文章编号:1004-0609(2013)S1-s0756-05

锻造对(TiB+TiC)/Ti复合材料组织和高温拉伸性能的影响

张长江1, 2,张树志1, 2,孔凡涛2,肖树龙2,刘 浩2,陈玉勇2

(1. 太原理工大学,材料科学与工程学院,太原 030024;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:采用原位熔铸的方法制备了3%(TiB+TiC)/Ti复合材料。用X射线分析(XRD)和能谱(EDS)进行了相分析,用金相显微镜(OM)和扫描电镜(SEM)研究了锻造对复合材料组织的影响,并对铸态和锻造后的复合材料进行了高温拉伸对比试验。结果表明,利用该方法制备的复合材料中增强体分布均匀,锻造后复合材料由等轴状的α晶粒构成;与铸态复合材料相比,锻态复合材料在600~800 ℃范围具有较高的抗拉强度和伸长率;锻造对复合材料的高温断裂方式也有明显的影响。

关键词:钛基复合材料;原位自生;高温锻造;显微组织;高温拉伸性能

中图分类号:TF 804.3 文献标志码:A

Effect of forging on microstructure and high temperature tensile properties of (TiB+TiC)/Ti composites

ZHANG Chang-jiang1, 2, ZHANG Shu-zhi1, 2, KONG Fan-tao2, XIAO Shu-long2, LIU Hao2, CHEN Yu-yong2

(1. School of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: 3% (volume fraction) (TiB+TiC)/Ti composite was fabricated using in-situ technology. The microstructure of the composite as-cast and after forging was studied by optical microscopy (OM). The phase identification was performed by X-ray and energy dispersion X-ray spectrometer (EDS). The mechanical properties of the composite in cast and after forging were tested by tensile tests at high temperature. The results show that the microstructure of the composite after forging consists of near equiaxed α grains totally. Compared with the as-cast composites, as-forged composites possess excellent high temperature tensile strength and elongation in 600-800 ℃ temperature range. Forging has obvious effect on the fracture mode and fracture process of the composite as well.

Key words: titanium matrix composites; in situ; high temperature forging; microstructure; high temperature tensile properties

钛基复合材料由于具有密度低、比强度与比模量高、高温强度优异,耐腐蚀性能好等突出优势,在航空航天、汽车、先进武器、化工工业等领域具有广泛的应用前景[1-2]。利用原位自生技术制备的钛基复合材料具有工艺简单、各向同性、成本低、性能优越等优点,而且该方法避免了外加法的界面污染的问题,得到了较广泛的研究[3-5]。然而,硬而脆的增强相的引入使得钛基复合材料塑性降低,机加工性能变差,使其应用受到限制。热加工(TMP)不仅可以改善钛基复合材料的基体组织还能改变增强相的分布特征从而改善钛基复合材料,因此具有很大的研究价值。对钛合金的研究发现,可以通过控制热加工工艺来得到特定的显微组织。近α钛合金通过热加工可以得到不同的组织和性能,其热加工后的组织可以是β转变组织(针状α和β层),该组织具有较高的蠕变抗力,也可以是等轴的(α+β)双态组织,该组织具有良好的低周疲劳性能。研究表明,近α钛合金及其复合材料的蠕变性能很大程度上取决于其显微组织[6]。ES-SOUNI[7]发现材料的蠕变速率随着组织中的等轴α晶粒体积分数的增加而增大。因此,当材料的显微组织为魏氏组织时,和双态组织相比该组织具有更高的蠕变抗力。这种力学性能的提高是由于较细的α片层能有效降低位错的滑移距离[8]。

在此,本文作者研究了锻造对原位自生3%(TiB+TiC)/Ti复合材料显微组织及高温拉伸性能的影响。

1 实验

本研究采用的材料是以TiB和TiC为增强相(TiB和TiC体积比为1:1)、以Ti-6Al-2.5Sn-4Zr-0.7Mo-0.3Si-Y(质量分数,%)高温钛合金为基体的3%(TiB+TiC)/Ti复合材料(体积分数)。原材料在真空自耗电弧炉(VAR)中熔炼,为了保证铸锭化学成分均匀,铸锭至少熔炼3次。熔炼过程中,TiB和TiC通过如下的化学反应生成:

5Ti+B4C=TiC+4TiB (1)

