文章编号:1004-0609(2007)11-1767-06

钛合金TC16中绝热剪切带的微观结构演化

汪冰峰,杨 扬

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:利用分离式Hopkinson压杆(SHPB)技术对钛合金TC16的帽形试样进行动态加载,采用光学显微镜和透射电镜技术观测TC16中绝热剪切带内的微观结构和相变情况。结果表明,剪切带的边缘由具有高位错密度的沿着剪切方向排列的宽度为0.2~0.5 μm的伸长组织构成,其与基体组织的形貌显著不同;剪切带中部由大量低位错密度的直径约为0.2 μm的再结晶等轴晶组成。衍射花样的标定表明α-Ti和α″相共存于剪切带中部,剪切带内发生了相变。绝热剪切变形过程中剪切带内的温度约为796 ℃。讨论了TC16中绝热剪切带内的相变规律和微观结构演化过程。

关键词:TC16合金;绝热剪切带;动态再结晶;相变

中图分类号:TG 456.6 文献标识码:A

Microstructure evolution in adiabatic shear band in

titanium alloy TC16

WANG Bing-feng, YANG Yang

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract:Dynamic loading was carried out in the hat-shaped specimens of titanium alloy TC16 by split Hopkinson pressure bar (SHPB) technique. The microstructure and the phase transformation in the adiabatic shear band (ASB) produced in TC16 alloy were investigated by means of OM and TEM. The results show that the boundary of the shear band is composed of grains of 0.2?0.5 μm in width with high dislocation density elongated along the shear direction, whose pattern is obvious different from the matrix grains. The center of shear band consists of a number of recrystallized equiaxed grains with diameters of about 0.2 μm with low dislocation density. The results of SAD indicate that α-Ti and α″ grains coexist in the shear band and the phase transformation occurs in the shear band. The temperature in the shear band during the adiabatic shearing deformation is about 796 ℃. The phase transformation and the microstructure evolution process within ASB in TC16 alloy were explained.

Key words:TC16 alloy; adiabatic shear band; dynamic recrystallization; phase transformation

绝热剪切是材料在高应变速率(>103 s?1)形变条件下塑性形变局域化的一种常见形式,相当普遍地存在于高速撞击、侵彻、冲蚀、切削、高速成型、爆炸复合等涉及冲击载荷的高应变速率形变过程中[1?2]。钛及钛合金由于具有低的比热容和高度的绝热剪切敏感性,因此易于产生绝热剪切带(ASB)。Meyers等[3]与Yang等[4?7]及Chichili等[8]研究了纯Ti和Ti-6Al-4V合金中ASB的微观结构,认为剪切带内的细小等轴晶粒的形成是动态再结晶的结果。TC16合金是一种新型的马氏体强化α+β型钛合金,具有良好的力学性能和工艺性能,如热变形性、焊接性、切削加工性和抗蚀性,可加工成棒材、型材、板材、锻件、模锻件等半成品[9]。国内外研究者已经对Ti-Al-Mo-V系列合金的常规变形做了大量的研究工作[9?11]。但是对于TC16合金的高速剪切变形研究,特别是其中的绝热剪切现象还报导较少。在晶粒细小和相组成复杂的钛合金TC16中所形成的ASB内具有怎样的微观结构,其微观结构演化的机制如何?

本文作者利用分离式Hopkinson压杆(SHPB)加载技术和Meyer等

[12]提出的帽形试样,对TC16合金行高速动态加载,并观测ASB内的微观结构特征,结合制备ASB时所获取的动态响应数据估算ASB内的绝热温升,研究TC16合金中ASB内微观结构演化的机制,对优化TC16合金的材料结构设计、提高其动态性能具有重要意义。

1 实验

实验材料为钛合金TC16,其化学成分为(质量分数,%):Al 2.5,Mo 5,V 5,Ti其余。材料初始状态为加工态。原始组织由六方的α-Ti相和立方的β-Ti相组成,晶粒尺寸很细小,约为1 μm。SHPB的加载过程参见文献[13]。

