文章编号:1004-0609(2016)-09-1952-07

烧结温度对ZrC-Y2O3复合增强细晶钨组织与性能的影响

李鹏飞,范景莲,章 曼,陈卓华,田家敏,段 涛

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用湿化学法制备W-3%ZrC-0.3%Y2O3(质量分数)材料,研究该材料在1800~1920 ℃的烧结致密化行为,通过与W-3ZrC材料及纯钨材料烧结态力学性能和显微组织的对比研究,分析复合添加ZrC和Y2O3对钨材料强韧化的作用和意义。结果表明:W-ZrC-Y2O3材料的致密度和抗拉强度均呈现出随烧结温度升高先增加后降低的趋势,其相对密度和抗拉强度均在1860 ℃达到最大值,分别为97.8%、446 MPa;添加第二相粒子能有效细化钨材料的晶粒,Y2O3/ZrC复合添加较单一ZrC能更有效细化钨晶粒,晶粒由W-3ZrC的10 μm降低至5~8 μm。复合强化相粒子改变了断裂过程中裂纹扩展的形状和长度,起到强化和韧化作用。

关键字:第二相粒子;复合强化;晶粒细化;致密度

中图分类号:TG146.4 文献标志码:A

钨具有高熔点、高溅射阀值、低氚滞留、良好的耐热震性、低热膨胀系数、良好的高温性能等特性,是未来聚变堆中面向等离子体的关键材料[1]。然而传统商用纯钨存在组织粗大、组织呈纤维状取向、脆性大、强度低等问题,制约了钨在聚变材料领域的应用[2-3]。为了提升钨材料的性能,目前国内外研究学者研究了添加第二相粒子(碳化物或稀土氧化物)对钨材料的强化作用,其中YAR等[4]和BATTABYAL等[5]分别研究添加La2O3 和Y2O3对钨材料的影响,发现添加稀土氧化物可明显细化晶粒,其中W-2%Y2O3材料晶粒为1~2 μm,室温抗弯强度为1277 MPa;KURISHITA等[6-8]和朱玲旭等[9]采用热等静压+高温锻造制备出W-(0~1.5%)TiC(质量分数)材料,晶粒可细化至200 nm,致密度达到99%,抗弯强度为1.6~2.0 GPa,并提高了室温韧性;KIM等[10-11]和ZHANG等[12-13]采用放电等离子体烧结或热压方法制备了W-(10%-30)%ZrC(体积分数)复合材料,结果显示ZrC能与钨形成利于提高强度的(Zr,W)C相,其抗弯强度可达到1210 MPa左右,晶粒为3~6 μm,较纯钨的断裂韧性得到较大提高。以上国内外研究表明,添加稀土氧化物或碳化物作为第二相强化粒子,能够细化材料的晶粒,提高材料的韧性。同时,CHEN等[14]研究TiC和La2O3协同增强的钨材料,其强度和断裂韧性较单一添加稀土氧化物或碳化物得到了提高。

ZrC较TiC具有更高熔点(3420℃),并且与钨具有相近的热膨胀系数等优点;作者前期研究发现,Y2O3较La2O3能够更有效提高材料的力学性能与密 度[15]。因此,作者设计复合添加ZrC和Y2O3,以进一步提高钨材料的性能。本文作者采用溶胶-非均相沉淀+煅烧制备稀土Y2O3包覆ZrC的复合粉末,并采用球磨方式添加ZrC和Y2O3在钨基体中,利用模压成形和常压氢气气氛烧结对材料进行成形和烧结,研究了该材料在1800~1920 ℃烧结时的致密度变化行为、力学性能与组织形貌,并对比复合强化较单一添加碳化物对钨材料组织和性能的影响。

1 实验

实验用原材料为钨粉(粒度2~3 μm,纯度≥99.5%)、ZrC粉(粒度50 nm,纯度≥99%(质量分数))、Y(NO3)3·6H2O粉末(纯度≥99.5%(质量分数))、30%的NH4OH溶液。首先采用溶胶-非均相沉淀制备出Y2O3包覆ZrC的复合粉末,其过程为:采用去离子水配制出ZrC悬浊液和Y(NO3)3溶液,混合均匀后添加NH4OH,控制pH值,经非均相沉淀-煅烧制备Y2O3包覆ZrC的粉末;然后将Y2O3包覆ZrC的复合粉末和钨粉经高能球磨制备出W-3ZrC-0.3Y2O3复合粉末,同时,采用未包覆的ZrC粉末经同样的球磨工艺制备出W-3ZrC粉末;然后在350 MPa压力下压制成“工”字形拉伸样品,为了便于进行性能参数比较,同时压制出W-3ZrC样品和纯钨样品;最后将样品置于钨棒炉中烧结,烧结气氛为H2,升温速度3~5 ℃/min,烧结温度分别为1800、1860、1890和1920 ℃,保温时间3 h,制备出W-3ZrC-0.3Y2O3材料。

