文章编号:1004-0609(2013)06-1701-11

加压浸出低品位锰矿的工艺

谢红艳1, 2,王吉坤1, 3,路 辉4,嵇晓沧5,杨世诚5

(1. 昆明理工大学 冶金与能源工程学院,昆明 650093;

2. 贵州大学 材料与冶金学院,贵阳 550088;3. 云南冶金集团总公司,昆明 650031;

4. 贵阳铝镁设计研究院,贵阳 550081;5. 云南建水锰矿有限责任公司,建水 654302)

摘 要:对低品位锰矿硫酸加压浸出工艺进行正交实验和单因素实验,通过正交实验得出:加压浸出低品位锰矿工艺中,影响锰浸出率的主要因素的较佳组合如下:初始酸浓度160 g/L、硫铁矿量50 g、液固比5:1(5 mL/g)、压力1 MPa、温度180 ℃、时间80 min。为分析低品位锰矿中锰、铁及铝的浸出行为,实现这3种金属元素的高效分离,参考正交实验结果适当地调整工艺参数,进行单因素实验研究,详细考察始酸浓度、反应温度、硫铁矿量、液固比、浸出时间和浸出压力对锰、铁及铝浸出率的影响,得到优化浸出工艺条件如下:低品位锰矿粉100 g,初始硫酸浓度120 g/L,浸出反应温度120 ℃,硫铁矿量50 g,液固比5:1(5 mL/g),浸出时间100 min,浸出压力0.7 MPa,搅拌转速500 r/min。本工艺具有良好的稳定性,在优化浸出条件下,锰的浸出率为96%,而铝和铁的浸出率分别为38.7%和7.12%,实现锰选择性高效溶出,锰和铝、铁等杂质的分离效果良好,为最终实现低品位锰矿中各种有价元素的清洁高效回收奠定了基础。

关键词:低品位锰矿;加压浸出;锰;铁;铝

中图分类号:TF533.2; TF803.21; R775.1 文献标志码:A

Technique of pressure leaching low grade manganese ore

XIE Hong-yan1, 2, WANG Ji-kun1, 3, LU Hui4, JI Xiao-cang5, YANG Shi-cheng5

(1. Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. College of Materials and Metallurgy, Guizhou University, Guiyang 550088, China;

3. Yunnan Metallurgy Group Parent Company, Kunming 650031, China;

4. Guiyang Aluminium and Magnesium Design Institute Co., Ltd., Guiyang 550081, China;

5. Yunnan Jianshui Manganese Mine Limited Liability Company, Jianshui 654302, China)

Abstract: The pressure leaching process of low grade manganese ore in a sulfuric acid medium was studied by orthogonal experiments and single-factor experiments. First, the better prescription of primary factors which affect the manganese leaching rate were determined through orthogonal experiments, namely initial acidity of 160 g/L, pyrite amount of 50 g, liquid-to-solid ratio of 5:1(5 mL/g), air pressure of 1MPa,leaching temperature of 180 ℃, leaching time of 80min. In order to analyze the leaching behavior of Mn, Fe and Al in the low grade manganese ore and realize highly effective separation of these three metallic elements, the technological parameters were adjusted refering to orthogonal experimental results. The effects of initial acidity, reaction temperature, pyrite amount, liquid-to-solid ratio, leaching time and leaching pressure on leaching rates of Mn, Fe and Al were examined through single-factor experiments. And the optimum leaching conditions were determined to be low grade manganese powdered ore of 100 g, initial acidity of 120 g/L, leaching temperature of 120 ℃, pyrite amount of 50 g, liquid-to-solid ratio of 5:1(5 mL/g), leaching time of 100 min, leaching pressure of 0.7 MPa, the agitation speed of 500 r/min. The experiments results indicate that this technology has good stability. Under the optimized leaching condition, the leaching rate of manganese is 96%, and the leaching rates of Al and Fe are 38.7% and 7.12%, respectively. The selectivity and highly effective dissolution of Mn are realized, the separation effect of Mn with impurities of Fe, Al, and so on, is good. These would lay a good foundation for realizing clean and highly effective recycling of each kind of valuable elements in the low grade manganese ore.

Key words: low grade manganese ore; pressure leaching; manganese; iron; aluminum

锰是一种重要的战略资源,中、高品位锰矿资源无法满足市场需要,从低品位锰矿中以较低成本浸出锰变得越来越重要[1]。当前,锰矿资源的贫乏正制约着我国锰系产品的生产和可持续发展。在我国一些锰系产品生产集中的地区,所使用碳酸锰矿的品位已经由含锰18%~20%降低到只有13%~15%。而另一方面,大量含锰20%~25%的软锰矿(主要成分为二氧化锰),却因为还原过程成本过高或污染环境严重等问题得不到利用。直接还原浸出工艺是低品位软锰矿加工利用的有效途径,目前使用的还原剂主要是硫化矿物和一些具有还原能力的无机物和有机物[2-3],但技术、成本和环境方面的原因限制了其大规模应用。因此,寻找一种廉价、高效、来源广泛的还原剂对低品位软锰矿的加工具有重要意义。湿法还原浸出锰矿包括以下方法:两矿一步法[4-7]、SO2直接浸出法[8]、连二硫酸钙法[9]、硫酸亚铁法[10-13]、金属铁直接浸出法[14]、闪锌矿(方铅矿)催化还原法[15-16]、农林副产物直接浸出法[17]、微生物浸出法[18-19]和两矿加浓硫酸熟化法[20]。另外,2000年, 等[21]报道在压力釜内FeS2-MnO2-O2-H2O体系下高温浸出锰的试验研究。近年来,各地都根据其资源条件开展了硫酸锰生产的各种工艺研究[22-25]与生产实践。生产硫酸锰的原料可采用碳酸锰矿[17, 26-27]、软锰矿[28-32]及富锰渣[33]和锰烟尘灰[34-35]等。

