文章编号:1004-0609(2007)02-0308-05

侧部导入超声处理对共晶Al-Si合金凝固特性的影响

刘清梅,龚永勇,侯 旭,戚飞鹏,翟启杰

(上海大学 材料科学与工程学院,上海 200072)

摘 要:研究了功率超声处理对ZL102铝硅合金凝固特性的影响。研究发现:在凝固过程中进行超声处理能显著细化共晶硅相,改善其形貌及分布;通过对比未处理、300 W超声波及500 W超声波处理条件下铝硅合金不同部位的力学性能及断口形貌,发现功率超声处理明显提高铝硅合金的力学性能,且随着处理功率的增大,合金的力学性能随之提高。并分析了超声波在铝硅合金中传播时衰减的原因,通过数学方法得到衰减方程,并探讨了其衰减规律。

关键词:共晶Al-Si合金;功率超声波;凝固组织;力学性能;衰减

中图分类号:TG 113 文献标识码:A

Influence of side ultrasonic treatment on solidification characterization of Al-Si eutectic alloy

LIU Qing-mei, GONG Yong-yong, HOU Xu, QI Fei-peng, ZHAI Qi-jie

(School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China)

Abstract: The influence of side-introduced power ultrasonic treatment on the solidification characterization of ZL102 Al-Si alloy was discussed. The results show that the ultrasonic treatment on the alloy during solidification can refine the structure, develop the morphology and distribution of eutectic silicon. The mechanical properties and fractographs of the alloy by treatments without ultrasonic, 300 W ultrasonic and 500 W ultrasonic treatment were also compared. The results indicate that the power ultrasonic treatment can enhance the tensile strength obviously, and the mechanical properties increase with increasing ultrasonic power. The reason of ultrasonic attenuation was analyzed and the law of ultrasonic attenuation into the melt was discussed by the mathematical method.

Key words: Al-Si eutectic alloy; power ultrasonic; solidification structure; mechanical property; attenuation

铸造铝合金是一种常用的铸造结构材料,其高比强度使其在汽车关键部件中有着广泛应用。但共晶成分的Al-Si合金中的共晶硅在凝固过程中容易产生组织粗大的缺陷,对力学性能的影响很大。事实上,共晶铝硅合金的铸造性能和耐磨性能均优于亚共晶铝硅合金的,但由于其力学性能较差使得其在工业上的应用不如亚共晶合金的广泛。因此,对共晶Al-Si合金进行细化处理和进行提高其性能的研究是非常必要的。

工业上通常采用变质处理来改善共晶铝硅合金的组织[1-4],然而加入到合金中的变质剂会改变合金的成分,造成合金“污染”,影响其回收利用性。超声处理细化金属凝固组织是一种绿色的凝固细晶技术,该研究始于20 世纪30 年代,并在进入21 世纪后有较大的发展[5]。但由于受变幅杆高温性能的限制,以往的研究主要集中在低熔点合金[6-8],对于较高熔点材料的研究甚少。本文作者采用具有自主知识产权的侧部导入超声波专利技术[9],研究了超声处理对共晶Al-Si合金凝固组织和力学性能的影响,并探讨了其衰减的规律。

