DOI:10.19476/j.ysxb.1004.0609.2019.01.04

Ca-Y复合变质对高硅 Mg-Si-Zn合金组织与性能的影响

童文辉,刘雨林,刘玉坤,王杰,莫春立,佟琳,许爽

(沈阳航空航天大学 材料科学与工程学院,沈阳 110136)

摘 要:为提高高硅Mg-Si-Zn合金的性能,实验通过调整Ca、Y变质剂的含量,研究在Ca变质、Ca-Y复合变质作用下高硅Mg-Si-Zn合金的凝固组织与性能。结果表明:在Mg-4Si-4Zn合金中加入Ca,可使合金凝固组织中初生Mg2Si相由粗大的枝晶形貌转变为细小的矩形块状形貌,共晶组织由粗大的汉字状转变为点棒状;当Ca加入量为0.7%时(质量分数)变质效果最为明显;当Ca加入量超过0.7%后,合金中会形成CaMgSi棒状相,这是Ca变质效果下降的一个主要原因。当合金中Ca加入量为0.7%时,再加入Y会将初生Mg2Si相由规则平整形貌转变为带有沟壑孔洞的复杂形貌,而相的尺寸基本不发生改变,这使得经Ca-Y复合变质的Mg-4Si-4Zn合金的硬度显著高于Ca单一变质合金的,硬度提高超过10%。

关键词:Mg-Si-Zn合金;复合变质;Mg2Si;凝固组织

文章编号:1004-0609(2019)-01-0027-08 中图分类号:TG292 文献标志码:A

镁合金是目前具有高比强度、比刚度、高电磁屏蔽性能等优良性能的最轻的结构材料,近年来已得到越来越广泛的应用。随着镁合金的研发和应用不断深入,对其力学性能,尤其是高温使用性能提出了更高的要求。目前,发展较为成熟的高温镁合金主要有两种,一种为Mg-Al系的Mg-Al-RE、Mg-Al-Zn、Mg-Al-Ca、Mg-Al-Si;而另一种则为Mg-RE系的Mg-RE-Zn、Mg-RE-Zn-Mn、Mg-RE-Ag-Zr以及Mg-RE-Y-Zr合金[1-2]。

Mg-Al合金常温力学性能良好,但合金中的强化相Mg17Al12高温稳定性差[3],严重影响了此类合金在高温下的力学性能。Mg-RE合金虽然在常温与高温性能方面均表现良好[4],但由于稀土等合金元素的使用导致该系合金的成本较高,商业化发展将受到局限[5]。

近几年,越来越多的研究趋向于将Si作为改善镁合金高温性能的手段之一,其原理是利用Mg与Si形成的具有耐高温、强度高等优良特点的Mg2Si相,以提高镁合金的综合性能[6-7]。但铸态下含硅镁合金中初生相Mg2Si粗大,共晶组织中Mg2Si呈复杂汉字状,难以满足工程使用对镁合金组织和性能的要求,因而对Mg2Si的变质细化、结构改善的研究便成为含硅镁合金研究领域的热点之一[8]。

目前对亚共晶与共晶成分的含硅镁合金已经开展了很多研究工作,取得了有益的效果。宋海宁等[9]研究了一种Mg-Si-Zn-Ca系合金,Si的含量控制在1% (质量分数)左右,该合金利用Ca元素有效变质了共晶组织中的Mg2Si,使共晶组织弥散而细小[10],其常温下拉伸强度可以达到170 MPa。李金锋等[11]研究 了一种Mg-Zn-Al-Si-Y合金,发现Y元素在细化组织的同时,对共晶Mg2Si也起到了变质作用,得到弥散而细小的共晶组织,该合金在200 ℃下的抗拉强度为126 MPa。

对于Si含量较高的过共晶Mg-Si合金而言,目前还处于开始研究阶段。豆琦等[12]研究了Ca对Mg-4.8Si合金中初生Mg2Si的影响,结果表明Ca含量在1.2%附近时初生相有良好的变质效果。刘辉等[13]对Y在Mg-5Si中的变质效果进行了研究,表明Y含量在1%(质量分数)附近会有很好的变质效果,其力学性能也最佳。JIANG等[14]对Y在Mg-5Si合金的变质效果进行了研究,实验表明Y含量在0.8%附近时,初生相与共晶组织皆具有良好的变质效果。