等[21]报道在压力釜内FeS2-MnO2-O2-H2O体系下高温浸出锰的试验研究。近年来,各地都根据其资源条件开展了硫酸锰生产的各种工艺研究[22-25]与生产实践。生产硫酸锰的原料可采用碳酸锰矿[17, 26-27]、软锰矿[28-32]及富锰渣[33]和锰烟尘灰[34-35]等。

在近50年内,加压湿法冶金及其过程化学发展迅速[36-37]。作为一种清洁高效、强化浸出的湿法冶金新工艺,加压浸出多应用于复杂难处理物料的处理。鉴于加压浸出的各种优越性,以及低品位锰矿的难处理性,本文作者研究加压浸出在低品位锰矿浸出中的应用。在较短的时间内,实现了锰选择性高效溶出,同时将铝、铁、钙、镁、硅等杂质固化入渣,锰和各种杂质的分离效果良好,为最终实现低品位锰矿中各种有价元素的清洁高效回收奠定了基础。

1 实验

1.1 原料

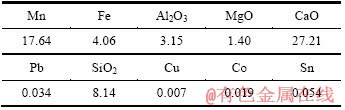

实验所用低品位锰矿和还原剂硫铁矿均来自云南建水地区,其化学成分见表1和2。从表1可看出,该低品位锰矿为高钙高硅矿,有价元素主要是锰、铁和铝。经化学物相分析可知,低品位锰矿中的锰主要以高价氧化锰形态存在(见表3)。由表3可以看出,低品位锰矿中锰的总含量达到16.08%(与表1中锰化学成分17.64%有偏差,可能是由于取样不均匀和分析误差共同影响),其中高价氧化锰矿含量最高,达到15.47%,占总含量的96.2%,是主要的存在形式;其次为碳酸锰,含量达到0.61%,占总含量的3.79%;最少的为硅酸锰,含量小于0.01%,占总含量的0.062%。

低品位锰矿的XRD分析结果见图1。由图1可知,低品位锰矿的主要成分为CaCO3、SiO2、Mn3O4、MnO1.88和Mn6Si4O10(OH)8。矿物中锰主要分布在高价氧化物Mn3O4和MnO1.88中,少部分以碳酸锰存在,只有极少部分赋存在Mn6Si4O10(OH)8中。钙主要以碳酸钙的形态存在,酸浸后大部分生成硫酸钙进入渣中。从试验结果来看,由于试验所得浸出液过滤效果良好,没有形成大量硅胶导致难过滤现象,因此推测原矿中的硅主要以石英形态存在,大部分SiO2不影响浸出过程和中和净化过程,少量与金属结合形成硅酸盐,在浸出过程中随锰浸出而进入溶液中,如果在浸出过程中能对含硅较高的矿石进行有效处理,对拓宽锰的冶金原料来源将有重要意义。

低品位氧化锰矿浸出实验所用浸出剂由硫酸(分析纯)配制,加压浸出过程中通入空气作为辅助氧化剂和催化剂。

表1 低品位锰矿的化学成分

Table 1 Chemical composition of low grade manganese ore (mass fraction, %)

表2 硫铁矿的化学成分

Table 2 Chemical composition of pyrite (mass fraction, %)

表3 低品位锰矿中锰的物相

Table 3 Phase analysis of manganese in low grade manganese ore

图1 低品位锰矿的XRD谱

Fig. 1 XRD pattern of low grade manganese ore

图2 低品位锰矿的SEM像

Fig. 2 SEM image of low grade manganese ore

图2所示为低品位锰矿的SEM像。从图2可以看出,低品位锰矿的颗粒粒径较小(由于已经用球磨机磨成粉状),形状不规则,粒度分布不均匀,直径在5~30 μm之间,部分粒径比较大的类球状颗粒是由许多小粒子团聚而成的,且大部分固体颗粒外表面粗糙,凸凹不平,呈现不平整的表观形貌。

1.2 实验设备

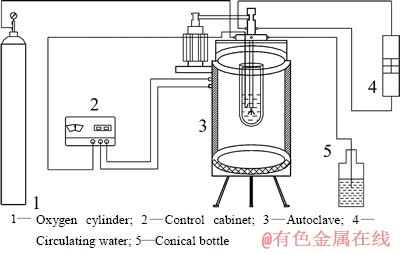

实验装置示意图如图3所示。

图3 实验装置示意图

Fig. 3 Schematic diagram of experimental apparatus

1.3 实验方法

低品位锰矿浸出实验在2.0 L磁力搅拌衬钛高压釜中完成。首先将还原剂硫铁矿和低品位锰矿按一定配比混合,再将浸出剂与混合物料按一定液固比加入钛胆中。然后放入加压釜中加盖密封,开启搅拌,开始升温,使釜内温度达到预定值,适当开启高压釜排空阀,排掉釜内部分气体,使釜内压力维持实验所需值。开始保温并计时,浸出过程中保持搅拌转速和压力恒定。浸出结束后通水冷却,待釜内温度降到90 ℃后打开排空阀,排出釜内气体,待表压归零,启釜后将矿浆取出过滤,分别将浸出液和浸出渣送样分析。

2 结果及讨论

2.1 正交实验结果

由于本试验属于液、固、气三相反应,因此,可以认定浸出温度、初始硫酸浓度、硫铁矿量、液固比、空气分压和浸出时间是本试验的主要影响因素。为优化加压浸出低品位锰矿工艺,选取浸出温度、初始硫酸浓度、硫铁矿量、液固比、空气分压和浸出时间6个因素,各取5个水平,设计六因素五水平正交实验,确定较佳加压浸出低品位锰矿工艺。正交实验设计和结果见表4和5。