采用阿基米德排水法测量烧结后样品的密度,使用BS-210S型电子分析天枰(精确度1 mg)称取质量;依次采用180、240、400、800、1500、2000号金刚石砂纸对烧结后样品进行水磨,并采用金刚石粉对其表面抛光制成金相样,使用金相腐蚀剂(H2O2)进行表面腐蚀,腐蚀时间200 s,腐蚀结束后,在Leica MeF3A型金相显微镜上进行显微组织观察。采用Instron-3369型力学试验机上测试样品的拉伸强度;采用捷克 NOVA TM NanoSEM230型超高分辨率场发射扫描电镜观察样品断口形貌,并利用EDX能谱仪进行选区或定点成分分析。

2 结果与讨论

2.1 W-3ZrC-0.3Y2O3材料的致密化行为

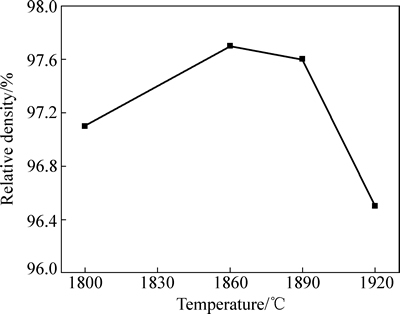

图1所示为W-3ZrC-0.3Y2O3材料的相对密度随烧结温度变化的曲线。由图1可看出,材料的相对密度随温度升高呈现先升高后降低的趋势,在1860 ℃附近达到最大值97.8%。钨、ZrC、Y2O3三相熔点均在3000 ℃以上,1920 ℃以下进行烧结时为三相均处于固相状态。根据固相烧结的致密化理论,材料密度提高的原因主要为孔隙在烧结过程中会在晶界处聚集长大,到一定程度时会由于塌陷而被钨原子取代,从而使得材料体内孔隙降低,相对密度增加。随着烧结温度升高,材料体内原子与孔隙的扩散能力得到增强,从更易于致密化过程发生,相对密度得到提高。然而,随着温度继续升高,钨晶界移动速率增大,当晶界移动速率大于气孔移动速率时,会把气孔包入晶粒内,生成含有封闭气孔的大晶粒。虽然温度升高材料的致密化速率得到提高,但是晶粒内的气孔难以排出坯体,从而造成烧结后材料相对密度的降低[16]。因此,W-3ZrC-0.3Y2O3材料在烧结时致密度呈现先升高后降低的趋势,并在1860 ℃达到最大值。

图1 不同烧结温度下W-3ZrC-0.3Y2O3材料的相对密度变化的曲线

Fig. 1 Change curves of density of W-3ZrC-0.3Y2O3 materials sintered at different temperatures

