文章编号:1004-0609(2011)08-1847-08

工艺参数对金属粉末共注射成形芯层熔体形貌的影响

王光耀,何 浩,李益民,张健光

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:分别以316L(40%,体积分数)、316L(60%)为芯、壳层喂料,研究工艺参数如壳层熔体温度、壳层注射速度和延迟时间对粉末共注射芯层熔体形貌的影响;分析工艺参数对金属共注射芯层形貌影响的流变学机理。结果表明:芯层熔体前沿呈蘑菇状;固定芯层熔体温度,随着壳层熔体温度的升高,芯层穿透深度从148 mm减小到136 mm,最大穿透宽度从133 mm增加到139 mm;随壳层注射速度的增加,芯层穿透深度从148 mm减小到143 mm,而芯层穿透宽度的变化规律不明显;随着芯层熔体延迟时间的增大,芯层穿透深度从146 mm增加到154 mm,穿透宽度从118 mm增加到136 mm。

关键词:金属粉末共注射成形;工艺参数;芯层熔体形貌;流变学;芯、壳层黏度比

中图分类号:TF124 文献标志码:A

Effects of processing parameters on core melt morphology of metal powder co-injection molding

WANG Guang-yao, HE Hao, LI Yi-min, ZHANG Jian-guang

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Using two feedstocks, 316L(60%) and 316L(40%), as core and skin feedstocks, the effects of processing parameters, such as skin melt temperature, skin velocity and delay time, on the core melt morphology of metal co-injection molding were studied. The mechanism of the effect of processing parameters on the core melt morphology was studied on the basis of rheological theory. The results show that core melt front shows the shape of mushroom. With the increase of skin melt temperature, the penetration depth decreases from 148 mm to 136 mm, and the largest penetration width increases from 133 mm to 139 mm. While there is no significant variation on the core penetration with the increase of skin velocity, the penetration depth decreases from 148 mm to 143 mm. With the increase of delay time, the core penetration depth and width change significantly from 146 mm to 154 mm and from 118 mm to 136 mm, respectively.

Key words: metal powder co-injection molding; processing parameters; core melt morphology; rheology; core-skin viscosity ratio

金属粉末共注射成形技术是由传统粉末注射成形和塑料共注射成形相结合而发展起来的一门新技术。该技术通过共注射把不同加工特性的材料在模具内一次复合注射成形,整合各组分的优越性能,可以在一个生产步骤内使产品同时获得功能性和形状复杂 性,从而一步完成制品的涂层、表面处理和组装等步骤,实现复杂形状、高性能的多功能一体化零件的近净成形和大批量生产,大大降低了零部件的生产成本。该技术为功能零件的开发和设计提供了一条全新的途径,满足了制备多功能复合材料的要求,具有巨大的发展潜力[1-2]。

对共注射成形技术而言,芯层熔体的形貌和分布直接影响着产品的质量及性能。近年来,在塑料共注射成形领域,研究者通过实验和数值模拟的手段对芯层物料分布进行了研究。LI等[3-5]、周国发等[6]、王丽霞等[7]分别选用不同的聚合物作为物料对夹芯注射进行研究,发现黏度比是影响界面形貌的最主要因素。JOHNSTON和SQUIRES[8]将聚丙烯作为壳层与芯层材料,并通过光学仪器观察观察芯层厚度。研究表明,在制品凸起部分或具有类似特征的区域,黏度是影响芯层穿透和壳层厚度的主要因素。MESSAOUD等[9]选用聚丙烯和玻纤增强聚丙烯进行物料组合研究后发现,壳层物料的注射速度对壳层-芯层物料分布的影响极为明显,而芯层注射速度基本没有影响。而SCHLATTER 等[10]的研究发现:当芯层流速不变时,壳层流速的改变对芯层穿透深度影响不大;若壳层流速不变,芯层流速改变会使得芯层穿透深度减小。除了注射速度外,其他工艺参数也在一定程度上影响物料的分布。LI等[3]认为,在非等温条件下,物料熔体温度对界面形状的影响非常复杂。周国发等[11]的模拟及实验结果表明,若芯层熔体温度固定,随着壳层熔体温度升高,芯层相对穿透深度减小,而相对宽度增大;若壳层温度固定,随着芯层温度升高,芯层相对穿透深度增大,相对宽度减小。

