe3O4,引起炉渣黏度增加。渣中铜含量受铁硅比影响较小,在0.4%~0.5%之间波动,其在渣中的分配约为10%。由于铋和铅的性质相近且更容易还原,渣中的铋含量随铁硅比变化趋势与铅类似,其在渣中的分配率仅为2.6%~7.4%。渣中锌含量约为3.5%,约有50%~60%的锌进入渣中。砷和锑由于含量较低,随铁硅比变化趋势波动较大,但在高铁硅比条件下进入渣相比例增大,有利于与其他有价元素分离。在铁硅比为1.3时,砷和锑在渣中的分配率达到55.86%和47.59%。综上所述,选取铁硅比为1.3。

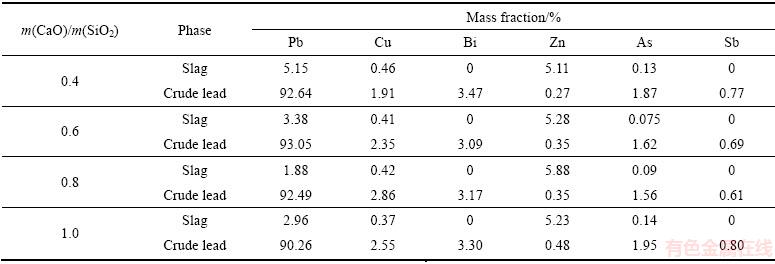

2.1.3 钙硅比的影响

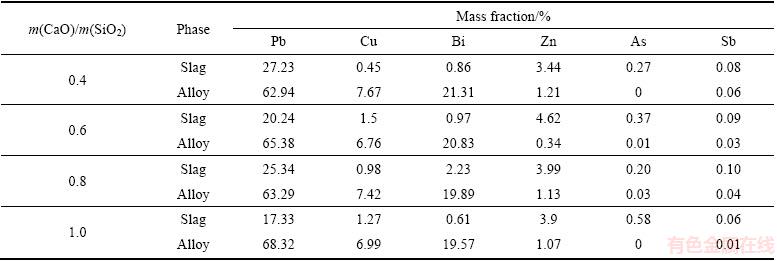

固定实验条件为通气速率1.0 L/min,通气时间40 min,铁硅比为1.3,分别控制钙硅比为0.4、0.6、0.8和1.0,考察钙硅比对元素分配的影响,结果如表4和图4所示。当钙硅比为0.4时,渣中铅含量达到27.23%。随着钙硅比增加,渣中铅含量降低,铅在渣中的分配比例从46.69%降至29.12%。由于CaO是碱性氧化物,加入CaO能够提高渣中酸性氧化物PbO的活度,从而降低渣中铅含量[16]。随着钙硅比的增加,铜在渣中的分配率从10.96%增加到38.83%。锌、锑和砷进入渣中的分配率分别为60%、50%和70%。

表3 铁硅比对渣和合金成分的影响

Table 3 Effect of m(FeO)/m(SiO2) on composition of slag and alloy

综上所述,选取钙硅比为0.4。

2.1.4 扩大实验

根据以上实验确定了氧化熔炼最优工艺条件如下:铁硅比为1.3,钙硅比为0.4,通氧量为200 L/kg。在该条件下使用500 g低品位铅铋物料进行扩大实验,氧化熔炼获得的铅铋合金与渣分离良好,氧化渣主要元素含量和物相分别如表5和图5所示。可以看到,除去脉石成分,渣中铅含量达到28.29%,铋含量则降低至0.86%,已初步实现了铅和铋的分离。铅在渣中主要以铅的氧化物形式存在,锌在氧化熔炼过程中与Fe3O4结合形成铁酸锌。

2.2 还原熔炼实验

相比于铅含量为45%~50%的高铅渣,本研究中低品位铅铋物料氧化熔炼得到的渣含铅小于30%,且其中铋、铜、锌等有价金属含量更高,需要对渣进行还原熔炼以进一步回收金属并研究其元素分配行为。在还原熔炼实验中,主要考察铁硅比、钙硅比、还原剂用量和还原时间对元素分配的影响。