Ti+C=TiC (2)

熔炼完成后,将铸锭车去表面层,随后进行高温锻造。铸锭在1 050 ℃经2次锻造得到钛基复合材料锻饼,锻饼的总变形量约为75%。锻造过程中,试样的温度用配备红外测温的仪器测定。铸态及锻态试样经切割、打磨、抛光,用标准Kroll试剂腐蚀后,采用OLYMPUS-TH3金相显微镜观察显微组织。在D/max-RB旋转阳极型X射线衍射仪上分析铸态试样的相组成。采用Instron-5500R(1186)电子万能试验机测试钛基复合材料的高温拉伸性能,拉伸速率取0.5mm/min。采用型号为Quanta 200FEG的场发射扫描电子显微镜观察拉伸试样断口。

2 结果与讨论

2.1 相鉴定与增强体观察

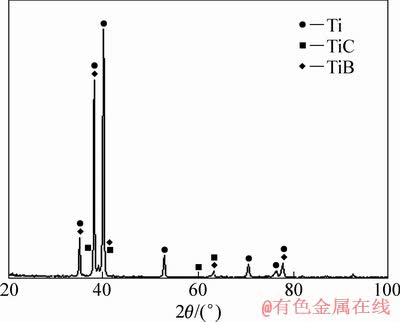

3%(TiB+TiC)/Ti复合材料的XRD测试结果如图1所示。从图1可以看出,复合材料主要由Ti,TiC和TiB三相组成,并没有发现亚稳硼化物或碳化物生成。

图1 3%(TiB+TiC)/Ti复合材料XRD谱

Fig. 1 XRD patterns of 3%(TiB+TiC)/Ti composites

XRD分析结果表明:采用真空自耗电弧熔炼技术结合Ti与B4C,C之间的原位反应成功制备了(TiB+TiC)/Ti复合材料。

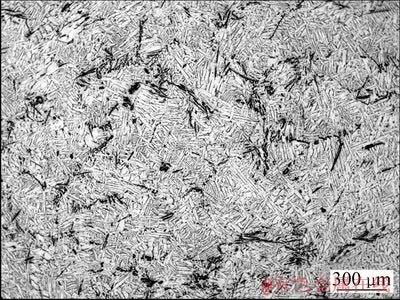

增强相在复合材料中的分布与形态如图2所示。从图2可以看出,增强相在基体中分布较为均匀,增强相主要有针状和近等轴状2种。能谱分析表明,针状的增强相为TiB,而近等轴状的为TiC。复合材料中的TiB和TiC增强相形态的不同主要与TiB和TiC的晶体结构以及凝固过程中它们不同的生长机制有关[9-10]。