根据Andrade和Meyers[13]的实验结果,剪切带内的剪切应力τ、应变值γ和应变速率值 可以通过式(1)、(2)和(3)计算。根据Culver[14]提出的公式(4)可以计算出真应变值ε。

可以通过式(1)、(2)和(3)计算。根据Culver[14]提出的公式(4)可以计算出真应变值ε。

利用线切割机平行于帽形试样的轴线取样分析。Tc16合金采用2.5 mL hf+3 mL HNO3 +5 mL hcl+91 mL h2o溶液进行侵蚀,并在POLYVAR? MET大型多功能金相显微镜上进行显微组织观察。透射电镜薄片试样经机械研磨后,首先在操作电压为20~30 V和温度不超过?30 ℃下选用300 mL甲醇+175 mL正丁醇+30 mL高氯酸的双喷电解液在剪切区附近进行穿孔,而后在穿孔的附近进行离子溅射减薄制备得到电镜薄膜,在Tecanai G2 20透射电子显微镜下分析剪切带及其周围的组织结构,操作电压为200 kV。

2 结果与讨论

2.1 高应变速率下的力学响应

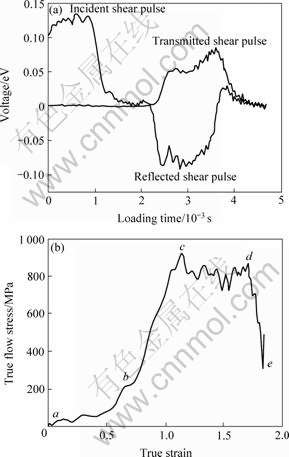

图1(a)所示为入射杆和透射杆上记录的应力波应变值。绝热剪切变形起始于应变速率的第一个峰值,终止于加载应力波的最后一个峰值[15?16]。由式(2)结合图1(a)可知,试样的绝热剪切变形时间为122 μs。

图1 剪切带形成过程的力学响应数据

Fig.1 Mechanical response data during formation of shear band: (a) Shear signals with hat-shaped specimen attached between bars; (b) True strain vs true flow stress in shear band during shear deformation

将SHPB的应变讯号数据和各参数值代入式(1)~(4)可以获得ASB形成过程中的流变应力—真应变曲线,如图1(b)所示。可知,试样在剪切变形过程中大致经历了3个阶段:在a→c流变应力随着真应变的增加而增加;然后在c→d流变应力值随着真应变增加在小范围内变化,这主要是由于热软化作用、应变强化和应变速率强化基本相持所致;最后在d→e的热软化效应越来越显著时,发生了热粘塑性失稳,并形成ASB。在剪切变形之初剪切区域内的真应变不会随着流变应力的增加而迅速的增加,如图1(b)中a→b所示,这是由于TC16合金基体晶粒很细小的缘故。

2.2 ASB的微观结构

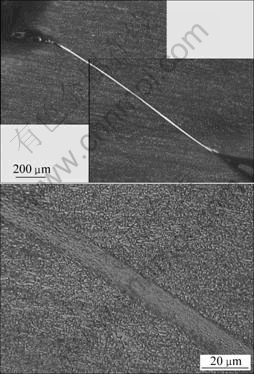

图2所示为剪切带微观形貌的光学显微照片。由图2(a)可见,ASB为一条贯穿整个剪切区“白亮” 带。由图2(b)可知,剪切带的宽度约为13 μm,数倍于基体晶粒的大小;剪切带两侧为细小的基体晶粒;边缘为细长结构,与基体组织存在显著的界面;剪切带中部的晶粒十分细密,在光学显微镜下不能够分辨出来。

图 2 ASB的光学金相形貌

Fig.2 Optical micrographs of ASB: (a) Montage of optical micrographs of ASB; (b) Local micrograph of ASB