图3 铁硅比对元素分配率的影响

Fig. 3 Effects of m(FeO)/m(SiO2) on distribution ratios of elements

图4 钙硅比对元素分配率的影响

Fig. 4 Effects of m(CaO)/m(SiO2) on distribution ratios of elements

表4 钙硅比对渣和合金成分的影响

Table 4 Effect of m(CaO)/m(SiO2) on composition of slag and alloy

表5 氧化渣中主要元素含量

Table 5 Elements content in oxidation slag (mass fraction, %)

图5 氧化渣XRD谱

Fig. 5 XRD pattern of oxidation slag

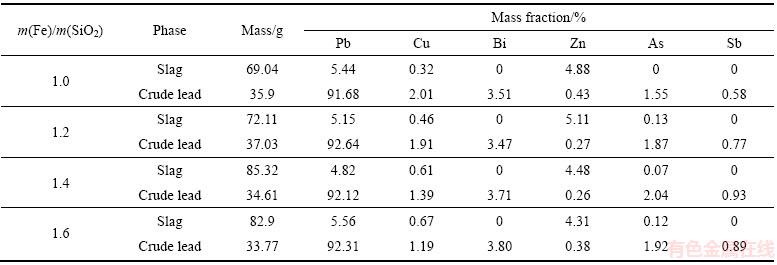

2.2.1 铁硅比的影响

固定实验条件还原时间为60 min,还原剂用量为理论量的1.0倍,钙硅比为0.4,研究铁硅比对有价元素分配率的影响。其中还原剂用量理论量为煤粉还原氧化渣中PbO、Cu2O、Bi2O3、As2O3和Sb2O3等氧化物的理论用量。研究结果如表6和图7所示。可以看出,铅、铜和铋主要进入粗铅。当铁硅比为1.2时,铅的直收率达到80.83%。铁硅比对铋的直收率影响不大,说明铋充分被还原。铜的直收率不高,且随铁硅比的增加而降低,这可能是由于铁硅比增加导致了高熔点Fe3O4和ZnFeO4的增多,加大了渣的黏度,增加了铜在渣中的机械夹杂[17]。锌主要分配在渣中,当铁硅比为1.2时,锌在渣中的分配率达到最高的67.64%。砷和锑在还原熔炼中主要进入粗铅。随着铁硅比的增加,砷和锑进入粗铅的比例增加,最高约达到60%和70%。综合考虑,最优条件选取铁硅比为1.2。

2.2.2 钙硅比的影响

固定实验条件还原时间为60 min,还原剂用量为理论量的1.0倍,铁硅比为1.2,研究钙硅比对有价金属分配率的影响。从表7和图7可知,钙硅比从0.4增加到0.8时,铜的直收率增加到81.12%;继续增加钙硅比到1.0,铜的直收率反而下降到77.46%。其原因在于钙硅比的增加会降低渣的熔点和铅还原反应的吉布斯自由能;但过高的钙硅比会导致渣的黏度增加,不利于铜与渣的分离[18]。铜的直收率随着钙硅比增大逐渐从33.18%增加到49.97%。钙硅比从0.4增加至1.0时,锌在渣中的分配率从67.64%增加至85.69%。这是因为钙硅比的增加可使Si-O及Fe-O-Zn的结合力减弱,提高了铁和锌的在炉渣中的活度。砷和锑在粗铅中含量增加会导致粗铅品质下降,而钙硅比为0.8时,砷和锑在粗铅中的分配率最小。综合考虑,最优条件选取钙硅比为0.8。

