DOI: 10.11817/j.issn.1672-7207.2019.07.004

铜浮渣富集熔炼过程金属分配行为

肖辉1,谢博毅1,陈霖1, 2,王志雄2,刘伟锋1,张杜超1,杨天足1

(1. 中南大学 冶金与环境学院,湖南 长沙,410083;

2. 湖南金旺铋业股份有限公司 博士后科研流动站协作研发中心,湖南 郴州,423000)

摘要:针对铜浮渣传统火法处理工艺存在能耗高,环保效果差,铅和铜分离不彻底的问题,采用熔池熔炼工艺处理铜浮渣,研究熔池熔炼过程中铁硅比(m(FeO)/m(SiO2))、钙硅比(m(CaO)/m(SiO2))、硫加入量、铁屑加入量、煤粉加入量和碳酸钠加入量对Pb,Cu,Bi,As,Sb和Sn元素分配的影响,并对熔炼产物渣相和锍相的物相组成进行检测。研究结果表明:在m(FeO)/m(SiO2)为1.9,m(CaO)/m(SiO2)为0.6,硫加入量为铜浮渣的3%,铁屑加入量为10%,煤粉加入量为5%,Na2CO3加入量为6%的最优条件下,Pb,Bi和Sb主要进入粗铅中,其在粗铅中的分配率分别为83.43%,99.09%和43.62%,Cu和As主要进入冰铜中,其在冰铜中的分配率分别为44.10%和88.80%,Sn主要进入烟气中,其在烟气中的分配率为78.58%。As易与Fe形成Fe-As相嵌入冰铜相中。

关键词:铜浮渣;粗铅;火法精炼;熔池熔炼;元素分配

中图分类号:TF811;TF812 文献标志码:A 文章编号:1672-7207(2019)07-1527-10

Metal distribution behavior in copper dross smelting for enrichment

XIAO Hui1, XIE Boyi1, CHEN Lin1, 2, WANG Zhixiong2, LIU Weifeng1, ZHANG Duchao1, YANG Tianzu1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Hunan Jinwang Bismuth Industry Co., Ltd., R & D Center of Post-doctoral Research Station, Chenzhou 423000, China)

Abstract: Based on the high energy consumption, poor environmental protection, and incomplete separation of lead and copper in the traditional pyrometallurgy process of copper dross, the effects of m(FeO)/m(SiO2), m(CaO)/m(SiO2), sulfur dosage, scrap iron dosage, coal dosage, and sodium carbonate dosage on elements distribution behaviors of Pb, Cu, Bi, As, Sb, and Sn in the smelting process were investigated by the bath smelting process. The phase composition of the slag and matte were detected. The results show that the optimum condition of bath smelting process is as follows: m(FeO)/m(SiO2) of 1.9, m(CaO)/m(SiO2) is 0.6, the mass fraction of sulfur to copper dross is 3%, the mass fraction of scrap iron to copper dross is 10%, the mass fraction of coal dosage to copper dross is 5%, the mass fraction of sodium carbonate to copper dross is 6%. Under the optimum condition, Pb, Bi and Sb are mainly distributed into the metal. The distribution ratios of Pb, Bi and Sb in metal are 83.43%, 99.09% and 43.62%, respectively. Meanwhile, Cu and As are mainly distributed into the matte. The distribution ratios of Cu and As in matte are 44.10% and 88.80%, respectively. Sn is mainly distributed into the gas. The distribution ratio of Sn in gas is 78.58%. As is easy to form Fe-As phase embedded in matte.

Key words: copper dross; crude lead; fire refining; bath smelting; elements distribution