1 实验

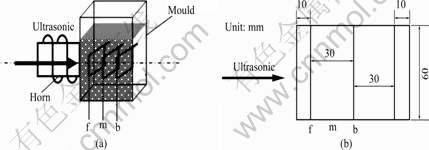

图1所示为实验装置和试样横截面示意图。在图1(a)中,利用电流通过线圈产生的电磁力,结合特殊设置的变幅杆与坩埚紧密接触,将超声波从侧部导入坩埚内的金属熔液中。与传统的超声波底部导入相比,侧部导入可以随着铸件性能的需求调整铸件处理的部位,达到最佳处理效果。实验合金为ZL102共晶铝硅合金,其化学成分列于表1。熔炼设备为SG-5-12型坩埚电阻炉。合金熔化后过热至750 ℃,经过除气处理后浇入尺寸为60 mm×80 mm×120 mm的金属模型。实验分3组,分别为不加超声处理(0 W)和经300 W及500 W超声处理,超声波处理阶段为共晶反应区,3组铸件凝固后空冷到室温。沿着超声波传播方向截取前、中、后3个区域的试样进行组织分析。其中,前试样距铸件壁10 mm,3片试样间的间距为30 mm(如图1(b)所示)。在相同部位切取标准的片状力学试样进行拉伸实验,力学实验在ZWICK-Z20万能材料实验机上进行,拉伸变形速度为0.5 mm/min。断口形貌在HITACHI S570型扫描电镜上观察。

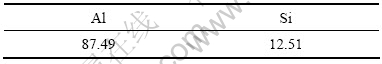

表1 近共晶Al-Si合金的化学成分

Table 1 Chemical composite of eutectic Al-Si alloy(mass fraction, %)

图1 实验装置(a)和横截面(b)示意图

Fig.1 Schematic diagram of experimental setup (a) and cross-section (b) (f: Front; m: Middle; b: Behind)

2 结果及分析

2.1 侧部导入超声波对共晶铝合金凝固组织的影响

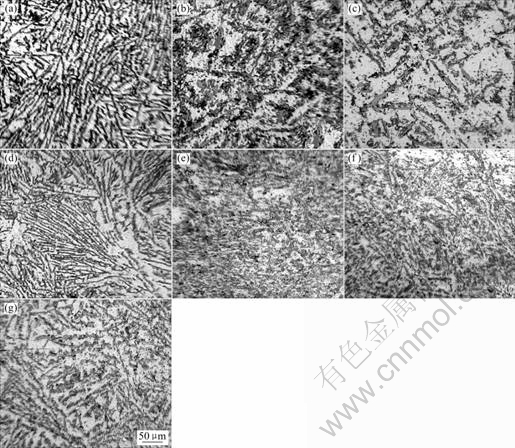

图2 所示为不同工艺下ZL102合金的凝固组织。由图2可看出,未处理组织中出现大量针片状共晶硅,这种组织会严重割裂合金基体,使合金变脆(图2(a))。将300 W处理的合金组织(图2(b), (c)和(d))与未处理的组织进行对比,可以看出经过300 W超声波处理后,在试样的前端(图2(b)),共晶硅形貌明显细化,基本变为颗粒状,残留的针状共晶硅变短且形状更为扭曲。图2(c)所示为试样的中部组织,部分共晶硅变成颗粒状,针状的共晶硅变短。和前端组织(图2(b))相比,这种短小的针状共晶硅较多。在试样的后端组织中(图2(d) ),基本没有颗粒状共晶硅,和未处理试样相比,共晶硅长度减小。由此可见,侧部导入300 W超声波传播到试样后端时强度很弱,对共晶硅的细化效果不明显。将超声波功率提高到500 W后,从图2(e), (f)和(g)可看出,共晶团簇很小,共晶硅均匀分布在整个试样中,显微组织上已经无法分辨出共晶硅的生长方向,共晶硅变为较细蠕虫状和弥散分布的颗粒,即使对后端试样,共晶体团簇细小,呈弥散颗粒化分布。因此,在本研究条件下,500 W超声波处理能够很好地细化共晶Al-Si合金。

