DOI: 10.11817/j.issn.1672-7207.2015.02.004

采用液相球磨法由氧化铋制备次硝酸铋的工艺

夏纪勇,蒋叶,唐朝波,叶龙刚,唐谟堂

(中南大学 冶金与环境学院,湖南 长沙,410083)

摘要:针对传统次硝酸铋制备过程中产生污染环境的有毒气体二氧化氮及大量氨氮废水等问题,提出采用液相球磨转化法制备次硝酸铋新工艺,运用正交试验和单因素试验方法对氧化铋球磨转化制备次硝酸铋工艺进行研究。研究结果表明:各因素对转化率影响性由大至小的顺序为液固比、球料比、硝酸浓度、反应时间;氧化铋球磨转化制备次硝酸铋的最佳工艺条件如下:硝酸浓度为0.5 mol/L,液固比为15:1 mL/g,球料比为10:1(质量比),反应时间为1 h,在此最佳工艺条件下,氧化铋的平均转化率为90.71%。制备的次硝酸铋主要呈棒状形态分布。

关键词:氧化铋;球磨转化;次硝酸铋;正交实验

中图分类号:TF8 文献标志码:A 文章编号:1672-7207(2015)02-0404-06

Preparation of bismuth subnitrate by liquid ball-milling transformation method from oxide

XIA Jiyong, JIANG Ye, TANG Chaobo, YE Longgang, TANG Motang

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: In order to solve the problem in traditional process of preparation of bismuth which produced toxic NO2 and ammonia-nitrogen waste water, a new process for preparation of bismuth subnitrate by ball-milling transformation method from bismuth oxide was proposed. The process of preparation of bismuth subnitrate by ball-milling transformation was investigated by using orthogonal and single factor experiment methods. The results show that the effect of factors on the conversion rate of Bi2O3 from strong to weak are liquid-solid ratio, the mass ratio of ball to bismuth oxide, concentration of nitric acid and reaction time. The optimum conditions for ball-milling process are determined as follows: the concentration of nitric acid is 0.5 mol/L, the liquid solid ratio is 15:1, the ball-powder mass ratio is 10:1, and the ball-milling time is 1 h. The conversion rate of bismuth oxide can reach 90.71% under the optimal conditions. The bismuth subnitrate products show rod-like structure.

Key words:bismuth oxide; ball-milling transformation; bismuth subnitrate; orthogonal experiment

我国是一个铋资源十分丰富的国家,尤其在湖南柿竹园地区,金属铋主要用于铋的下游产品制备。次碳酸铋作为铋的深加工产品,在医药领域[1-3]、铋化学品合成[4-5]、催化剂制备[6-7]等方面都得到广泛应用。采用传统湿法工艺制备次硝酸铋[8],都需经过硝酸铋阶段,即由精铋溶解在硝酸中制备硝酸铋,再以硝酸铋为原料,采用纯水水解法或中和水解法制备。纯水水解法的反应式为

5[Bi(NO3)3·5H2O]+nH2O=4BiNO3(OH)2·BiO(OH)+11HNO3+(15+n)H2O (1)

中和沉淀法的反应式为

5Bi(NO3)3+11NH4OH=4BiNO3(OH)2·BiO(OH)+11NH4NO3+H2O (2)

上述制备方法都必须先制备硝酸铋溶液,在硝酸溶解金属铋的过程中会产生有毒NOx气体且硝酸消耗量大,同时还会产生大量的稀硝酸和硝酸铵废水。研究表明:氧化铋性质较稳定[9-10],在自然状态下氧化铋与碳酸氢铵或其他铵类溶液反应的转化率极低。机械活化由于能够使反应物粒度变小、晶格能增大、缺陷增加,因而可加快化学反应进行[11-12],在材料制 备[13-15]、冶金过程强化[16-18]中都有应用和研究。本文作者在氧化法制备氧化铋[8]的基础上探究以Bi2O3粉体为原料,经湿法球磨[19-20]制备次硝酸铋的新工艺。采用氧化锆球作为活性介质在球磨过程中对物料表面产生摩擦和冲击,强化反应过程,所需硝酸的量大大减少,使氧化铋和略超过理论量的硝酸直接完全反应,反应后分离的母液循环使用,反应式为

