文章编号:1004-0609(2010)S1-s0857-05

钛合金型材挤压玻璃润滑工艺的有限元模拟

柏春光1,徐东生1,雷家峰1,刘羽寅1,徐 哲2,刘明辉2,吕培成2,段素杰3,杨 锐1

(1. 中国科学院 金属研究所,沈阳 110016;

2. 宝钛集团有限公司,宝鸡 721014;

3. 北京天力创玻璃科技开发有限公司,北京 100000)

摘 要:采用平模挤压工艺并利用玻璃润滑制备钛合金型材。挤压制品的组织均匀、表面状态以及尺寸精度均受模具设计、润滑情况以及挤压工艺参数等诸多因素的影响,玻璃润滑是其关键工艺之一。通过有限元模拟结合试验对钛合金型材挤压过程的玻璃润滑工艺的诸多参数进行分析,研究其对体系温度分布和变形的影响。针对不同流动特性和结构设计的玻璃防护涂层、滚涂玻璃粉和玻璃垫对钛合金型材挤压制品润滑状态进行模拟,预测不同工况下的玻璃润滑膜的温度分布和黏度变化规律,并根据玻璃软化规律预测玻璃润滑膜的厚度,并提出玻璃润滑工艺的改进方案。

关键词:钛合金;型材挤压;玻璃润滑;有限元模拟

中图分类号:TG 146.4 文献标志码:A

FEM simulation of glass lubrication during section extrusion of titanium alloy

BAI Chun-guang1, XU Dong-sheng1, LEI Jia-feng1, LIU Yu-yin1, XU Zhe2, LIU Ming-hui2,

L? Pei-cheng2, DUAN Su-jie3, YANG Rui1

(1. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. Baoji Titanium Industry Co., Ltd., Baoji 721014, China;

3. Beijing Tianlichuang Glass Technology Development Co. Ltd, Beijing 100000, China)

Abstract: Glass lubrication in metal extrusion was studied by combining finite element analysis and experiments to investigate the temperature and viscosity distribution in oxidation-resistant glass lubricant, rolled glass powder layer and glass pad for high temperature metal extrusion. These simulations provide some fundamental information to the selection and design of glass lubricants and extrusion process. The preliminary conclusions are shown as follows. It is necessary to use Ugine-Sejournet process for the extrusion of titanium alloys. The glass lubrication is categorized into two aspects: container lubrication and die lubrication. The container lubrication is controlled by the sprayed coating and the glass powder coating. The die lubrication is mainly controlled by glass pad. FEM simulation is helpful to select the glass and control temperature distribution of oxidation resistant coating, glass powder coating and glass pad, which give good suggestion to the design and control of glass lubrication.

Key words: titanium alloy; section extrusion; glass lubrication; finite element simulation

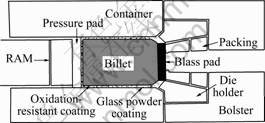

在金属的塑性变形过程中,摩擦和润滑在变形过程中起着重要的作用[1]。由于挤压加工在变形初期和变形后期的非稳态金属流动,在所有的金属塑性加工工艺中,挤压加工可能是针对润滑问题最为敏感的加工方法,常常伴随着挤压制品的表面质量下降和与模具黏接等问题[2]。玻璃润滑挤压工艺于1941年由SCHEY[3]发明,并应用于钢铁的挤压生产中。挤压工装示意图如图1所示。

图1 玻璃润滑挤压装置示意图[3]

Fig.1 Schematic diagram of glass-lubricated extrusion setting[3]

玻璃润滑剂主要有3种不同的应用方式:1) 可以在加热前以喷涂或者刷涂的方式在挤压工件表面附着玻璃防护涂层;2) 可以采用滚涂玻璃粉的形式在挤压加工前附着于工件表面;3) 可以将玻璃润滑剂制作成玻璃垫,并放置于模具和挤压工件之间,使之在挤压过程中随挤压制品一起变形,并逐层流下,进而形成连续的玻璃润滑膜,从而起到有效的润滑作用。良好的润滑剂可以在制品挤压过程中提供厚度合适的玻璃润滑膜,润滑膜过厚容易造成制品表面异常粗糙(表面晶粒无约束变形),润滑膜过薄,很难形成连续的润滑膜,从而形成边界润滑方式,也会造成制品表面的划伤。润滑膜的厚度受控于几个重要的参数,试验证明玻璃润滑膜的厚度随着Stribeck参数ηv/p(其中:η 为玻璃润滑剂的黏度;v为挤压速度;p为玻璃润滑膜承受的压力)的增加而增加,随着锥模半角的增加而减小,如图2所示。较大的玻璃黏度和较高的变形速度以及较低的挤压压力会形成较厚的润滑膜,玻璃润滑膜的厚度h和摩擦因数μ是Stribeck参数(ηv/p)的函 数[3-5]。

