Effect of TiB2 addition on microstructure of

spray-formed Si-30Al composite

GAN Gui-sheng1, 2, ZHANG Lei1, BEI Shu-yu1, LU Yi1, YANG Bin1

1. State Key Laboratory for Advanced Metals and Materials,

University of Science and Technology Beijing, Beijing 100083, China;

2. School of Materials Science and Engineering,

Chongqing University of Technology, Chongqing 400050, China

Received 4 November 2010; accepted 19 April 2011

Abstract: An in situ reaction and spray forming technique were employed in the synthesis of 2% TiB2/ Si-30Al composite. The formation mechanism of TiB2 particulates was explained based on thermodynamic theory. The modification of the primary Si in the Si-30Al alloy was interpreted in the light of the knowledge of atomic diffusion. The experimental results show that adding 2% TiB2 to the Si-30Al alloy can effectively refine the primary Si. Moreover, the coarsening and growth of primary Si phase in its semi-solid state was retarded effectively due to the existence of the TiB2 particulates.

Key words: spray forming; TiB2 particulate; coarsening; semi-solid state

1 Introduction

Si-Al alloys with high Si content are attractive candidate materials for electronic packaging applications due to their excellent physical and mechanical properties, such as relatively high thermal conductivity, low density and thermal expansion coefficient [1-4]. However, early pioneering studies on the spray-formed Si-Al alloys with high Si content showed that there were still some problems encountered in the production of the alloys [5]. For example, the size of primary Si is not uniform and it will be increased when the alloys are reheated to the semi-solid state [6-7]. Recently, a novel technique to generate in situ particulate-reinforced metal matrix composites was developed (MMCs) [8-9]. In this technique, the matrix alloy was first melted, and then the reinforcements were in situ formed in the molten alloy by chemical reactions between elements or between the elements and the ceramic compounds. Among the reinforcement particulates, TiB2 is particularly attractive because of its high melting point, hardness, electrical conductivity and thermal conductivity. In fact, TiB2 particulates were widely used in Al matrix composites as reinforcement and grain refiner [10-13]. However, there is very little information available on how to modify the primary Si in Al-Si alloys, especially in Si-Al alloys with high Si content [6-7]. The aim of this work is to elucidate the effect of TiB2 additions on the microstructure of spray-formed Si-30Al composite.

2 Experimental

The mixture of K2TiF6 and KBF4 was put into the molten pure aluminum (99.85%) at 850 °C. After stirring at 850 °C for about 30 min and degassing by C2Cl6, the molten composite was cast into a metal mold to get a TiB2/Al master alloy. Then the master alloy was remelted at 1 420 °C, and commercial pure Si was put into it to get 2%TiB2/Si-30Al materials according to Si-Al mass ratio of 7:3. Finally, the master alloy was spray-formed in order to get a 2%TiB2/Si-30Al billet. The melt was atomized using argon gas at 0.6 MPa. An atomizer-substrate distance of 600 mm, and a delivery tube (Al2O3) with a diameter of 4 mm were used.

The phase identification of the samples was performed by X-ray diffraction (XRD) using Cu Kα radiation. After sanding and polishing, the specimens were etched in a solution of mixed acids (1 mL HF+ 1.5 mL HCl+2.5 mL HNO3+95 mL H2O). The microstructures of the alloy and composite were examined using ZEISS SUPRA55 scanning electron microscope (SEM) and electron probe micro-analyzer (EPMA).