铜浮渣是粗铅火法精炼除铜过程中夹杂金属铅的固体杂质化合物,其主要成分是铅和铜,此外还含有锡、砷、锑、铋、锌、钴、镍等元素[1]。铜浮渣是铅冶炼过程中重要的二次资源,如果不加以回收利用,不仅会造成有价金属的浪费,而且其中的重金属会对环境造成严重的污染[2-3]。目前,处理铜浮渣的工艺主要包括火法工艺、湿法工艺、火法-湿法联合工艺、微生物冶金工艺和真空冶金工艺[4-6]等。火法工艺中的苏打-铁屑法是国内铅冶炼企业处理铜浮渣最常用的方法[7]。苏打-铁屑法中作为熔剂加入的苏打和铁屑主要用来降低炉渣与锍的黏度,形成钠锍和硫化亚铁降低冰铜含铅;采用的设备主要包括反射炉、电炉和转炉等[8]。虽然传统设备用于处理铜浮渣具有原料适应性强、设备简单等优点,但是也存在处理能力低下、人工劳动强度大、工作环境恶劣、能耗高、设备寿命短等缺点[9-10]。近年来,随着铅冶炼原料的复杂化和低品位化[11],铜浮渣产出量增多,对其工艺处理规模及处理过程的环保提出了更高的要求,传统火法冶金工艺的这些缺点逐渐成为制约铜浮渣高效清洁处理的瓶颈[12]。研究人员投入了大量精力用于开发新的强化冶炼方法来替代传统火法工艺[13-14]。杨崇方等[15]基于不同金属化合物沸点差别,采用真空强化蒸馏-分级冷凝的工艺处理铜浮渣,结果表明在压力为100 Pa,蒸馏温度为1 523 K,保温为4.5 h的条件下,可获得铅质量分数为87.55%的粗铅和铜质量分数为57.38%的铜银锑合金。河南某厂采用富氧底吹熔池熔炼法处理铜浮渣进行了半工业化试验,该冶炼厂将铜浮渣、焦炭、石灰石、铁屑、氧化铁粉还有吹炼渣按比例连续加入富氧底吹炉中,可产出含铅96%(质量分数,下同)的粗铅和含铜40%的冰铜[16]。张立等[17]采用氧气侧吹炉处理铜浮渣的工艺生产实践,将铜浮渣、纯碱、铁屑和硫铁矿按一定的比例配料,均匀不间断地加入侧吹炉中,可产出品位为35%~45%的冰铜,且冰铜含铅仅为3%~6%。一系列工业化探索研究结果表明,采用富氧强化熔炼方法处理铜浮渣具有良好的应用前景。然而,在当前冶炼原料复杂化的背景下,铜浮渣中除铅、铜以外其他元素的回收价值逐渐凸显[18],探明其分配规律不仅可以提高有价元素的综合回收率,而且可以避免杂质元素对产品质量的影响,获取更高的经济和环保效益[19]。而铜浮渣中微量元素在熔炼过程中的分配行为,之前火法处理工艺的研究中均没有报道。本文作者以低品位复杂铅铋物料火法冶炼过程产出的铜浮渣为研究对象,研究其熔池熔炼过程中多元多相分配行为。研究结果有利于提高对铜浮渣富氧熔炼处理过程控制参数与元素分配行为的理解,推进富氧熔池熔炼技术在复杂物料处理中的应用。

表1 铜浮渣的主要成分(质量分数)

Table1 Main composition of copper dross%

表2 还原煤粉的主要成分(质量分数)

Table 2 Main composition of coal %

1 实验

1.1 实验原料

实验所用原料来自郴州某企业的铜浮渣,其主要成分如表1所示。从表1可以看出:Pb,Cu,Sb,Bi和Sn质量分数分别为53.38%,18.20%,4.03%,3.90%和0.88%,具有较高的综合回收价值。

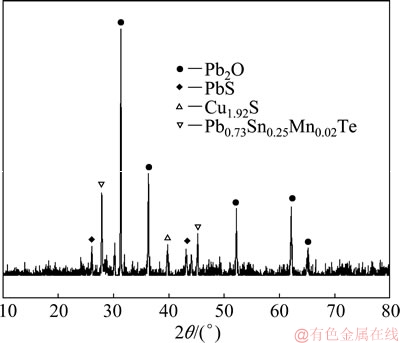

原料XRD分析的结果如图1所示。从图1可以看出:铜浮渣中的主要成分是Pb2O,PbS,Cu1.92S以及Pb和Sn等元素的复合金属间化合物。

图1 铜浮渣的XRD图谱

Fig. 1 XRD pattern of copper dross

实验使用氧化钙、二氧化硅、氧化铁、无水碳酸钠、硫粉和铁屑(化学纯,西陇化学)配制熔剂,以煤粉作为还原剂,煤粉成分如表2所示。

1.2 实验设备

实验设备为高温井式炉(合肥科晶,VTF1600X),反应容器采用黏土坩埚(直径为90 mm,高度为70 mm)。对渣、锍中成分半定量分析采用X线荧光仪(XRF-1800,Shimadzu,日本岛津)。对金属中主要元素定量分析采用ICP-AES(IRIS,InterpridⅢXRS,美国热电),物相分析使用X线衍射仪(SmartLab,日本理学)。

1.3 实验方法

实验中选用的渣型为FeO-SiO2-CaO渣型,其中渣中铁硅比为氧化亚铁与二氧化硅的质量比(m(FeO)/m(SiO2)),渣中钙硅比为氧化钙与二氧化硅的质量比(m(CaO)/m(SiO2))。称取100 g铜浮渣,并按实验条件加入所需的氧化铁、氧化钙、二氧化硅、煤粉、硫粉、铁屑和碳酸钠。实验中m(FeO)/m(SiO2)、m(CaO)/m(SiO2)、煤粉加入量等实验参数的研究范围基于本文作者之前对于FeO-SiO2-CaO渣系的相关研究及铜浮渣反射炉工艺相关参数[4,9]设定。将混合料充分搅拌混匀,倒入预先称质量的500 mL的黏土坩埚内,并称总质量。调节井式炉使其以一定的升温速率升温至800 ℃,然后将坩埚放入井式炉内,继续升温到设定温度1 300 ℃,保温90 min。反应完成后将坩埚取出,在空气中快速冷却。待坩埚冷却至室温后称质量,将坩埚破碎后得到渣相、冰铜相和粗铅相,分别收集称质量,渣相质量记为mS,冰铜相质量记为mM,粗铅质量记为mP。将收集的渣和冰铜用密封式制样粉碎机粉碎成粉末后进行元素含量分析。收集到的粗铅直接取样、溶解进行元素含量分析及表征。元素分配率按式(1)~(4)计算:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:Dp,DM,DS和Dg分别为元素Me在粗铅、冰铜、渣和烟气中的分配比例;wMeP,wMeM和wMeS分别为元素Me在粗铅、冰铜和渣中的质量分数;mP,mM和mS分别为粗铅、冰铜和渣的质量;mMe-tot为铜浮渣中元素Me的总质量。