对于含硅镁合金,添加Ca或Y都呈现出较好的变质效果,但过共晶Mg-Si合金中尚未发现开展Ca和Y复合变质的研究。陈可等[15]研究了Ca-Sb和Ba-Sb复合变质对Mg-5Si合金中初生与共晶Mg2Si的影响,结果表明,同时添加两种变质剂时初生相表现出了更加良好的变质效果,平均尺寸更加细小。本文将以Mg-4Si-4Zn合金为研究对象,通过Ca-Y的复合变质,研究对镁合金的组织和力学性能的影响规律,分析变质剂的相互作用,探索揭示变质机理,以改善初生与共晶Mg2Si的组织状态,从而提高镁合金的力学性能。

1 实验

1.1 实验原料及合金成分设计

实验中配制镁合金采用工业纯镁(99.95%,质量分数)、工业纯锌(99.9%)、Mg-10Si中间合金,变质剂以中间合金形式加入,选用材料为Mg-30Ca、Mg-30Y中间合金。所熔炼的镁合金成分设计如表1所列。

表1 镁合金成分设计方案

Table 1 Composition of Magnesium alloy

1.2 镁合金的熔炼

镁合金熔炼前,根据镁合金成分设计方案进行配料,然后按如下方法进行合金熔炼和样品制作:1) 采用带有自制保护气体混合装置的SG-7.5-12型气氛井式电阻炉开展镁合金熔炼实验,将坩埚预热同时预热合金原料,待炉温为500 ℃时,向炉内坩埚中装入纯镁并通入CO2和SF6混合气体,体积比为100:1,进行保护熔炼。2) 待炉温升至750 ℃,纯镁完全熔化后,将镁硅合金加入到坩埚中,保温2 h,并进行搅拌,以保证成分均匀。3) 结束保温后,向镁合金熔体中加入Zn与变质剂,搅拌并保温静置5~10 min,去除金属液表面熔渣,将熔制好的镁合金熔体浇入圆形的石墨铸模中,冷却制成合金试样,待分析。

1.3 分析和测试方法

将所制得的试样经过切割、磨制、抛光,然后将试样表面用无水乙醇冲洗干净,并吹干。将制备好的金相试样,采用金相显微镜(Olympus OM)和场发射扫描电子显微镜SEM(SIGMA)进行金相组织分析,采用能谱分析仪EDS(X-Maxn)进行合金的微区成分分析和物相判别,并采用维氏硬度计测试合金的硬度,从而分析Ca、Y元素对Mg-4Si-4Zn基体合金中的初生与共晶Mg2Si的变质机理以及复合变质时的相互影响,并根据研究结果对合金中的Ca和Y添加量进行优化。

2 结果与讨论

2.1 Ca对Mg-4Si-4Zn合金凝固组织的影响

2.1.1 Ca对Mg-4Si-4Zn合金的变质作用

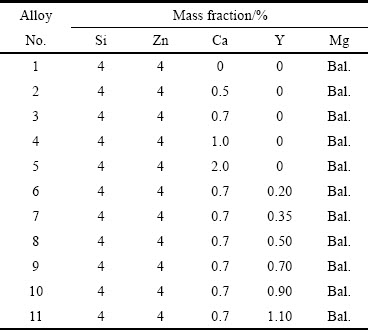

图1所示为Mg-4Si-4Zn镁合金添加Ca前后的合金凝固组织金相照片。其中,图1(a)和1(c)所示分别为添加Ca前后镁合金试样横截面直径1/4处的金相组织;而图1(b)和1(d)所示分别为添加Ca前后合金试样横截面中心附近的金相组织。从图1可看到,不管是否添加Ca,Mg-4Si-4Zn合金试样的横截面的外部和中部组织主要由初生相Mg2Si、α-Mg、共晶Mg2Si组织组成(见图1(a)、(c)),而心部组织则完全为共晶组织(见图1(b)、(d)),未发现初生相。在Mg-4Si-4Zn合金中加入Ca,使得合金凝固组织中初生相从粗大的枝晶形貌转变为细小的矩形块状形貌(见图1(a)、(c));共晶Mg2Si形貌由复杂的多笔画的汉字状结构转变为短点棒状(见图1(b)、(d))。