表4 正交实验因素和水平

Table 4 Factors and levels of orthogonal experiments

表5 正交实验结果

Table 5 Results of orthogonal experiments

如表5所示,浸出时间的极差值(RF)最大,其次是液固比(RC)、始酸浓度(RA)、硫铁矿量(RB)、温度(RE) 和压力(RD),即RF>RC>RA>RB>RE>RD,说明了影响锰浸出率的因素的主次关系,浸出时间对锰的浸出效果的影响是显著的,压力对锰的浸出率的影响强度最小。通过正交实验可以得出,加压浸出低品位锰矿工艺中主要因素的较佳组合为A4B3C3D4E5F3,即始酸浓度160 g/L、硫铁矿量50 g、液固比5:1、压力1 MPa、温度180 ℃和时间80 min。参考上述正交实验结果,在单因素条件实验中可以适当地调整参数,相应地降低初始酸浓度、浸出温度和反应压力,尽量降低能耗,并能达到良好的锰的浸出效果。

2.2 单因素实验结果

低品位锰矿物相分析显示锰元素主要存在于高价氧化锰中,在浸出过程中有效实现锰与铁、铝等杂质元素的分离是关键。为分析低品位锰矿中锰、铁及铝的浸出行为,实现这3种金属元素的高效分离,得到最优浸出工艺条件,进行了单因素实验研究,详细考察了液固比、始酸浓度、硫铁矿量、温度、压力和浸出时间对锰、铁及铝浸出率的影响。

2.2.1 初始硫酸浓度的影响

试验条件如下:固定低品位锰矿粉100 g,浸出温度130 ℃,液固比5 mL/g,硫铁矿量50 g,空气压力0.8 MPa,浸出时间120 min,搅拌转速500 r/min。考察初始硫酸浓度对锰、铁、铝浸出率的影响,结果见图4。溶液酸度是重要的影响因素(高价氧化锰以MnO2为例):

当pH<2时,反应如下[15]:

FeS2+MnO2+2H2SO4=MnSO4+FeSO4+2H2O+2S0 (1)

2FeS2+9MnO2+10H2SO4=9MnSO4+Fe2(SO4)3+10H2O+2S0 (2)

2FeS2+3MnO2+6H2SO4=3MnSO4+Fe2(SO4)3+6H2O+4S0 (3)

而当pH>2时,容易生成HSO4-或SO42-,反应如下:

FeS2+7MnO2+7H2SO4=Fe(HSO4)2+7MnSO4+6H2O (4)

2FeS2+15MnO2+14H2SO4=15MnSO4+Fe2(SO4)3+14H2O (5)

同时,料液中生成的硫也可能与MnO2发生氧化还原反应:

3MnO2+2H2SO4+S=3MnSO4+2H2O (6)

在有高价氧化锰存在的情况下,S0和HSO3-或SO32-会迅速被氧化为SO42-,中间产物HSO3-和SO32-难以积累到较大的浓度,也就是说不会生成SO2。而且随着浸出反应的进行,溶液的pH逐步升高,也有利于反应向生成SO42-的方向发展。高价氧化锰不仅可以使硫从-1价氧化成单质硫,而且可以进一步将单质硫氧化为+2价、+4价和+6价,至于反应产物究竟是什么,则和反应温度、硫酸浓度、硫铁矿量等因素有关。

当浸出体系酸度降低时,浸出液中的Fe3+将水解生成赤铁矿重新进入渣相,同时产生酸供其他组分继续浸出[38]。由于这一反应属于吸热反应,在160℃以上的高温条件下尤为明显,相关方程式[39]如下:

2Fe3++3H2O→Fe2O3↓+6H+ (7)

从图4可以看出,当初始硫酸浓度低于120 g/L时,锰的浸出率随初始酸度升高而增大;当初始酸度高于120g/L时,锰浸出率基本不受其影响。这主要是因为与锰相比,矿中钙、镁等元素更易被浸出,当初始酸度较低时,这些元素浸出消耗了大部分酸,剩余酸量不能满足锰的大量浸出,从而锰浸出率较低;当酸度升高时,用于锰浸出的酸量增加,因此,进入液相的锰也逐渐增多,浸出率上升;当酸度升高到一定值后,锰浸出所需的酸量接近临界值,锰浸出率则基本不受酸度的影响。铝的浸出率随着初始硫酸浓度的增加而不断增大。铁的浸出率同样随初始酸度的升高而增大,尤其在初始酸度达100 g/L后,铁浸出率随酸度升高迅速上升。这主要是因为初始酸度升高使浸出后期溶液中H+浓度升高,由Fe3+水解方程式(7)可知,H+的增加将不利于Fe3+水解反应,从而使液相中Fe3+含量增加,铁浸出率升高。综上所述,为使锰、铁、铝高效选择性分离,选择120 g/L为较优初始硫酸浓度。