2.2 侧部导入超声波对共晶铝合金力学性能的影响

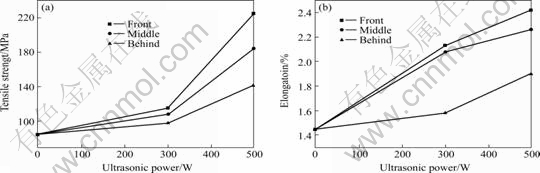

图3所示为超声波处理对合金抗拉强度和延伸率的影响。由图3可以看出,随着超声波功率的增加,合金的抗拉强度和延伸率明显提高,且不同部位的力学性能指标有相似的变化趋势,未处理的试样抗拉强度为185 MPa;经过300 W和500 W超声波处理后,对于前端试样,抗拉强度分别为218 MPa和232 MPa;相应的延伸率也从未处理的1.45%提高至300 W和500 W处理的2.26%和2.42%。在试样的中部和后端,由于超声波衰减,抗拉强度和延伸率的增长幅度都不同程度减小,但均超过未处理的试样;力学性能随超声波处理的进行而发生的变化可以从组织的改善中得到解释;经过超声波处理后,组织中的共晶硅形貌细小且均匀,这种组织状态决定了力学性能可以达到更高的指标。

图2 不同处理下ZL102合金显微组织

Fig.2 Microstructures of ZL102 alloy by different treatments: (a) 0 W; (b) 300 W, front; (c) 300 W, middle; (d) 300 W, behind; (e) 500 W, front; (f) 500 W, middle; (g) 500 W, behind

图 3 不同处理下合金的抗拉强度(a)和延伸率(b)

Fig.3 Tensile strength (a) and elongation (b) of alloy by different treatments

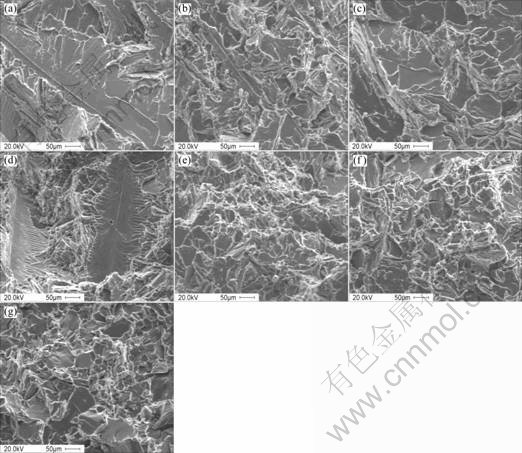

图4所示为不同处理条件下各个部位力学试样的断口形貌。由图4可看出,未经超声处理的共晶铝硅合金的断裂倾向于脆性断裂方式,解理初裂纹起源于晶界、亚晶界或相界面,有河流花样的特征(图4(a));经过300 W超声波处理后的断口形貌显示,前端试样断口形貌没有明显的河流花样,细小的解理面周围分布着韧窝,有从解理断裂向韧性断裂的趋势,断裂机制为准解理断裂(图4(b));中部试样的断口有明显的河流花样,属于典型的解理断裂(图4(c));而后端试样出现较大的解理面(图4(d));经500 W功率超声波处理后,前端试样断口有大量密集韧窝,断裂由显微空穴集聚产生,仅有很少量的小准解理面,已经有较好的韧性断裂特征,为韧-脆混合性断裂(图4(e));中部试样断口有少量的小解理面(图4(f));后端试样的断口出现许多小的解理面,混夹着韧窝,属于准解理断裂(图4(g))。

图4 不同处理合金的断口形貌

Fig.4 Fractographs of alloy by different treatments: (a) 0 W; (b) 300 W, front; (c) 300 W, middle; (d) 300 W, behind; (e) 500 W, front; (f) 500 W, middle; (g) 500 W, behind