图2 铸态复合材料中TiB纤维和TiC颗粒

Fig. 2 TiB whiskers and TiC particles within as-cast composites

2.2 复合材料基体显微形貌

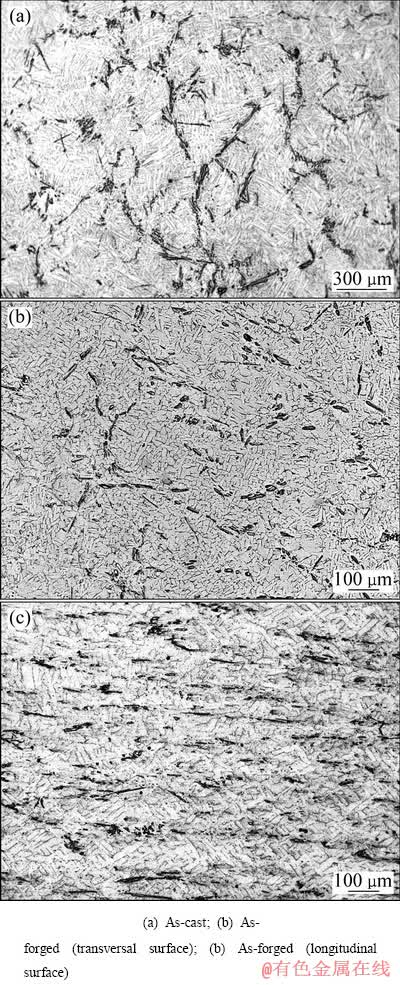

复合材料的铸态与锻态的光学显微形貌如图3所示。由图3(a)可以看出,铸态3%(TiB+TiC)/Ti复合材料基体组织为魏氏组织,TiB及TiC分布在初始β晶界,初始β晶粒平均尺寸约为269.8 μm,α相为层片状,片层尺寸约为7.38 μm。锻态复合材料的显微组织如图3(b)~(c)所示。在锻饼横截面上,增强相无定向分布特征,高长径比的TiB晶须和尺寸较大的TiC颗粒折断明显并重新分布(图3(b));在锻饼纵截面上,TiB及TiC增强相趋向于沿垂直于锻造方向定向分布,部分高长径比的TiB晶须和尺寸较大的TiC颗粒发生折断(图3(b))。这是由于在锻造过程中,TiB及TiC增强相的相对位置会发生改变以实现与基体的协调变形。值得一提的是,无论在锻饼的横截面或纵截面上,增强相与基体的界面处均未发现明显的孔洞,表明锻态复合材料基体与增强相的界面结合良好。

图3 复合材料显微组织

Fig. 3 Microstructures of composites

与铸态不同,锻态复合材料基体中α相呈近等轴状分布,α晶粒尺寸为7.2~12.6 μm,如图3(b)~(c)所示。本试验中,得到的组织完全是由等轴的α晶粒构成,这种组织的形成与锻造过程中α相的析出和长大机制有关[11]。本试验采用的在1 333 K开锻(处于(α+β)相区,金相法测定的该材料的β转变温度为1 398 K)。在锻造过程中,当试样的温度低于β/α+β转变温度时,β相开始转变为α相。由于在锻造过程中试样的冷却温度较低,新析出的α相优先在初生α相边上析出长大,这样最终形成等轴状的α晶粒,残余的β相分布在α晶粒边界上。

2.3 高温拉伸性能

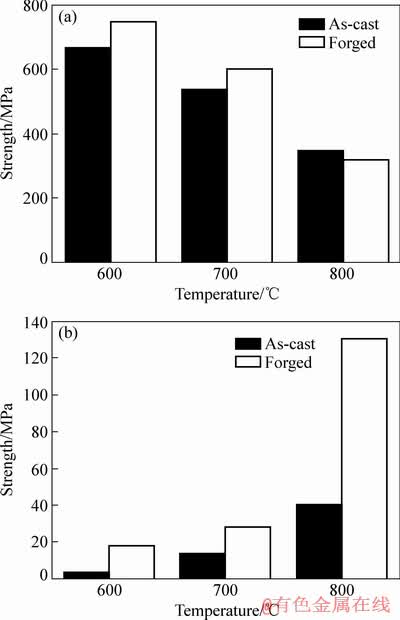

图4所示为铸态及锻态3%(TiB+TiC)/Ti复合材料在600~800 ℃的拉伸性能。从图4(a)可以看出,在600和700 ℃下,铸态复合材料的抗拉强度分别为665.5和538.86 MPa,经锻造后,抗拉强度有了显著提高,分别达到了748.2和600.3 MPa;而在800 ℃下,铸态复合材料的抗拉强度为346.6 MPa,经锻造后,抗拉强度为319.8 MPa,较铸态降低7.73%。

图4 不同温度下铸态及锻态复合材料拉伸强度和伸长率对比

Fig. 4 Comparison of (a) tensile strengths and (b) elongation of as cast and as forged TMCs at different temperatures

从图4(b)可以看出,经锻造后复合材料的伸长率有了明显提高。600 ℃时,铸态及锻态复合材料伸长率分别为3.64%和17.8%;随着温度的升高,铸态及锻态伸长率均有明显提高,且锻态伸长率随温度升高而提高的趋势更为明显,在800 ℃时,锻态复合材料的伸长率可达130.5%,较铸态时提高了223.8%。

