文章编号: 1004-0609(2005)04-0608 -06

工艺参数对含钛高炉渣合成

(Ca, Mg)α′-Sialon-AlN-TiN粉的影响

姜 涛1, 2, 薛向欣1, 段培宁1, 刘然1, 董学文1, 茹红强1

(1. 东北大学 材料与冶金学院, 沈阳 110004; 2. 辽宁科技学院 冶金工程系, 本溪 117022)

摘 要: 以含钛高炉渣、 硅灰、 高铝矾土熟料和炭黑为原料, 采用碳热还原氮化法合成了(Ca, Mg)α′-Sialon-AlN-TiN粉。 用X射线衍射法测定了产物相组成及相对含量, 研究了合成温度和恒温时间对反应过程的影响, 并对合成机理进行了探讨。 结果表明: 合成温度对(Ca, Mg)α′-Sialon-AlN-TiN粉的合成过程影响显著, 随着合成温度升高, 产物中α′-Sialon相含量增大, 1480℃时α′-Sialon含量达最大, 是最佳的合成温度。 恒温时间对产物相组成的影响不十分显著, 但较长的恒温时间可使还原氮化反应进行得更充分, 恒温8h的试样中α′-Sialon含量最高, 是较理想的恒温时间。 合成过程中SiO的挥发导致试样较大的质量损失, 且随着合成温度升高和恒温时间延长而增大。

关键词: 含钛高炉渣; 碳热还原氮化; (Ca, Mg)α′-Sialon-AlN-TiN; 工艺参数; 合成机理 中图分类号: TF09; TQ174.58

文献标识码: A

Influence of process parameters on synthesis of

(Ca, Mg)α′-Sialon-AlN-TiN powders from titanium-bearing

blast furnace slag by carbothermal reduction-nitridation

JIANG Tao1, 2, XUE Xiang-xin1, DUAN Pei-ning1, LIU Ran1,

DONG Xue-wen1, RU Hong-qiang1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;2. Department of Metallurgy Engineering,

Liaoning Institute of Science and Technology, Benxi 117022, China)

Abstract: With titanium-bearing blast furnace slag, silica fume, bauxite chalmette and carbon black as raw materials, (Ca, Mg)α′-Sialon-AlN-TiN powders were synthesized by carbothermal reduction-nitridation (CRN). Phase composition of reaction products was determined by X-ray diffractometry. The influence of synthesis temperature and holding time on synthesis was studied and synthesis mechanism was discussed in detail. The results show that synthesis temperature affects the formation of (Ca, Mg)α′-Sialon-AlN-TiN significantly. Content of α′-Sialon in the products increases with the increase of synthesis temperature and reaches the maximum at 1480℃, which is assumed to be the best synthesis temperature. Holding time does affect the phase composition significantly, but with holding time expending, carbothermal reduction-nitridation reaction proceeds much sufficiently. Content of α′-Sialon in the samples reaches the maximum at 8h, which is perfect holding time. Volatilization of SiO results in great mass loss of the samples and increases with synthesis temperature increasing and holding time expending.

Key words: titanium-bearing blast furnace slag; carbothermal reduction-nitridation; (Ca, Mg)α′-Sialon-AlN-TiN; process parameter; synthesis mechanism