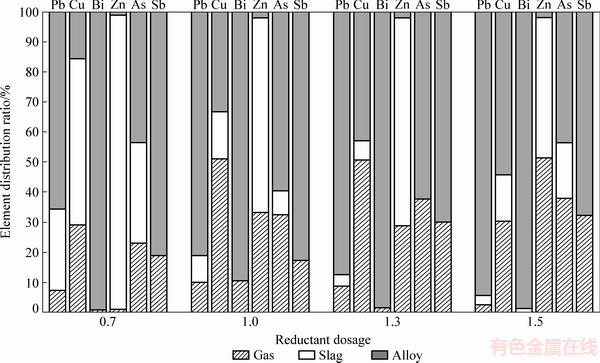

2.2.3 还原剂用量的影响

固定实验条件铁硅比为1.2,钙硅比为0.4,还原时间为60 min,考察还原剂用量(还原煤用量与理论用量的质量比)对有价金属分配率的影响。如表8和图8所示,还原剂用量从0.7增加到1.3时,铅、铜和砷在粗铅中的分配率分别从65.42%、15.35%和43.22%增加到87.17%、42.72%和62.02%。继续增加还原剂用量到1.5,铅在渣中的分配率降低不明显,而铜和砷在渣中的分配率稍有增加。这是因为还原气氛过强改变了渣型,导致铜和砷在渣中的溶解增大。锑的分配率受还原剂用量影响较小,其在粗铅中的分配率维持在70%。当还原剂用量从0.7增加到1.5时,锌在渣中的分配率从97.61%降低至46.58%。这是因为还原性气氛过强会导致锌挥发进入烟尘,不利于锌的后续回收。综合考虑,最优条件选择还原剂用量为1.3。

表6 铁硅比对渣和粗铅成分的影响

Table 6 Effects of m(Fe)/m(SiO2) on composition of slag and lead

图6 铁硅比对元素分配率的影响

Fig. 6 Effects of m(Fe)/m(SiO2) on distribution ratios of elements

表7 钙硅比对渣和粗铅成分的影响

Table 7 Effects of m(CaO)/m(SiO2) on composition of slag and lead

图7 钙硅比对元素分配率的影响

Fig. 7 Effects of m(CaO)/m(SiO2) on distribution ratios of elements

表8 还原剂用量对渣和粗铅成分的影响

Table 8 Effects of reductant dosage on composition of slag and lead

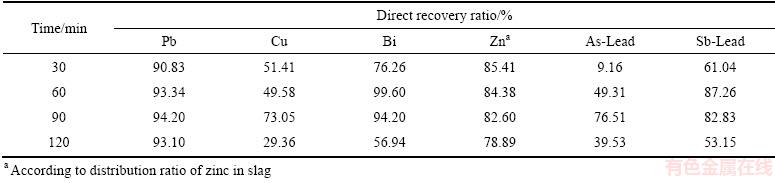

2.2.4 还原时间的影响

固定实验条件铁硅比为1.2,钙硅比为0.8,还原剂用量为理论量的1.3倍,考察还原时间对有价元素直收率的影响,结果如表10所列。随着还原时间由30 min增加至90 min,铅的直收率由90.83%增大至94.20%。铜的直收率波动较大,最高直收率为73.05%,最低为29.36%,可能与铜在渣中机械夹杂有关。当还原时间为60 min时,铋的直收率达到99.60%。锌的直收率随时间的增长而降低,因为还原时间越长,锌的挥发越严重。砷和锑的直收率随还原时间变化波动较大,控制还原时间为60 min有利于增加锑的直收率而降低砷在粗铅中的分配。综合考虑,最优条件选择还原时间为60 min。

图8 还原剂用量对元素分配比例的影响

Fig. 8 Effects of reductant dosage (i.e. mass ratio of reductive coal dosage to theoretical coal dosage) on distribution ratios of elements

表9 还原时间对元素直收率的影响

Table 9 Effects of reduction time on direct recovery ratios of elements

3 结论

1) 氧化熔炼最佳工艺条件如下:通氧量200 L/kg,铁硅比为1.3,钙硅比为0.4。最佳工艺条件下,渣中铅和铋含量分别为27.23%和0.86%。铅、铋、铜、锌、砷和锑在氧化渣中的分配率分别为46.69%、7.37%、10.93%、55.12%、55.86%和47.59%,通过氧化熔炼已初步实现了铅和铋的分离。

2) 还原熔炼最佳工艺条件如下:铁硅比为1.2,钙硅比为0.8,还原剂用量为理论量的1.3倍,还原时间为60 min。最佳工艺条件下,还原渣中铅、铜、铋、锌、砷和锑含量分别为1.88%、0.22%、0%、4.44%、0.09%和0%。铅、铋、铜、锌、砷和锑直收率分别为93.34%、99.60%、49.58%、84.38%、49.31%和87.26%,取得了较高的有价元素回收率。

REFERENCES

[1] 李 俊. 铋精矿富氧熔池熔炼的工艺及基础研究[D]. 长沙: 中南大学, 2013.