2 结果与讨论

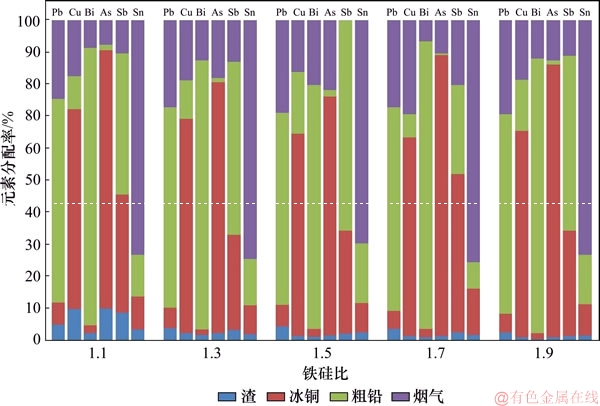

2.1 铁硅比的影响

固定实验条件如下:硫粉加入量为铜浮渣质量的6%,铁屑加入量为10%,煤粉加入量为7%,钙硅比为0.4。通过改变Fe2O3加入量,考察m(FeO)/m(SiO2)分别为1.1,1.3,1.5,1.7和1.9时对元素分配的影响,其结果如表3和图2所示。从表3和图2可以看出:随着m(FeO)/m(SiO2)从1.1升高到1.9,渣中Pb和Cu质量分数分别从9.59%和6.39%降低至4.05%和0.57%,当m(FeO)/m(SiO2)为1.9时,Pb在粗铅中的分配率达到62.37%,Cu在冰铜中的分配率达到64.34%。由于铁硅比增大会导致渣黏度降低,有利于不同密度物相的分离,使得渣中Pb和Cu含量降低。Bi和Pb的性质相近且更容易还原,因此,渣中Bi含量随铁硅比变化趋势与Pb的类似,随铁硅比增大,渣流动性增强,渣中Bi含量降低,大部分Bi分配在粗铅中;当m(FeO)/m(SiO2)为1.9时,Bi在粗铅中的分配率达到85.66%。由于As易与Fe结合形成Fe-As相进入冰铜中,因此,As在熔炼过程中主要分配在冰铜中,当m(FeO)/m(SiO2)为1.9时,As在冰铜中的分配率达到85.20%。Sb在熔炼过程中主要分配在粗铅中;随铁硅比增大,Sb在粗铅中的分配率先增大后减小,由于Sb在粗铅中含量增加会导致粗铅品质下降;而当m(FeO)/m(SiO2)为1.9时,Sb在粗铅中分配率仅为54.72%。Sn在熔炼过程中易挥发,因此,Sn主要分配在烟气中,Sn的分配受铁硅比的影响较小,其在烟气中的分配率基本维持在75 %左右。经综合考虑,选取铁硅比为1.9为最优条件。

