DOI: 10.11817/j.issn.1672-7207.2017.11.005

基于有限元分析的中间坯温度预报策略

彭文,陈树宗,马更生,张殿华

(东北大学 轧制技术及连轧自动化国家重点实验室,辽宁 沈阳,110004)

摘要:在辊道运输过程中,中间坯上、下表面的换热边界条件不同,使表面温降过程存在差异,影响到精轧入口温度的预报,对厚度设定模型的精度也会产生影响。为提高模型精度,采用有限元法对传热过程进行系统分析,基于分析获得轧件辊道停留时间、粗轧出口温度及轧件厚度对表面温度的影响规律,进一步通过拟合得到轧件到达精轧入口时表面温度,并对轧件平均温度预报模型进行优化。研究结果表明:优化模型的预测精度能够有效满足实际控制要求。

关键词:热连轧;有限元分析;对流换热;温度预报

中图分类号:TG333.5 文献标志码:A 文章编号:1672-7207(2017)11-2873-08

Temperature prediction strategy of intermediate slabs based on finite element method

PENG Wen, CHEN Shuzong, MA Gengsheng, ZHANG Dianhua

(State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110004, China)

Abstract: During the transport process, the heat transfer boundary conditions between the upper and lower surfaces of the intermediate slab are different, so there exist certain differences in the surface temperature drop process, and the prediction of the finishing entrance temperature will be influenced, as well as the set-up model precision. In order to enhance the model precision, the heat transfer process was analyzed systematically by the finite element method, and on the basis of the analysis, the impact of residence time, initial temperature and the strip thickness on the surface temperature were obtained. The mathematical description of the surface temperature were obtained by fitting, and the average temperature prediction model was optimized. The results show that the predicted precision of the optimized model can meet the actual control requirements effectively.

Key words: hot strip rolling; finite element method; convection; temperature prediction

在热带轧制过程中,温度是极为重要的工艺参数,准确预报轧制过程中厚度方向的温度分布是实现热连轧过程控制的重要前提[1]。精轧入口温度作为精轧设定模型的重要参数,其预报精度直接影响到轧制力能参数的预报精度,对成品厚度控制精度起着决定性的作用。在轧件由粗轧与精轧入口之间的辊道运输过程中会产生氧化铁皮,直接影响到精轧入口测温仪对轧件表面温度的测量精度;使用热电偶测量运行中的轧件温度也难以实现[2];由于运输辊道的影响,轧件上、下表面的换热边界条件存在差异,导致上、下表面温降存在差异,因此,宋勇等[3]提出的在实际生产过程中使用上表面温度计算平均温度的方法存在一定的误差。有限元仿真是轧制过程温度场分析的有效手段,DING等[4-5]分析了不同轧制条件轧件在变形区轧制过程中温度的分布情况,提出了一种有效的温度预报策略;王晓晨等[6-7]建立了三维有限元模型,分析了热卷箱中轧件头尾及边部的温度分布情况;张大志等[8]建立带钢温降二维有限差分方程模型,得到了层流冷却过程中带钢温度变化和温度场分布;MATS等[9-10]在分析传热和边界条件方程的基础上,提出并建立了成品卷冷却过程数学模型,分析了不同参数对瞬态热分布的影响规律;在诸多的分析过程中,通常将轧件作为上、下表面对称单元分析,忽略了由于运输辊道造成的轧件上、下表面换热差异性。本文作者针对轧件在运输辊道上的换热问题,在对轧件上、下表面换热边界条件进行分析的基础上,通过热力学分析轧件厚度方向上的温度分布情况,并进一步得到轧件温度分布与运输时间、初始温度和轧件厚度之间的关系,最终通过拟合得到轧件表面温度的变化规律及轧件平均温度计算公式,实现精轧入口平均温度的准确预报,对于提高精轧入口的温度预报精度具有非常重要的 意义。