目前,国际上对金属粉末共注射成形的研究仍停留在尝试阶段,并没有对影响材料芯、壳层厚度、芯、壳层界面形貌的因素进行系统的研究,更没有对金属粉末共注射成形的充填机理进行系统、成功的理论解释。本文作者分别以316L(40%)、316L(60%)为芯、壳层原料,研究了工艺参数如注射温度、壳层熔体温度、延迟时间对芯层穿透距离的影响。建立金属共注射成形工艺参数与芯层穿透距离的关系,并对其流变学机理进行了研究。

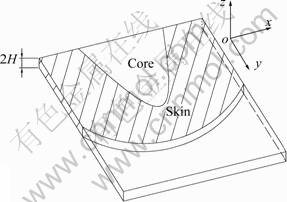

1 实验

实验选用尺寸为160 mm×160 mm×5 mm正方体平板模具,浇口为线浇口,位于160 mm×5 mm平面的底部,尺寸为6 mm×1 mm×5 mm,如图1所示。

粉末材料选用英国Ospery公司生产的气雾化316L不锈钢粉,其平均粒度为22 μm。粘结剂选用蜡基粘结剂,其组成成分主要有石蜡+乙烯-醋酸乙烯+ 高密度聚乙烯+苯乙烯磺酸钠。另外,为了便于观察样品芯层熔体的形貌,实验在芯层喂料中加入了少量的石墨粉末,其质量配比为1:150。按照粉末与粘结剂装载量分别为40%和60%的配比,用捏合机捏合1.5~ 2 h,在XSMY密炼机上密炼3 h后,于YHL04型单螺杆挤料机上经3次挤条,使粉末和粘结剂混合均匀,设定温度为165 ℃。再通过V68型制粒机进行制粒,喂料制成长3~5 mm、直径约为2 mm的条状,得到适合注射成形的均匀喂料。将装载量为40%的喂料作为芯层,装载量为60%的喂料作为壳层。再采用Rheo5000型高压毛细管流变仪测定喂料在剪切速率为40~1 200 s-1范围内不同温度下的黏度值,结果如图2和3所示。然后,在宁波海天塑机集团有限公司生产的HTF90W2型塑料注射成型机上完成喂料的注射,注射工艺参数如表1所列。将获得的试样沿中面平剖,分别测量芯层熔体的穿透深度和穿透宽度。穿透深度在注射方向上芯层熔体料流前沿与浇口位置的距离,用y表示,单位为mm;穿透宽度是指将芯层穿透深度沿着注射方向分成三等分,则熔体在垂直于注射方向上扩展的距离,分别用x1,x2,x3表示。试样芯层熔体穿透距离测量示意图如图4所示。

图1 共注射平板模具示意图

Fig.1 Geometry of square plate co-injection mold (mm)

图2 316L-40%喂料在不同温度下的黏度—剪切速率关系曲线

Fig.2 Viscosity—shear rate curves of 316L-40% feedstock at different temperatures

表1 注射实验工艺参数

Table 1 Technique parameters of injection conditions

图3 316L-60%喂料在不同温度下的黏度—剪切速率关系曲线

Fig.3 Viscosity—shear rate curves of 316L-60% feedstock at different temperatures

图4 芯层穿透深度y、宽度x示意图

Fig.4 Schematic diagram of measurement of core penetration in directions x and y

2 实验结果

图5所示为芯层温度为158 ℃时芯层穿透距离随壳层温度变化的实物照片。从图5可以很明显的看出,芯层熔体前沿呈蘑菇形状。这与NGUYEN等[12]、WATANABE等[13-14]通过实验研究发现,共注射过程中芯层熔体前沿往往成蘑菇形或“V”字形流动相符。

根据图5,可以获得芯层温度为158 ℃时芯层穿透距离随壳层温度的变化曲线,如图6所示。从图6可以看到,芯层穿透深度y值随着壳层温度的升高而减小,穿透宽度x1,x2则随着壳层温度的升高而升高。图6数据显示,随着壳层温度的升高,芯层穿透深度从148 mm减小到136 mm,而最大穿透宽度则从133 mm增加到139 mm。