3Bi2O3+5HNO3+2H2O=Bi6O5(OH)3(NO3)5·3H2O (3)

该工艺流程短,工艺简单,原料消耗少,成本低,最大的优点在于避免了传统旧工艺中因溶解金属铋而产生的有毒气体NOx,且球磨转化后的母液经处理便可循环使用,对环境无污染,具有广阔的工业应用前景。

1 试验

1.1 试验原料

试验所用原料为氧化铋和硝酸。氧化铋粉末为湖南金堂铋业公司生产,其成分如表1所示。硝酸为分析纯,浓度取14.76 mol/L。

表1 试验用氧化铋化学成分(质量分数)

Table1 Chemical composition of bismuth oxide %

1.2 试验方法

每次称取20 g氧化铋置于球磨罐中,按液固比加入一定浓度的硝酸溶液,按球料比加入适量直径为1 cm的氧化锆球。将不锈钢球磨罐置于匀速滚动的球磨机上进行反应并计时,到达反应终点后,取出罐内反应物,过滤、洗涤、干燥后,称取一定质量干燥后的产物(记为m1)在500 ℃下煅烧2 h,煅烧产物在干燥器中自然冷却至室温,称质量(m2);根据煅烧前后的质量差,计算氧化铋的转化率。

反应所得产物次硝酸铋为白色粉状固体,加热灼烧时分解成黄色的氧化铋和氮氧化物及水蒸汽,反应如下:

2Bi6O5(OH)3(NO3)5·3H2O 6Bi2O3+5N2O5↑+9H2O↑ (4)

6Bi2O3+5N2O5↑+9H2O↑ (4)

根据煅烧前后的质量差,可以计算发生反应的氧化铋质量,按下式计算转化率:

(5)

(5)

式中:W为氧化铋的转化率;Δm=m1-m2,为煅烧前后的质量差,g。

1.3 正交试验

正交试验拟考察硝酸浓度、液固比、反应时间、球料比对转化率的影响。为了找出影响转化率的主要因素,在固定每次取20 g氧化铋的条件下,选择硝酸浓度(因素A)、液固比(因素B)、球料比(因素C)、反应时间(因素D)进行四因素四水平正交试验。根据探索实验选择的相关因素及其水平分布如表2所示。

表2 正交试验因素及水平

Table 2 Factors and levels of orthogonal test

2 结果及讨论

2.1 正交试验

按设定的因素和水平组合进行正交试验。其结果及方差分析如表3所示。

从表3可看出:在正交实验的最佳工艺条件下,氧化铋的转化率最大可达91.49%;液固比是显著影响因素,各因素对氧化铋转化率由大至小的影响程度依次为液固比、球料比、硝酸浓度和反应时间。根据分析结果可知球磨转化制备次硝酸铋的最佳水平组合为A2B3C4D1,即硝酸浓度为0.5 mol/L,液固比为18:1 mL/g,球料比为19:1,反应时间为0.50 h。