ROGERS和ROWE[6]通过试验研究了玻璃润滑剂的流动行为,并分析挤压压力对玻璃润滑膜的影响,MALE[7]的研究结果也表明一种特定润滑剂的使用必须结合模具的锥模角度、挤压速度和挤压比等参数,并给出了玻璃润滑剂的选择原则。QVALE和WILTSHIRE[8]研究玻璃润滑膜黏度的变化,但是该研究仅限于一维计算。WALLACE等[9]研究高强材料玻璃润滑挤压过程的润滑行为。WILSON和MAHDAVIAN[10]建立了冷挤压变形过程中的玻璃润滑模型,并针对稳态润滑和非稳态润滑过程给出了模具入口区域和挤压变形区域的表面温度以及对黏度 的影响,从而计算挤压力。DAMODARAN等[11]和

图2 玻璃黏度和玻璃膜厚度与Stribeck参数ηv/p的关系[4]

Fig.2 Relationship among μ and h and Stribeck parameter ηv/p[4]

BAQUE等[12]建立了玻璃润滑热挤压过程的有限元模型,并研究了模具设计和工艺参数的影响。本文作者采用有限元方法针对钛合金型材挤压玻璃润滑工艺中的玻璃防护涂层、滚涂玻璃粉和玻璃垫的润滑行为和温度分布进行系统的研究,以期望直接或间接地为钛合金型材挤压润滑工艺方案的制定提供参考。

1 玻璃防护涂层

玻璃的软化点黏度为107.6 Pa?s,流动点黏度η在103~105之间,低于102时,防护涂层会在锭坯表面发生部分流淌现象,黏度越低,流淌越严重。根据玻璃的黏度特性进行选择:在加热温度下,即950 ℃时,防护涂层TB10的黏度在102~103 Pa?s之间,这样的黏度既可保证涂层的防氧化作用,同时又不至于涂层发生流淌现象;在挤压过程中,即接触挤压筒后,防护涂层和滚粉涂层的黏度在103~105 Pa?s之间,由此可以根据各种玻璃的温度黏度曲线确定其在工作范围内是否起到润滑作用。

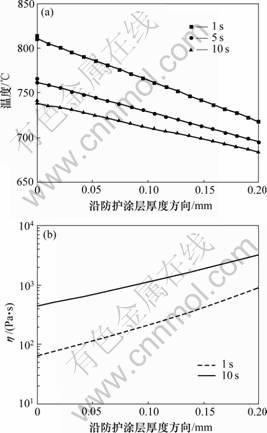

图3 经950 ℃挤压不同挤压时间后TB10玻璃防护涂层温度和黏度的分布

Fig.3 Temperature (a) and viscosity (b) distribution in oxidation resistant coating of TB10 glass extruded at 950 ℃ for different extruding times

钛合金型材的挤压温度为950 ℃,锭坯半径为80 mm, 防护涂层为0.2 mm,滚粉涂层为0.2 mm,挤压筒预热温度为450 ℃,挤压时间为1~10 s。其中,挤压1 s时代表挤压初期,挤压5 s时代表挤压稳定期,挤压10 s时代表挤压后期。挤压温度为950 ℃时,锭坯采用的玻璃防护涂层为TB10玻璃。本研究通过有限元方法对挤压过程中的玻璃防护涂层的温度以及润滑能力进行考察,以确定玻璃种类选择的合理性以及挤压筒侧壁润滑膜的厚度。