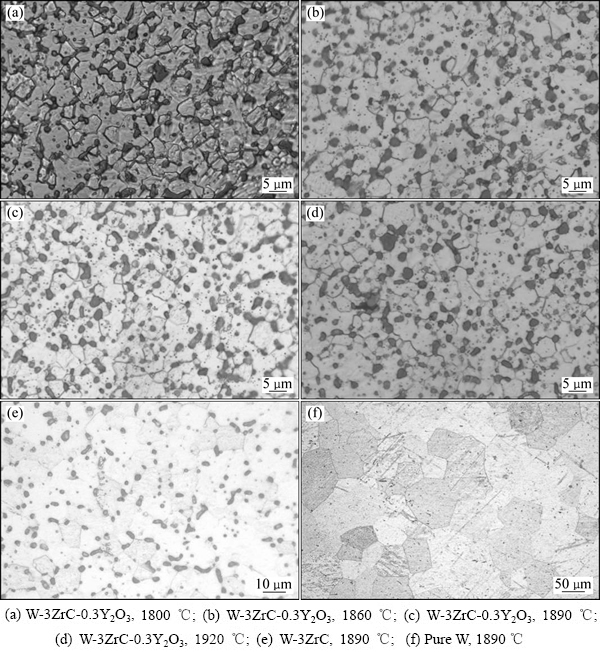

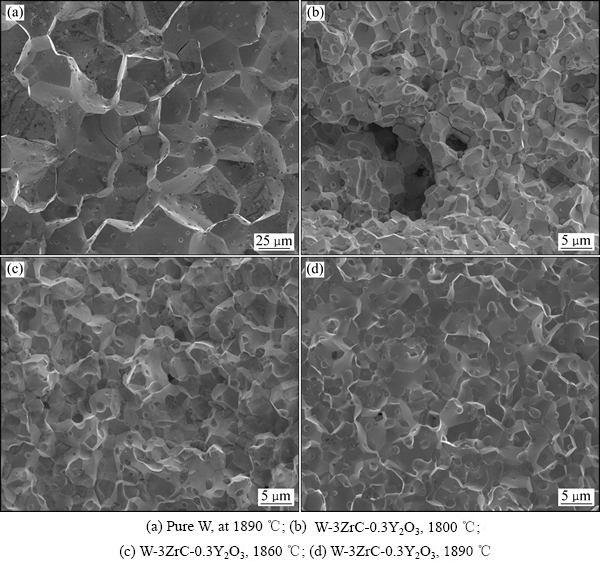

图2所示为W-3ZrC-0.3Y2O3、W-3ZrC和纯钨在不同烧结温度下的金相组织。由图2可看出,纯钨的晶粒基本在50~80 μm之间,添加ZrC后晶粒明显细化,晶粒为10 μm左右,进一步复合添加Y2O3晶粒,细化作用更加明显,W-3ZrC-0.3Y2O3材料的平均晶粒尺寸为5~8 μm。值得注意的是,材料中ZrC与Y2O3粒子相大部分分布在晶界上,只有少部分分布在晶粒内,而且第二相颗粒随温度升高有聚集长大的趋势。其原因是由于随着温度升高,原子扩散能力增加,晶粒界面更易互相吞并和推移以降低体系的界面能。

2.2 W-3ZrC-0.3Y2O3材料的力学性能

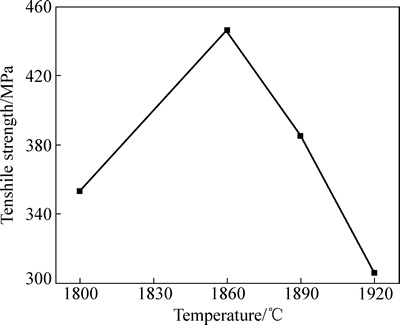

图3所示为W-3ZrC-0.3Y2O3材料的抗拉强度随烧结温度变化的曲线。由图3可看出,材料的抗拉强度随烧结温度升高呈现先升高后降低趋势,在1860 ℃烧结时,材料强度达到最大值446 MPa。根据钨材料的致密化行为,随烧结温度升高,首先表现出相对密度增加,材料中缺陷如孔隙等得到降低;然而烧结温度继续升高时,致密度出现降低,说明材料中孔隙的缺陷增加。结合材料金相组织,随温度升高,出现了第二相颗粒团聚的现象,ZrC化学性质稳定,较钨在高温下更难发生塑性变形和物质迁移,因此,在ZrC团聚区域中容易出现孔洞等缺陷,容易在应力作用下成为裂纹源,导致材料性能降低。因此,W-3ZrC-0.3Y2O3材料存在最佳烧结温度,这也是其在1860 ℃时出现较大抗拉强度的原因。