随着我国钢铁工业的发展, 高炉渣的排放量日益增大。目前,攀钢每年能排放约300万t的含钛高炉渣(TiO2含量为22%~26%), 它的堆积已造成资源浪费和环境污染等不良后果。 因此, 如何全面有效地利用含钛高炉渣已经越来越引起人们的重视。 由于含钛高炉渣具有独特的物理化学性质, 因而对它的综合利用难度很大, 而且始终存在处理成本高、 经济效益差、 技术效果不明显、 处理量有限、 产品附加值低和二次污染等问题, 难以实现工业化处理规模。 含钛高炉渣的主要化学成分包括SiO2, Al2O3, CaO, MgO和TiO2等氧化物。 其中, SiO2, Al2O3, CaO和MgO是采用碳热还原氮化法(CRN)合成(Ca, Mg)α′-Sialon的原料, 而TiO2则可在该过程中被还原氮化为熔点高、 硬度大且具有较高导电性质的TiN相, 有助于改善合成材料的综合性能。α′-Sialon具有硬度高、 耐磨性好、 抗氧化和抗热震性好等优点, 其缺点是强度和韧性较差[1]。 最近研究发现[2-5], 利用改变组分和工艺条件可制备出既有等轴又有长柱状α′-Sialon晶粒的α′-Sialon陶瓷, 其中长柱状晶粒对α′-Sialon陶瓷有明显的自增韧作用, 很大程度上改善了α′-Sialon陶瓷的韧性。 同时, 由于α′-Sialon晶胞中可容纳一定数量的金属阳离子如Li+, Ca2+, Y3+, Mg2+以及一些稀土元素阳离子, 从而减少了晶界相数量, 改善了材料的高温性能。 以含钛高炉渣为原料, 采用碳热还原氮化法可望合成出(Ca, Mg)α′-Sialon-AlN-TiN复合材料, 该材料可作为新一代的耐火材料和高温结构陶瓷材料。同时, 由于TiN具有良好的导电性, 因此该材料又可能成为一种新的功能材料。 目前, α′-Sialon常用的合成方法主要有反应烧结法、 自蔓延烧结法和碳热还原氮化法。 其中, 碳热还原氮化法既可采用纯SiO2和Al2O3等氧化物为主要原料[6], 也可利用廉价的天然原料[7, 8]或工业废渣[9-11]等作为主要原料来合成低成本、 高质量的α′-Sialon粉。 由此法制备的α′-Sialon粉末可作为后续合成α′-Sialon先进陶瓷的原料。 迄今为止, 国内外还鲜有采用高炉渣合成先进陶瓷粉体的报道, 更未见利用含钛高炉渣合成(Ca, Mg)α′-Sialon-AlN-TiN粉的报道。

本文作者以攀钢含钛高炉渣作为主要原料, 采用碳热还原氮化法进行合成(Ca, Mg)α′-Sialon-AlN-TiN粉的研究, 主要考察合成温度和恒温时间对反应过程的影响, 并对合成过程的机理进行探讨。

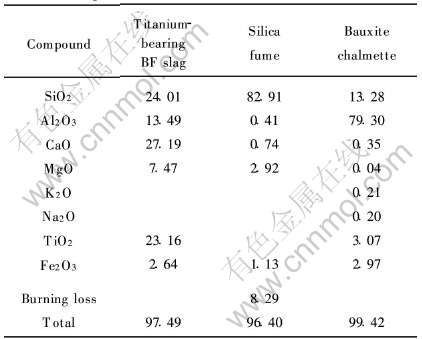

1实验 实验所用主要原料为含钛高炉渣(攀枝花钢铁集团公司), 采用硅灰(内蒙古铁合金厂)和高铝矾土熟料(山西阳泉地区)调整成分, 以满足合成α′-Sialon所需的硅铝比。 采用炭黑(抚顺石油公司)作还原剂, 其中固定碳为95.44%, 用量为理论配碳量的1.5倍。 原料主要成分见表1。 本工作选取m=2n的(Ca, Mg)α′-Sialon组分作为研究对象, 即组分位于α′-Sialon平面上x(Si3N4)和x(MO)∶3x(AlN)(M为Ca2+或Mg2+)的连线上, 此时α′-Sialon的化学式可简化为(Ca, Mg)xSi12-3xAl3x-OxN16-x。 选取x为1.8的组分进行配料。

表1实验原料主要成分

Table 1 Compositions of raw material powders (mass fraction, %)

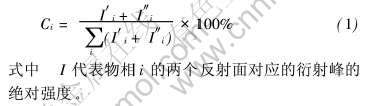

将配制好的混合料置于聚氨酯球磨罐中, 以无水乙醇为介质湿混24h, 然后将料浆放入烘箱中于60℃下烘干。 待混合料充分干燥后再干混4h, 以确保混合料充分均匀。 称取一定量坯料放入钢模中, 于25MPa下单轴向机压成d15mm的小圆坯。 将素坯装入石墨坩埚中, 置于立式硅钼棒电阻炉恒温带中, 由炉底连续通入高纯氮气(质量分数>99.999%), 常压下进行烧结。 烧结温度为1200~1500℃, 恒温时间为0~14h, N2流量400mL/min。 采用XMTA-1型温控仪(上海亚太精密仪表厂)进行控温, 升温速度约5℃/min, 降温速度约4℃/min。 烧成后的试样于580℃空气中恒温6h, 以去除残余的游离碳, 同时防止了烧成试样中TiN的氧化。 采用日本理学D/MAX-RB型X射线衍射仪进行相组成分析, 测试条件为Cu靶Kα辐射, 工作电压40kV。 采用下式可近似估计各相的相对含量Ci:

2结果与讨论

2.1合成温度的影响

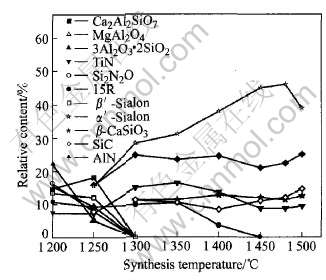

图1所示为试样在1200~1500℃, 恒温8h(N2流量400mL/min)后产物的X射线衍射谱。 图2所示为产物中各物相相对含量随合成温度的变化。 由于式(1)的近似性, 该图仅代表各相含量的变化趋势。 由图1和图2可以看出, 当温度达到1200℃时, 产物中有莫来石(3Al2O3·2SiO2)、 尖晶石(MgAl2O4)和铝黄长石(Ca2Al2SiO7)生成, 说明此时SiO2, Al2O3, CaO和MgO彼此之间发生了固相反应, 并分别生成了各自的复合氧化物。 同时, 部分SiO2和TiO2分别被还原氮化为Si2N2O和TiN。 此外, 产物中还有少量β′-Sialon和15R相出现。 当温度升至1250℃时, 除上述物相外产物中开始出现α′-Sialon, 但由于此时温度较低, 生成的α′-Sialon量很少, 且与x=0.8的Ca-α′-Sialon衍射标准卡片对比, 生成的α′-Sialon衍射峰都向衍射角大的方向偏移, 说明此时Ca2+, Mg2+在α′-Sialon中的固溶量很小。 同时, 在该温度下, Al2O3的还原氮化反应也开始进行并部分转化为AlN。 随合成温度的升高, 莫来石、 尖晶石、 Si2N2O和β′-Sialon含量不断减少, 并在1300℃时完全消失。 Ca2Al2SiO7在1250℃时达到最大后迅速减少并在1300℃时完全消失。 1300℃时, 合成产物中主要包括α′-Sialon, AlN, TiN以及少量SiC, 15R和β-CaSiO3(硅灰石), 此时α′-Sialon已成为产物中的主晶相。 热力学分析表明, 在标准状态下SiC只有在较高的温度下才能生成。 但如果体系中存在较多的杂质相(如Fe3+等), 这些杂质相通过改变体系的热力学活度而改变了相平衡关系, 促进了体系中液相的生成, 使得SiC可在较低的温度下形成。 由于本研究所用的初始原料均为天然矿物和冶金废渣, 内含较多杂质相, 降低了体系中液相的形成温度, 促使SiC在1300℃较低温度开始形成, 并随温度的升高含量逐渐增加。 1250℃时, 实验产物中存在较多非晶, 这是由于Ca-Mg-Si-Al-O体系的共晶温度为1250℃[12], 超过该温度体系中将产生大量液相, 但由于此时温度较低, 液相未充分参与还原氮化反应, 而在降温过程中以非晶相形式保存下来。 当温度大于1350℃时, 产物相组成与1300℃时的基本相同, 只是15R相在1450℃后完全消失。 在产物中α′-Sialon含量迅速增加的同时AlN的含量呈下降趋势, 说明AlN参与了α′-Sialon的合成。 1400℃以上, 还原氮化反应进行较充分, 故残存的非晶相较少。 1480℃后, α′-Sialon含量逐渐减少, 这可能是由于高温下α′-Sialon发生了分解所致。 由此可见, 合成温度对产物相组成影响显著。 提高合成温度可促进碳热还原氮化反应的进行, 有利于α′-Sialon的合成, 但温度过高时α′-Sialon相减少, 同时SiC含量增加。 1480℃时整个还原氮化反应进行较充分, 产物中α′-Sialon的含量最高, 是本研究中比较理想的合成温度。