表3 正交试验结果

Table 3 Result of orthogonal test

2.2 氧化铋球磨转化单因素条件试验

2.2.1 硝酸浓度的影响

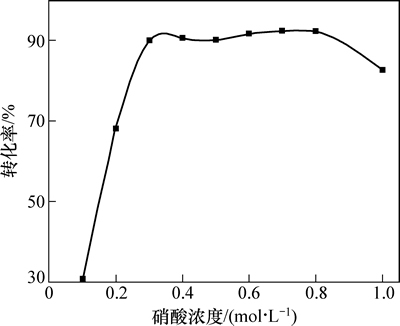

在球料比为10:1,液固比为15:1 mL/g,反应时间为1.00 h,温度为室温的固定条件下考察硝酸浓度对氧化铋转化率的影响,结果如图1所示。

从图1可以看出:在一定范围内,随着硝酸浓度的升高,反应物浓度增加,Bi2O3转化率增大;随着硝酸浓度从0.1 mol/L升高至0.4 mol/L,转化率增大的趋势十分明显,从30.61%上升到90.55%;在0.4~0.8 mol/L范围内,氧化铋的转化率随浓度的增加并没有明显变化,在90.16%~92.24%的范围内波动,当硝酸浓度为0.7 mol/L时,转化率达到最大值92.24%;而当硝酸浓度达到1.0 mol/L后,转化率反而随浓度增大而略有下降,这可能是由于酸度过高不利于铋的水解反应进行。由此可见,保持适当的终点平衡酸度对氧化铋的转化有利,综合考虑硝酸的用量及转化率,选取0.5 mol/L作为硝酸的最佳反应浓度。

图1 硝酸浓度对转化率的影响

Fig. 1 Effect of concentration of nitric acid on conversion rate

2.2.2 液固比的影响

在硝酸浓度为0.5 mol/L,球料比为10:1,反应时间为1 h,温度为室温的固定条件下,考察液固比对反应过程的影响,结果如图2所示。

图2 液固比对转化率的影响

Fig. 2 Effect of liquid-solid ratio on conversion rate

从图2可以看出:在液固比达到15:1之前,液固比对氧化铋的转化率影响十分显著;当液固比为6:1~15:1时,转化率随液固比的增大而明显升高,从44.10%增加到90.16%,液固比为18:1时氧化铋达到最大值90.29%,随后液固比的增加对转化率的影响不大。液固比太大则相当于稀释了溶液,有效离子浓度降低,综合考虑选择液固比为18:1 mL/g。

2.2.3 球料比的影响

在硝酸浓度为0.5 mol/L,液固比为18:1 mL/g,反应时间为1.00 h,温度为室温的固定条件下,考察球料比对反应过程的影响,结果如图3所示。

图3 球料比对转化率的影响

Fig. 3 Effect of ball-to-powder mass ratio on conversion rate

从图3可知:氧化铋的转化率随着球料比的增大而升高,从2:1时的40.37%上升到10:1时的89.77%,增加锆球的量相当于增大了接触面积和反应面积,活化也更充分。此后继续增大球料比,氧化铋的转化率可认为基本保持恒定,在89.77%~90.66%的范围内波动,可认为活化强度已足够,因此选择球料比为10:1。

2.2.4 反应时间的影响

在硝酸浓度为0.5 mol/L,液固比为18:1 mL/g,球料比为10:1,温度为室温的固定条件下,考察反应时间对转化率的影响,结果如图4所示。

图4 反应时间对转化率的影响

Fig. 4 Effect of reaction time on conversion rate

从图4可以看出:氧化铋的球磨反应进行很快;当反应时间为15 min时,转化率就已达77.11%;在90 min内延长反应时间,氧化铋的转化率有所升高,反应时间为60 min时转化率达到91.04%;继续延长反应时间对氧化铋转化率的提高并无明显作用,可认为反应已进行较完全。从生产效率和氧化铋转化率两方面综合考虑,选择1 h为最优反应时间。

2.3 综合条件试验

根据单因素条件试验的结果,选取最优条件即硝酸浓度为0.5 mol/L,液固比为18:1 mL/g,球料比为10:1,反应时间为1 h进行综合扩大试验。考虑到球磨罐的有效容积限制,试验规模为25 g氧化铋/次,结果如表4所示。

表4 三次综合试验结果

Table 4 Result of three comprehensive experiment

由表4可知:综合扩大试验效果较理想,氧化铋的平均转化率达到90.71%,达到预期效果。对所得次硝酸酸铋产物进行ICP全分析,结果如表5所示。

表5 次硝酸铋样品的化学成分(质量分数)