1 传热模型

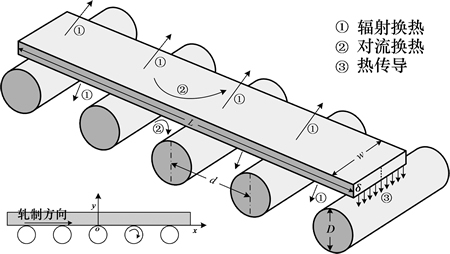

轧件在中间运输辊道的冷却过程中,边界条件为与环境的辐射换热、与空气的对流换热以及与辊道的接触传热3种,换热主要以瞬态方式进行,图1所示为轧件运输过程换热方式示意图。轧件温度场非稳态导热方程为

图1 轧件运输过程换热方式示意图

Fig. 1 Schematic diagram of heater transfer modes during transferring process of rolled piece

式中: 为轧件的温度,K;

为轧件的温度,K; 为轧件的密度,kg/m3;c为轧件的比热容,kJ/(kg·K);kx,ky和kz为轧件导热系数,W/(m·K)。

为轧件的密度,kg/m3;c为轧件的比热容,kJ/(kg·K);kx,ky和kz为轧件导热系数,W/(m·K)。

1.1 轧件与环境的辐射换热模型

辐射是物体本身产生的电磁波传递能量的现象,任何物体在不断地向外辐射能量的同时不断吸收外界辐射的能量[11-12]。在轧件的运输过程中,轧件不断散出热量导致轧件温度降低。轧件与环境之间的热辐射换热系数hr可根据斯蒂芬-玻尔兹曼定律和牛顿定律推出

(1)

(1)

式中: 为热辐射率;

为热辐射率; 为玻尔兹曼常数,

为玻尔兹曼常数, = 5.67×10-8 W/(m2·K4);

= 5.67×10-8 W/(m2·K4); 为轧件温度;

为轧件温度; 为环境温度。

为环境温度。

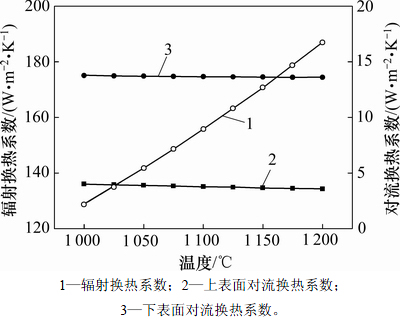

图2所示为中间坯厚度为30 mm,轧件速度为3.0 m/s的条件下,不同温度下轧件的辐射换热系数随温度的变化情况。由图2可知:随着轧件温度的升高,辐射换热系数显著升高。

图2 轧件辐射和对流换热曲线

Fig. 2 Curves of radiation and convective coefficient of rolled piece

1.2 轧件与空气的对流换热模型

对流是指冷、热流体相互掺混所引起的热量传递过程。以轧件作为参照物,可认为空气以一定的速度掠过轧件表面时发生对流换热。对流换热不仅取决于流体的物性(导热系数、比热容、黏度和密度等)以及换热表面的形状、面积与布置,还与流速密切相关。受辊道运输辊的影响,空气在轧件上、下表面的运动形态是不一样的。对流换热系数可以根据表征流态的雷诺数确定,当雷诺数Re<50 000时,空气与轧件的流动边界层为层流流动,当雷诺数Re≥50 000时,空气与轧件的流动边界层为紊流流动,由文献[13]可知,平均对流换热系数hc与雷诺数Re存在以下关系:

(2)

(2)

式中: 为空气的热导率,W/(m·K);x为特征长度,m,对于轧件上表面,特征长度为中间坯的长度,对于轧件下表面,特征长度为相邻辊道辊之间的距离;Rec为临界雷诺数,Rec=5×105;Rex是以x为特征长度的雷诺数,

为空气的热导率,W/(m·K);x为特征长度,m,对于轧件上表面,特征长度为中间坯的长度,对于轧件下表面,特征长度为相邻辊道辊之间的距离;Rec为临界雷诺数,Rec=5×105;Rex是以x为特征长度的雷诺数, ,