图1 不同温度条件下合成试样的X射线衍射谱

Fig.1 XRD patterns for samples prepared at different synthesis temperatures

图2 各物相相对含量随合成温度的变化

Fig.2 Variation of phase compositions of samples with synthesis temperature

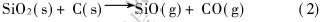

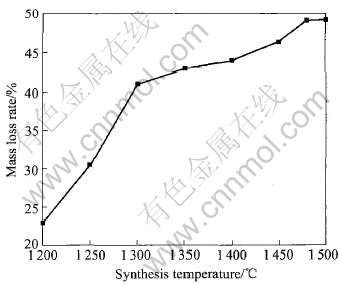

图3所示为试样质量损失率随合成温度的变化。 由图可见, 随合成温度的升高, 试样的质量损失率增大。 1480℃和1500℃反应后试样的质量损失率均超过了49%的理论损失率, 而在1200℃较低温度下, 虽然原料中尚有大量氧化物未被还原氮化, 但也有接近23%的质量损失率。 各国学者在研究SiO2-C-N2体系时都注意到了这一现象, 且目前已就此基本达成共识, 即这些额外的质量损失主要是由于1300℃左右发生如下反应:

图3试样质量损失率随合成温度的变化

Fig.3Variation of mass loss rate of samples with synthesis temperature

反应(2)生成的SiO被流动的N2携带出体系, SiO的挥发会导致体系中p(SiO)降低, 并使SiO2大量损失而改变原料的SiO2与C的比例, 所以是决定反应产物相组成的最重要因素之一。 影响SiO损失的参数有: N2流速、 反应温度、 恒温时间等[13]。 在其他实验条件一定的情况下, 随合成温度升高, 该反应速率及气体流速加快, 被N2携带出体系的SiO增加, 从而导致质量损失率显著增加。 1480℃, 8h后还原氮化反应已进行得比较充分, SiO损失量明显减少, 因此试样质量损失率的增加明显减慢。

2.2 恒温时间的影响

图4所示为1480℃时产物中各相相对含量随恒温时间的变化。 由图可见, 1480℃时不同恒温时间试样的产物相组成基本相同, 都主要由α′-Sialon, AlN, TiN以及少量SiC和硅灰石组成, 只是在含量上有所差别。 恒温时间为0h的试样中主要物相为AlN, SiC, α′-Sialon和TiN, 其中AlN为产物的主晶相。 由此可知, 在温度升高至1480℃的过程中, 还原氮化反应已开始进行, 原料中大部分Al2O3和TiO2都已被还原氮化为AlN和TiN, 这也说明了在本实验条件下二者的还原氮化温度较低, 前面分析结果也证实了这一点。 由于在合成温度下未进行恒温处理, 因此整个还原氮化反应进行得很不充分, 实验产物中存在较多的非晶相也说明了这一点。 此时, 产物中的α′-Sialon相含量很低。 随恒温时间的延长, α′-Sialon相含量不断增加, 且Ca2+, Mg2+在α′-Sialon中的固溶度也有所增加。 恒温8h时, α′-Sialon相含量达最大, 继续延长恒温时间, α′-Sialon含量有所减少。 AlN则呈现出与α′-Sialon相反的变化规律。 SiC含量在恒温2h时达到最大, 之后随α′-Sialon含量的增加而略有下降。 恒温1h的试样中有15R相出现, 且随恒温时间的延长而不断减少, 并在恒温6h后完全消失。

图41480℃时产物中各相相对含量随恒温时间的变化

Fig.4Variation of phase compositions of reaction products with holding time at 1480℃

这说明15R相在恒温初期形成, 但在随后的恒温过程中可能发生了分解而转变成为AlN相[14], 图4中15R相迅速减少的同时AlN含量略有增加基本上可证明这一点。 不同恒温时间的试样中始终有少量TiN存在, 但含量变化不大, 说明在恒温开始前, TiO2已基本被还原氮化成为TiN。 由此可见, 在1480℃条件下, 恒温时间对产物相组成的影响不十分显著, 但较长的恒温时间可使还原氮化反应进行得更充分。 恒温8h的试样中α′-Sialon含量最高, 是较理想的恒温时间。