图4 初始硫酸浓度对金属浸出率的影响

Fig. 4 Effect of initial sulfuric acid concentration on leaching rate of metals

2.2.2 浸出温度的影响

试验条件如下:固定低品位锰矿粉100 g,初始硫酸浓度120 g/L,液固比5 mL/g,硫铁矿量50 g,空气压力0.8 MPa,浸出时间120 min,搅拌转速500 r/min。考察浸出温度对锰、铁及铝浸出率的影响,结果见图5。从图5可看出,当反应温度低于120 ℃时,锰的浸出率随反应温度升高而增大。这主要是因为负载锰的低品位锰矿物在较高温度下的硫酸介质中具有更高的反应活性,更易浸出,因此有更多的锰被浸出而进入液相。反应温度高于120 ℃后继续升高温度,锰浸出率变化不大,反而稍有降低。原因可能是浸出反应过程中,高价锰对硫铁矿的氧化作用形成氧化产物硫,当温度高于119 ℃时,未反应完全的锰矿粉将会被硫膜包裹,由于S0的强疏水性和非导电性,从而阻止了锰矿粉和反应介质的接触,阻碍了浸出反应进一步进行。克服这一问题有效的办法就是破坏硫膜,即选择一种有效的添加剂(如木质素磺酸钠、褐煤等)以改变锰矿粉的表面性质,阻止硫膜形成。铁浸出率则随反应温度升高而减小,当温度从100 ℃升到180 ℃,铁浸出率从15.6%降为5.93%,这主要是因为矿粉中的铁化合物在浸出反应初期与酸反应生成Fe3+,随浸出后期体系酸度降低,Fe3+又逐步水解生成赤铁矿而进入渣相,并且随着浸出反应温度的升高,Fe3+水解反应速度逐步加快。由图5还看出,随着浸出反应温度的升高,Al的浸出率稍有降低,但变化不大。综上所述,选择120 ℃为较优浸出反应温度。

图5 浸出温度对金属浸出率的影响

Fig. 5 Effect of leaching temperature on leaching rate of metals

2.2.3 硫铁矿量的影响

试验条件如下:固定低品位锰矿粉100 g,初始硫酸浓度120 g/L,液固比5 mL/g,浸出温度120 ℃,空气压力0.8 MPa,浸出时间120 min,搅拌转速500 r/min。考察硫铁矿量对锰、铁、铝浸出率的影响,结果见图6。以硫铁矿作为还原剂,空气作为辅助氧化剂和催化剂,使低品位锰矿中高价氧化锰转化为MnO,再MnO与硫酸反应生成硫酸锰溶液。在一定的温度、压力和合适的还原气氛下,锰氧化物的还原过程是从高价氧化物到低价氧化物依次进行[40]:

MnO2→Mn2O3→Mn3O4→MnO→Mn

从图6可以看出,随还原剂硫铁矿量增加,Mn浸出率呈上升趋势。硫铁矿量由20g增加至50g,Mn浸出率呈明显的增加趋势,说明还原剂增加对整个反应过程有促进作用;继续增加硫铁矿量,锰浸出率基本处于稳定状态。由图6还可看出,随硫铁矿量增加,铁浸出率也逐渐增加,对铝浸出率几乎没有影响。

另外,若加入硫铁矿量过多,将带入过多的杂质元素,给后续除杂工序带来困难,并造成浪费,增加成本;加入量过少,则不利于氧化还原反应的充分进行,达不到预期的反应效果。综上所述,硫铁矿加入量选择50g为宜。

图6 硫铁矿用量对金属浸出率的影响

Fig. 6 Effect of pyrite mass on leaching rate of metals

2.2.4 液固比的影响

试验条件如下:固定低品位锰矿粉100 g,初始硫酸浓度120 g/L,硫铁矿量50 g,浸出温度120 ℃,空气压力0.8 MPa,浸出时间120 min,搅拌转速500 r/min。考察液固比对锰、铁及铝浸出率的影响,其结果见图7。从图7可看出,随着液固比由2 mL/g提高至5 mL/g,锰浸出率急剧上升;当液固比继续增加至7 mL/g时,锰浸出率基本不变。铁和铝的浸出率随着液固比的增加不断增大。这是因为当固定始酸浓度时,改变液固比会使浸出料液的酸量发生改变,液固比较低时虽然初始酸度相同,但此时矿浆太粘稠,在一定搅拌强度下很难混合均匀,不利于传质、传热及反应进行,故锰、铁及铝浸出率均较低;随着液固比的增大,由于初始酸度相同,酸量也相应的增多,矿浆逐渐变稀,流动性变好,混合逐渐充分,传质、传热性能得到改善,锰、铁及铝浸出率得到提高;当液固比增大到一定值后,一定搅拌强度可保证矿浆充分混合,传质、传热不再受阻,酸量充足,若再增加液固比,过量的酸将使铁、铝等杂质元素的浸出率继续增大,而锰浸出所需的酸量已接近临界值,因此,锰的浸出率基本不变。同时,终酸残余量也随液固比的增大而增加,从而给后续的净化除杂增加负担,能耗大、成本高。综上所述,选择5 mL/g为较优液固比。