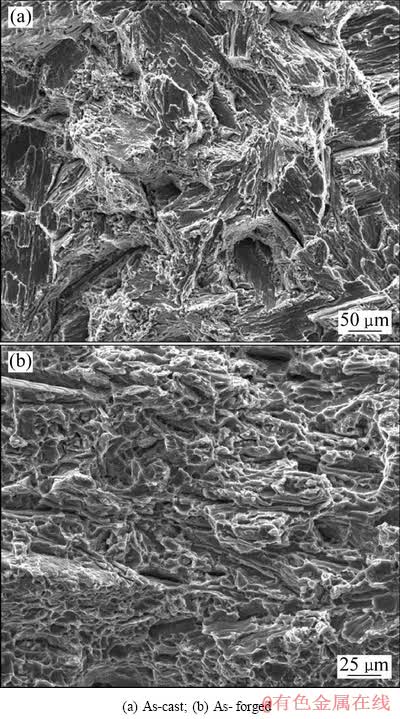

图5所示为铸态及锻态3%(TiB+TiC)/Ti复合材料在600 ℃高温拉伸后的断口形貌。铸态复合材料断口组织由随机分布的增强相的解理断面和基体的撕裂棱及少量韧窝组成,为一种准解理脆性断口,如图5(a)所示。经锻造后,复合材料断口组织中可观察到很多细小的韧窝,表明锻态复合材料的断裂模式为增强相的脆性断裂和基体韧性断裂共存。从图4(b)所示的伸长率变化特征中也可证实这一特征。

图5 铸态及锻态复合材料在600 ℃拉伸断口的SEM形貌

Fig.5 SEM images of tensile fracture surfaces of composites with different processing states at 600 ℃

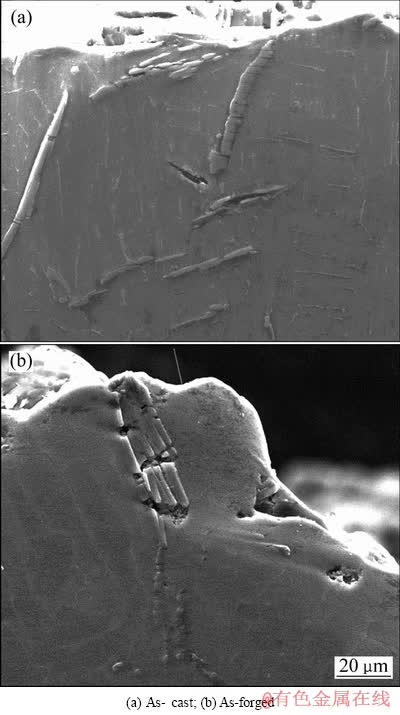

为了更好地研究复合材料的断裂过程,对拉伸试样断口附近变形区的显微组织进行了SEM观察,如图6所示。铸态时,复合材料拉伸变形区内的TiB增强相发生了明显与基体开裂,这说明在拉伸过程中,在这些地方的拉伸应力超出了这里的TiB与基体的结合强度;而在断口变形区内未观察到TiC颗粒的断裂现象,如图6(a)所示。经锻造后,TiB晶须沿锻造过程中金属的流动方向分布,在拉伸过程中TiB断裂,同时也未观察到TiC颗粒的断裂现象,如图6(b)所示。

图6 铸态及锻态复合材料在600 ℃下拉伸变形区形貌

Fig. 6 Micrographs of longitudinal sections near fracture surfaces of differently processed composites at 600 ℃

按照Kelly理论[12],由于基体和增强体之间的载荷传递作用,复合材料中的纤维状增强体有一个临界长径比,在拉伸过程中,长径比超过临界值的增强体就会断裂。通常,按照Kelly公式临界长径比lc/d可以用下式表示:

(3)

(3)

式中:lc,d,σfb和τi分别为纤维临界长度、纤维直径、界面剪切强度以及纤维剪切强度。由于在拉伸过程中没有出现TiB增强体被拔出的现象,因此假定拉伸过程中界面强度足够高,这样增强体中的τi就取决于基体的剪切强度τm,即:

τi=τm (4)

τm和σfb分别假定为基体合金的屈服强σym(1 000 MPa)和TiB纤维的强度(3 500 MPa),这样得到的临界长径比为1.75。在本试验中TiB纤维的平均长径比达到了9.6,显著地大于计算的临界长径比,因此TiB纤维在拉伸过程中就会断裂。和TiB相比,TiC颗粒的长径比较低,另外,由于其近等轴的形状造成的应力集中也比较低,因此在拉伸过程中TiC不容易开裂。

3 结论

1) 3%(TiB+TiC)/Ti复合材料基体为魏氏组织,TiB晶须和TiC分布在初始β晶界;(α+β)相区锻造后,基体为近等轴组织,TiB及TiC增强相发生折断使得长径比降低,增强相分布更为均匀。