如图1(c)和图2(a)所示,在添加Ca的Mg-4Si-4Zn合金凝固组织中,可看到一种针棒状相,其形貌尺寸为:长度10~15 μm,宽度3~5 μm,截面形状为正六边形,该相分布于距初生相20~40 μm的周边区域,扫描电镜结果如图2所示,据参考文献[13]可推断该相为CaMgSi相。

Mg-4Si-4Zn合金熔体在凝固时,初生相将先形核成正八面体结构,而后在非平衡凝固条件下,沿着棱角和尖端以非平衡方式快速生长,最终形成枝晶状粗大组织(见图1(a))。但合金熔体中加入Ca后,合金凝固过程中,Ca元素会在棱角尖端及表面富集,根据现有文献[12]中的“毒化”理论,Ca原子会在生长界面发生“占位”现象,从而限制了初生相的优先快速生长,进而使初生相保持多面体状,显著改变了初生相的尺寸与形貌。

图1 Ca对Mg-4Si-4Zn合金凝固组织的变质影响

Fig. 1 Effect of Ca addition on modification of solidified microstructure of Mg-4Si-4Zn alloy

图2 Mg-4Si-4Zn合金加Ca后的凝固组织、SEM像及EDS结果

Fig. 2 Solidified microstructure (a), SEM image (b) and EDS result (c) of Mg-4Si-4Zn alloy with Ca modification

共晶组织尺寸与形貌受到金属液中Ca添加量的影响,共晶组织中Mg2Si与α-Mg共生共长,其生长的特殊性必然会造成Ca在生长前沿聚集,最终抑制了共晶Mg2Si的汉字状生长,使其由粗大的复杂汉字状转变为短小的点棒状,且弥散而细小。

含Ca镁合金在凝固过程中,随着初生相Mg2Si的生长,由于溶质再分配,Ca原子不断被排出到初生相周围的合金熔体中,使其Ca含量不断升高,从而为CaMgSi相在该区域形核创造了成分条件;另一方面,随着初生相生长,Si原子大量消耗,尽管合金熔体中的Si原子通过扩散快速补充,仍然不足以弥补Si原子的快速消耗,使得初生相生长停滞,此时,在初生相周围富集的Ca原子由于扩散较慢而保持高浓度[16],于是,CaMgSi相开始形核生长,合金熔体中的Ca和Si含量逐渐降低,最终在Mg2Si和CaMgSi相的周围,α-Mg开始形核生长,这可以从组织中α-Mg相包裹Mg2Si和CaMgSi相生长的形态得到推断(见图2(a))。在凝固后期,剩余合金熔体将达到共晶成分,在相边界处形成共晶组织。整个凝固过程中,由于Si扩散较快,随着凝固由外而内进行,合金熔体中的Si含量不断下降,以至在合金铸件的心部无法形成初生相,而Ca原子在凝固界面前沿富集,向合金熔体中扩散又较慢,以至于在初生相Mg2Si周围形成了CaMgSi相,在心部却因不能达到所需的成分条件而几乎不形成。