图7 液固比对金属浸出率的影响

Fig. 7 Effect of liquid-to-solid ratio on leaching rate of metals

2.2.5 浸出时间的影响

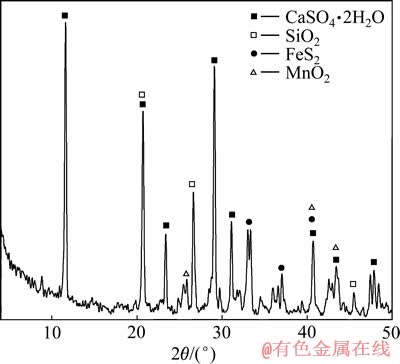

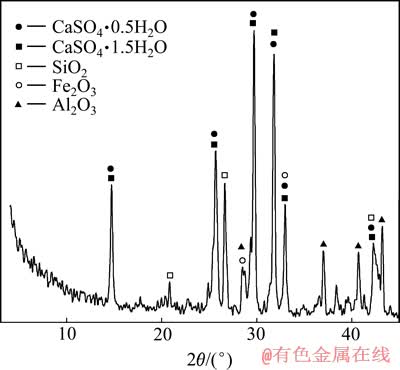

试验条件如下:固定低品位锰矿粉100 g,初始硫酸浓度120 g/L,硫铁矿量50 g,浸出温度120 ℃,空气压力0.8 MPa,液固比5 mL/g,搅拌转速500 r/min。考察浸出时间对锰、铁及铝浸出率的影响,结果见图8。从图8可看出,锰的浸出率随浸出时间延长而增大,80 min后,再延长时间对锰的浸出率影响不大,这是因为负载锰的低品位锰矿物在一定的反应条件下浸出需要足够长的时间。在本实验条件下浸出时间80 min能保证可浸出的含锰矿物基本浸出完全,继续延长时间,锰的浸出率变化不大。铁的浸出率先随浸出时间的延长而缓慢升高,当时间在80 min以上时,铁的浸出率又逐渐下降。这是因为在浸出反应初期,铁的浸出率随时间的延长而增大,当浸出时间80 min以后,锰基本浸出完全,浸出终酸14.64 g/L,因此,随时间的延长,铁又逐渐水解进入渣相,浸出率逐渐降低,且随时间的继续延长变化不大。铝的浸出率随浸出时间的延长而减小,这是因为随时间延长逐渐水解进入渣相,浸出100 min以后,铝的浸出率随时间延长变化不大。当浸出时间为20 min和90 min时浸出渣的XRD分析结果见图9和10。由图9可以看出,浸出时间为20 min时,部分锰矿和硫铁矿还未反应完全。从图10可知,浸出时间90 min时,锰矿和硫铁矿已基本反应完全,且铁和铝大部分水解入渣。综上所述,选择100 min为较优浸出时间。

图8 浸出时间对金属浸出率的影响

Fig. 8 Effect of leaching time on leaching rate of metals

图9 浸出时间为20min时浸出渣的XRD谱

Fig. 9 XRD pattern of leaching residue at leaching time of 20 min

图10 浸出时间为90min时浸出渣的XRD谱

Fig. 10 XRD pattern of leaching residue at leaching time of 90 min

图11 压力对金属浸出率的影响

Fig. 11 Effect of pressure on leaching rate of metals

2.2.6 空气压力的影响

试验条件如下:固定低品位锰矿粉100 g,初始硫酸浓度120 g/L,硫铁矿量50 g,浸出温度120 ℃,浸出时间100 min,液固比5 mL/g,搅拌转速500 r/min。考察空气压力对锰、铁及铝浸出率的影响,结果见图11。浸出过程中,溶解的氧分子只有在裂解为活性氧原子后才能与硫化矿进行反应,因此,氧化动力学方程可表示为V=KpO21/2,其中,V为氧化反应速度,K为速率常数,pO2为氧分压。随氧分压增大,反应速度加快。扩散速度也随氧分压增大而加快[41]。在加压浸出过程中可能发生的化学反应如下:

2H2SO4+2FeS2+O2=2FeSO4+2H2O+2S0 (8)

MnO2+2FeSO4+2H2SO4=MnSO4+Fe2(SO4)3+2H2O (9)

Mn3O4+2FeS2+O2+6H2SO4=3MnSO4+Fe2(SO4)3+6H2O+4S0 (10)

Mn6Si4O10(OH)8+6H2SO4=6MnSO4+4H2SiO3+6H2O (11)

反应(8)是吸热反应,升高温度对生成FeSO4有利。在酸性条件下,Fe3+能加快反应速率,起到催化剂作用[42]:

Fe2(SO4)3+FeS2=3FeSO4+2S0 (12)

Fe2(SO4)3+H2S=2FeSO4+H2SO4+S0 (13)

由图11可知,随压力增大,锰浸出率呈上升趋势。当压力高于0.5 MPa后,锰浸出率变化不明显。由图11可知,当压力由0.3 MPa增至0.7 MPa时,铁的浸出率缓慢增加,压力高于0.7 MPa时,Fe浸出率变化不大。还可看出,当压力由0.3 MPa增大至0.6 MPa时,铝浸出率随空气压力的增加而增大,压力高于0.6 MPa后,铝浸出率下降,继续增加压力,铝浸出率基本不变。这是由于随着空气压力的不断增加,反应速率和扩散速率都加快,锰和铝的浸出率都增大,当压力增大到一定值时,锰和铝都达到了较高的浸出率,继续增大空气压力时,由于低品位锰矿和硫铁矿的反应速度加快,使得锰很快就基本浸出完全,而余酸量减少使得铝的浸出率降低。而继续增大压力,锰、铁及铝的浸出率都基本不变。这就体现了加压浸出过程的强选择性浸出的优势。

但压力过高会对高压釜材料性能要求提高,并增加制造成本,故在兼顾锰浸出率的前提下,宜选择较低的空气压力,选择0.7 MPa为较优浸出压力。

2.3 优化浸出工艺稳定性研究

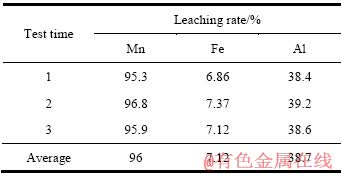

通过上述正交实验和单因素实验结果可知,在硫酸介质中加压还原浸出低品位锰矿的优化浸出工艺条件如下:低品位锰矿粉100 g,初始硫酸浓度120 g/L,浸出反应温度120 ℃,硫铁矿量50 g,液固比5 mL/g,浸出时间100 min,浸出压力0.7 MPa,搅拌转速500 r/min。为了验证优化浸出条件下的工艺稳定性,特进行了重复实验,具体结果见表6。从表6可看出,本工艺在优化浸出条件下重复性很好,工艺稳定。从实验结果可知,锰的浸出率为96%,而铝和铁的浸出率分别为38.7%和7.12%,实现了锰与铝和铁的高效分离。