Table 5 Chemical analyses of bismuth subnitrate %

从表5可看出:各种杂质元素的总质量分数小于0.1%,可见本实验制取的次硝酸铋纯度较高。对所得的次硝酸铋产物进行XRD分析,结果如图5所示。从图5可以看出:衍射峰主要为次硝酸铋,由标准卡片检索可知次硝酸铋的分子式为Bi6O5(OH)3(NO3)5·3H2O,峰形较为纯净和尖锐,同时还有部分未反应完全的氧化铋杂质。取次硝酸酸铋产品进行SEM扫描电镜表征,其结果如图6所示。

从图6可以看出:次硝酸铋产物主要呈棒状形态分布,可能受球磨过程的影响。结晶性好,产品形貌大致相同,晶粒粒度多在10 μm左右,无明显团聚现象,杂质形貌较少。

图5 次硝酸铋的XRD图

Fig. 5 XRD pattern of bismuth subnitrate

图6 次硝酸铋产品的SEM图

Fig. 6 SEM images of bismuth subnitrate

3 结论

1) 对氧化铋球磨转化制备次硝酸铋进行了四因素四水平的正交试验,探讨了影响氧化铋转化率的显著因素,各因素对转化率影响由大至小的顺序液固比、球料比、硝酸浓度、反应时间。依据直观分析结果,确定氧化铋球磨转化制备次硝酸铋的最优因素水平组合为A2B3C4D1,即硝酸浓度为0.5 mol/L,液固比为18:1,球料比为19:1,反应时间为0.5 h。

2) 设计一系列单因素条件试验,分别考察硝酸浓度、液固比、球料比、反应时间对球磨转化过程的影响,确定了氧化铋球磨转化制备次硝酸铋的最佳工艺条件如下:硝酸浓度为0.5 mol/L,液固比为15:1 mL/g,球料比为10:1,反应时间为1 h。在此最优条件下进行3次综合扩大试验,氧化铋的平均转化率为90.71%。所得产物是分子式为Bi6O5(OH)3(NO3)5·3H2O的次硝酸铋,形貌主要呈棒状态。

参考文献:

[1] Lars H P, Meredin S, Erik E, et al. Leydig cell death in rats exposed to bismuth subnitrate[J]. Journal of Applied Toxicology, 2003, 23(4): 235-238.

[2] Yukihiro K, Seiichiro H, Masahiko S, et al. Citrate enhances the protective effect of orally administered bismuth subnitrate against the nephrotoxicity of cis-diamminedichlorphatinum[J]. Cancer Chemother Pharmacol, 2004, 53(1): 33-38.

[3] Meredin S, Allen F, Liselotte G S, Jorgen R. Decreased serum testosterone levels in rats exposed intraperitoneally to bismuth subnitrate[J]. Journal of Applied Toxicology, 2002, 22(2): 111-115.

[4] Ioannou P A. Evaluating the non-hygroscopic bismuth subsalicylate, bismuth oxychloride and bismuth subnitrate monohydrate as starting reagents for the preparation of bismuth (Ⅲ) thiolates[J]. Main Group Chemistry, 2014, 13(4): 329-341.

[5] Ali R P, Fatemeh F. Selective nitration of phenols using bismuth subnitrate/charcoal in the presence of trichloroisocyanuric acid under aprotic conditions[J]. Chinese Chemical Letters, 2010, 21(11): 1283-1286.

[6] WU Shuisheng, DAI Weili, YIN Shuangfeng, et al. Bismuth subnitrate as an efficient heterogeneous catalyst for acetalization and ketalization of carbonyl compounds with diols[J]. Catalysis, 2008, 124(1/2): 127-132.

[7] Reddy Y T, Rajitha B, Reddy P N, et al. Bismuth subnitrate catalyzed efficient synthesis of 3,4-dihydropyrimidin-2(1H)-ones: An improved protocol for the biginelli reaction[J]. Synthetic Communications, 2004, 34(20): 3821-3825.

[8] 厦门冰醋厂. 次碳酸铋、次硝酸铋的生产方法[J]. 无机盐工业, 1997(2): 54-56.

Xiamen factory of ice vinger. The preparation methods of bismuth subcarbonate and bismuth subnitrate[J]. Inorganic Chemicals Industry, 1997(2): 54-56.