表3 铁硅比对产物成分的影响

Table 3 Effect of m(FeO)/m(SiO2) on composition of products

图2 铁硅比对元素分配率的影响

Fig. 2 Effect of m(FeO)/m(SiO2) on distribution ratios of elements

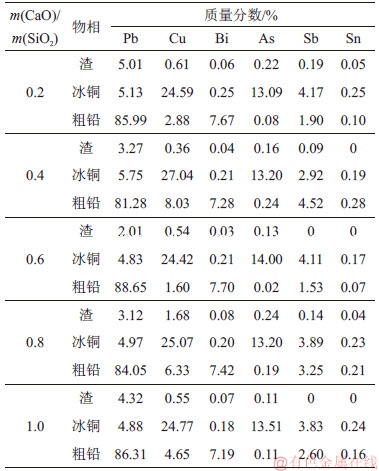

2.2 钙硅比的影响

固定实验条件如下:硫粉加入量为铜浮渣质量的3%,铁屑加入量为10%,煤粉加入量为7%,铁硅比为1.9。通过改变CaO加入量,考察m(CaO)/m(SiO2)分别为0.2,0.4,0.6,0.8和1.0时对元素分配的影响,其结果如表4和图3所示。从表4和图3可以看出:随着m(CaO)/m(SiO2)增大,渣中Pb质量分数先减小后增大,当m(CaO)/m(SiO2)=0.6时Pb质量分数最小,为2.01%。Pb在粗铅中的分配率先增大后减小,在m(CaO)/m(SiO2)=0.6时最大为81.12 %,由于CaO会破坏渣中高黏度 网状结构,使得渣黏度降低,因此,可有效降低渣含Pb。而当钙硅比过高时,高熔点的CaO会导致渣熔点增大,从而增大渣黏度,导致渣含Pb升高。Cu和As在冰铜中的分配率、Bi在粗铅中的分配率以及Sn在烟气中的分配率均随钙硅比增大表现为先增加后减小的趋势,这是因为渣黏度先降低后增大,从而使得渣流动性先增大后减小。当m(CaO)/m(SiO2)为0.6时,Cu和As在冰铜中的分配率、Bi在粗铅中的分配率以及Sn在烟气中的分配率分别达到最大的47.58%,90.26%,96.80%和89.25%。Sb在粗铅中的分配率在m(CaO)/m(SiO2)为0.6时达到最低,为18.61%。经综合考虑,选取钙硅比为0.6为最优条件。

网状结构,使得渣黏度降低,因此,可有效降低渣含Pb。而当钙硅比过高时,高熔点的CaO会导致渣熔点增大,从而增大渣黏度,导致渣含Pb升高。Cu和As在冰铜中的分配率、Bi在粗铅中的分配率以及Sn在烟气中的分配率均随钙硅比增大表现为先增加后减小的趋势,这是因为渣黏度先降低后增大,从而使得渣流动性先增大后减小。当m(CaO)/m(SiO2)为0.6时,Cu和As在冰铜中的分配率、Bi在粗铅中的分配率以及Sn在烟气中的分配率分别达到最大的47.58%,90.26%,96.80%和89.25%。Sb在粗铅中的分配率在m(CaO)/m(SiO2)为0.6时达到最低,为18.61%。经综合考虑,选取钙硅比为0.6为最优条件。

表4 钙硅比对产物成分的影响

Table 4 Effect of m(CaO)/m(SiO2) on composition of products

图3 钙硅比对元素分配率的影响

Fig. 3 Effect of m(CaO)/m(SiO2) on distribution ratios of elements

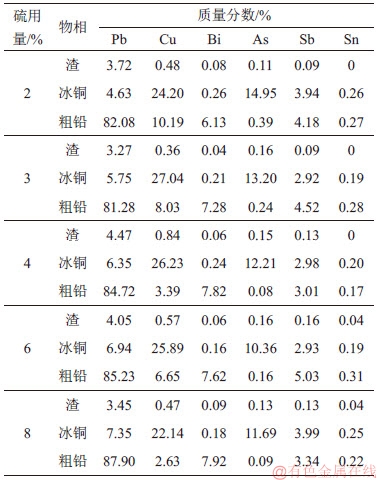

2.3 硫用量的影响

实验所用铜浮渣中硫含量较低,因此,通过硫的加入使铜浮渣中的Cu与S结合进入冰铜,从而达到增加冰铜含铜的目的。固定实验条件如下:铁屑加入量为铜浮渣质量的10%,煤粉加入量为7%,铁硅比为1.9,钙硅比为0.4。通过改变硫粉加入量,考察加入量分别为2%,3%,4%,6%和8%时对元素分配的影响,其结果如表5和图4所示。从表5和图4可知:随着升华硫用量的增加,Cu在冰铜中的分配率先增大后减小,当升华硫加入量为3%时,可达55.45%;由于升华硫的加入,冰铜中硫化亚铜含量增加,冰铜中Cu质量分数升高;继续加入升华硫,锍相的质量增加较快,冰铜中Cu质量分数相对变低。粗铅中Pb和Bi的分配率先增大后减小,当升华硫加入量为3%时分别达到73.62%和90.59%。As和Sn分配率受升华硫的影响很小,其在冰铜和烟气中的分配率分别维持在90%和75%。粗铅中Sb的分配率在升华硫加入量为3%时仅为54.43%,有利于与其他有价元素分离。经综合可知,选取升华硫加入量为铜浮渣的3%为最优条件。