, 为流体速度,

为流体速度, 为运动黏度;Pr称为普朗特数,

为运动黏度;Pr称为普朗特数, ,a为热扩散系数。

,a为热扩散系数。

由图2可知:由于受辊道运输辊的影响,轧件下表面流动边界层为层流流动,上表面为紊流流动,因此,下表面的换热系数较大。同时,上、下表面的对流换热系数随温度升高基本不发生变化,而辐射换热系数逐渐变大,因此,对流换热占总换热比例逐渐减小,只占总换热的5%~7%。

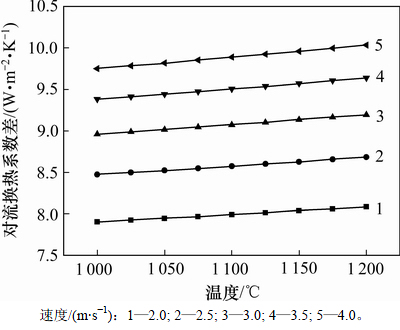

图3所示为厚度为3.00 mm的轧件在不同运行速度下轧件上、下表面的对流换热系数差。由图3可以看出:随着轧件运行速度增大和轧件温度的升高,上、下表面的对流换热系数差有升高的趋势。

图3 表面对流换热系数差

Fig. 3 Difference of convective coefficient between surfaces

1.3 轧件与运输辊道接触导热模型

轧件在输出辊道上运行时,由于轧件和输送辊材质相近,两者之间的总变形可认为是2个圆柱体侧面互相压缩时所产生的变形,轧件与输送辊接触弧长larc近似[14]为

(3)

(3)

式中:D为辊道辊直径,m; 为轧件密度,kg/m3;d为辊间距,m;

为轧件密度,kg/m3;d为辊间距,m; 为轧件厚度,m;g为重力加速度;

为轧件厚度,m;g为重力加速度; 为泊松比;E为弹性模量,N/m2。

为泊松比;E为弹性模量,N/m2。

根据接触弧长larc和输送速度v即可求得轧件与输送辊接触时间t,因此,轧件与运输辊道之间的接触传热系数hR为

(4)

(4)

式中: 为轧件导热系数,W/(m·K);

为轧件导热系数,W/(m·K); 为轧件热扩散系数,

为轧件热扩散系数, ,m2/s。

,m2/s。

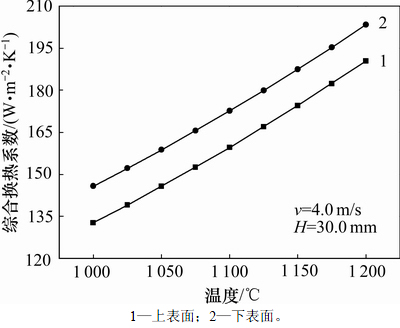

考虑轧件下表面与辊道之间的热传导,根据轧件与辊道和外界环境的接触时间比例,可以求得上、下表面的综合换热系数,如图4所示,H为轧件厚度。由图4可以看出:轧件上、下表面的综合等效换热系数与轧件辐射换热系数随温度的变化趋势基本一致,其差异主要来源于下表面的对流和热传导换热。

图4 轧件综合换热系数曲线

Fig. 4 Curves of comprehensive heat transfer coefficient of rolled piece

2 有限元模拟

在热连轧的生产过程中,中间坯的厚度一般为30~55 mm,根据轧件厚度的不同,中间坯在中间辊道的运输速度一般为2.0~4.0 m/s,中间坯在中间辊道的运行时间一般为20~50 s。

本文作者使用ANSYS有限元分析软件进行分析,选取宽度为1 000 mm,厚度为30~55 mm的中间坯作为分析对象,建模时单元类型选取实体单元“Solid70”,且在其表面覆盖“Shen152”表面效果单元,以便加载辐射边界条件。划分网格时最小网格长度为5.0 mm。以带钢与单根辊道辊的接触时间作为时间步长,周期性加载带钢上、下表面不同的传热条件。另外,为便于分析,假设轧件到达粗轧出口初始时中间坯在进入中间辊道时沿宽度和厚度方向上的温度均匀分布,另外轧件在运输过程中,上、下表面的氧化铁皮对辐射温降的影响效果等效转化为轧件黑度随时间的变化。模拟过程中材料基本属性如表1所示。