图3(a)和(b)所示分别为经950 ℃挤压的TB10玻璃防护涂层在不同挤压时间下温度和黏度的分布。由图3可以看出,TB10玻璃防护涂层随着挤压时间的延长,温度逐渐下降,黏度也逐渐增加。但整个防护涂层的黏度绝大部分为102~105 Pa?s,因此,在挤压过程中可以起到充分的润滑作用,而整个涂层在挤压过程中均可形成有效的玻璃润滑膜。故950 ℃挤压实验中采用的TB10防护涂层是合适的,既可起到防氧化作用,又可起到润滑作用。

2 滚粉涂层

在不同规格型材的挤压过程中,挤压筒的的侧壁润滑状况直接影响到锭坯流动的均匀性以及挤压力的载荷情况。因此,在挤压工艺中应充分考虑挤压筒的侧壁润滑情况。侧壁润滑的润滑剂来源主要有玻璃防护涂层和滚涂的玻璃粉。其中,如何选择和判断合适的玻璃种类和润滑剂厚度是实验中较为棘手的问题。玻璃涂层在挤压过程中能否起到润滑作用直接和涂层本身的温度和黏度分布有关。根据挤压初期及挤压中期坯料以及润滑涂层温度的分布,可以确定对防护涂层材料的选择。通过前面的研究,确定了950 ℃时的玻璃防护涂层,并且保证其在挤压过程中起到润滑作用。本工作将对不同温度下的玻璃滚粉涂层是否起到润滑作用进行计算和分析。

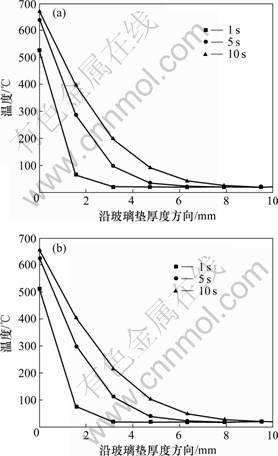

图4(a)和(b)所示分别为经950 ℃挤压的TB8玻璃滚粉涂层在不同挤压时间下温度和黏度的分布。由图

图4 经950 ℃挤压不同挤压时间后TB8玻璃滚粉涂层温度和黏度的分布

Fig.4 Temperature (a) and viscosity (b) distribution of glass lubricant powder layer of TB8 glass extruded at 950 ℃ for different extruding times

4可以看出,TB8玻璃滚粉涂层随着挤压时间的延长,温度分布趋于均匀,以滚粉涂层的中间部位为界限,外层滚粉温度随着挤压时间延长逐渐升高,黏度逐渐下降,内侧滚粉涂层的温度随挤压时间延长而逐渐下降,黏度也逐渐增加。但整个滚粉涂层的黏度绝大部分在102~105 Pa?s之间,因此,在挤压过程中可以起到充分的润滑作用,且整个涂层在挤压过程中均可形成有效的玻璃润滑膜。故950 ℃挤压实验中,采用的TB8滚粉涂层是合适的,该层玻璃粉完全起到润滑作用。

3 玻璃垫设计

对于不同规格的型材挤压工艺,在950 ℃进行挤压时需要加玻璃垫。其中玻璃垫选择为TB5或者TB8玻璃,TB5玻璃的软化温度为700 ℃,流动温度为800 ℃,TB8玻璃的软化温度为560 ℃,流动温度为700 ℃。以下分别考察工件接触玻璃垫并进行挤压时,整个坯料及润滑涂层温度的变化,其中摩擦热和变形热仍不进行考虑,同时也忽略了玻璃垫在挤压过程中的流动行为。通过对玻璃垫在挤压过程中温度分布进行计算,可以确定玻璃垫的黏度分布规律,其中黏度在103~105 Pa?s范围内的区间认为玻璃达到了暖融的要求,即可形成有效的玻璃润滑膜,该区间的大小定性地反映了玻璃润滑膜的厚度大小。

在950 ℃挤压时,玻璃垫分别选用了TB5玻璃和TB8玻璃2种材料压制而成。其中TB5玻璃的软化点和流动点温度较高,而TB8玻璃的流动温度较低。图5(a)和(b)所示分别为2种不同的玻璃垫在挤压过程中温度的分布。其中,钛合金锭坯选择TA15材料,锭坯经过40 s的出炉、滚涂玻璃粉以及转移过程然后进行挤压。由图5可以看出,2种玻璃垫的温度分布规律都近似相同,都存在着较大的温度梯度,而且玻璃垫的温度值也近似相等。随着挤压时间的延长,玻璃垫的温度逐渐升高,温度梯度也逐渐减小。但是由于2种玻璃垫的黏度温度变化规律不同,其黏度分布规律也不同。