2) 在600~700 ℃时,锻态复合材料的抗拉强度和伸长率较铸态均有大幅度提高;在800 ℃时,锻态复合材料抗拉强度较铸态略有较低,伸长率急剧提高。

3) 在600 ℃下,铸态复合材料的失效机制为脆性断裂,锻态复合材料为脆性和韧性共存的断裂机制;在铸态及锻态复合材料的断口变形区内,高长径比的TiB在拉伸过程中断裂,但均未发现TiC颗粒的断裂。

REFERENCES

[1] 胡加瑞, 肖来荣, 罗 锴, 刘 彦, 李 威, 蔡一湘. TiC颗粒增强钛基复合材料的高温变形行为[J]. 中国有色金属学报, 2010, 20(S1): s193-s197.

HU Jia-rui, XIAO Lai-rong, LUO Kai, LIU Yan, LI Wei, Cai Yi-xiang. Hot deformation behavior of titanium based matrix composites reinforced by TiC particulates[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s193-s197.

[2] RANGANATH S. Review on particulate-reinforced titanium matrix composites[J]. Journal of Materials Science, 1997, 32(1): 1-16.

[3] 吕维洁, 徐 栋, 覃继宁, 张 荻. 原位合成多元增强钛基复合材料(TiB+TiC+Y2O3)/Ti[J]. 中国有色金属学报, 2005, 15(11): 1727-1732.

Lü Wei-jie, XU Dong, QIN Ji-ning, ZHANG Di. In-situ synthesis of multiple ceramic particulates reinforced titanium matrix composites (TiB+TiC+Y2O3)/Ti[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1727-1732.

[4] ZHANG Yu-zi, HUANG Lu-jun, LIU Bao-xi, GENG Lin. Hot deformation behavior of in-situ TiBw/Ti6Al4V composite with novel network reinforcement distribution[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: s465-s471.

[5] 李 伟, 宋卫东, 宁建国, 毛小南. 应变速率对TP-650钛基复合材料拉伸力学行为的影响[J]. 中国有色金属学报, 2010, 20(6): 1131-1136.

LI Wei, SONG Wei-dong, NING Jian-guo, MAO Xiao-nan. Effect of strain rate on tensile mechanical behavior of TP-650 titanium matrix composite[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1131-1136.

[6] SAUER C, LüTJERING G. Thermomechanical processing of high strength β-titanium alloys and effects on microstructure and properties[J]. Journal of Materials Processing Technology, 2001, 117(3): 311-317.

[7] ES-SOUNI M. Primary, secondary and anelastic creep of a high temperature near α-Ti alloy Ti6242Si [J]. Materials Characterization, 2000, 45(2): 153-164.

[8] LüTJERING G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 32-45.

[9] ZHANG Xiao-nong, Lü Wei-jie, ZHANG Di, WU Ren-jie, BIAN Yu-jun, FANG Ping-wei. In situ technique for synthesizing (TiB+TiC)/Ti composites[J]. Scripta Materialia, 1999, 41(1): 39-46.

[10] 吕维洁, 张小农, 张 荻, 吴人洁, 卞玉君, 方平伟. 原位(TiB+TiC)/Ti复合材料中TiB/Ti界面的微结构研究[J]. 电子显微学报, 2002, 20(1): 56-62.

Lü Wei-jie, ZHANG Xiao-nong, ZHANG Di, WU Ren-jie, BIAN Yu-jun, FANG Ping-wei. Study on TiB/Ti interfacial microstructure of in situ synthesized (TiB+TiC)/Ti composite[J]. Journal of Chinese Electron Microscopy Society, 2002, 20(1): 56-62.

[11] MA Feng-cang, Lü Wei-jie, QIN Ji-ning, ZHANG Di. Microstructure evolution of near α titanium alloys during thermomechanical processing[J]. Materials Science and Engineering A, 2006, 416: 59-65.

[12] KELLY J, TYSON W R. Tensile properties of fiber-reinforced metals: Copper/tungsten and copper/molybdenum[J] Journal of the Mechanics and Physics of Solids, 1965, 13: 29-50.

(编辑 赵 俊)

基金项目:国家自然科学基金资助项目(51001040);太原理工大学人才基金资助项目(tyut-rc201343a)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:张长江,讲师,博士;电话:0351-6010022;E-mail:zcj0408@163.com