表6 优化浸出条件下重复实验结果

Table 6 Repeated experiments results under optimum leaching conditions

3 结论

1) 由低品位锰矿硫酸加压浸出工艺的正交实验和单因素实验的试验研究得到优化浸出工艺条件为:低品位氧化锰矿粉100 g,初始硫酸浓度120 g/L,浸出反应温度120 ℃,硫铁矿量50 g,液固比5 mL/g,浸出时间100 min,浸出压力0.7 MPa,搅拌转速500 r/min。本工艺具有良好的稳定性,在优化浸出条件下,锰的浸出率为96%,而铝和铁的浸出率分别为38.7%和7.12%,实现了Mn选择性高效溶出,Mn和Al、Fe等杂质的分离效果良好。

2) 本工艺方法以低品位锰矿和硫铁矿作为原料,原料来源广,价格低廉,生产成本低,操作过程简单易行。本方法既能提高锰的浸出率,又能够缩短浸出时间,同时为后续净化除杂降低了难度,为相应工艺工业化推广奠定了基础。

REFERENCES

[1] 粟海锋, 崔勍焱, 文衍宣, 童张法. 低品位软锰矿降解糖蜜酒精废液中焦糖色素的脱色动力学[J]. 过程工程学报, 2009, 9(3): 480-485.

SU Hai-feng, CUI Qing-yan, WEN Yan-xuan, TONG Zhang-fa. Decolorizing kinetics of caramel in molasses alcohol wastewater degraded by low-grade pyrolusite[J]. The Chinese Journal of Process Engineering, 2009, 9(3): 480-485.

[2] CHENG C Y, ZHANG W. Manganese metallurgy review: Part I. Leaching of ores/secondary materials and recovery of electrolytic/chemical manganese dioxide[J]. Hydrometallurgy, 2007, 89(3/4): 137-159.

[3] 粟海锋, 孙英云, 文衍宣, 董张法, 裴锐南, 薛敏华. 废糖蜜还原浸出低品位软锰矿[J]. 过程工程学报, 2007, 7(6): 1089-1093.

SU Hai-feng, SUN Ying-yun, WEN Yan-xuan, TONG Zhang-fa, PEI Rui-nan, XUE Min-hua. Reductive leaching of manganese from low-grade pyrolusite using cane molasses[J]. The Chinese Journal of Process Engineering, 2007, 7(6): 1089-1093.

[4] 袁明亮, 梅贤功, 陈 荩, 邱冠周. 两矿法浸出软锰矿的工艺与理论[J]. 中南工业大学学报: 自然科学版, 1997, 28(4): 329-332.

YUAN Ming-liang, MEI Xian-gong, CHEN Jin, QIU Guan-zhou. Technique and theory of two ore method to leach manganese dioxide ore[J]. Journal of Central South University of Technology: Natural Science, 1997, 28(4): 329-332.

[5] 卢宗柳, 都安治. 两矿法浸出氧化锰矿的几个工艺问题[J]. 中国锰业, 2006, 24(1): 39-42.

LU Zong-liu, DU An-zhi. Some technical problems on soaking methods of MnO ore[J]. China Manganese Industry, 2006, 24(1): 39-42.

[6] 华毅超, 陈国松, 张红漫, 张之翼, 蒋皎梅, 吴小伟, 洪 颖, 卢 伟. 工业硫酸锰湿法还原生产工艺[J]. 南京工业大学学报, 2004, 26(5): 50-53.

HUA Yi-chao, CHEN Guo-song, ZHANG Hong-man, ZHANG Zhi-yi, JIANG Jiao-mei, WU Xiao-wei, HONG Ying, LU Wei. Laboratory procedure and pilot-plant scale production of industrial manganese sulfate by wet-method reducing technique[J]. Journal of Nanjing University of Technology, 2004, 26(5): 50-53.

[7] 陈 蓉, 陈启明, 陈金芳, 李飞阔. 低品位锰矿制备硫酸锰的研究[J]. 武汉工程大学学报, 2008, 30(1): 20-22.

CHEN Rong, CHEN Qi-ming, CHEN Jin-fang, LI Fei-kuo. A study on preparation of manganese sulfate with low grade manganese ore[J]. Journal of Wuhan Institute of Chemical Technology, 2008, 30(1): 20-22.

[8] 张 昭, 刘立泉, 彭少方. 二氧化硫浸出软锰矿[J]. 化工冶金, 2000, 21(1): 103-107.

ZHANG Zhao, LIU Li-quan, PENG Shao-fang. Sulfur dioxide leaching of pyrolusite[J]. Chemical Engineering and Metallurgy, 2000, 21(1): 103-107.

[9] 余逊贤. 锰[R]. 长沙: 冶金工业部长沙黑色冶金矿山设计研究院, 1980: 105-150.

YU Xun-xian. Manganese[R]. Changsha: Ministry of Metallurgical Industry Changsha Black Metallurgical and Mining Design Institute, 1980: 105-150.

[10] 朱道荣. 软锰矿-硫酸亚铁的酸性浸出[J]. 中国锰业, 1992, 10(1): 30-31.

ZHU Dao-rong. Acid leaching of pyrolusite-ferrous sulfate[J]. China Manganese Industry, 1992, 10(1): 30-31.

[11] 袁明亮, 庄剑鸣, 陈 荩. 用硫酸亚铁渣直接浸出低品位软锰矿[J]. 矿产综合利用, 1994(6): 6-9.

YUAN Ming-liang, ZHUANG Jian-ming, CHEN Jin. Directly leaching of low grade pyrolusite with ferrous sulfate residue[J]. Multipurpose Utilization of Mineral Resources, 1994(6): 6-9.

[12] 王德全, 宋庆双. 用硫酸亚铁浸出低品位锰矿[J]. 东北大学学报: 自然科学版, 1996, 17(6): 606-609.

WANG De-quan, SONG Qing-shuang. Leaching of low-grade manganese ores with FeSO4[J]. Journal of Northeastern University: Natural Science, 1996, 17(6): 606-609.