表5 硫用量对产物成分的影响

Table 5 Effect of S dosage on composition of products

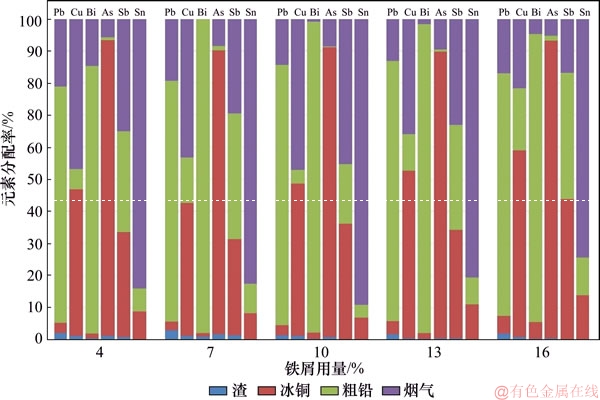

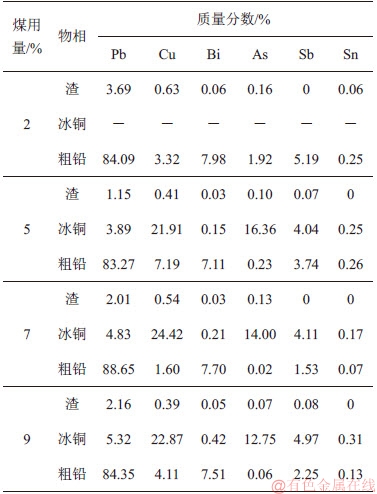

2.4 铁屑用量的影响

铁屑的加入可以将金属铅从硫化铅里置换出来,从而降低冰铜含铅,提高冰铜中铜的品位。固定实验条件如下:升华硫加入量为铜浮渣质量的3%,煤粉加入量为7%,铁硅比为1.9,钙硅比为0.6。考察铁屑加入量分别为4%,7%,10%,13%和16%时对元素分配的影响,其结果如表6和图5所示。从表6和图5可知:随着铁屑量的不断增加,Pb在冰铜中的分配率先减小后增大,当铁屑加入量为10%时,仅为3.23%;相对地,Pb和Bi在粗铅中的分配率先增大后减小,当铁屑加入量为10%时,分别可达81.12%和96.80%,这与其在冰铜中质量分数的变化相反。这是由于Fe将PbS从冰铜中还原成金属Pb,从而导致冰铜中Pb质量分数减小,随着铁屑加入过量,渣的铁硅比过大,反而使黏度增大,物相分离不彻底,使得冰铜中Pb和Bi质量分数增大。当铁屑加入量为10%时,Cu在冰铜中的分配率逐渐增大,为47.58%,这说明渣中铁质量分数的增加提高了Cu在渣中的活度系数,使得Cu在渣中的溶解度降低。As在冰铜中的分配率受铁屑加入量的影响较小,且基本维持在90%。Sb在粗铅中的分配率先减小后增大,为不影响铅的品质,选择铁屑加入量为10%时其分配率最小为18.61%。Sn基本不分配在渣相中,其主要分配在烟气中,当铁屑加入量为10%时达到最大的89.25%。经综合可知,铁屑最优加入量为铜浮渣的10%。