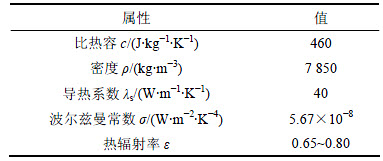

表1 模拟使用的材料的属性

Table 1 Material properties used in simulation

3 分析与讨论

分别从停留时间、粗轧出口初始温度以及中间坯厚度3个方面来对轧件宽度中心位置厚度方向温度变化进行分析和讨论。虽然中间坯在中间辊道的运行时间一般为20~50 s,但为获得各因素对上、下表面温度产生的影响规律,模拟计算周期取100 s。

3.1 停留时间对上、下表面温度的影响

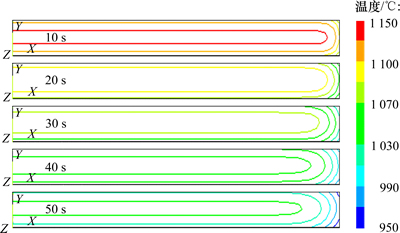

为分析轧件在中间辊道的停留时间对上、下表面中心位置温度的影响规律,模拟条件取轧件厚度为30 mm,运行速度3.0 m/s,初始温度为1 150 ℃,轧件宽度方向1/2断面温度分布如图5所示。

图5 轧件宽度方向1/2断面温度分布

Fig. 5 Temperature distribution of fracture surface (1/2) in width direction of rolled piece

由图5可以看出:轧件在中间辊道运输过程中,随着暴露在空气中的时间逐渐增长,中间坯的上、下表面温度均逐渐降低,而下表面的温降更快;当暴露时间为10 s时,轧件上表面的温度为1 092 ℃左右,而此时的轧件下表面的温度为1 075 ℃;当暴露时间为50 s时,轧件上表面的温度为970 ℃左右,而此时的轧件下表面的温度为955 ℃左右;轧件宽度最外侧由于底面和侧面同时冷却,温降更快,边部温度显著低于表面中心位置的温度。

3.2 初始温度对上、下表面温度的影响

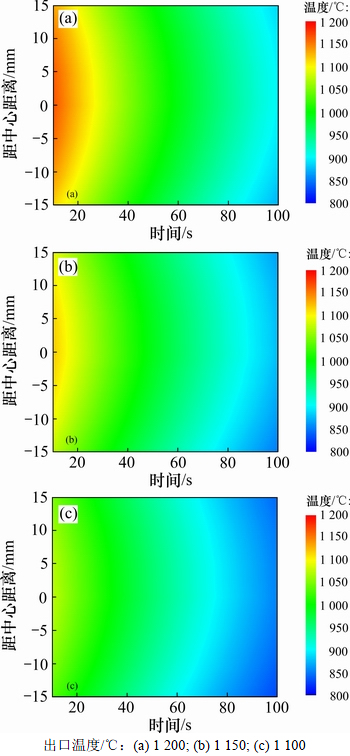

为分析轧件上、下表面温度随粗轧出口温度的变化情况,模拟条件为轧件厚度为30 mm,运行速度为3.0 m/s时,粗轧后出口温度分别取1 100~1 200 ℃,取轧件宽度中心位置厚度方向(定义上表面为正方向,下表面为负方向)为观察方向。轧件在100 s内厚度方向上的温度变化情况如图6所示。

图6 初始温度对厚度方向温度分布的影响

Fig. 6 Effect of initial temperature on temperature distribution in thickness direction