3 Results and discussion

3.1 Formation of in situ TiB2 in molten Si-30Al alloy

The possible reaction to form TiB2 in the molten Si-30Al alloy fabricated by this technique can be expressed as [14]:

(1)

(1)

In addition to the expected TiB2, it is found that TiAl3, AlB2, KF, AlF3 and F2 are also present in the reactants. F2 can be degassed easily from the final reactants. On the other hand, the possible reactions in Al-Ti-B system can be expressed as:

Al(l)+2B=AlB2(s), 993-1 300 K (2)

(3)

(3)

(4)

(4)

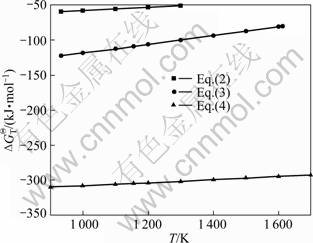

Figure 1 shows the standard Gibbs free energy for the possible reactions as a function of temperature when the mixture of K2TiF6 and KBF4 is put into the molten Si-Al alloy. By comparing the  values of three reactions in Eqs. (2)-(4), it is found that TiAl3 and AlB2 are not more stable than TiB2. Moreover, the reaction between TiAl3 and AlB2 to form TiB2 can be expressed as:

values of three reactions in Eqs. (2)-(4), it is found that TiAl3 and AlB2 are not more stable than TiB2. Moreover, the reaction between TiAl3 and AlB2 to form TiB2 can be expressed as:

TiAl3(s)+AlB2(s)=TiB2(s)+4Al(l), (933-1 300 K) (5)

Fig. 1 Standard Gibbs free energy for possible reactions as function of temperature when the mixture of K2TiF6 and KBF4 is put into the molten Si-30Al alloy

Thus Eq. (1) can be rewritten as:

(6)

(6)

KF and AlF3 in Eq. (6) can be eliminated from the dregs. Figures 2 shows XRD patterns of the top and bottom of the as-cast 2%TiB2/Si-30Al composite. It can be seen from the bottom of the sample that the microstructure consists of Si, Al and TiB2 phases, showing that the TiB2/Si-30Al composite was successfully produced (Fig. 2(b)). TiB2 phase was not found in the top of the sample (Fig. 2(a)), suggesting that relatively high density makes TiB2 particulates tend to agglomerate in the bottom of the sample [15-16].

Fig. 2 XRD patterns of 2%TiB2/Si-30Al in the top of sample (a) and in the bottom of sample (b)

3.2 Microstructure of as-cast 2%TiB2/Si-30Al composite

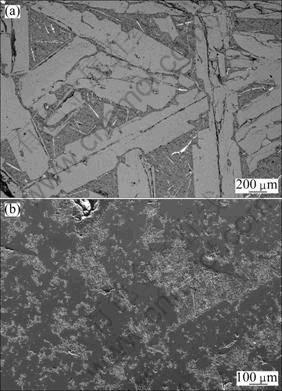

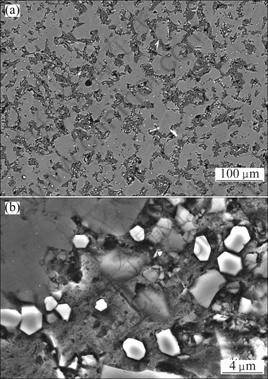

The SEM images of the 2%TiB2/Si-30Al in the top and bottom of sample are shown in Fig. 3. It is found that a lot of coarse dendrite primary Si exist in the top of as-cast Si-30Al alloy samples. Some primary Si of millimeter-size with cracks on the surface are found in the sample. Contrarily, the size of primary Si in the bottom of the sample is fine. Moreover, the primary Si particulates tend to be equiaxed-like.

Fig. 3 SEM images of 2%TiB2/Si-30Al in the top of sample (a) and in the bottom of sample (b)

In order to further study the distribution of TiB2 particulates, higher resolution SEM images were obtained from the bottom of the as-cast Si-30Al alloy. It is found that a lot of in situ TiB2 particulates (bright phase) agglomerate between the grain boundary of α(Al) and primary Si. A few TiB2 particulates exist in the interior of α(Al) or primary Si, as shown in Fig. 4. It is worthy of noting that some needle-like eutectic Si phase can be also detected.