LI Jun. Research on the fundamental and process of smelting bismuth concentrate with oxygen in bath[D]. Changsha: Central South University, 2013.

[2] 唐朝波, 刘 永, 叶龙刚, 陈永明, 唐谟堂, 杨声海. 硫化铋精矿还原造锍熔炼一步炼铋[J]. 中国有色金属学报, 2017, 27(2): 363-370.

TANG Chao-bo, LIU Yong, YE Long-gang, CHEN Yong-ming, TAGN Mo-tang, YANG Sheng-hai. Production of bismuth by direct reducing-matting smelting from bismuth sulfide concentrate[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 363-370.

[3] 北京有色设计总院主编. 重有色金属冶炼设计手册(铅锌铋卷)[M]. 北京: 冶金工业出版社, 1996: 643-645.

Beijing Nonferrous Metals Design Institute. Handbook of heavy non-ferrous metal smelting design (lead zinc bismuth volume)[M]. Beijing: Metallurgical Industry Press, 1996: 643-645.

[4] 杨继生, 杨德香. 硫化铋精矿处理新工艺研究[J]. 有色金属(冶炼部分), 2014(11): 9-11.

YANG Ji-sheng, YANG De-xiang. New processing to treat bismuth sulfide concentrate[J]. Nonferrous Metals (Extractive Metallurgy), 2014(11): 9-11.

[5] 王成彦, 邱定蕃, 江培海. 国内铋湿法冶金技术[J]. 有色金属, 2001, 53(4): 15-18.

WANG Cheng-yan, QIU Ding-fan, JIANG Pei-hai. Bismuth hydrometallurgy technology in China[J]. Nonferrous Metal, 2001, 53(4): 15-18.

[6] 杜新玲, 马科友, 葛道健. 湿法处理氧化铋渣分离铋的研究[J]. 有色金属(冶炼部分), 2016(6): 26-30.

DU Xin-ling, MA Ke-you, GE Dao-jian. Study on bismuth separation from bismuth oxide slag by hydrometallurgical process[J]. Nonferrous Metals (Extractive Metallurgy), 2016(6): 26-30.

[7] CHEN Lin, HAO Zhan-dong, YANG Tian-zu, LIU Wei-feng, ZHANG Du-chao, ZHANG Li, BIN Shu, BIN Wan-da. A comparison study of the oxygen-rich side blow furnace and the oxygen-rich bottom blow furnace for liquid high lead slag reduction[J]. JOM, 2015, 67(5): 1123-1129.

[8] LI Yan-chun, YUAN Ying-zhen, LIU Hui, PENG Bing, LIU Zhi-lou. Iron extraction from lead slag by bath smelting[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(8): 1862-1869.

[9] 郭学益, 王亲猛, 田庆华, ZHAO Bao-jun. 氧气底吹铜熔炼工艺分析及过程优化[J]. 中国有色金属学报, 2016, 26(3): 689-698.

GUO Xue-yi, WANG Qin-meng, TIAN Qing-hua, ZHAO Bao-jun. Analysis and optimization of oxygen bottom blowing copper smelting process[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(3): 689-698.

[10] 刘 军, 刘燕庭. 富氧侧吹直接炼铅工艺研究与应用[J]. 中国有色冶金, 2013, 42(1): 34-36.

LIU Jun, LIU Yan-ting. Research and application of oxygen side blown direct lead smelting process[J]. China Nonferrous Metallurgy, 2013, 42(1): 34-36.

[11] CHEN Lin, HAO Zhan-dong, YANG Tian-zu, XIAO Hui, LIU Wei-feng, ZHANG Du-chao, BIN Shu, BIN Wan-da. An efficient technology for smelting low grade bismuth-lead concentrate: oxygen-rich side blow process[J]. JOM, 2015, 67(9): 1997-2004.

[12] ZHANG Du-chao, ZHANG Xin-wang, YANG Tian-zu, WEN Jian-feng, LIU Wei-feng, CHEN Lin, RAO Shuai, XIAO Qing-kai, HAO Zhan-dong. Reduction smelting on bismuth oxide residue in FeO-SiO2-CaO ternary slag system[J]. Journal of Central South University, 2016, 23(6): 1326-1331.

[13] 余 刚, 吴晓松, 周晓源. 湖南某企业铋冶炼工艺设计[J]. 有色金属工程, 2014, 4(5): 75-78.