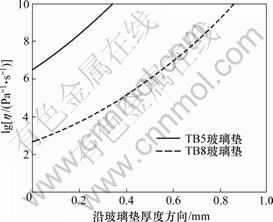

图6所示为2种不同玻璃垫在挤压5 s时(挤压稳定期)黏度的分布。由图6可以看出,TB5玻璃垫的黏度在106 Pa?s以上,在挤压过程中不能起到润滑作用,而TB8玻璃垫可以提供0.4 mm左右的玻璃润滑剂初始润滑膜厚度。当考虑玻璃垫的流动时,会加速玻璃垫的熔化过程,从而得到的膜厚比计算的值偏大。因此,在950 ℃挤压钛合金型材时,玻璃垫推荐使用TB8玻璃垫,或者对TB5玻璃垫提前预热,提高玻璃垫的熔化速度,保证其提供足够的润滑剂。

图5 950 ℃挤压时TB8玻璃垫和TB5玻璃垫温度分布

Fig.5 Temperature distribution of glass pads TB8 (a) and TB5 (b) during extrusion at 950 ℃

图6 950 ℃挤压时TB8玻璃垫和TB5玻璃垫的黏度分布

Fig.6 Viscosity distribution of glass pads TB8 and TB5 during extrusion at 950 ℃

4 结论

1) 钛合金型材挤压玻璃润滑工艺是可行的,同时采用有限元模拟结合实验研究对挤压润滑工艺参数的制定提供参考依据。

2) 根据温度场和黏度分布的计算,提出950 ℃时采用TB10玻璃作为防护涂层,TB8玻璃作为滚粉涂层,TB8玻璃作为玻璃垫是合适的,并且证明其在挤压过程中起到了润滑作用。

REFERENCES

[1] AVITZER B. Handbook of metal-forming processes[M]. New York: A Wiley-Interscience Publication, 1983: 55-87.

[2] DIETER G E, KUHN H A, SEMIATIN S L. Handbook of workability and process design[M]. Ohio: ASM International, 1984: 102-135.

[3] SCHEY J A. Tribology in metalworking: friction, lubrication and wear[M]. Ohio: American Society for Metals, Metals Park, 1983.

[4] BOOSER E R. Handbook of lubrication: Theory and practice of tribology. Vol Ⅱ. Theory & design[M]. Boca Raton, Florida: CRC Press, 1983: 120-155.

[5] SEJOURNET J. Friction and lubrication in metal processing[M]. New York: ASME, 1966: 147-184.

[6] ROGERS J A, ROWE G W. An evaluation of lubrication during hot extrusion[J]. Proc Instn Mech Engrs, 1964, 179(3): 93-102.

[7] MALE A T. Lubricants for extrusion[J]. American Machinist, 1970: 81-82.

[8] QVALE E B, WILTSHIRE F R. The performance of hydrodynamic lubricating films with viscosity variations perpendicular to the direction of motion[J]. Transactions of the ASME, 1972: 44-48.

[9] WALLACE P W, KULKARNI K M, SCHEY J A. Thick-film lubrication in model extrusions with low extrusion ratios[J]. Journal of the Institute of Metals, 1972, 2677: 78-85.

[10] WILSON W R D, MAHDAVIAN S M. Unsteady-hydrostatic extrusion[C]//Proc 3rd NAMRC, SME, Dearborn, 1975: 52-71.

[11] DAMODARAN D, SHIVPURI R. Prediction and control of part distortion during the hot extrusion of titanium alloys[J]. J Mater Process Technol, 2004,150: 70-75.

[12] BAQUE P, PANTIN J, JACOB G. Theoretical and experimental study of the glass lubricated extrusion process[J]. J Lubr Tech Trans ASME, 1975: 18-24.

(编辑 陈爱华)

通信作者:柏春光;电话:024-23748832;E-mail: cgbai@imr.ac.cn