2.1.2 Ca添加量对Mg-4Si-4Zn合金组织的影响

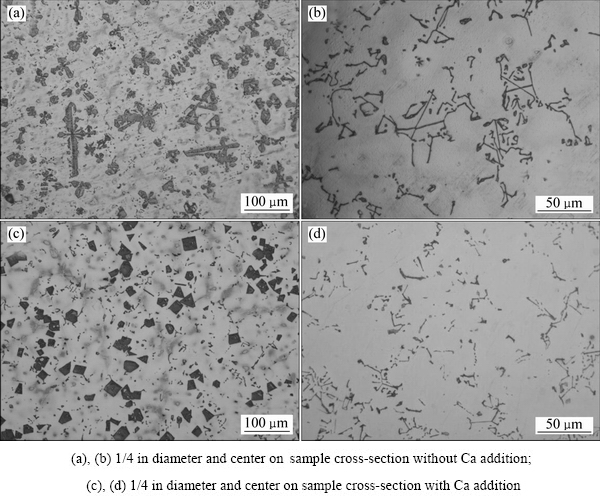

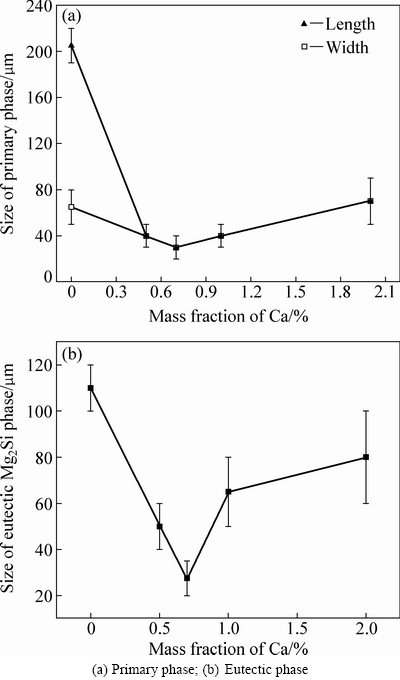

对不同Ca添加量的Mg-4Si-4Zn合金进行了凝固组织金相分析,结果如图3所示,通过统计分析得到凝固组织Mg2Si初生相与共晶组织尺寸与Ca添加量的关系如图4所示。

从图3和图4(a)可看出,当Mg-4Si-4Zn合金中Ca添加量小于0.7%时,随着Ca添加量的增加,合金凝固组织初生相由长度为200~250 μm、宽度为50~80 μm的枝晶形貌,转变为边长为20~40 μm的矩形块状形貌;当Ca添加量大于0.7%时,初生相尺寸随Ca添加量增加而增大,并由规则平整形貌转变为非规则孔洞状。图3中的共晶组织也发生了相应的变化:随Ca添加量增加,共晶Mg2Si由粗大的复杂汉字状组织转变为细小的点条状组织,而后又向粗大汉字状生长,且笔画更加复杂。共晶Mg2Si尺寸变化如图4(b)所示,当Ca添加量小于0.7%时,随着Ca添加量的增加,共晶Mg2Si区域尺寸由长度100~120 μm变为20~35 μm。

由图3可知,当合金中Ca添加量低于0.5%时,凝固组织中几乎观察不到CaMgSi相,而当Ca添加量高于0.7%后,CaMgSi相随Ca添加量增大而增加,生长于距离初生相20~40 μm的周边区域。CaMgSi相呈棒状,尺寸约为15~20 μm,且CaMgSi相尺寸几乎不随Ca添加量变化而变化。合金凝固组织中形成CaMgSi相,使Ca对合金中Mg2Si相的变质作用呈现随Ca添加量增加而先增强后减弱的变化规律。

图3 Ca添加量对Mg-4Si-4Zn合金凝固组织的影响

Fig. 3 Effect of Ca content on solidified microstructure of Mg-4Si-4Zn alloy

图4 初生Mg2Si相和共晶Mg2Si的尺寸与Ca添加量的关系

Fig. 4 Relationships between sizes of primary phase and eutectic Mg2Si phase and addition of Ca