图4 硫用量对元素分配率的影响

Fig. 4 Effect of S dosage on distribution ratios of elements

表6 铁屑用量对产物成分的影响

Table 6 Effect of Fe dosage on composition of products

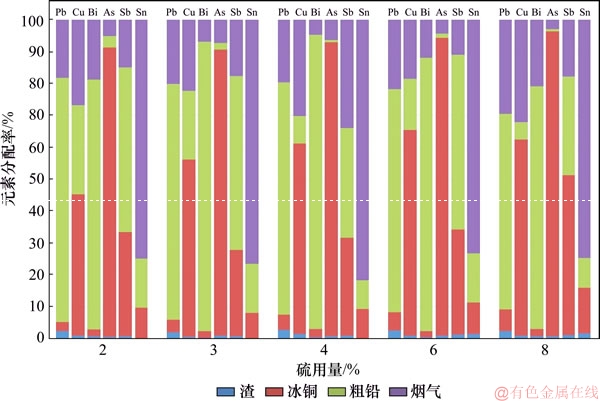

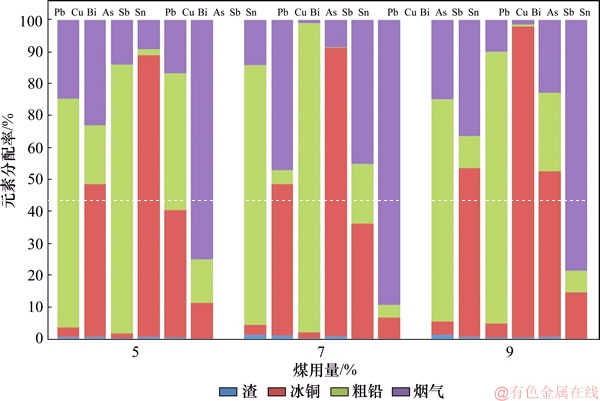

2.5 煤用量的影响

煤粉主要是还原氧化铅获得金属铅并且保证炉内有一定的还原性气氛。固定实验条件如下:升华硫加入量为铜浮渣质量的3%,铁屑加入量为10%,铁硅比为1.9,钙硅比为0.6。通过改变煤粉加入量,考察其分别为2%,5%,7%,9%和11%时对元素分配的影响,其结果如表7和图6所示。从表7和图6可知:当煤粉加入量为2%时,熔炼后锍相很少,不能得到完整的锍相研磨分析结果,而且此时渣含Pb也较高,可见煤粉加入量过少;当煤粉加入量为11%时,冷却得到的熔炼渣呈粉末颗粒状,而不是层状的渣,可见煤粉加入量为11%时渣明显过量;随着煤粉的加入,渣中Pb质量分数先降低后升高,在煤粉加入量5%时Pb质量分数最低,为1.15%,此时,Pb在粗铅中的分配率为71.68%,由于煤粉的加入,渣中氧化铅还原为金属铅,使得渣中Pb质量分数降低,进一步加入煤粉,煤粉过量导致渣熔点升高,黏度增大,渣中Pb质量分数升高。Cu受煤粉的影响较小,当煤粉加入量为5%时,Cu在冰铜中的分配率达到47.85%,而As在冰铜中的分配率逐渐增大。Bi在粗铅中的分配率呈先增大后减小的趋势。Sb和Sn基本不分配在渣相中,Sb主要分布在粗铅中,其分配率随煤粉加入而逐渐降低,Sn主要分布在烟气中,其分配率随煤粉加入而呈先增大后减小的趋势。综合可知,最终确定最优煤粉加入量为铜浮渣的5%。

图5 铁屑用量对元素分配率的影响

Fig. 5 Effect of Fe dosage on distribution ratios of elements

表7 煤用量对产物成分的影响

Table 7 Effect of coal dosage on composition of products

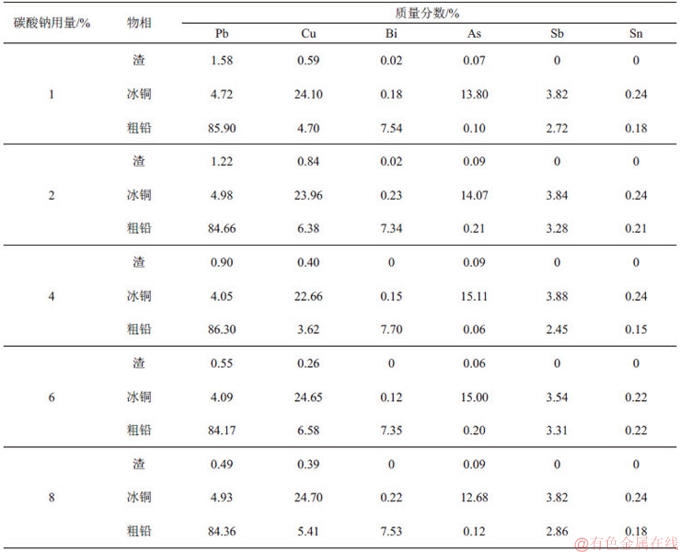

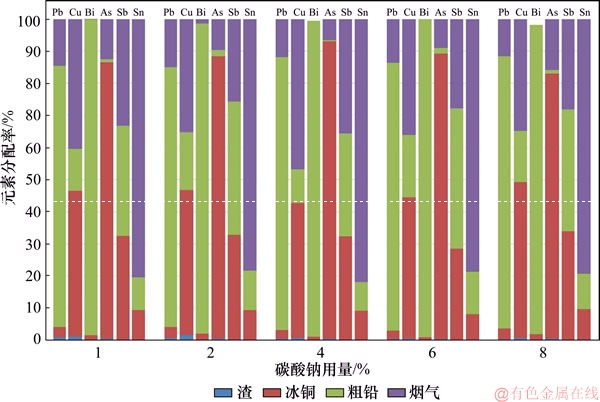

2.6 碳酸钠用量的影响

实验中加入碳酸钠的作用在于降低炉渣和冰铜的熔点,使其在熔炼条件下具有更好的流动性,从而提高有价元素的回收率。固定实验条件如下:升华硫加入量为铜浮渣质量的3%,铁屑加入量为10%,煤粉加入量为5%,铁硅比为1.9,钙硅比为0.6。通过改变碳酸钠加入量,考察其分别为1%,2%,4%,6%和8%时对元素分配的影响,其结果如表8和图7所示。从表8和图7可知:随着碳酸钠用量的增加,渣中Pb和Cu质量分数分别从1.58%和0.59%降低到0.49%和0.26%,Pb在粗铅中的分配率和Cu在冰铜中的分配率都呈逐渐增加的趋势,由于碳酸钠的加入,形成钠碱渣,降低了炉渣的熔点和密度,使渣的黏度降低,从而降低了渣中Pb质量分数。Bi,Sb和Sn基本不分配在渣中,说明碳酸钠的加入显著降低了渣的黏度,提高渣的流动性,从而促进有价元素的分离,Bi和Sb在粗铅中的分配率和Sn在烟气中的分配率随碳酸钠用量的增加影响不大。As在冰铜中的分配率先增大后减小。综上所述,最终确定最优碳酸钠加入量为铜浮渣的6 %。此时,Pb,Bi和Sb在粗铅中的分配率分别为83.43%,99.09%和43.62%,Cu和As在冰铜中的分配率分别为44.10%和88.80%,Sn在烟气中的分配率为78.58%。