3 讨论

3.1 超声波细化组织的机理

将功率超声波导入到液体介质中将会产生诸多的非线性效应,例如声流效应、空化效应、乳化作用和辐射声压场效应等 [10-14]。其中,空化效应和声流效应对金属凝固过程中起着重要的作用。当超声波在液态铝合金中传播时,局部熔体会产生交替的拉压力。当拉力足以克服液体分子间的结合力(液体强度)时,熔体微区将被拉断而形成空化泡。空化泡瞬间膨胀至原始尺寸的许多倍后在超声波的压力作用下破碎。熔体中经历着空化泡周期性闭合、长大和破碎过程。在空化气泡闭合和长大过程中,气泡会从其表面熔体中吸收大量的热量,造成表面熔体大而过冷。根据形核率公式[15]可知,当过冷度加大时,形核速率随着增大,因此在铝合金凝固初始阶段导入高能超声波后,由于空化效应而形成大量的初始核心。这些核心在声流的作用下均匀地分布在熔体中。当空化气泡崩溃时会在熔体内部微小区域形成强烈的冲击力。根据参考文献[16]中对铝合金的研究表明,半固态合金的切应力数值约为500 kPa,而根据计算得到空化气泡破碎瞬间局部压力能达到数千兆帕,因此这个压力足以破碎硬而脆的共晶硅相,而破碎相表面尖锐的棱角将冲刷成钝面,减少了在接触点的应力集中,提高了金属的力学性能。且随着超声波功率的增加,作用在熔体中的能量将加大,在铝合金中形成的空化效应和声流作用也更明显,增加超声波输入功率能细化组织和改善共晶硅形貌。

3.2 超声波在熔体中的衰减规律

超声波在熔体中传播时,其强度随着距离的增加而逐渐减弱。这时随着凝固过程的进行,铝合金液的粘度增大,空化阈也随之增大,与此同时,声流速度却随之迅速减小,熔体中的空化现象和声流的搅拌作用也随之减弱[17-18]。且由于硅颗粒的不断形成,对超声波的散射增强,衰减也增大。在试样的后端,仅在刚开始凝固时有一定的声流效应,且随着凝固的进行,超声波衰减加剧。因此,对于300 W超声波处理,在最终凝固组织中,试样前端共晶硅基本变成颗粒状,而后端共晶硅形貌依然为针状,或仅仅变短变圆。且不同部位试样的力学性能差异也非常明显。

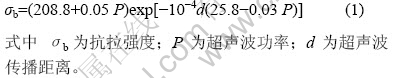

将图3(a)中不同功率下各个部位抗拉强度的值进行数学拟合,得到抗拉强度与超声波功率和传播位移的关系式:

由式(1)可以得到,在本研究条件下,对导入的超声波功率在500W以内,沿着超声波传播的方向,金属的抗拉强度与超声波功率满足线性关系,而与传播距离呈负指数关系。根据数学分布关系得知,随着超声波传播距离的增大,抗拉强度的值迅速减小。因此,超声波传播的有效距离是确定超声波作用效果的重要工艺参数。在实验过程中,根据拟合关系式可以计算出不同超声波功率下超声波传播的有效距离,从而确定最佳的超声波处理效果。

4 结论

1) 在共晶铝硅合金凝固过程中采用侧部导入方法进行功率超声处理能够明显细化共晶硅相形貌和分布。且随着超声波功率的增加,细化效果越明显。

2) 采用功率超声波处理共晶铝硅合金可以使抗拉强度和塑性同时得到提高,且随着处理功率的加大,力学性能的改善更加明显。

3) 相同功率超声波处理下,不同部位试样组织和力学性能有较大差异,说明功率超声波对合金的细化作用必须在有效作用区域内,越靠近超声波源,细化效果越佳。

REFERENCES

[1] 廖恒成, 夏锦宏, 孙国雄. Sr+B联合熔体处理对Al2Si2Mg合金组织和力学性能的影响 [J]. 中国有色金属学报, 2003, 13(1): 27-34.

LIAO Heng-cheng, XIA Jing-hong, SUN Guo-xiong. Influence of combined melt treatment of Sr+B on microstructure and mechanical properties of Al2Si2Mg casting alloy [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 27-34.

[2] 张静武, 李 慧, 刘春海. ZL101合金的变质 [J]. 中国有色金属学报, 2001, 11(S2): 91-94.

ZHANG Jing-wu, LI Hui, LIU Chun-hai. Modification of ZL101 alloy [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S2): 91-94.

[3] Kulnk B, Zulian D J. Applications for the strontium treatment of wrought and die-cast Al [J]. JOM, 1996, 48(10): 60-63.