[13] 彭荣华, 李晓湘. 用钛白副产的硫酸亚铁浸锰制备高纯二氧化锰[J]. 无机盐工业, 2006, 38(12): 48-50.

PENG Rong-hua, LI Xiao-xiang. Preparation of high-purity manganese dioxide by leaching manganese ore with ferrous sulfate from by-product of titanium white[J]. Inorganic Chemicals Industry, 2006, 38(12): 48-50.

[14] 张东方, 田学达, 欧阳国强, 张 熠. 银锰矿中锰矿物的铁屑还原浸出工艺研究[J]. 中国锰业, 2007, 25(1): 24-26.

ZHANG Dong-fang, TIAN Xue-da, OU YANG Guo-qiang, LI Yi. Reducing leaching of manganese mineral in silver- manganese ore with scrap iron as reductant[J]. China Manganese Industry, 2007, 25(1): 24-26.

[15] 唐尚文. 用闪锌矿(方铅矿)精矿催化还原软锰矿(大洋锰结核矿)制取硫酸锰[J]. 无机盐工业, 2005, 37(6): 46-49.

TANG Shang-wen. The preparation of manganese sulfate from manganese dioxide/oceanic manganese nodule ore by catalytic reduction with refined zinc blende/plumbag ore[J]. Inorganic Chemicals Industry, 2005, 37(6): 46-49.

[16] 唐尚文. 氧化锰矿和硫化锌(或硫化铅)精矿在稀酸中直接、同时浸出的方法. 中国: CN1465723A[P]. 2004-01-07.

TANG Shang-wen. The method of direct, simultaneous acid leaching manganese oxide ore and ZnS (or PbS) concentrate. China: CN1465723A[P]. 2004-01-07.

[17] 衷水平, 梁 杰, 朱茂兰. 碳酸锰矿浸出工艺条件的研究[J]. 贵州工业大学学报, 2005, 34(5): 14-17.

ZHONG Shui-ping, LIANG Jie, ZHU Mao-lan. Study on the leaching process of manganese from rhodochrosite[J]. Journal of Guizhou University of Technology, 2005, 34(5): 14-17.

[18] 李浩然, 冯雅丽. 微生物催化还原浸出氧化锰矿中锰的研究[J]. 有色金属, 2001, 53(3): 5-8.

LI Hao-ran, FENG Ya-li. Microbe catalyses oxidation-reduction reaction to leach Mn from black manganese mineral[J]. Nonferrous Metals, 2001, 53(3): 5-8.

[19] 杜竹玮, 李浩然. 微生物还原浸出法回收废旧电池粉末中的金属锰[J]. 环境污染治理技术与设备, 2005(9): 62-64.

DU Zhu-wei, LI Hao-ran. Recovery of manganese from waste batteries using microbe and organic waste through bioreduction process[J]. Techniques and Equipment for Environmental Pollution Control, 2005(9): 62-64.

[20] 滕英才, 马集成. 两矿加浓硫酸熟化法生产硫酸锰[J]. 化工技术与开发, 2006, 35(2): 1-2.

TEN Ying-cai, MA ji-cheng. Production of manganous sulfate by curing process with pyrite, pyrolusite and concentrated sulfuric acid[J]. Technology and Development of Chemical Industry, 2006, 35(2): 1-2.

[21]  K P. Manganese leaching in the FeS2-MnO2-O2-H2O system at high temperature in an autoclave[J]. Hydrometallurgy, 2000, 55: 79-92.

K P. Manganese leaching in the FeS2-MnO2-O2-H2O system at high temperature in an autoclave[J]. Hydrometallurgy, 2000, 55: 79-92.

[22] 谭立群. 硫酸锰厂新工艺的设计[J]. 中国锰业, 2000, 18(4): 33-35.

TAN Li-qun. New design of Mn sulphate plant national Mn technology committee[J]. China Manganese Industry, 2000, 18(4): 33-35.

[23] 杨新科. 制备硫酸锰最佳工艺条件的研究[J]. 中国锰业, 2001, 19(3): 15-16.

YANG Xin-ke. The optimum technology of preparing manganese sulfate[J]. China Manganese Industry, 2001, 19(3): 15-16.

[24] 周凌风. 冷法浸出硫酸锰溶液[J]. 中国锰业, 2002, 20(4): 20-22.

ZHOU Ling-feng. Leaching of manganese sulfate solution in normal temperature[J]. China Manganese Industry, 2002, 20(4): 20-22.

[25] 谢红艳, 王吉坤, 杨世诚, 马 进, 李天杰, 纳吉信, 彭 东. 从软锰矿中湿法浸出锰的研究进展[J]. 中国锰业, 2011, 29(1): 5-12.

XIE Hong-yan, WANG Ji-kun, YANG Shi-cheng, MA Jin, LI Tian-jie, NA Ji-xin, PENG Dong. Review on research of wet way leaching of manganese from pyrolusite[J]. China Manganese Industry, 2011, 29(1): 5-12.

[26] 朱茂兰, 衷水平, 梁 杰. 菱锰矿浸出工艺研究[J]. 有色金属: 冶炼部分, 2006(5): 13-14.

ZHU Mao-lan, ZHONG Shui-ping, LIANG Jie. Study on the leaching of rhodochrosite[J]. Nonferrous Metals: Extractive Metallurgy, 2006(5): 13-14.

[27] DWIVEDY K K, MATHUR A K. 硫酸浸出加纳恩苏塔碳酸锰矿[J]. 杨 红,译. 中国锰业, 1996, 14(3): 54-57.

DWIVEDY K K, MATHUR A K. Sulfuric acid leaching of manganese carbonate in Ghana Nsuta[J]. YANG Hong, transl. China Manganese Industry, 1996, 14(3): 54-57.