2.7 熔炼产物物相组成

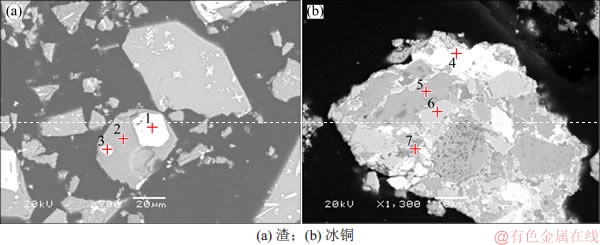

为了进一步明确铜浮渣熔炼产物的物相组成,对渣和冰铜进行扫描电镜分析,结果见图8,图8中各区域元素组成EDS分析结果见表9。

由SEM-EDS分析结果可知:亮点区域1和区域3主要是Fe相,区域2主要是Fe-Si-Ca相,在Fe-Si-Ca相中夹杂着Fe相,说明参加反应的铁屑部分进入渣相中被包裹于Fe-Si-Ca相中。亮点区域4主要是Pb相,区域5主要是Fe-Cu-S相,区域6主要是Fe-As相,区域7主要是Fe-S相,说明冰铜相中掺杂着少量的Pb,且As易与Fe形成Fe-As相嵌入在冰铜相中,从而达到富集As的目的。

图6 煤用量对元素分配率的影响

Fig. 6 Effect of coal dosage on distribution ratios of elements

表8 碳酸钠用量对产物成分的影响

Table 8 Effect of Na2CO3 dosage on composition of products

图7 碳酸钠用量对元素分配率的影响

Fig. 7 Effect of Na2CO3 dosage on distribution ratios of elements

图8 熔炼产物的SEM图

Fig. 8 SEM images of smelting products

表9 熔炼产物EDS分析

Table 9 EDS analysis of smelting products

3 结论

1) 采用单因素实验考察铁硅比、钙硅比、升华硫、铁屑、煤粉和碳酸钠用量等对铜浮渣熔池熔炼过程中Pb,Cu,As,Sb,Bi和Sn元素分配的影响。确定熔池熔炼最优工艺条件如下:m(FeO)/m(SiO2)=1.9,m(CaO)/m(SiO2)=0.6,升化硫加入量为铜浮渣质量的3%,铁屑加入量为10%,煤粉加入量为5%,碳酸钠加入量为6%。

2) 在最优工艺条件下,Pb,Bi和Sb主要进入粗铅中,其在粗铅中的分配率分别为83.43%,99.09%和43.62%;Cu和As主要进入冰铜中,其在冰铜中的分配率分别为44.10%和88.80%;Sn主要进入烟气中,其在烟气中的分配率为78.58%。

3) As易与Fe形成Fe-As相嵌入在冰铜相中,从而达到富集As的目的。

参考文献:

[1] 彭容秋. 铅冶金[M]. 长沙: 中南大学出版社, 2004: 75-76.

PENG Rongqiu. Lead metallurgy[M]. Changsha: Central South University Press, 2004: 75-76.

[2] 姚建明. 铜浮渣火法处理工艺的研究现状及发展[J]. 有色冶金节能, 2015, 31(2): 14-17.

YAO Jianming. Research status and development of copper dross treatment with pyrometallurgical process[J]. Energy Saving of Nonferrous Metallurgy, 2015, 31(2): 14-17.

[3] HUSSAIN Z, GRIMES S, SHAHID M, et al. Leaching of copper secondary wastes: possible soil contaminants[J]. Asian Journal of Chemistry, 2013, 25(7): 4051-4054.

[4] 曹雷斌, 杨文. 提高铜浮渣反射炉生产指标的措施[J]. 湖南有色金属, 2017, 33(6): 32-33, 63.

CAO Leibin, YANG Wen. Measures of improving the production index of copper scum reverberatory[J]. Hunan Nonferrous Metals, 2017, 33(6): 32-33, 63.

[5] LIU Dafang, FAN Xingxiang, SHI Yifeng, et al. Research on the effect of alkali roasting of copper dross on leaching rate of indium[J]. IOP Conference Series: Earth and Environmental Science, 2017, 94: 012123.

[6] LEE J I, HWANG J, HONG C W, et al. Synthesis of nanocrystalline SnO2 by a selective dissolution of copper alloy dross[J]. Journal of Ceramic Processing Research, 2015, 16(4): 428-431.

[7] XU Baoqiang, GUO Xutao, DENG Yong, et al. Removal of sulfur from copper dross generated by refining lead[C]// HWANG J Y, JIANG Tao, KENNEDY M W, et al. High-Temperature Metallurgical Processing. Phoenix: TMS, 2018: 259-267.