[9] 陈萃, 夏纪勇, 唐朝波, 等. 低温氧化法制备Bi2O3粉体新工艺研究[J]. 材料导报, 2008, 22(8): 124-130.

CHEN Cui, XIA Jiyong, TANG Chaobo, et al. Studies on the preparation of Bi2O3 powders by the oxidation process at loss temperature[J]. Materials Reviews, 2008, 22(18): 124-130.

[10] XIA Jiyong, TANG Motang, CHEN Cui, et al. Preparation of α-Bi2O3 from bismuth powders through low-temperature oxidation[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2289-2294.

[11] Martin K B, Hauke C S. Mechanochemistry: The mechanical activation of colvalent bonds[J]. Chemical Review, 105(8): 2921-2948.

[12] Boldyrev V V. Mechanochemistry and mechanical activation of solids[J]. Russian Chemical Reviews, 2006, 75(3): 177-189.

[13] Kim J K, Cheruvally G, Choi J W, et al. Effect of mechanical activation process parameters on the properties of LiFePO4 cathode material[J]. Journal of Power Sources, 2007, 166: 211-218.

[14] Markmaitree T, Ren R M, Shaw L. Enhancement of lithium amide to lithium lmide transition via mechanical activation[J]. The Journal of Physical Chemistry B, 2006, 110(41): 20710-20718.

[15] 张有新, 何利华, 刘旭恒. 机械活化对磁黄铁矿浸出动力学的影响[J]. 中南大学学报(自然科学版), 2010, 41(6): 2085-2090.

ZHANG Youxin, HE Lihua, LIU Xuheng. Effect of mechanical activation on leaching kinetics of pyrrhotite[J]. Journal of Central South University (Science and Technology), 2010, 41(6): 2085-2090.

[16] TAO Tao, CHEN Qiyuan, HU Huiping, et al. TiO2 nanoparticles prepared by hydrochloric acid leaching of mechanically activated and carbothermic reduced ilmenits[J]. Transaction of Nonferrous Metals Society of China, 2012, 22(5): 1232-1238.

[17] Maurice D, Hawk J A. Ferric chloride leaching of mechanically activated chalcopiryte[J]. Hydrometallurgy, 1998, 49(1/2): 103-123.

[18] Boldyrev V V. Mechanochemicstry and mechanical activation of solids[J]. Russian Chemical Reviews, 2006, 75(3): 177-189.

[19] 吕奕菊. 湿法球磨-喷雾干燥-碳热还原制备碗状纳/微结构LiFePO4/C及其性能研究[D]. 贵阳: 广西大学化工学院, 2014: 20-52.

L Yiju. Synthesis and properties of nano/micro bowl-like LiFePO4/C composites prepared by wet milling-spray drying-carbothermal reduction[D]. Guiyang: Guangxi University. School of Chemical Engineering, 2014: 20-52.

Yiju. Synthesis and properties of nano/micro bowl-like LiFePO4/C composites prepared by wet milling-spray drying-carbothermal reduction[D]. Guiyang: Guangxi University. School of Chemical Engineering, 2014: 20-52.

[20] 孟振强, 刘如铁, 熊拥军, 等. 球磨方式对多壁碳纳米管形貌和结构的影响[J]. 中国有色金属学报, 2012, 22(12): 3421-3426.

MENG Zhenqiang, LIU Rutie, XIONG Yongjan, et al. Effect of ball milling on morphology and structure of multi-walled carbon nano tubes[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3421-3426.

(编辑 陈灿华)

收稿日期:2014-03-22;修回日期:2014-05-20

基金项目(Foundation item):国家自然科学基金资助项目(50774099);中南大学-湖南有色基金资助项目(2010年)(Project (50774099) supported by the National Natural Science Foundation of China; Project (2012) supported by Non-ferrious Foundation of HNG-CSU)

通信作者:唐朝波,博士,副教授,从事清洁冶金新工艺研究;E-mail:tangchaobo9043@163.com