3.3 Microstructure of spray-formed 2%TiB2/Si-30Al

Figure 5 shows XRD patterns of the top and bottom of the spray-formed 2%TiB2/Si-30Al composite. It is found that both the specimens consist of Si, Al and TiB2, showing that the distribution of the TiB2 particulates is fairly good under the spray forming procedure. It means that spray forming technique is beneficial to improve the distribution of TiB2 particulates even in the top of the sample.

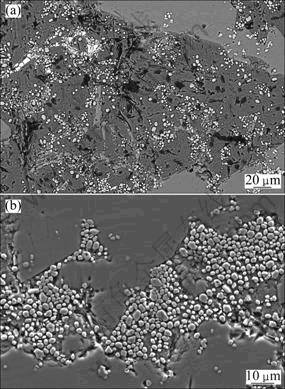

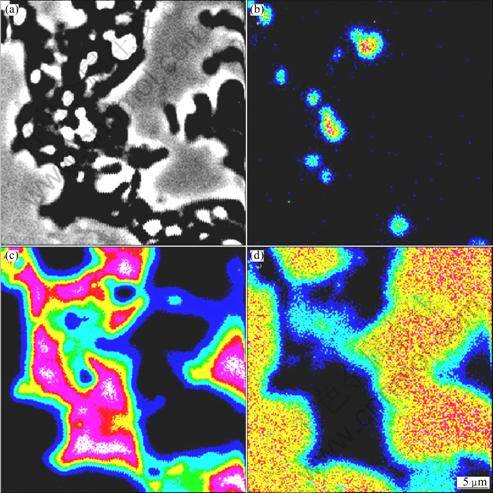

Figure 6 shows the typical SEM images of spray-formed 2%TiB2/Si-30Al composite. It can be seen that the microstructure of the composite consists of primary Si (light grey, ~35 μm), interpenetrating Al phase (dark grey), and fine TiB2 particulates (bright). The morphologies of TiB2 particulates with a mean grain size of 1-2 μm are hexagonal or tetragonal platelet. Some regular and irregular pores (dark holes) are found in the as-deposited 2%TiB2/Si-30Al composite. The TiB2 particulates play a role in heterogeneous nucleation. This is beneficial to delete the needle-like eutectic Si phase, as shown in Fig. 4(a), and refine the primary Si. The fact that the needle-like eutectic Si phase is deleted can be proved further by EPMA results, in which no needle-like Al-Si eutectic phase between the primary Si particulates was found, as shown in Fig. 7.

Fig. 4 SEM images of bottom of 2%TiB2/Si-30Al composite (a) and magnified image showing distribution of TiB2 particulates (b)

Fig. 5 XRD patterns of spray-formed 2%TiB2/Si-30Al in the top (a) and bottom (b) of samples

Fig. 6 SEM images of spray-formed 2%TiB2/Si-30Al composite (a) and TiB2 (b)

3.4 Effect of TiB2 on primary Si in semi-solid state during heating

The microstructures of 2%TiB2/Si-30Al composite samples after being heated to the semi-solid state at different temperatures and held for 90 min are shown in Fig. 8. The primary Si did not obviously grow, but became smooth and had a tendency to be sphere-like with the increase of temperature. The reason is that the energy between primary Si boundaries is relatively high and Si atoms in the boundaries are more active than others at a higher temperature. Hence Si atoms located at the boundaries are easier to diffuse with increasing temperature. Although the primary Si did not grow obviously when the samples were held in the semi-solid state, α(Al) phase in the matrix was melted partly and seeped on the surface of the sample as Al droplets.