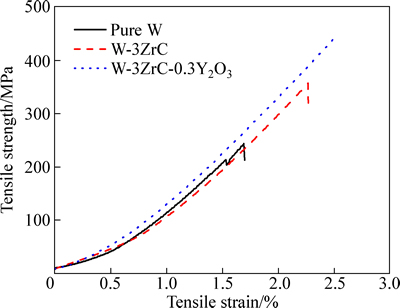

图4所示为在1860 ℃烧结时纯钨、W-3ZrC和W-3ZrC-0.3Y2O3材料的应力-应变曲线。由图4可看出,添加ZrC后,W-3ZrC材料的强度和应变较纯钨得到较大的提升,进一步添加Y2O3第二相粒子,其强度得到进一步的提高,W-3ZrC-0.3Y2O3材料强度和应变由纯钨的246 MPa、1.6%增大至W-3ZrC-0.3Y2O3材料的446 MPa、2.4%,得到较大的提高。钨为体心立方晶体结构,在变形过程中的滑移系统较面心立方少,其在室温下一般沿着(100)面进行解理,呈现脆性的断裂。添加ZrC后,材料的晶粒得到明显细化,致密度也较纯钨得到提升,同时在断裂过程中当裂纹遇到第二相粒子时,会避开粒子而偏转,在粒子间走“之”字;裂纹的形状和长度发生改变,新的断裂表面形成都会消耗变形中的能量,从而提高了材料的韧性[17]。进一步同时添加ZrC和Y2O3后,晶粒细化效果更加明显,使得材料的拉伸强度和韧性得到进一步的提高。

图2 W-3ZrC-0.3Y2O3材料、W-3ZrC、纯钨不同温度下的金相照片

Fig. 2 Optical microstructures of W-3ZrC-0.3Y2O3, W-3ZrC and pure W materials at different temperatures

图3 烧结温度对W-3ZrC-0.3Y2O3材料抗拉强度的影响

Fig. 3 Effect of sintering temperature on tensile strength of W-3ZrC-0.3Y2O3 materials

图4 纯钨、W-3ZrC和W-3ZrC-0.3Y2O3材料的应力-应变曲线

Fig. 4 Stress-strain curves of pure W, W-3ZrC and W-3ZrC-0.3Y2O3 materials

2.3 W-3ZrC-0.3Y2O3材料的断口形貌

图5所示为W-3ZrC-0.3Y2O3材料在不同温度下拉伸断口的形貌。由图5可看出,在1800 ℃烧结时,样品的拉伸断口存在较多的孔隙,断口为典型脆性解理断裂;在1860 ℃和1890 ℃烧结时样品断口的孔隙明显减少,样品拉伸强度得到一定的提高,样品断口依然为冰糖状沿晶解理断裂形貌,但存在少量穿晶断裂,该形貌特征与不同温度下烧结时材料的密度、强度相符合。对比纯钨样品在1890 ℃下烧结样品拉伸的断口形貌,添加ZrC、Y2O3后由纯钨晶粒的50~80 μm细化至5 μm左右,说明钨晶界遇到ZrC与Y2O3第二相粒子时不易挣脱质点的障碍向前移动,使得钨材料晶粒得到了有效的细化。

图5 纯钨和W-3ZrC-0.3Y2O3材料在不同温度下的断口形貌

Fig. 5 Tensile fracture morphologies of pure W and W-3ZrC-0.3Y2O3 materials at different temperatures

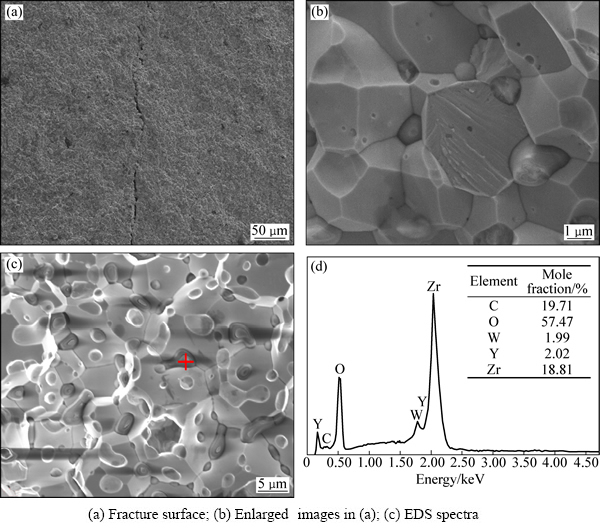

图6 W-3ZrC-0.3Y2O3材料在1860 ℃烧结样品的断口形貌和EDX分析

Fig. 6 Tensile fracture morphologies and EDX analysis of W-3ZrC-0.3Y2O3 materials at 1860 ℃