图7所示为芯、壳层温度均为164 ℃、芯层注射速率为60 g/s下芯层穿透距离随壳层注射速度的变化曲线。从图7可以看到,芯层穿透深度y随壳层速度的增加而减小,而芯层穿透宽度的变化规律则不明显。但是,壳层注射速度的变化对芯层穿透距离的影响很小,变化量基本在2~3 mm之间。这一点与SCHLATTER等[10]的研究结论一致。与壳层注射速率相比,壳层温度引起的芯层穿透距离变化量更大。

图8所示为芯层穿透距离随延迟时间变化的关系曲线。从图8可以看到,随着延迟时间的增长,芯层穿透深度y、穿透宽度x3随均明显增加,其中,芯层穿透深度从146 mm增加到154 mm。该结果与注射速度相比,引起的芯层穿透距离变化大,而相对于注射温度而言,则较小。即改变延时时间比改变壳层注射速度能更有效地调节芯、壳层形貌分布,但效果不如改变注射温度的明显。

3 分析与讨论

3.1 工艺参数影响芯层熔体形貌分布的流变学分析

由实验发现,分别改变壳层熔体注射温度、壳层熔体注射速度和延迟时间等工艺参数,均使芯层的熔体形貌发生了规律性的变化,这种调整工艺参数影响芯层熔体形貌的现象可以从流变学的角度进行解释。

图5 芯层温度为158 ℃时芯、壳层穿透距离随壳层温度变化的实物照片(mm)

Fig.5 Photographs showing penetration changes with skin temperature for co-injected parts molded parts at constant core temperature of 158 ℃ and different skin temperatures (mm): (a) 152 ℃; (b) 158 ℃; (c) 164 ℃; (d) 170 ℃; (e) 176 ℃

图6 芯层温度为158 ℃时芯层穿透距离随壳层注射温度的变化曲线

Fig.6 Change curves of core penetration with skin temperature at core temperature of 158 ℃

如图9所示,如果型腔中的芯、壳层熔体为牛顿流体,则根据Hele-Shaw润滑理论,芯、壳层的平均流动速率分别为[15]

(1)

(1)

(2)

(2)

式中:vcore,vskin分别表示芯、壳层熔体的流动速率; ,

, 分别表示芯、壳层熔体的黏度;H为型腔厚度的一半;

分别表示芯、壳层熔体的黏度;H为型腔厚度的一半; ,

, 分别表示芯、壳层压力pcore、pskin在流动方向上的梯度。

分别表示芯、壳层压力pcore、pskin在流动方向上的梯度。

图7 芯层注射速率固定为60 g/s时芯层穿透距离随壳层注射速率的变化曲线

Fig.7 Change curves of core penetration with skin injection velocity at core velocity of 60 g/s

在芯、壳层界面处,存在如下关系:

pcore=pskin (3)

=

= (4)

(4)

图8 芯层穿透距离随芯层延迟时间变化的关系曲线

Fig.8 Change curves of core penetration with delay time

图9 充模流动过程流变学示意图

Fig.9 Schematic diagram of rheological analysis for mold-filling process

通过式(1)~(2),可以得到:

(5)

(5)

即

(6)

(6)

通过式(6)可以看出,如果 <

< ,那么

,那么 >

> ,即当芯层熔体黏度低于壳层熔体黏度时,芯层熔体比壳层熔体流动的更快,芯层熔体向前运动的趋势越大,充填结束时芯层熔体在型腔中的位置更接近壳层前沿位置。芯、壳层黏度比调节范围越大,芯、壳层熔体的流动速率比的变化范围越大,从而能够更有效地调节芯层熔体的分布。所以,可以通过调节芯、壳层黏度比来调节芯层熔体的分布。由于牛顿流体的黏度只与温度有关,因此,在实际生产过程中,可以直接或者间接地调节熔体的温度,这样使芯、壳层黏度比改变,从而使芯、壳层的速度之比发生变化,进而达到调节芯层熔体分布的目的。

,即当芯层熔体黏度低于壳层熔体黏度时,芯层熔体比壳层熔体流动的更快,芯层熔体向前运动的趋势越大,充填结束时芯层熔体在型腔中的位置更接近壳层前沿位置。芯、壳层黏度比调节范围越大,芯、壳层熔体的流动速率比的变化范围越大,从而能够更有效地调节芯层熔体的分布。所以,可以通过调节芯、壳层黏度比来调节芯层熔体的分布。由于牛顿流体的黏度只与温度有关,因此,在实际生产过程中,可以直接或者间接地调节熔体的温度,这样使芯、壳层黏度比改变,从而使芯、壳层的速度之比发生变化,进而达到调节芯层熔体分布的目的。