2.2 Y添加量对Mg-4Si-4Zn-0.7Ca合金凝固组织的影响

2.2.1 复合变质对Mg-4Si-4Zn组织的影响

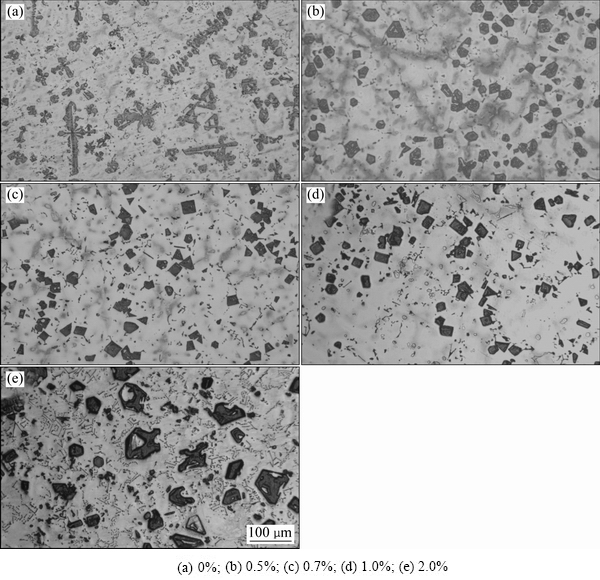

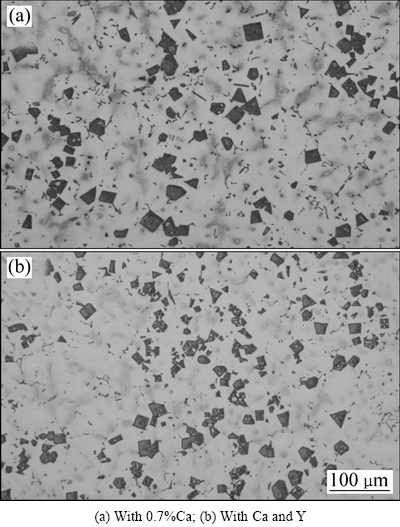

在Mg-4Si-4Zn-0.7Ca合金中添加Y,合金凝固试样横截面直径1/4位置的凝固组织如图5所示。其中,图5(a)所示为Mg-4Si-4Zn合金经0.7%Ca变质的凝固组织,图5(b)所示为Mg-4Si-4Zn-0.7Ca合金中添加Y,进行复合变质后的凝固组织。从图5可明显看出, Ca-Y复合变质前后,初生相Mg2Si在尺寸上并无明显变化,但初生相形貌由平整块状转变为带有沟壑与孔洞的非规则形状,共晶组织几乎没有变化。

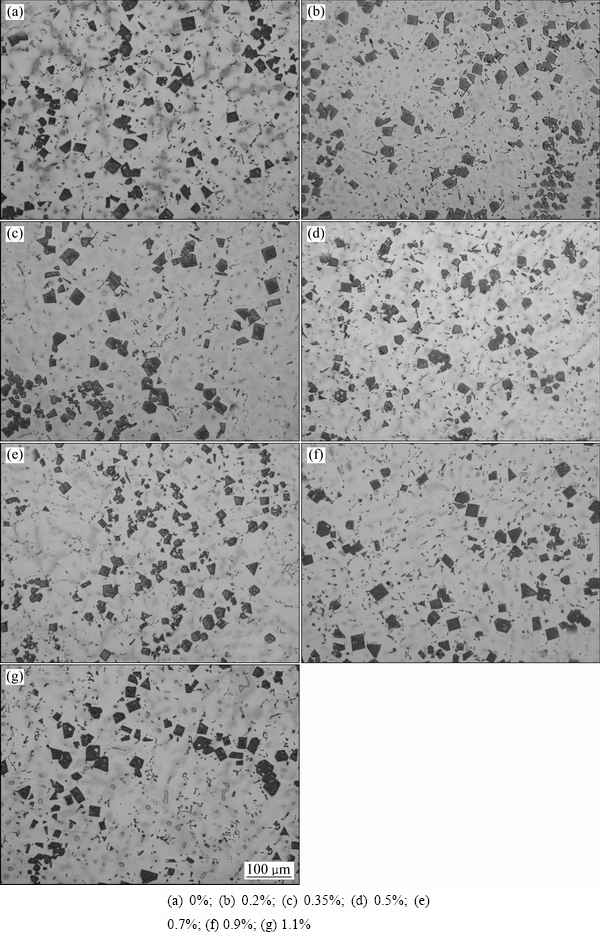

2.2.2 Y添加量对Mg-4Si-4Zn-0.7Ca凝固组织的影响

在Mg-4Si-4Zn-0.7Ca合金中,Y添加量不同时,得到的凝固组织照片如图6所示。随着Y添加量的增加,初生相尺寸基本不变化,但形貌改变十分明显,当Y添加量低于0.7%时,初生相形貌由平整规则形貌转变为带有孔洞与沟壑的非规则形貌,而当Y添加量高于0.7%时,初生相形貌又逐渐转变为相对平整规则的形貌。从图6中可看到,随着Y添加量的变化,共晶组织的尺寸与形貌以及数量并未发生显著变化。