值得注意的是,在W-3ZrC-0.3Y2O3材料拉伸失效时能清晰地观察到材料中裂纹,如图6所示为材料中的扩展裂纹和第二相粒子的EDX能谱分析。钨在室温下为脆性断裂,在宏观上裂纹基本表现为直线扩展,但仔细观察后裂纹扩展过程中存在裂纹偏转现象,这说明了裂纹遇到第二相粒子发生偏转从而提高材料在断裂过程中的韧性[12];进一步放大材料的组织,发现第二相粒子紧紧附着钨颗粒,晶粒的完整度较高,颗粒与颗粒间、碳化物与颗粒间的结合非常紧密,并且部分钨晶粒存在明显的河流状解理台阶(见图6(b)),说明第二相粒子一定程度的增强了晶界的强度,提升了材料的强度。通过对第二相粒子进行EDX能谱分析发现,第二相粒子中含有W、Zr、Y、C、O,说明ZrC与Y2O3复合添加形成了部分的ZrC与Y2O3的复合第二相粒子。

3 结论

1) W-3ZrC-0.3Y2O3材料随烧结温度升高致密度、强度均呈现先升高后降低的趋势,是由于随烧结温度升高,晶界移动速度逐渐超过孔隙排出速度,导致晶粒中包含孔隙而成为缺陷源,弱化了材料的性能。

2) 复合添加ZrC和0.3Y2O3能够较单一碳化物更有效的细化材料的晶粒,由W-3ZrC晶粒的10 μm降低至W-3ZrC-0.3Y2O3晶粒的5~8 μm,对钨材料起到了进一步的细晶强化和韧化作用。

3) ZrC和Y2O3作为强化第二相,能够改变断裂过程中裂纹扩展的形状和长度,一定程度上对材料起到韧化效果。

REFERENCES

[1] 王 钦, 杨发展, 朱海龙, 练友运, 李宗秦, 刘 翔, 童洪辉, 沈丽如. W/CuCrZr合金热等静压焊接[J]. 中国有色金属学报, 2015, 25(2): 360-366.

WANG Qin, YANG Fa-zhan, ZHU Hai-long, LIAN You-yun, LI Zong-qin, LIU Xiang, TONG Hong-hui, SHEN Li-ru. Hot isostatic pressing joining of W/CuCrZr alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 360-366.

[2] WURSTER S, BALUC N, BATTABYAL M, CROSBY T, et al. Recent progress in R&D on tungsten alloys for divertor structural and plasma facing materials[J]. Journal of Nuclear Materials, 2013, 442(1/3): S181-S189.

[3] 王玉金, 宋桂明, 周 玉, 雷廷权. 合金元素及第二相对钨的影响[J]. 宇航材料工艺, 1998, 5(1): 11-17.

WANG Yu-jin, SONG Gui-ming, ZHOU Yu, LEI Ting-quan. Influence of alloying elements and secondary dispersiods on tungsten alloy[J]. Aerospace Materials & Technology, 1998, 5(1): 11-17.

[4] YAR M A, WAHLBERG S, BERGQVIST H, SALEM H G., JOHNSSON M, MUHAMMED M. Chemically produced nanostructured ODS-lanthanum oxide-tungsten composites sintered by spark plasma[J]. Journal of Nuclear Materials, 2011, 408: 129-135.

[5] BATTABYAL M, SCHAUBLIN R, SPATIG P, BALUC N. W-2wt%Y2O3 Composite: Microstructure and mechanical properties[J]. Materials Science and Engineering A, 2012, 538: 53-57.

[6] KURISHITA H, AMANO Y, KOBAYASHI S, NAKAI K, ARAKAWA H, HIRAOKA Y, TAKIDA T, TAKEBE K, MATSUI H. Development of ultra-fine grained W-TiC and their mechanical properties for fusion applications[J]. Journal of Nuclear Materials, 2007, 367/370: 1453-1457.

[7] KURISHITA H, MATSUO S, ARAKAWA H, NARUI M, YAMAZAKI M, SAKAMOTO T, KOBAYASHI S, NAKAI K, TAKIDA T, TAKEBE K, KAWAI M, YOSHIDA N. High temperature tensile properties and their application to toughness enhancement in ultra-fine grained W-(0-1.5)wt% TiC[J]. Journal of Nuclear Materials, 2009, 386/388: 579-582.

[8] KURISHITA H, MATSUO S, ARAKAWA H, SAKAMOTO T, KOBAYASHI S, NAKAI K, TAKIDA T, KATO M, KAWAI M, YOSHIDA N. Development of re-crystallized W-1.1%TiC with enhanced room-temperature ductility and radiation performance[J]. Journal of Nuclear Materials, 2010, 398: 87-92.