由图6可以看出:随时间的增长,轧件上、下侧的温度呈不对称分布,下表面的温度低于上表面的温度,说明下表面的温降较快。

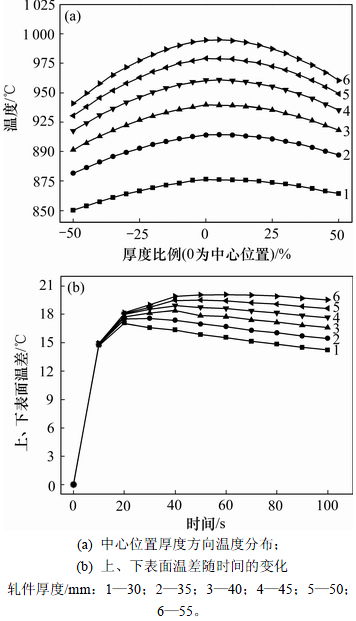

图7(a)所示为轧件在运行100 s时沿中心位置厚度方向温度的分布情况,由图7(a)可以看出:轧件的中心位置至上、下表面温度呈明显的非对称分布。图7(b)所示为上、下表面温差随时间的变化情况。由图7(b)可知:初始时刻轧件上、下表面温度为初始温度,差值为0 ℃。随着时间的增长,下表面温降快,随着温度的降低,上表面辐射温降大于下表面的温降,导致上、下表面的温度差幅度变小,呈现先大后小的趋势,在20 s到达最大值17.8 ℃。

图7 不同时刻下的轧件表面温度分布

Fig. 7 Surface temperature distribution of rolled piece with different time

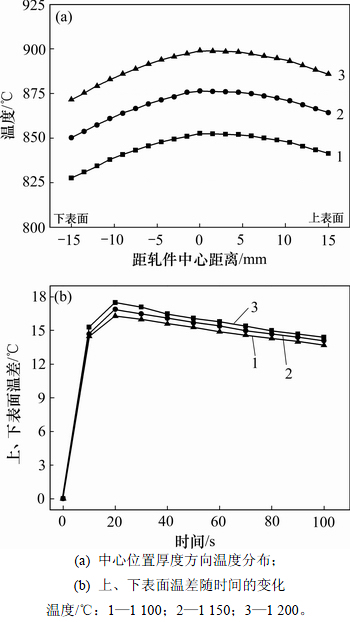

3.3 中间坯厚度对上、下表面温度的影响

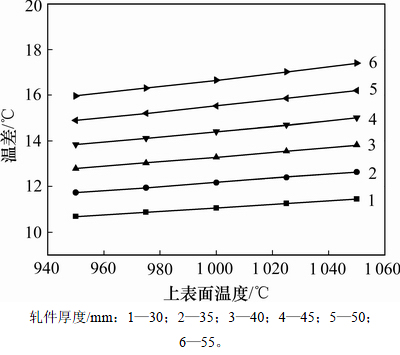

为分析轧件上、下表面温度随轧件厚度的变化规律,模拟条件轧件厚度为30,35,40,45,50和55 mm,运行速度为3.0 m/s,粗轧后出口温度为1 150 ℃,取轧件宽度中心位置厚度方向为观察方向,观察轧件在100 s内,此厚度方向上的温度变化情况,如图8所示。

图8 不同厚度下的轧件表面温度差

Fig. 8 Surface temperature deviation of rolled piece with different thickness

由图8(a)可以看出:轧件的中心位置至上、下表面温度呈明显的非对称抛物线分布。由图8(b)可以看出:初始时刻轧件上、下表面温度为初始温度,差值为0 ℃;随着时间的增长,上、下表面温差呈先上升后平稳的变化趋势,与图7(b)所示结果一致;随着轧件厚度的增加,轧件内部温度逐渐向上、下表面进行热传导导致辐射维持在较高水平,上、下表面温差逐渐趋于平稳;当轧件厚度为55 mm时,上、下表面的温差达20 ℃左右。