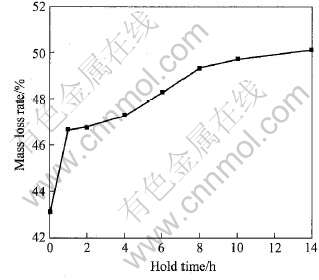

图5所示为试样质量损失率随恒温时间的变化。 由图可见, 试样在达到合成温度之前质量损失率就已达43.1%, 接近49.0%的理论质量损失率。 随恒温时间的延长, 质量损失率逐渐增大, 恒温8h时质量损失率达49.4%, 已超过理论值。 此时恰好α′-Sialon的含量也达到最大值。 试样额外的质量损失主要是由反应(2)产生的SiO气体未完全被氮化而被流动的N2流携带出体系所致。 上述分析表明, 恒温0h的产物中已有少量α′-Sialon相生成, 说明此时N2已开始参与反应, 部分SiO被氮化。 但此时还原氮化反应进行得很不完全, 有大量的SiO未能被充分氮化而同CO一起被流动的氮气带出体系。 随恒温时间的延长, 上述反应速率逐渐减慢, 而氮化反应速率加快, 故被携带出体系的CO和SiO的量相应减少, 因而使质量损失率随时间的变化表现为: 恒温初期质量损失增加速度较快, 之后随恒温时间延长逐渐变缓。 恒温8h之前, 产物质量损失率始终未超过理论值, 这一方面是由于反应尚未进行完全; 另一方面也是产物中生成的SiC减少了SiO2还原为SiO过程中造成的硅损失。

图5试样的质量损失率随恒温时间的变化

Fig.5Variation of mass loss rate of reaction products with holding time

2.3合成过程机理探讨

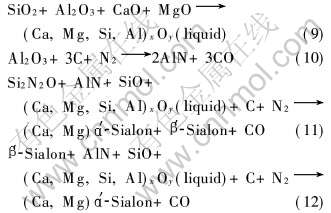

当合成温度达到1200℃时, 原料中SiO2, Al2O3, CaO和MgO相互间开始发生反应生成莫来石、 铝黄长石和尖晶石。 然后生成的莫来石又开始发生还原氮化反应生成β′-Sialon和15R相。 此时, 一部分SiO2与C和N2开始发生反应生成了Si2N2O, 而大部分TiO2也已被还原氮化为TiN。 由于此时温度较低, α′-Sialon的合成反应尚未开始进行。 该阶段可能发生的反应如下:

当温度升高到1250℃时, 反应(4)和(7)继续进行, 使得产物中铝黄长石的含量不断增加, 而莫来石的含量不断减少。 此时, 反应(2)也开始进行, 并且体系中的SiO2, Al2O3, CaO和MgO开始发生共晶反应而生成一定量的液相。 Al2O3的还原氮化反应在该阶段也开始进行并生成了AlN。 随后, Si2N2O, AlN及液相与SiO, C, N2反应, 生成α′-Sialon和β′-Sialon。 此过程生成的β′-Sialon以及反应(7)生成的β′-Sialon与AlN和液相一起被SiO, C和N2进一步还原氮化为α′-Sialon。 图2中的β′-Sialon含量在该阶段基本保持不变也证实了这一推测。 该阶段可能发生的反应如下:

随温度继续升高, 初始生成的中间产物莫来石、 尖晶石、 铝黄长石、 Si2N2O和β′-Sialon相进一步向α′-Sialon和AlN相转化而逐渐完全消失。 此时, SiO2与C开始反应生成SiC。 少量未反应的SiO2与CaO作用生成了β-CaSiO3。 当温度超过1480℃后, 产物中α′-Sialon含量有所降低, 15R相完全消失, 这可能是15R和部分α′-Sialon在高温下发生了分解所致。 该阶段可能发生的反应如下:

3 结论

1) 合成温度对(Ca, Mg)α′-Sialon-AlN-TiN粉的合成有显著影响。 随着合成温度升高, 产物中α′-Sialon相含量增大, 1480℃时α′-Sialon含量达最大, 是最佳的合成温度。

2) 恒温时间对产物相组成的影响不十分显著, 但较长的恒温时间可使还原氮化反应进行得更充分。 恒温8h的试样中α′-Sialon含量最高, 是较理想的恒温时间。

3) 合成过程中反应SiO2+C[FY]SiO+CO产生的SiO气体被流动的N2带出体系造成试样较大的质量损失, 且随着合成温度的升高和恒温时间的延长, 试样质量损失增大。