图5 Ca-Y复合变质对Mg-4Si-4Zn合金凝固组织的影响

Fig. 5 Effect of Ca-Y complex modification on solidified microstructure of Mg-4Si-4Zn alloy

图6 Y添加量对Mg-4Si-4Zn-0.7Ca合金凝固组织的影响

Fig. 6 Effect of addition of Y on solidified microstructure of Mg-4Si-4Zn-0.7Ca alloy

根据文献[12]可知,Y的变质作用使初生相形貌变为非规则的短小枝晶,能有效抑制二次枝晶生长,且枝晶宽度得到明显细化。与Ca变质作用相比,Y对于初生相的棱角与尖端处的变质效果有限,即在非密排面处的变质效果比Ca差,但在初生相的密排面变质效果十分明显。在Ca-Y复合变质的合金凝固时,Ca、Y会同时在初生相表面富集,此时,初生相的尖端处界面窄小,根据毒化理论的“占位”原则,此处可供原子占位的空间有限,其变质效果取决于变质原子种类,所以Y的加入基本不影响初生相的棱角与尖端处的变质效果。而初生相的表面(密排面)处因界面较宽,可供原子占位的空间充足,该处的变质效果取决于变质原子的数量,因此,加入Y变质后,初生相表面的变质效果增强,其生长速度会相比单纯的Ca变质还低,以至于初生相棱角和尖端的生长会将密排面渐渐地包裹起来,于是,Ca-Y复合变质时,初生相形貌表现为孔洞与沟壑状。

当Y添加量低于0.7%时,Y与Mg、Si和Zn结合生成第二相的趋势不明显,因而其变质效果随Y添加量的增加而增强,形貌更趋向于带有孔洞与沟壑的非规则状,而当Y添加量高于0.7%时,合金凝固时Y生成第二相的趋势增大,变质效果便随着Y添加量的增加而降低,初生相形貌向规则状转变。

2.3 Ca、Y变质对于Mg-4Si-4Zn合金硬度的影响

对Mg-4Si-4Zn合金中Ca添加量不同时和Mg-4Si-4Zn-0.7Ca合金Y添加量不同时的合金试样分别进行了硬度测试,测试位置选择在合金试样横截面直径1/4处,其结果如图7所示。

由图7可看出,在单纯Ca变质条件下,当Ca添加量低于0.7%时,Mg-4Si-4Zn合金硬度随Ca添加量增加而增大;而当Ca添加量高于0.7%时,合金硬度反而随Ca添加量增加而减小,这与合金的组织变化规律是一致的;在Mg-4Si-4Zn-0.7Ca合金中加入Y的复合变质条件下,当Y添加量在0~0.7%之间,合金硬度随Y添加量增加而增大,当Y添加量超过0.7%后,合金硬度随Y添加量增加而减小。对比图7中两条曲线可看出,当Ca-Y复合变质时,合金的硬度均大于单纯Ca变质时合金的硬度。

图7 Mg-4Si-4Zn合金硬度与Ca或Y添加量变化间的关系

Fig. 7 Relationship between hardness of Mg-4Si-Zn alloy and addition of Ca or Y

从组织上看,Mg-4Si-4Zn合金中单纯加入Ca时,Ca添加量为0.7%时的合金凝固组织变质效果最佳。从图7中可看到,当Ca添加量为0.7%时,合金硬度要高于其他Ca添加量合金的;Ca-Y复合变质时,Y的加入有效改变了初生相形貌,由表面规则形貌变为呈孔洞状的复杂形貌,在初生相尺寸相同时,其复杂的形貌与基体间的结合将比规则块状形貌与基体结合更加牢固,从而使合金的硬度不同程度提高。