3.4 表面温度预报模型

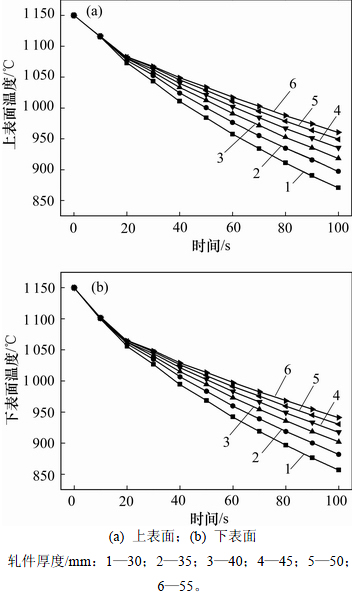

图9所示为当粗轧出口温度初始温度1 150 ℃时,不同厚度下的轧件上、下表面温度的变化情况。

精轧入口轧件表面温度 与粗轧出口表面温度

与粗轧出口表面温度 、厚度h、运行时间t满足下列关系:

、厚度h、运行时间t满足下列关系:

图9 轧件上、下表面温度变化趋势

Fig. 9 Changing trends of surface temperature of rolled piece

(5)

(5)

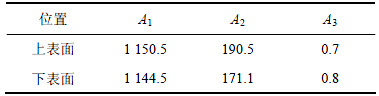

式中:A1~A3为拟合系数。

使用麦夸特法(Levenberg-Marquardt)和全局优化法拟合出各参数[15-16],如表2所示。

表2 表面温度函数拟合系数

Table 2 Fitting coefficient of surface temperature

3.5 平均温度预报模型

在模型设定计算过程中使用轧件平均温度进行计算。在带钢厚度方向,温度从中心到表面呈抛物线状分布,平均温度 和表面温度

和表面温度 满足

满足

(6)

(6)

式中:ri为轧件内部热阻,(m2·s·K)/kJ, ;rs为轧件表面热阻,(m2·s·K)/kJ,

;rs为轧件表面热阻,(m2·s·K)/kJ,

,

, 为上表面温度,

为上表面温度, 为下表面温度;

为下表面温度; 为修正系数。

为修正系数。

传统计算模型认为轧件上、下表面温度相同,即满足 ,在考虑上、下表面存在温差的情况下,使用式(6)计算平均温度,2种方法计算所得结果之间的差值如图10所示。

,在考虑上、下表面存在温差的情况下,使用式(6)计算平均温度,2种方法计算所得结果之间的差值如图10所示。

图10 2种模型的温度预报结果比较

Fig. 10 Comparison of two models of temperature prediction

由图10可以看出:在精轧入口温度为950~1 050 ℃,厚度为30~55 mm内,由于改进模型考虑了轧件低温下表面的影响,平均温度计算结果较传统方式的计算结果低10 ℃以上;两者的平均温度差随着轧件入口温度的升高和轧件厚度增大呈增长趋势。

4 现场实际应用

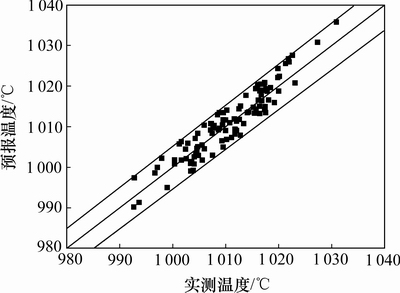

本文作者提出的精轧入口温度和平均温度预报模型已成功应用在某1 580 mm 7机架热连轧机组的过程控制系统中。通过对比温度模型预测值与实测值,从表面温度和平均温度2方面验证模型有效性。

4.1 表面温度预测模型验证

精轧入口上表面的温度由精轧入口测温仪测得,下表面温度采用手持式测温枪测得。使用式(5)得到的轧件在精轧入口表面温度与实际精轧入口表面温度如图11所示。

图11 轧件表面温度变化趋势

Fig. 11 Changing trends of surface temperature of rolled piece

由图11可以看出:使用拟合公式计算得到的轧件表面温度与实际的轧件上表面温度误差为±5 ℃,证明了预报模型的有效性,因此,使用拟合结果进行轧件上、下表面的温度计算是可行的。当轧件上表面测量环境较差或入口测温仪故障时,能够完成温度的准确预报过程,保证了轧制过程的稳定性。