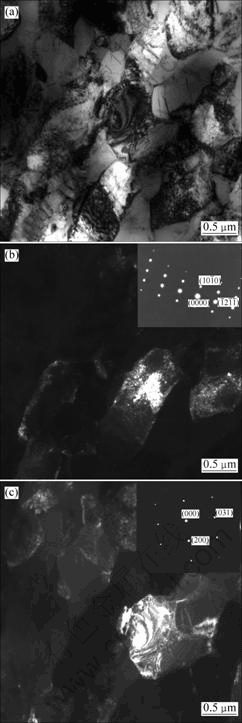

图3所示为ASB两侧基体的组织形貌及其衍射斑点。由图3可知,TC16合金的晶粒大小在1 μm左右;基体组织为由六面的α相(α-Ti)和立方的β相(β-Ti)所组成的弥散混合组织;晶粒上厚的位错胞结构表明合金的基体中存在大量的变形。

图3 基体组织的TEM形貌

Fig.3 TEM micrographs of matrix region: (a) Bright field image of matrix grains; (b), (c) Dark field images and their corresponding SADs of α-Ti phase and β-Ti phase in Fig.3(a), respectively.

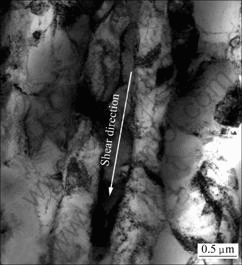

图4所示为剪切带与基体过渡区间的晶粒组织形貌。由图可见,剪切带边缘晶粒沿着剪切方向拉长排列,具有厚的位错胞结构特征,宽为0.2~0.5 μm。这是由于剪切带边缘受到强剪切变形的作用所致;拉长晶粒垂直剪切方向可以分裂成数个取向差较小的亚晶粒。

图4 剪切带与基体过渡区间组织的明场形貌

Fig.4 TEM bright field image of transition zone between shear band and matrix

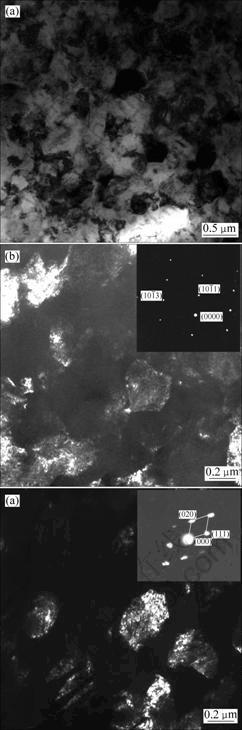

图5所示为剪切带中部的晶粒组织形貌。由图5(a)可知,剪切带中部由大量低位错密度的直径约为 0.2 μm的等轴晶粒组成,这些等轴晶粒具有典型的再结晶组织特征。由衍射花样的标定(如图5(b)所示)可知,在剪切带中部的等轴晶粒存在α-Ti相结构。由图5(a)和图5(b)可见,在剪切带中部还存在大量片状结构的晶粒。因为这些晶粒尺寸小于选区光栏的直径,所以在图5(c)中得到片状结构晶粒的两套位置接近的单晶衍射花样,经标定可知这些晶粒为马氏体α″相(斜方马氏体[9])组织。因此,在剪切带中部发生了相变,具有α-Ti相和α″相的细小等轴晶粒混合共存于剪切带中部,光学显微镜下的“白亮”带是剪切带内相变所致。

图5 剪切带中部组织的TEM形貌

Fig.5 TEM micrographs of center of shear band: (a) Bright field image of center of shear band; (b), (c) Dark field images and their corresponding SADs of α-Ti phase and α″-Ti phase in (a), respectively

2.3 ASB中微观结构的演化

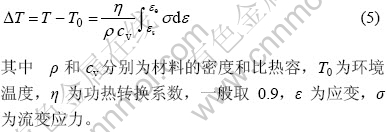

ASB内的绝热温升是研究其中微观结构演化的一个重要参数。当应变速率大于103 s?1时,整个剪切变形过程可以近似认为是绝热的过程。因此,绝热温升的计算可采用以下公式[3?5, 17]:

对于TC16合金ρ=4 647 kg/m3,在室温下cv= 470 J/(kg?℃)。

结合式(5)与绝热剪切变形过程中的动态响应数据(图1(b)),可以计算出剪切区内绝热温升:

将Si依次代入式(6),可计算得到剪切变形过程中剪切带内的最大绝热温升约为503 ℃,即ASB内的最大温度约为796 ℃。剪切带中部的微观结构分析(图5)表明,具有α-Ti和片状α″马氏体相的细小等轴晶混合共存。剪切带中部没有发生α+β→β的相变,剪切带内的温度并没有达到该相变的发生温度820~840 ℃。因此,在剪切变形过程中ASB内的温度低于TC16合金在常规条件下的再结晶温度820~870 ℃。然而,在剪切带中部却发生了再结晶,这是由于在冲击载荷下绝热剪切变形在材料中产生了高压高剪受力和聚集了大量的变形能,从而使材料发生动态再结晶的温度低于常规条件下的静态再结晶温度。由图5可知,在TC16合金的ASB中发生了β相转变为α″马氏体相的相变过程。从晶体学上,这是由于该合金具有较高的β相稳定元素,晶格转变阻力大,β相不能直接转变为六方晶格,而只能转变为斜方晶格α″马氏体相[9, 11]。由力学响应数据(图1(a))可知,TC16合金的绝热剪切变形时间约为122 μs。冲击实验发现一片马氏体可以在0.1 μs甚至更短时间内形成。在冷却过程中,ASB内的冷却速度高达105 ℃/s[4?5, 18?19]。因此,在绝热剪切变形过程中,剪切带中的β相拉长晶粒通过充分的晶界旋转产生等轴晶粒以后,有足够的时间和动力发生马氏体相变,形成直径约为0.2 μm的α″马氏体相。

由此可知,TC16合金中ASB内微观结构演化是动态再结晶的结果。其演化过程可描述为:变形初期剪切区内晶粒在压力和剪切力的共同作用下,沿着剪切方向被剧烈拉伸而产生拉长的大变形晶粒,剪切带中部具有比边缘更为显著的变形;当晶粒拉长至宽度为0.2 μm左右时,拉长晶粒内的位错胞壁合并形成多个取向差较小的等轴亚晶;亚晶通过亚晶界旋转30?左右形成细小的等轴晶,变形产生的位错消失在大角度等轴晶界内。此时,β相等轴晶通过切变方式迅速形成斜方结构的α″马氏体相。动力学计算结果表明[5],在冷却过程中由于缺乏机械力辅助,等轴晶不再转动,冷却速度过大不足以发生晶粒的长大。

3 结论

1) TC16合金中ASB的边缘由具有高的位错密度的沿着剪切方向的宽度为0.2~0.5 μm的拉长组织构成,与基体组织的形貌显著不同;ASB中部由大量低位错密度的直径约为0.2 μm的等轴晶组成,具有典型的再结晶组织特征,与之对应的衍射花样表明α-Ti和α″相混合共存于剪切带中部。

2) 在绝热剪切变形过程中ASB内的平均绝热温升为503 ℃左右。TC16合金中ASB内经历了如下微观结构演化过程:剪切区内晶粒沿着剪切方向被剧烈拉伸产生拉长的大变形晶粒,当晶粒拉长至宽度为0.2 μm左右时,拉长晶粒内的位错胞壁合并形成多个取向差较小的等轴亚晶,并最终通过亚晶界旋转30?左右形成细小的等轴晶粒,变形产生的位错消失在大角度等轴晶界内,此时β相等轴晶通过切变方式迅速形成斜方结构的α″马氏体相,在冷却过程中由于缺乏机械力辅助,等轴晶不再转动,冷却速度过大不足以发生晶粒的长大。

REFERENCES

[1] BAI Yi-long. Adiabatic shear banding[J]. Res Mechanics, 1990, 31: 133?203.

[2] 杨 扬, 程信林. 绝热剪切的研究现状及发展趋势[J]. 中国有色金属学报, 2002, 12(3): 401?408.

YANG Yang, CHENG Xin-lin. Current status and trends in researches on adiabatic shearing[J]. The Chinese Journal of Nonferrous Metals, 2002,12(3): 401?408.