Fig. 7 EPMA results of spray-formed 2%TiB2/Si-30Al composite: (a) Scanning area; (b) B element; (c) Al element; (d) Si element

Fig. 8 Microstructures of spray-formed 2%TiB2/Si-30Al composite after being reheated to semi-solid state at different temperatures and held for 90 min: (a) 600 °C; (b) 650 °C; (c) 700 °C; (d) 750 °C

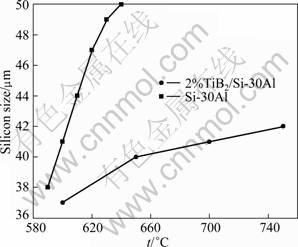

ZHANG et al [7] studied the microstructure of spray-formed Si-30Al alloy reheated and held in semi-solid state, and reported that there was no obvious growth of primary Si when the alloy sample was held below 590 °C for 90 min. When the samples were held above 590 °C for 90 min, however, a number of Al droplets were seeped out of samples. Under the condition, the size of primary Si was found to increase obviously. The size of primary Si held in the temperature range of 600-640 °C for 90 min increased by 2-12 μm [7]. Comparing Zhang’s and our results presented in Fig. 9, it is found that the grain size of primary Si in the 2%TiB2/Si-30Al composite is smaller than that in the Si-30Al alloy. This is because the TiB2 particulates are in situ formed in the Si-30Al alloy and can play a role in heterogeneous nucleation. As we all know, TiB2 has high melting point and is thermodynamically stable. TiB2 has been synthesized in the melt matrix before the primary Si phase is crystallized. Moreover, the presence of TiB2 particulates increases the nucleation kinetics of primary Si phase by increasing the density of nuclei in the melt, which is beneficial to the formation of fine primary Si phase. Finally, the TiB2 particulates located in the grain boundary can hinder the Si atoms from diffusing of the Si-30Al alloy in the semi-solid state. Therefore, the growth rate of primary Si is decreased.

Fig. 9 Size of primary Si of spray-formed Si-30Al alloy and 2%TiB2/Si-30Al composite held at different temperatures for 90 min

4 Conclusions

1) 2%TiB2/Si-30Al composite was prepared by melt in situ reaction. The TiB2 particulates can modify the morphology of primary Si and refine the size of Si particulates.

2) The microstructure of spray-formed 2%TiB2/ Si-30Al composite consists of primary Si (~35 μm), interpenetrating Al-rich phase, and dispersively distributed fine TiB2 particulates (1-2 μm).

3) Adding 2% TiB2 to the Si-30Al alloy can effectively retard primary Si from coarsening when the spray-formed 2%TiB2/Si-30Al composite was reheated to the semi-solid state.

References

[1] WANG F, XIONG B Q, ZHANG Y A, ZHU B H, LIU H W, WEI Y G. Microstructure, thermo-physical and mechanical properties of spray-deposited Si-30Al alloy for electronic packaging application [J]. Materials Characterization, 2008, 59(10): 1455-1457.

[2] HOGG S C, LAMBOURNE A, OGILVY A, GRANT P S. Microstructural characterization of spray formed Si-30Al for thermal management applications [J]. Scripta Materialia, 2006, 55: 111-114.

[3] LIU Hong-wen, ZHU Bao-hong, ZHANG Yong-an, XIONG Bai-qing. Microstructure and properties of spray-formed 70Si30Al alloy [J]. Rare Metals, 2009, 33(5): 742-745. (in Chinese )

[4] WANG Lei, ZHANG Yong-an, LIU Hong-wei, ZHU Bao-hong, WANG Feng, WEI Yan-guang. Microstructures and properties of sprayformed 70Si30Al alloy packaging material [J]. Rare Metals, 2007, 31(1): 1-4. (in Chinese )

[5] SANGHA S P S. Novel aluminum silicon alloys for electronics packaging [J]. Journal of Engineering Science and Education, 1997, 6(5): 195-201.

[6] ZHANG Di, YANG Bin, ZHANG Ji-shan, ZHANG Yong-an, XIONG Bai-qing. Effect of deformation temperature and strain rate on the semi-solid deformation behavior of spray-formed Al-70% Si alloys [J]. Transactions of Nonferrous Metals Society of China, 2005, 15(5): 1125-1129.