另外,通过改变芯、壳层的注射速率,可以直接改变芯、壳层的注射速率之比,这样使芯、壳层的相对流动速度发生变化,从而使芯层熔体的分布发生变化。

对于满足幂律黏度模型的非牛顿流体,型腔中芯、壳层的平均速度可以表示为[15]

(7)

(7)

(8)

(8)

式中:ncore、nskin分别表示芯、壳层熔体流动指数;kcore、kskin分别为芯、壳层稠度系数。

为了便于分析,令ncore=nskin,则

(9)

(9)

(10)

(10)

式中:A、Ta为熔体物性常数。

对于非牛顿流体充填型腔,通过式(6)可以得出类似牛顿流体充填型腔的规律,如果kcore<kskin,那么vcore>vskin,即当芯层熔体稠度系数低于壳层熔体稠度系数时,芯层熔体要比壳层熔体流动的更快,芯层熔体向前运动的趋势越大,充填结束时芯层熔体在型腔中的位置更接近壳层前沿位置。因此,调节芯、壳层熔体的稠度系数k和流动指数n可以有效地调节芯、壳层的流动速率之比,进而能够有效地调节芯层熔体的分布。非牛顿流体的稠度系数和流动指数均与温度有关。因此,在实际的生产过程中,可以直接或者间接地调节熔体的温度,这样使芯、壳层熔体的稠度系数之比和流动指数改变,从而使芯、壳层的速度之比发生变化,进而达到调节芯层熔体分布的目的。

本实验的充填过程可视为非牛顿流体在型腔中的运动过程,由以上分析可以发现,实验中调节壳层注射温度或注射延迟时间是直接或间接地调节了芯、壳层的注射温度,使芯、壳层熔体的稠度系数和流动指数发生变化,从而改变了芯、壳层的注射速率之比,进而调节了芯层熔体的分布。改变壳层的注射速率,即直接改变芯、壳层的注射速率之比,这样使芯、壳层的相对流动速度发生变化,从而使芯层熔体的分布发生变化。

3.2 工艺参数对芯层形貌分布的影响

本研究发现,改变不同的工艺参数对芯、壳层形貌分布的影响程度不同,即分别改变壳层注射温度以及芯层延迟时间比改变壳层注射速度能更有效地调节芯、壳层形貌分布。本文作者从芯、壳层黏度比的角度对这一现象进行了分析[3-5, 16-18]。

根据幂律黏度模型,黏度与剪切速率的关系为

(11)

(11)

其中: 为表观黏度;k为熔体稠度系数;

为表观黏度;k为熔体稠度系数; 为剪切速率;n为流动指数。

为剪切速率;n为流动指数。

剪切速率与模具尺寸、喂料注射速率存在如下关系[19]:

(12)

(12)

式中:Q为注射速率;W为模具的宽度;h为模具高度。

图10和11所示分别为316L-40%和316L-60%粉末喂料在不同温度下的黏度—剪切速率对数曲线,由图10和11可以分别拟合得到幂律模型的相关参数k和n的值。那么,通过式(11)和(12)可以获得芯、壳层熔体在不同温度下,不同注射速率时芯、壳层的黏度比。

表2所列为芯、壳层注射速率为60 g/s,芯层温度为158 ℃,不同壳层温度情况下,芯、壳层对应的k值、n值以及黏度η。由表2可以看出:芯层在注射速率为60 g/s下,壳层熔体温度变化对芯、壳层黏度比的影响。即壳层温度为152 ℃时,芯、壳层的黏度比为0.49,而到176 ℃时,芯、壳层的黏度比为1.06。

同样地,可以得到改变壳层熔体注射速率对芯、壳层黏度比的影响。根据图10和11可以获得在芯、壳层熔体温度为164 ℃时的幂律黏度模型的相关系数k和n的值,即kcore=292.1,ncore=0.66,kskin=789.9,nskin=0.55,进而根据式(11)、(12)获得壳层注射速率分别为30和90 g/s时,芯、壳层黏度比分别为0.7和1.15。可以看出,改变注射速度得到的芯、壳层黏度比变化为0.7到1.15,而改变温度芯、壳层黏度的变化为0.49到1.06。所以说,与改变注射速度相比,改变壳层注射温度能更有效地调节芯、壳层形貌分布。