4.2 平均温度预测模型验证

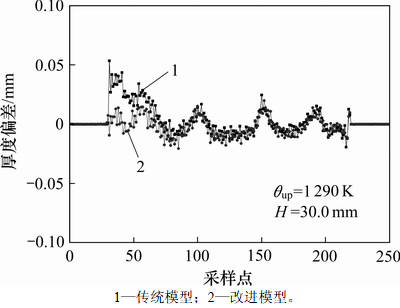

为验证模型的温度预报精度,选取稳定轧制过程中相邻的2块带钢,分别使用传统计算模型(上、下表面温度相等)和本文提出的温度预报改进模型(上、下表面温度分别预报)进行精轧入口平均温度预报,不考虑模型自学习对学习系数的修正,设定计算得到2个轧制规程,实际成品出口厚度偏差如图12所示。

图12 厚度偏差比较

Fig. 12 Comparison of thickness deviation

由图12可以看出:当采用传统计算模型得到的平均温度作为设定点时,成品头部厚度精度偏厚,这与孙一康[17]所得轧制特性分析结果基本一致,当精轧入口平均温度偏差为15 ℃左右时,出口厚度将会产生约40 μm的波动。这是由于采用传统模型预报时,预报得到的轧件实际的平均温度高于轧件的实际平均温度,导致模型设定计算过程中轧件的轧制力偏小,引起弹跳计算的预报偏差。而采用改进的模型之后,避免了这一误差的产生,有效地提高了设定模型的预报精度,达到了提高厚度控制精度的目的。

5 结论

1) 通过ANSYS有限元仿真,对轧件在中间辊道运行过程的温度变化情况进行了仿真分析,得到了轧件断面厚度方向的温度分布情况。受运输辊道的影响,轧件下表面的对流换热系数更大,导致轧件下表面温降更快。

2) 随着粗轧后出口温度的增大,轧件上、下表面的温差呈现先增后减的变化趋势;随着轧件厚度的增大,轧件上、下表面温差越大,并且随着时间变化上、下表面温差趋于稳定,在出口温度为1 150 ℃,厚度为55 mm时,上、下表面的温度差稳定在20 ℃左右。

3) 拟合得到了轧件表面中心位置厚度方向温度随轧件运输时间、粗轧出口温度及轧件厚度的函数关系式,并对平均温度的公式进行了改进。现场实际应用表明,改进的平均温度计算模型预报精度能够有效满足实际控制要求。

参考文献:

[1] LENARD J G. Primer on flat rolling[M]. London: Elsevier Science Ltd, 2007: 116-118.

[2] MANSOURI N, MIRHOSSEINI M, SABOONCHI A. Thermal modeling of strip across the transfer table in the hot rolling process[J]. Application Thermal Engineering, 2012, 38: 91-104.

[3] 宋勇, 荆丰伟, 殷实, 等. 厚规格热轧带钢高精度卷取温度控制模型[J]. 工程科学学报, 2015, 37(1): 106-110.

SONG Yong, JING Fengwei, YIN Shi, et al. High-precision coiling temperature control model for heavy gauge strip steel[J]. Chinese Journal of Engineering, 2015, 37(1): 106-110.

[4] DING Yunpeng, ZHU Qiang, LE Qichi, et al. Analysis of temperature distribution in the hot plate rolling of Mg alloy by experiment and finite element method[J]. Journal of Material Process Technology, 2015, 225: 286-294.

[5] MEI Ruibin, LI Changsheng, LIU Xianghua. Analysis of strip temperature in hot rolling process by finite element method[J]. Journal of Iron and Steel Research International, 2010, 17(2): 17-21.

[6] 王晓晨, 杨荃, 刘瑞军, 等. 基于ANSYS有限元法的热卷箱内中间坯温度场分析[J]. 北京科技大学学报, 2013, 35(4): 454-458.

WANG Xiaochen, YANG Quan, LIU Ruijun, et al. Temperature field analysis of intermediate slabs in the hot coil box based on ANSYS finite element method[J]. Journal of University Science Technology Beijing, 2013, 35(4): 454-458.