YU Gang, WU Xiao-song, ZHOU Xiao-yuan. Industrial design of bismuth smelting in an enterprise in Hunan[J]. Nonferrous Metal Engineering, 2014, 4(5): 75-78.

[14] 白 猛. 铜冶炼伴生元素砷、锑、铋、铼的增值冶金新方法研究[D]. 长沙: 中南大学, 2013.

BAI Meng, Research on novel methods of value-added metallurgy of associated elements arsenic, antimony, bismuth and rhenium in copper smelting process[D]. Changsha: Central South University, 2013.

[15] 张乐如. 现代铅冶金[M]. 长沙: 中南大学出版社, 2013: 230-232.

ZHANG Le-ru. Modern lead metallurgy[M]. Changsha: Central South University Press, 2013: 230-232.

[16] WANG JIN-liang, WEN XIAO-chun, ZHANG CHUAN-fu. Thermodynamic model of lead oxide activity in PbO-CaO-SiO2-FeO-Fe2O3slag system[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1633-1639.

[17] 谭鹏夫, 张传福. 渣中铁硅比对铜熔炼中伴生元素行为的影响[J]. 上海有色金属, 1997(4): 152-155.

TAN Peng-fu, ZHANG Chuan-fu. Effect of iron to silicon ratio in slag on behavior of associated elements in copper smelting[J]. Shanghai Nonferrous Metals, 1997(4): 152-155.

[18] 陈 霖, 杨天足, 刘伟锋, 张杜超, 宾 舒, 宾万达. 高铅渣液态还原过程中有价金属分布[J]. 中国有色金属学报, 2014, 24(4): 1056-1062.

CHEN Lin, YANG Tian-zu, LIU Wei-feng, ZHANG Du-chao, BIN Shu, BIN Wan-da. Distribution of valuable metals in liquid reduction of high lead slag[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 1056-1062.

Elements behavior in bath smelting of low-grade lead-bismuth material

YANG Tian-zu1, XIAO Hui1, CHEN Lin1, 2, CHEN Wei1, LIU Wei-feng1, ZHANG Du-chao1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2.Hunan Jinwang Bismuth Industry Co., Ltd., R & D center of post-doctoral research station, Chenzhou 423000, China)

Abstract: The high impurity content of low grade complex material proposes great influence on bath smelting process parameters as well as product quality. The oxidation smelting of low-grade lead-bismuth materials and reduction smelting of the oxidized slag were studied experimentally. The effects of various factors on elements distribution behaviors in the smelting process was investigated. The results show that the optimum process conditions of oxidation smelting process are as follows: 200 L/kg oxygen to raw material, m(FeO)/m(SiO2) of 1.3, m(CaO)/m(SiO2) of 0.4. Under the optimum condition, the distribution ratios of Pb, Bi, Cu, Zn, As and Sb in the oxidized slag are 46.69%, 7.37%, 10.93%, 55.12%, 55.86% and 47.59%, respectively. At the reduction smelting step, the optimum smelting conditions are as follows: m(FeO)/m(SiO2) of 1.2, m(CaO)/m(SiO2) of 0.8, 1.3 times of the theoretical reducing coal consumption, reducing time 60 min. Under the optimum conditions, the direct recoveries of Pb, Bi, Cu, As and Sb can reach 93.34%, 99.60%, 49.58%, 84.38%, 49.31% and 87.25%, respectively.

Key words: lead; bismuth; low-grade complex material; bath smelting; element distribution

Foundation item: Project(51404296) supported by the National Natural Science Foundation of China; Project (2016M60247) supported by the Postdoctoral Science Foundation of China; Project(2018JJ3662) supported by the Natural Science Foundation of Hunan Province, China

Received date: 2017-08-24; Accepted date: 2018-05-11

Corresponding author: CHEN Lin; Tel: +86-15111045540; E-mail: chenlin0210@csu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学青年基金资助项目(51404296);中国博士后科学基金面上项目(2016M602427);湖南省自然科学青年基金资助项目(2018JJ3662)

收稿日期:2017-08-24;修订日期:2018-05-11

通信作者:陈 霖,副教授,博士;电话:15111045540;E-mail:chenlin0210@csu.edu.cn