[4] Chai G, Backrud L. Factors affecting modification of Al-Si alloys by adding Sr-containing master alloys [J]. AFS Trans, 1992, 100 (5) : 847-854.

[5] 范金辉, 翟启杰. 物理场对金属凝固组织的影响 [J]. 中国有色金属学报, 2002, 12(S1): 11-17.

FAN Jin-hui , ZHAI Qi-jie. Effect of physical fields on solidification structure of metals [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): 11-17.

[6] ZHANG Hai-bo, ZHAI Qi-jie. Effect of side transmission of power ultrasonic on structure of AZ81magnesium alloy [J]. Trans. Nonferrous Met Soc, 2004, 14(1): 28-32.

[7] ZHAI Qi-jie, QI Fei-peng. Microstructure refinement of Sn-Sb peritectic alloy under high-intensity ultrasound treatment [J]. Journal of Shanghai University, 2005, 9(1): 74-77.

[8] 高守雷, 戚飞鹏, 翟启杰. 超声场下熔体温度对SnSb合金凝固组织的影响 [J]. 特种铸造及有色合金, 2003, 3: 21-23.

GAO Shou-lei, QI Fei-peng, ZHAI Qi-jie. Effects of melt temperature on solidified structure of Sn-Sb peritectic alloy in ultrasonic field [J]. Special Casting & Nonferrous Alloys, 2003, 3: 21-23.

[9] 翟启杰,龚永勇,戚飞鹏. 改善金属凝固组织的功率超声导入 [P]. 中国ZL 03 1 41467.2, 2005-09-21.

ZHAI Qi-jie, GONG Yong-yong, QI Fei-peng. Power Ultrasonic Introduction to Improve Solidification Structure of Metals [P]. China ZL 03 1 41467.2, 2005-09-21.

[10] Jhang K Y, Kim K C. Evaluation of material degradation using nonlinear acoustic effect [J]. Ultrasonics, 1999, 37(1): 39-44.

[11] Dalecki D, Raeman C H, Child S Z, Carstensen E L. Effects of pulsed ultrasound on the frog heart: Ⅲ. the radiation force mechanism [J]. Ultrasound in Medicine and Biology, 1997, 23(3): 277-285.

[12] Chaparro J G, Mondragon L S, Flores A V. Application of an ultrasound technique to control the modification of Al-Si alloys [J]. Materials & Design, 1995, 16(3): 47-50.

[13] Lu Y, Riyanto N, Weavers L K. Sonolysis of synthetic sediment particles: particle characteristics affecting particle dissolution and size reduction [J]. Ultrasonics Sonochemistry, 2002, 9(1): 181-188.

[14] Cramer A, Eckert S, Galindo V, Gerbeth G , Willers B. Liquid metal model experiments on casting and solidification processes [J]. Journal of Materials Science, 2004, 39(3): 7285-7294.

[15] Davies G J. Solidification and Casting [M]. England: Great Yarmouth, 1973.

[16] 周尧和, 胡壮麒, 介万奇. 凝固技术 [M]. 北京: 机械工业出版社,1998.

ZHOU Yao-he, HU Zhuang-qi, JIE Wan-qi. Solidification Technique [M]. Beijing: China Machine Press, 1998.

[17] Eskin G I. Ultrasonic Treatment of Light Alloy Melts [M]. Amsterdam: Gordon and Breach, 1998.

[18] Li J, Momono T. Effect of ultrasonic output power on refining the crystal structures of ingot sand its experimental simulation [J]. Journal of Materials Science and Technology, 2005, 21(2): 47-52.

基金项目:国家自然科学基金资助项目(50374046; 50574056)

收稿日期:2006-06-05;修订日期:2006-10-08

通讯作者:翟启杰,教授;电话/传真:021-56331218; E-mail: qjzhai@mail.shu.edu.cn

(编辑 李艳红)