[7] MCKENNEY C, ORESTI J. Coil box technology continues to extend application boundaries[C]// Proceedings of the 10th International Conference on Steel Rolling. Beijing, China: Metallurgical Industry Press, 2010: 79-83.

[8] 张大志, 叶海丽, 谢新亮, 等. 热轧带钢层流冷却仿真系统的开发及应用[J]. 中南大学学报(自然科学版), 2011, 42(8): 2318-2323.

ZHANG Dazhi, YE Haili, XIE Xinliang, et al. Development and application of laminar cooling simulation system for hot strip rolling[J]. Journal of Center South University (Science and Technology), 2011, 42(8): 2318-2323.

[9] MATS K. Modelling of the temperature distribution of coiled hot strip products[J]. ISIJ International, 2011, 51(3): 416-422.

[10] AHMAD S, SAEID H. Simulation-based prediction of hot-rolled coil forced cooling[J]. Application Thermal Engineering, 2008, 28(13): 1630-1637.

[11] 彭良贵, 张殿华, 郭涛, 等. 热轧带钢发射率软测量及影响因素分析[J]. 东北大学学报(自然科学版), 2013, 34(8): 1118-1122.

PENG Lianggui, ZHANG Dianhua, GUO Tao, et al. Emissivity indirect-measurement and analysis for hot strip mill[J]. Journal of Northeastern University (Nature Science), 2013, 34(8): 1118-1122.

[12] CHEN Qun, WANG Yifei, ZHANG Mengqi. Optimization strategies of heat transfer systems with consideration of heat transfer and flow resistance[J]. International Journal of Heat & Mass Transfer, 2017, 112: 137-146.

[13] 刘恩洋. 板带钢热连轧高精度轧后冷却控制的研究与应用[D]. 沈阳: 东北大学轧制技术及连轧自动化国家重点实验室, 2012: 27-31.

LIU Enyang. Study and application of high-precision run-out table cooling control in hot strip mill[D]. Shenyang: Northeastern University. State Key Laboratory of Rolling and Automation, 2012: 27-31.

[14] 许云波, 郑辉, 刘相华, 等. 400 MPa 级超级钢热连轧过程中温度及 MFS 的预测[J]. 东北大学学报(自然科学版), 2002, 23(6): 569-572.

XU Yunbo, ZHENG Hui, LIU Xianghua, et al. Prediction of temperature distribution and flow stress evolution during the multipass hot rolling of 400MPa super-steel[J]. Journal of Northeastern University (Nature Science), 2002, 23(6): 569-572.

[15] CHEN Ling, WANG Guifang, HE Hongjin. A new Levenberg-Marquardt type algorithm for solving non-smooth constrained equations[M]. Amsterdam: Elsevier Science Inc, 2014: 107-122.

[16] 覃银江, 潘清林, 何运斌, 等. 基于人工神经网络的ZK60镁合金热压缩变形行为[J]. 中国有色冶金学报, 2010, 20(1): 17-23.

QIN Yinjiang, PAN Qinglin, HE Yunbin, et al. Hot compression deformation behavior of ZK60 magnesium alloy based on artificial neural network[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 17-23.

[17] 孙一康. 冷热轧板带轧机的模型与控制[M]. 北京: 冶金工业出版社, 2010: 265-267.

SUN Yikang. Model and control of cold and hot strip mill[M]. Beijing: Metallurgical Industry Press, 2010: 265-267.

(编辑 刘锦伟)

收稿日期:2016-11-15;修回日期:2017-01-08

基金项目(Foundation item):国家重点研发计划资助项目(2017YFB0304100);国家自然科学基金资助项目(51704067, 51774084, 51634002) (Project(2017YFB0304100) supported by the National Key R&D Program of China; Projects(51704067, 51774084, 51634002) supported by the National Natural Science Foundation of China)

通信作者:彭文,助理研究员,从事板带轧制过程自动控制、模型优化、故障诊断等研究;E-mail: pengwen233@163.com