3 结论

1) Mg-4Si-4Zn合金加入Ca可使合金凝固组织初生Mg2Si相,由粗大枝晶形貌转变为细小的矩形块状形貌,共晶组织由粗大的汉字状转变为点棒状。

2) 当Ca加入量为0.7%时,Mg-4Si-4Zn合金的变质效果最为明显;当Ca添加量超过0.7%后,合金中会形成CaMgSi棒状相,使Ca变质效果降低。

3) 当Mg-4Si-4Zn合金中添加Ca量为0.7%时,再添加Y会将初生Mg2Si相由规则平整形貌转变为带有沟壑孔洞的复杂形貌,而相尺寸基本不发生改变。

4) Mg-4Si-4Zn合金经Ca-Y复合变质后的硬度(组织初生相为复杂形貌)明显高于经过Ca变质后的硬度(初生相为规则形貌),硬度提高超过10%。

REFERENCES

[1] 王宝刚, 王 旭, 周吉学, 张国福, 唐守秋, 刘运腾, 李卫红. 耐热镁合金的研究进展[J]. 山东科学, 2013, 26(3): 31-36.

WANG Bao-gang, WANG Xu, ZHOU Ji-xue, ZHANG Guo-fu, TANG Shou-qiu, LIU Yun-teng, LI Wei-hong. Research advances of heat-resistant magnesium alloy[J]. Shandong Science, 2013, 26(3): 31-36.

[2] AJITHKUMAR K K, VISWANATH A, PILLAIi U T S. Influence of neodymium addition on the microstructure, mechanical and thermal properties of Mg-Si alloys[C]//6th International Conference on Creep, Fatigue and Creep-Fatigue Interaction[CF-6]. Kalpakkam: Elsevier Procedia, 2013: 103-108.

[3] LOTFPOUR M, EMAMY M, ALLAMEH S H, POURBAHARI B. Effect of hot extrusion on microstructure and tensile properties of Ca Modified Mg-Mg2Si composites[J]. Procedia Materials Science, 2015, 11: 38-43.

[4] SU C Y, LI D J, LUO A A, YING T, ZENG X Q. Effect of solute atoms and second phases on the thermal conductivity of Mg-RE alloys: A quantitative study[J]. Journal of Alloys and Compounds, 2018, 747(30): 431-437.

[5] FANG Xiao-gang, LV Shu-lin, ZHAO Li, WANG Jing, LIU Long-fei, WU Shu-sen. Microstructure and mechanical properties of a novel Mg-RE-Zn-Y alloy fabricated by rheo-squeeze casting[J]. Materials & Design, 2016, 94(15): 353-359.

[6] WANG Li-ping, GUO Er-jun, MA Bao-xia. Modification effect of lanthanum on primary phase Mg2Si in Mg-Si alloys[J]. Journal of Rare Earths, 2008(1): 105-109.

[7] PENG Lei, CHEN Gang, ZHAO Yu-tao, HUANG Kang, SHAO Yang. Influence of solution treatment on microstructure and properties of in-situ Mg2Si/AZ91D composites[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2365-2371.

[8] MOSLISH S, EMAMY M, MAJDI H. The effect of Si and extrusion process on the microstructure and tensile properties of Mg-Mg2Si composite[J]. Procedia Material Science, 2015, 6(12): 79-83

[9] 宋海宁, 袁广银, 王渠东, 朱燕萍, 丁文江. 耐热Mg-Zn-Si-Ca合金的显微组织和力学性能[J]. 中国有色金属学报, 2002, 12(5): 956-960.

SONG Hai-ning, YUAN Guang-yin, WANG Qu-dong, ZHU Yan-ping, DING Wen-jiang. Microstructure and mechanical properties of heat resistant Mg-Zn-Si-Ca alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 956-960

[10] 郝 帅, 邱克强, 尤俊华, 曲广学. Ca和Sr对铸态Mg-Sn-Si合金组织和性能的影响[J]. 材料与冶金学报, 2012, 11(4): 285-291.