图10 316L-40%粉末喂料不同温度下的 —

— 曲线

曲线

Fig.10  —

— curves of 316L-40% feedstock at different temperatures

curves of 316L-40% feedstock at different temperatures

图11 316L-60%粉末喂料不同温度下的 —

— 曲线

曲线

Fig.11  —

— curves of 316L-60% feedstock at different temperatures

curves of 316L-60% feedstock at different temperatures

表2 芯层和壳层注射速率分别为60 g/s、不同壳层温度下芯层和壳层熔体对应的黏度(η)值

Table 2 Viscosity of core and skin melts at different temperatures and velocity of 60 g/s

本文作者认为,改变延迟时间是间接地改变了壳层的注射温度,因此也可以从温度改变芯、壳层黏度比的角度,解释改变延迟时间比改变壳层注射速度能更有效地调节芯层熔体形貌分布这一实验现象。随着延迟时间的增长,由于型腔中的壳层熔体与模壁的热传导的作用,壳层熔体耗散的能量也就越多,壳层熔体的温度越低。由表2可知,熔体的黏度随着温度的下降而下降,因此,黏度比发生变化,从而影响了芯层熔体的形貌分布。目前,延迟时间对芯层熔体形貌分布的影响的定量解释还在进一步的研究之中。

通过分析可以发现,给定工艺参数,相当于给定黏度比,给定流动速度,改变工艺参数,黏度比、流动速度之比均随之变化,导致芯、壳层形貌变化。当芯、壳层黏度比变化大时,芯、壳层熔体流动速度比变化大,导致芯、壳层形貌变化也大。

4 结论

1) 当固定芯层熔体温度、壳层熔体温度在152~176 ℃之间改变时,随着壳层熔体温度的升高,芯层熔体穿透深度减小,最大穿透宽度增加;随壳层注射速度的增加,芯层穿透深度减小,而芯层穿透宽度的变化规律则不明显;随着芯层熔体延迟时间的增大,芯层熔体穿透深度,穿透宽度变化明显。与改变注射速度工艺参数相比,改变壳层注射温度、芯层延迟时间能更有效地调节芯、壳层形貌分布。

2) 芯层熔体的形貌分布与芯、壳层在型腔中的运动速度之比有关。根据流变学分析,对于非牛顿流体充填型腔过程,调节芯、壳层熔体的稠度系数和流动指数可以有效调节芯、壳层的流动速率比,进而能够有效调节芯层熔体的分布。因此,直接或者间接地调节熔体的温度,使芯、壳层熔体的稠度系数比和流动指数改变,从而使芯、壳层的速度比发生变化,进而调节芯层熔体分布。另外,通过改变芯、壳层的注射速率,直接改变芯、壳层的注射速率比,从而使芯层熔体的分布发生变化。

REFERENCES

[1] 周桂莲, 张慧敏. 共注射成型新工艺及设备特性[J]. 现代制造工程, 2003(11): 87-89.

ZHOU Gui-lian, ZHANG Hui-min. Co-injection molding technology equipment and application of liquid silicone rubber[J]. Modern Manufacturing Engineering, 2003(11): 87-89.

[2] 朱 计, 类彦威, 张 杰. 共注射成型技术及其发展[J]. 工程塑料应用, 2007, 35(4): 31-35.

ZHU Ji, LEI Yan-wei, ZHANG Jie. Co-injection moulding and its development[J]. Engineering Plastics Application, 2007, 35(4): 31-35.

[3] LI C T, ISAYEV A I. Interface development and encapsulation in simultaneous co-injection molding of disk (Ⅰ): Two- dimensional modeling and formulation[J]. Journal of Applied Polymer Science, 2003, 88: 2300-2309.

[4] LI C T, LEE D J, ISAYEV A I. Interface development and encapsulation in simultaneous coinjection molding of disk (Ⅱ): Two-dimensional simulation and experiment[J]. Journal of Applied Polymer Science, 2003, 88: 2310-2318.

[5] LI C T, LEE D J, ISAYEV A I. Interface and encapsulation in simultaneous co-injection molding of disk: Two-dimensional simulation and experiment[C]//Annual Technical Conference 2002, Society of Plastics Engineers. America: Robert Malloy, 2002, 48: 465-469.