4) 合成过程机理为: 原料中SiO2, Al2O3, CaO和MgO相互间先发生反应生成莫来石、 铝黄长石和尖晶石。 随后生成的莫来石又与C, N2反应生成β′-Sialon和15R相。 同时, 部分SiO2和TiO2分别与C, N2发生反应生成Si2N2O和TiN。 随后, Al2O3还原氮化生成的AlN与中间产物Si2N2O和β′-Sialon以及液相进一步反应生成(Ca, Mg)α′-Sialon。 少量未反应的SiO2与CaO作用生成了β-CaSiO3。 在1480℃恒温8h后, 15R和部分α′-Sialon发生分解。

REFERENCES

[1]Ekstrm T, Nygren M. SiAlON ceramics[J]. J Am Ceram Soc, 1992, 75: 259-276.

[2]Hampshire S, Park H K, Thompson D P, et al. α′-Sialon ceramics[J]. Nature, 1978, 274: 880-882.

[3]Wood C A, Zhao H, Cheng Y B. Microstructural development of Ca-α′-Sialon ceramics with elongated grains[J]. J Am Ceram Soc, 1999, 82(2): 421-428.

[4]Chen I W, Rosenflanz A. A tough Sialon ceramic based on α-Si3N4 with a whisker-like microstructure[J]. Nature, 1997, 389: 701-704.

[5]Wang P L, Zhang C, Sun W Y, et al. Characteristics of Ca-α′-Sialon—phase formation, microstructure and mechanical properties[J]. J Eur Ceram Soc, 1999, 19: 553-560.

[6]Komeya K, Zhang C, Hotta M, et al. Hollow beads composed of nanosize Ca-α′-Sialon grains[J]. J Am Ceram Soc, 2000, 83(4): 995-997.

[7]Zhang C, Komeya K, Tatami J, et al. Synthesis of Mg-α′-Sialon powders from talc and halloysite clay minerals[J]. J Eur Ceram Soc, 2000, 20: 1809-1814.

[8]van Rutten J W T, Terpstra R A, van der Heijde J C T, et al. Carbothermal preparation and characterization of Ca-α′-Sialon[J]. J Eur Ceram Soc, 1995, 15: 599-604.

[9]刘克明, 王福明, 李文超, 等. 高炉渣合成Ca-α′-Sialon -SiC粉的热力学分析及工艺优化[J]. 北京科技大学学报, 2001, 23(5): 404-408.

LIU Ke-ming, WANG Fu-ming, LI Wen-chao, et al. Synthesis of Ca-α′-Sialon-SiC powders from blast furnace slag and optimization of its synthesis[J]. Journal of University of Science and Technology Beijing, 2001, 23(5): 404-408.

[10]Chen W W, Wang P L, Chen D Y, et al. Synthesis of (Ca, Mg)α′-Sialon from slag by self-propagation high-temperature synthesis[J]. J Mater Chem, 2002, 12: 1199-1202.

[11]姜涛, 薛向欣. 含钛高炉渣合成(Ca, Mg)α′-Sialon-AlN-TiN粉末的研究[J]. 中国有色金属学报, 2004, 14(12): 2009-2015.

JIANG Tao, XUE Xiang-xin. Study of Synthesis of (Ca, Mg)α′-Sialon-AlN-TiN powders from titanium-bearing blast furnace slag[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2002-2015.

[12]Robbins C R, McMurdie H F, Levin E M. Phase Diagrams for Ceramists[M]. Columbus, Oh: American Ceramics Society, 1964. 291.

[13]Sopicka Lizer M, Terpstra R A, Metselaar R. Carbothermal production of β′-Sialon from alumina, silica and carbon mixture[J]. J Mater Sci, 1995, 30: 6363-6369.

[14]Qiu J Y, Tatami J, Zhang C, et al. Influence of starting material composition and carbon content on the preparation of Mg-α′-Sialon powders by carbothermal reduction-nitridation[J]. J Eur Ceram Soc, 2002, 22: 2989-2996.

基金项目: 国家高技术研究发展计划资助项目(2002AA334080); 国家自然科学基金资助项目(50034010)

收稿日期: 2004-10-09; 修订日期: 2005-01-04

作者简介: 姜涛(1973-), 男, 讲师, 博士研究生.

通讯作者: 薛向欣, 教授, 博士生导师; 电话: 024-83687371; 传真: 024-23906316; E-mail: xuexx@mail.neu.edu.cn

(编辑陈爱华)