HAO Shuai, QIU Ke-qiang, YOU Jun-hua, QU Guang-xue. Effect of Ca and Sr additions on microstructure and mechanical properties of as-cast Mg-Sn-Si alloys[J]. Journal of Materials and Metallurgy, 2012, 11(4): 285-291.

[11] LI Jin-feng, GENG Hao-ran, WANG Ying-zi, QI Xiao-gang. Effects of Si and Y on microstructure and properties of Mg-Zn-Al magnesium alloy[J]. Hot Working Technology, 2004(12): 7-9.

[12] 豆 琦, 杜 军, 吴华懂, 李 伟. Ca对过共晶Mg-Si合金中初生Mg2Si相变质的影响[J]. 热加工工艺, 2012, 41(7): 18-20, 23.

DOU Qi, DU Jun, WU Hua-dong, LI Wei. Effect of calcium on modification of primary Mg2Si crystals in hypereutectic Mg-Si alloy[J]. Hot Working Technology, 2012, 41(7): 18-20, 23.

[13] 刘 辉. 变质对过共晶Mg-5Si合金组织及力学性能的影响[D]. 南昌: 南昌航空大学, 2014.

LIU Hui. Effect of modification on microstructure and mechanical properties of hypereutectic Mg-5Si alloy[D]. Nanchang: Nanchang Hangkong University, 2014.

[14] JIANG Q C, WANG H Y, WANG Y, MA B X, WANG J G. Modification of Mg2Si in Mg-Si alloys with yttrium[J]. Materials Science and Engineering A, 2005, 392(1/2): 130-135.

[15] CHEN Ke, LI Zi-quan. Effect of co-modification by Ba and Sb on the microstructure of Mg2Si/Mg-Zn-Si composite and mechanism[J]. Journal of Alloys and Compounds, 2014, 592(15): 196-201.

[16] 毛丽萍, 王 峰, 刘 正. 镁合金热力学相图[M]. 北京: 机械工业出版社, 2014: 11.

MAO Li-ping, WANG Feng, LIU Zheng. Thermodynamics and diagram of magnesium alloy[M]. Beijing: China Machine Press, 2014: 11.

Effects of Ca-Y compound modification on microstructure and properties of Mg-Si-Zn alloy with high Si content

TONG Wen-hui, LIU Yu-lin, LIU Yu-kun, WANG Jie, MO Chun-li, TONG Lin, XU Shuang

(School of Materials Science and Engineering, Shenyang Aerospace University, Shenyang 110136, China)

Abstract: By changing the addition of Ca and Y, the solidified microstructure and properties of Mg-Si-Zn alloy with high Si content were investigated under the condition of Ca modification and Ca-Y compound modification. The results show that, the Ca addition in to Mg-4Si-4Zn alloy has obvious modification effect, with the primary phase morphology of Mg2Si transforming from big dendrite to small regular square block and the morphology of eutectic Mg2Si changing from complex Chinese pattern to point bar. The most obvious effect of modification is near the Ca addition of 0.7% (mass fraction), and CaMgSi bar phase will precipitate from the alloy melt while Ca addition is more than 0.7%, reducing the Ca modification. When the Ca addition is 0.7%, the primary Mg2Si transforms from regular square to complex morphology with ravine holes without the obvious change of phase size by the Y addition. The alloy hardness after Ca-Y compound modification is obviously higher than that after Ca modification, with the hardness increasing by more than 10%.

Key words: Mg-Si-Zn alloy; compound modification; Mg2Si; solidified microstructure

Foundation item: Project(L2015410) supported by Department of Education of Liaoning Province, China

Received date: 2018-01-05; Accepted date: 2018-06-10

Corresponding author: TONG Wen-hui; Tel: +86-24-89728968; E-mail: 2407089517@qq.com

(编辑 龙怀中)

基金项目:辽宁省教育厅项目(L2015410)

收稿日期:2018-01-05;修订日期:2018-06-10

通信作者:童文辉,副教授,博士;电话:024-89728968;E-mail:2407089517@qq.com