[28] 陈孟平. MnO2矿直接浸取生产EMD用硫酸锰液的工艺实践[J]. 无机盐工业, 1995(3): 28-31.

CHEN Meng-ping. The craft practice of leaching manganese sulfate by MnO2 ore used for producing EMD[J]. Inorganic Chemicals Industry, 1995(3): 28-31.

[29] 李同庆. 低品位软锰矿还原工艺技术与研究进展[J]. 中国锰业, 2008, 26(2): 4-14.

LI Tong-qing. Technology of low grade pyrolusite ore reduction process and recent advances[J]. China Manganese Industry, 2008, 26(2): 4-14.

[30] 黄自力, 李 密, 胡 华, 蒋天明. 低品位软锰矿制备硫酸锰的工业实验研究[J]. 矿产保护与利用, 2008(3): 36-38.

HUANG Zi-li, LI Mi, HU Hua, JIANG Tian-ming. Industrial experiment study on production of manganese sulfate from low-grade pyrolusite ore[J]. Conservation and Utilization of Mineral Resources, 2008(3): 36-38.

[31] 贺周初, 彭爱国, 郑贤福, 余长艳, 刘昱霖. 两矿法浸出低品位软锰矿的工艺研究[J]. 中国锰业, 2004, 22(2): 35-37.

HE Zhou-chu, PENG Ai-guo, ZHENG Xian-fu, YU Chang-yan, LIU Yu-lin. A study on the two-ores method of leaching low grade pyrolusite[J]. China Manganese Industry, 2004, 22(2): 35-37.

[32] 田宗平, 朱介忠, 王雄英, 李 力. 两矿加酸法生产硫酸锰的工艺研究与应用[J]. 中国锰业, 2005, 23(4): 37-39.

TIAN Zong-ping, ZHU Jie-zhong, WANG Xiong-ying, LI Li. Technology research and application of the production of Mn-sulphate of adding acid[J]. China Manganese Industry, 2005, 23(4): 37-39.

[33] 汪锦瑞, 方 刚, 杨浙云. 富锰渣制备工业硫酸锰的工艺研究[J]. 中国锰业, 2008, 26(4): 24-26.

WANG Jin-rui, FANG Gang, YANG Zhe-yun. A technical research of Mn sulphuric acid to produce with rich Mn dregs[J]. China Manganese Industry, 2008, 26(4): 24-26.

[34] 唐华应, 杨君臣, 郑华峰. 从锰除尘灰中湿法回收锰[J]. 湿法冶金, 2003(1): 39-40.

TANG Hua-ying, YANG Jun-chen, ZHENG Hua-feng. Extraction of manganese from electric furnace dust by wet method[J]. Hydrometallurgy of China, 2003(1): 39-40.

[35] 谢红艳, 王吉坤, 李天杰, 马 进, 杨世诚, 纳吉信, 张学文. 含锰冶炼粉尘的加压硫酸浸出[J]. 过程工程学报, 2011, 11(4): 86-91.

XIE Hong-yan, WANG Ji-kun, LI Tian-jie, MA Jin, YANG Shi-cheng, NA Ji-xin, ZHANG Xue-wen. Pressure leaching of manganese-containing dust from smelting with sulfuric acid[J]. The Chinese Journal of Process Engineering, 2011, 11(4): 86-91.

[36] DERRY R. Pressure hydrometallurgy: A review[J]. Minerals Sci Eng, 1972(1): 3-24.

[37] 邱定蕃. 加压湿法冶金过程化学与工业实践[J]. 矿冶, 1994, 3(4): 55-67.

QIU Ding-fan. Process chemistry and industrial practice of pressure hydrometallurgy[J]. Mining and Metallurgy, 1994, 3(4): 55-67.

[38] 马保中, 王成彦, 杨 卜, 尹 飞, 张永禄. 硝酸加压浸出红土镍矿的中试研究[J]. 过程工程学报, 2011, 11(4): 561-566.

MA Bao-zhong, WANG cheng-yan, YANG Bo, YIN Fei, ZHANG Yong-lu. Pilot plant study on pressure leaching of nickel laterite in nitric acid medium[J]. The Chinese Journal of Process Engineering, 2011, 11(4): 561-566.

[39] 张永禄, 王成彦, 徐志峰. 低品位碱预处理红土镍矿加压浸出过程[J]. 过程工程学报, 2010, 10(2): 263-269.

ZHANG Yong-1u, WANG Cheng-yan, XU Zhi-Feng. Pressure leaching of alkali-pretreated limonitic laterite ore[J]. The Chinese Journal of Process Engineering, 2010, 10(2): 263-269.

[40] 任世觉. 工业矿产资源开发利用手册[M]. 武汉: 武汉工业大学出版社, 1993: 18-37.

REN Shi-jue. Industrial minerals resource exploitation and processing handbook[M]. Wuhan: Wuhan Industry University Press, 1993: 18-37.

[41] 李小康, 许秀莲. 低品位铜锌混合矿加压浸出研究[J]. 南方冶金学院学报, 2004, 25(4): 5-9.

LI Xiao-kang, XU Xiu-lian. Study on pressure leaching of low-grade copper-zinc bulk concentrate[J]. Journal of Southern Institute of Metallurgy, 2004, 25(4): 5-9.

[42] 吴晓春. 用软锰矿制取硫酸锰实验[J]. 中国锰业, 2005, 23(2): 32-35.

WU Xiao-chun. The experiment of producing manganese sulfate with pyrolusite[J]. China Manganese Industry, 2005, 23(2): 32-35.

(编辑 李艳红)

收稿日期:2011-12-09;修订日期:2013-04-20

通信作者:王吉坤,教授级高工;电话:13708867007;E-mail: wjk@cymco.cn