[3] Meyers M A, Pak H R. Observation of an adiabatic shear band in titanium by high-voltage transmission electron microscopy[J]. Acta Metallurgica, 1986, 34(12): 2493?2499.

[4] YANG Yang, ZHANG Xin-ming, LI Zheng-hua, LI Qing-yun. Adiabatic shear band on the titanium side in the Ti/mild steel explosive cladding interface[J]. Acta Mater, 1996, 44(2): 561?565.

[5] YANG Yang, WANG Bing-feng, XIONG Jun. Adiabatic shear bands on the titanium side in the titanium/mild steel explosive cladding interface: Experiments, numerical simulation and microstructure evolution[J]. Metallurgical Materials Transaction A, 2006, 37(10): 3131?3137.

[6] YANG Yang, WANG Bing-feng. Dynamic recrystallization in adiabatic shear band in α-titanium[J]. Materials Letters, 2006, 60(17/18): 2198?2202.

[7] YANG Yang, WANG Bing-feng, HU Bin, LI Zhi-gang. The collective behavior and spacing of adiabatic shear bands in the explosive cladding plate interface[J]. Mater Sci Eng A, 2005, 398(1/2): 291?296.

[8] Chichili D R, Ramesh K T, Hemker K J. Adiabatic shear localization in α-titanium: Experiments, modeling and microstructural evolution[J]. Journal of the Mechanics and Physics of Solids, 2004, 52(8): 1889?1909.

[9] Bophcoba E А. 钛合金金相学[M]. 陈石卿, 译. 北京: 国防工业出版社, 1986.

Bophcoba E А. Metallography of titanium alloy[M]. CHEN Shi-qing, transl. Beijing: National Defence Industry Press, 1986.

[10] Zong Y Y, Shan D B, Lu Y. Microstructural evolution of a Ti-4.5Al-3Mo-1V alloy during hot working[J]. Journal of Materials Science, 2006, 41(2): 3753?3760.

[11] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Cheng-guang. Titanium alloy and its application[M]. Beijing: Chemical Industry Press, 2005.

[12] Meyer L W, Manwarig S. Critical adiabatic shear strength of low alloyed steel under compressive loading[C]//Metallurgical Applications of Shock-Wave and High-Strain -Rate Phenomena. New York: Marcel Dekker, 1986: 657.

[13] Andrade U, Meyers M A. Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper[J]. Acta Mater, 1994, 42(8): 3183?3195.

[14] Culver R S. Thermal instability strain in dynamic plastic deformation[C]// Metallurgical Effects at High Strain Rates. New York: Plenum Press, 1973: 519?530.

[15] Hines J A, Vecchio K S. Recrystallization kinetics within adiabatic shear bands[J]. Acta Mater, 1997, 45(2): 635?649.

[16] Li Q, Xu Y B, Lai Z H, Shen L T, Bai Y L. Dynamic recrystallization induced by plastic deformation at high strain rate in a Monel alloy[J]. Mater Sci Eng A, 2000, 276(1): 250?256.

[17] 杨 扬, 安宇龙, 汪冰峰. T2/QBe2爆炸复合界面结合层内的形变特征[J]. 中国有色金属学报, 2004, 14(8): 1259?1264.

YANG Yang, AN Yu-long, WANG Bing-feng. Deformation behaviors in T2/QBe2 explosive cladding interface[J]. The Chinese Journal of Nonferrous Metals, 2004,14(8): 1259?1264.

[18] Liao S C, Duffy J. Adiabatic shear bands in a Ti-6Al-4V titanium alloy[J]. J Mech Phys Solids, 1998, 35(11): 2201?2231.

[19] YANG Yang, XIONG Jun, YANG Xu-yue. Microstructure evolution of adiabatic shear band of titanium[J]. Trans Nonferrous Met Soc China, 2004, 14(4): 670?674.

基金项目:国家自然科学基金资助项目(50471059,50671121)

收稿日期:2007-03-23;修订日期:2007-08-30

通讯作者:汪冰峰,讲师,博士;电话:0731-8830770;传真:0731-8876692; E-mail: bingfeng_wang@yahoo.com.cn

(编辑 袁赛前)