[9] 朱玲旭, 燕青芝, 郎少庭, 徐 磊, 葛昌纯. 钨基面向等离子体材料的研究进展[J]. 中国有色金属学报, 2012, 22(12): 3522-3528.

ZHU Ling-xu, YAN Qing-zhi, LANG Shao-ting, XU Lei, Ge Chang-chun. Research progress of tungsten-base materials as plasma facing materials[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3522-3528.

[10] KIM J H, SEO M, KANG S. Effect of carbide particle size on the properties of W-ZrC composites[J]. Journal of Refractory Metals and Hard Materials, 2012, 35: 49-54.

[11] KIM J H, PARK C, LIM J, KANG S. Microstructures and properties of ultrafine grained W-ZrC composites[J]. Alloys Compd, 2015, 623: 282-289.

[12] ZHANG T Q, WANG Y J, ZHOU Y, SONG G M. Effect of heat treatment on microstructure and mechanical properties of ZrC particles reinforced tungsten-matrix composites[J]. Materials Science and Engineering A, 2009, 512: 19-25.

[13] ZHANG T Q, WANG Y J, ZHOU Y, SONG G M. Effect of ZrC particle size on microstructure and room temperature mechanical properties of ZrCp/W composites[J]. Materials Science and Engineering A, 2010, 527: 4021-4027.

[14] CHEN Y, WU Y C, YU F W, CHEN J L. Microstructure and mechanical properties of tungsten composites co-strengthened by dispersed TiC and La2O3 particles[J]. International Journal of Refractory Metals and Hard Materials, 2008, 26: 525-529.

[15] FAN J L, HAN Y, LI P F, SUN Z Y, ZHOU Q. Micro/nano composited tungsten material and its high thermal loading behavior[J]. Journal of Nuclear Materials, 2014, 455: 717-723.

[16] 赖和怡. 烧结与扩散[J]. 稀有金属合金加工, 1978(2): 1-22.

LAI He-yi. Sintering and diffusion[J]. The Processing Rare Metal Alloy, 1978(2): 1-22.

[17] 黄培云. 粉末冶金原理[M]. 北京: 机械工业出版社, 2008: 442.

HUANG Pei-yun. The principle of powder metallurgy[M]. Beijing: China Machine Press, 2008: 442.

Effect of sintering temperature on properties and microstructure of tungsten composites reinforced by ZrC-Y2O3 particles

LI Peng-fei, FAN Jing-lian, ZHANG Man, CHEN Zhao-hua, TIAN Jia-min, DUAN Tao

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The composite materials of W-3%ZrC-0.3%Y2O3 (mass fraction) were prepared by wet chemical methods. The densification behavior was studied when the composite materials was sintered at 1800-1920 ℃. By comparing with mechanical properties and microstructure of W-3ZrC materials and pure tungsten material, the function and meaning of compounding adding ZrC and Y2O3 were researched. The results show that the relative density and intensity increase at first, and then decrease with increasing sintering temperature. And the relative density and tensile strength reach 97.8% and 446 MPa, respectively, when sintered at 1860 ℃. The second phase particles can effectively refine the grain size of tungsten material, and the composite adding Y2O3/ZrC is more effective. The grain decreases from 10 μm of W-3ZrC to 5-8 μm of W-3ZrC-0.3Y2O3. The composite strengthening phase particles can change the shape and length of crack propagation, which proves that ZrC and Y2O3 are helpful to improve the strength and toughness of composites.

Key words: second phase particles; composite reinforcement; grain refinement; density

Foundation item: Project(2014GB115000) supported by National Magnetic Confinement Fusion Program; Project (20130162130002) supported by Research Fund for the Doctoral Program of Higher Education of China

Received date: 2015-09-08; Accepted date: 2016-06-17

Corresponding author: FAN Jing-lian; Tel: +86-731-88836652; E-mail: fjl@csu.edu.cn

(编辑 李艳红)

基金项目:国际热核聚变实验堆(ITER)计划专项(2014GB115000);高等学校博士点专项科研基金资助项目(20130162130002)

收稿日期:2015-09-08;修订日期:2016-06-17

通信作者:范景莲,教授,博士;电话:0731-88836652;E-mail:fjl@csu.edu.cn