[8] 杨华锋. 纯氧侧吹熔池熔炼旋转炉处理铜浮渣的方法: 中国, CN104263951A[P]. 2015-01-07.

YANG Huafeng. Method for processing copper dross by using rotary furnace through pure oxygen side-blown bath smelting: China, CN104263951A[P]. 2015-01-07.

[9] ZHANG Duchao, ZHANG Xinwang, YANG Tianzu, et al. Reduction smelting on bismuth oxide residue in FeO-SiO2-CaO ternary slag system[J]. Journal of Central South University, 2016, 23(6):1326-1331.

[10] 郭学益, 王亲猛, 田庆华, 等. 基于区位氧势硫势梯度变化下铜富氧底吹熔池熔炼非稳态多相平衡过程[J]. 中国有色金属学报, 2015, 25(4): 1072-1079.

GUO Xueyi, WANG Qinmeng, TIAN Qinghua, et al. Non-steady multiphase equilibrium process of copper oxygen-enriched bottom blowing bath smelting with gradual change of oxygen and sulfur potential of different positions in furance[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 1072-1079.

[11] CHEN Lin, HAO Zhandong, YANG Tianzu, et al. An efficient technology for smelting low grade bismuth-lead concentrate: oxygen-rich side blow process[J]. JOM, 2015, 67(9): 1997-2004.

[12] BAI Lu, XIE Minghui, ZHANG Yue, et al. Pollution prevention and control measures for the bottom blowing furnace of a lead-smelting process, based on a mathematical model and simulation[J]. Journal of Cleaner Production, 2017, 159: 432-445.

[13] 王亲猛, 郭学益, 廖立乐, 等. 氧气底吹炼铜多组元造锍行为及组元含量的映射关系[J]. 中国有色金属学报, 2016, 26(1): 188-196.

WANG Qinmeng, GUO Xueyi, LIAO Lile, et al. Mapping relationship between multicomponent matte formating behavior and content in copper oxygen bottom blowing bath smelting process[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 188-196.

[14] 赵红梅, 朱海成, 聂文斌. 富氧顶吹炉处理铜浮渣新工艺研究与实践[J]. 矿冶, 2015, 24(5): 49-53.

ZHAO Hongmei, ZHU Haicheng, NIE Wenbin. The new technology research and practice of copper dross treatment by rich oxygen top-blown furnace[J]. Mining and Metallurgy, 2015, 24(5): 49-53.

[15] 杨崇方, 许娜, 蒋文龙, 等. 真空蒸馏-分级冷凝法处理铜浮渣的应用研究[J]. 真空科学与技术学报, 2016, 36(1): 57-63.

YANG Chongfang, XU Na, JIANG Wenlong, et al. Recycling of copper dross by distillation and two-stage condensation in vacuum[J]. Chinese Journal of Vacuum Science and Technology, 2016, 36(1): 57-63.

[16] 杨明, 狄聚才. 底吹炉处理铜浮渣的半工业试验[J]. 中国有色冶金, 2012, 41(4): 22-24, 30.

YANG Ming, DI Jucai. Pilot test on treatment of copper scum by bottom-blown furnace[J]. China Nonferrous Metallurgy, 2012, 41(4): 22-24, 30.

[17] 张立, 王媛媛, 李小兵, 等. 氧气侧吹炉处理铜浮渣的生产实践[J]. 中国有色冶金, 2016, 45(3): 13-15.

ZHANG Li, WANG Yuanyuan, LI Xiaobing, et al. Production practice of copper dross treatment with oxygen side-blowing furnace[J]. China Nonferrous Metallurgy, 2016, 45(3): 13-15.

[18] YANG Tianzu, XIAO Hui, CHEN Lin, et al. Element distribution in the oxygen-rich side-blow bath smelting of a low-grade bismuth-lead concentrate[J]. JOM, 2018, 70(6): 1005-1010.

[19] LEE J I, PARK J B, KIM T W, et al. Selective recovery of Sn from copper alloy dross and its heat-treatment for synthesis of SnO2[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(S): s157-s161.

(编辑 杨幼平)

收稿日期: 2018 -12 -06; 修回日期: 2019 -03 -12

基金项目(Foundation item):国家重点研发计划项目(2018YFC1901604);国家自然科学青年基金资助项目(51404296);湖南省自然科学青年基金资助项目(2018JJ3662);中国博士后科学基金面上资助项目(2018M632988);国家留学基金委访问学者项目(201706375005)(Project(2018YFC1901604) supported by the National Key Research and Development Program of China; Project(51404296) supported by the Young Scientists Fund of National Natural Science Foundation of China; Project(2018JJ3662) supported by the Young Scientists Fund of Natural Science Foundation of Hunan Province; Project(2018M632988) supported by the Postdoctoral Science Foundation of China; Project(201706375005) supported by the Visiting Scholar of China Scholarship Council)

通信作者:陈霖,博士,副教授,从事有色金属熔池熔炼技术等研究; E-mail: chenlin0210@csu.edu.cn