[7] ZHANG Di, CUI Hua, WEI Yan-guang, ZHANG Yong-an, XIONG Bai-qing, ZHANG Ji-shan. Structural evolution of sprayformed Al-70%Si alloys during isothermal holding in the semi-solid state [J]. Rare Metals, 2005, 24(4): 317-324. (in Chinese)

[8] YANG B, WANG F, ZHANG J S, XIONG B Q, DUAN X J. TiC particulate-reinforced Al-20Si-5Fe composite fabricated by melt in-situ reaction spray forming [J]. Journal of Materials Processing Technology, 2003, 137: 187-190.

[9] YANG B, SUN M, GAN G S, XU C G, HUANG Z J, ZHANG H B, FANG Z Z. In situ Al2O3 particle-reinforced Al and Cu matrix composites synthesized by displacement reactions [J]. Journal of Alloys and Compounds, 2010, 494 (1-2): 261-265.

[10] HAGHAYEGHI R, ZOQUI E J, ESKIN D G, BAHAI H. Grain refinement of an Al-10% Mg alloy by intensive shearing in the liquid state [J]. Journal of Alloys and Compounds, 2009, 485(1-2): 807-811.

[11] RAVI K R, SARAVANAN M, PILLAI R M, MANDAL A, MURTY B S, HAKRABORTY M, PAI B C. Equal channel angular pressing of Al–5wt% TiB2 in situ composite [J]. Journal of Alloys and Compounds, 2008, 459(1-2): 239-243.

[12] YU L, LIU X F, DING H M, BIAN X F. A new nucleation mechanism of primary Si by peritectic-like coupling of AlP and TiB2 in near eutectic Al–Si alloy [J]. Journal of Alloys and Compounds, 2007, 432(1-2): 156-162.

[13] YU L, LIU X F. The relationship between viscosity and refinement efficiency of pure aluminum by Al–Ti–B refiner [J]. Journal of Alloys and Compounds, 2006, 425(1-2): 245-250.

[14] TJONG S C, MA Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites, materials science and engineering [J]. Materials Science and Engineering, 2000, 29(3-4): 49-113.

[15] SCHAFFER P L, ARNBERG L, DAHIE A K. Segregation of particles and its influence on the morphology of the eutectic silicon phase in Al-7wt.%Si alloys [J]. Scripta Materialia, 2006, 54: 677-682.

[16] YAN Wei-ping, RONG Fu-jie, SONG Guo-jin, ZHAI Hu, MA Zhi-yi, FENG Zhi-jun. Present status of studying of TiB2/AI composite fabricated by mixed salts method [J]. Foundry, 2006, 55(11): 1114-1117. (in Chinese )

TiB2颗粒对喷射沉积Si-30Al复合材料显微组织的影响

甘贵生1, 2, 张 磊1, 贝舒瑜1, 卢 毅1, 杨 滨1

1. 北京科技大学 新金属材料国家重点实验室,北京100083;

2. 重庆理工大学 材料科学与工程学院,重庆400050

摘 要:结合原位反应技术和喷射沉积技术制备2% TiB2 /Si-30Al铝基复合材料。应用热力学讨论TiB2颗粒的原位反应合成原理,根据原子扩散理论分析TiB2对初晶硅的改性作用。结果表明:Si-30Al中添加2%(质量分数)的TiB2能明显细化初晶硅相。在半固态二次加热过程中,TiB2颗粒能明显抑制初晶硅的粗化、长大。

关键词:喷射沉积;TiB2颗粒;粗化;半固态

(Edited by YANG Hua)

Foundation item: Project (707007) supported by the Cultivation Fund of the Key Scientific and Technical Innovation, China; Project (2093040) supported by Beijing Municipal Natural Science Foundation, China

Corresponding author: YANG Bin; Tel: +86-10-62333351; E-mail: byang@ustb.edu.cn

DOI: 10.1016/S1003-6326(11)61002-9