[6] 周国发, 柳和生, 何成宏, 张效迅, 孙 懋. 共注成型芯、壳层熔体黏度对芯、壳层界面和移动前沿形貌的影响[J]. 复合材料学报, 2004, 21(4): 24-30.

ZHOU Guo-fa, LIU He-sheng, HE Cheng-hong, ZHANG Xiao-xun, SUN Mao. Effect of core-skin viscosity ratio on the formation of layer interface and moving melt fronts during molding filling if co-injection[J]. Acta Materiae Compositae Sinica, 2004, 21(4): 24-30.

[7] 王丽霞, 卢松涛, 朱文娜, 申长雨. 共注射成型中芯/壳层材料黏度比对追赶距离的影响[J]. 高分子材料科学与工程, 2010, 26(3): 116-118.

WANG Li-xia, LU Song-tao, ZHU Wen-na, SHEN Chang-yu. Influence of core-skin viscosity ratio on chase distance in co-injection molding[J]. Polymer Materials Science and Engineering, 2010, 26(3): 116-118.

[8] JOHNSTON S, SQUIRES S. Effects of processing parameters and wall thickness on core geometry and core penetration for co-injection parts[C]//Annual Technical Conference 2003 Society of Plastics Engineers. America, Robert Malloy, 2003, 49: 3348-3352.

[9] MESSAOUD D A, SANSCHAGRIN B, DERDOURI A. Co-injection molding: Effect of processing on material distribution and mechanical properties of short glass fiber reinforced polypropylene test bars[C]//Annual Technical Conference 2002, Society of Plastics Engineers. America: Robert Malloy, 2002, 48: 645-648.

[10] SCHLATTER G, AGASSANT J F, DAVIDOFF A, VINCENT M. An unsteady multifluid flow model: Application to sandwich injection molding process[J]. Polymer Engineering and Science, 1999, 39(1): 78-88.

[11] 周国发, 孙 懋, 柳和生,李绅元, 罗忠民. 顺序共注成型的实验研究[J]. 中国塑料, 2003, 17(4): 53-57.

ZHOU Guo-fa, SUN Mao, LIU He-sheng, LI Shen-yuan, LUO Zhong-min. Experimental study of sequential co-injection molding[J]. China Plastics, 2003, 17(4): 53-57.

[12] NGUYEN K T, TURCOTT E, DERDOURI A, KOPPI K A. Polymer melt flow behavior in the co-injection molding process[C]//Annual Technical Conference 2000, Society of Plastics Engineers. America: Robert Malloy, 2000, 46: 533-537.

[13] WATANABE D, HAMADA H, TOMARI K. Flow behavior of core material in sandwich injection molding with sequential and simultaneous injection[C]//Annual Technical Conference 2002, Society of Plastics Engineers. America: Robert Malloy, 2002, 48: 567-571.

[14] WATANABE D, HAMADA H, TOMARI K. The developing behavior of core material and breakthrough phenomenon in sandwich injection[C]//Annual Technical Conference 2001, Society of Plastics Engineers. America: Robert Malloy, 2001, 47: 656-660.

[15] YOUNG S S, WHITE J L, CLARK E S, OYANAGI Y. A basic experimental study of sandwich injection molding with sequential injection[J]. Polym Eng Sci, 1980, 20(12): 798-804.

[16] SOMNUK P, SMITH G F. Experimental study of simultaneous co-injection moulding process[C]//Annual Technical Confeernce 1995, Society of Plastics Engineers. America: Robert Malloy, 1995, 41: 760-764.

[17] PARSONS M, TOYODA P. Co-injection molding of PVC with other thermoplastics: Porcessing, properties and application[J]. Jounral of Vinyl and Additive Technology, 2002, 18(3): 202-208.

[18] GOODSHIP V, KIRWAN K, SMITH G F. Interfacial instabilities in multimaterial co-injection mouldings (Part 2): Interfacial mixing in transparent moulding[J]. Plastics Rubber and Composites, 2003, 32(3): 98-103.

[19] SMITH J B. Injection moulding-gates and runners[EB/OL]. http://www.pcn.org/Technical Notes-Gates and runners. htm. [2010-06-09].

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2007AA03Z114);国家自然科学基金创新研究群体基金资助项目(50721003)

收稿日期:2010-02-22;修订日期:2010-11-15

通信作者:何 浩,博士;电话:0731-88836113;E-mail: he_hao555@yahoo.com.cn