工艺参数对Al7034-T6复合材料冲蚀磨损行为的影响

来源期刊:中国有色金属学报(英文版)2017年第10期

论文作者:B. A. MUDASAR PASHA Kaleemulla MOHAMED

文章页码:2163 - 2171

关键词:混合金属基复合材料;冲蚀腐蚀;搅拌铸造;SiC;Al2O3;Taguchi法

Key words:hybrid metal matrix composite; erosive wear; stir casting; SiC; Al2O3; Taguchi design

摘 要:采用Taguchi法预测工艺参数对不同含量SiC和Al2O3增强Al7034-T6复合材料冲蚀磨损行为的影响。用一种简单的工艺即搅拌铸造技术制备此混合金属基复合材料。用扫描电镜研究复合材料的表面形貌及其随加工时间的演变规律。利用基于Taguchi法的L16正交实验法进行冲蚀磨损实验以确定影响磨损率的关键因素。结果表明,相对于其他参数,增强剂含量和冲击速度对此复合材料的冲击磨损速率的影响最大,且其抗磨损性能随增强剂SiC和Al2O3含量的增加而增强。

Abstract: Taguchi technique was used to predict the influence of processing parameters on the erosive wear behavior Al7034-T6 composite reinforced with SiC and Al2O3 particles in different mass fractions. These hybrid metal matrix composites (HMMCs) were fabricated by using a simple technique called stir casting technique. Scanning electron microscope (SEM) was used to study the surface morphology of the composite and its evolution according to processing time. The design of experiment (DOE) based on Taguchi’s L16 orthogonal array was used to identify various erosion trials. The most influencing parameter affecting the wear rate was identified. The results indicate that erosion wear rate of this hybrid composite is greatly influenced more by filler content and impact velocity respectively compared to other factors. This also shows the significant wear resistance with the increase in the filler contents of SiC and Al2O3 particles, respectively.

Trans. Nonferrous Met. Soc. China 27(2017) 2163-2171

B. A. MUDASAR PASHA1, Kaleemulla MOHAMED2

1. Department of Mechanical Engineering, GMIT, Davanagere 577004, Karnataka, India;

2. Department of Mechanical Engineering, UBDTCE, Davanagere 577004, Karnataka, India

Received 6 August 2016; accepted 21 January 2017

Abstract: Taguchi technique was used to predict the influence of processing parameters on the erosive wear behavior Al7034-T6 composite reinforced with SiC and Al2O3 particles in different mass fractions. These hybrid metal matrix composites (HMMCs) were fabricated by using a simple technique called stir casting technique. Scanning electron microscope (SEM) was used to study the surface morphology of the composite and its evolution according to processing time. The design of experiment (DOE) based on Taguchi’s L16 orthogonal array was used to identify various erosion trials. The most influencing parameter affecting the wear rate was identified. The results indicate that erosion wear rate of this hybrid composite is greatly influenced more by filler content and impact velocity respectively compared to other factors. This also shows the significant wear resistance with the increase in the filler contents of SiC and Al2O3 particles, respectively.

Key words: hybrid metal matrix composite; erosive wear; stir casting; SiC; Al2O3; Taguchi design

1 Introduction

Aluminium is widely used in engineering applications such as in automobile, aerospace, and defense owing to its excellent physical and mechanical properties. The use of such materials has increased substantially in the present scenario. This has led to the development of many new composite materials. However, for many applications, pure aluminium cannot be used because of its lower strength and ductility. In the category of lightweight, high-performance material, the aluminium matrix composites (AMCs) are widely used by several industries. Due to their exceptional properties, a composite made of aluminium, reinforced with hard particles is of wide interest. Primary fabrication methods used for aluminium metal matrix composites are stir casting, squeeze casting, compo castings, infiltration, spray deposition, direct melt oxidation process and powder metallurgy. However, MMCs suffer from various problems viz, insufficient process stability, reliability, and ability to operate in the high-temperature environment. To overcome these problems, the hybrid metal matrix composites (HMMCs) were developed [1]. The increase in demand for high-performance materials has led to the development of HMMCs reinforced with hard particles. These HMMCs possess excellent mechanical and wear resistant properties and are considered as potential engineering materials for many wear-related applications. Some researchers have studied different wear mechanisms of MMCs reinforced with ceramic particulates like SiC, Al2O3 and facing sand particles, and have observed improvement in wear resistance, abrasion resistance and creep resistance [2]. It is hard to choose the desired hard metal type and grade because of the lack of a standard measure of assessment that enables estimates to be made of serviceability in erosive wear conditions. The as-cast aluminium alloys are versatile engineering materials. It is very hard to get properties such as strength, toughness, rigidity, bearing performance and economical cast ability, from other alloy system. Aluminium alloys are feasible matrix materials owing to their good bearing and wear properties, lower casting temperatures, and lower cost. Aluminium alloys reinforced with SiC show better wear and abrasion resistance with increasing SiC contents [3]. Al/SiC alloys are critical bearing materials, especially suitable for high-performance applications, particularly in the aerospace sector. It is not conducive for applications where low cost and high volume are as important as performance [4]. The critical parameters such as reductions in cost, lightweight, and high strength, when reinforced with suitable alloy, make these alloys dominate over other alloys. However, the major limitations associated with these alloys are their ability to operate at elevated temperature [5]. The mechanical and wear resistance properties of metals and alloys such as aluminum, magnesium, titanium, and nickel-chromium alloys which undergo extensive plastic deformation under impact are of interest in many erosive wear applications. These materials can be substantially strengthened by various surface treatment techniques [6]. In general, MMCs in commercial use rely on discontinuous reinforcements, although applications exist for MMCs with continuous graphite, SiC and Al2O3 fibers. For example, discontinuously reinforced aluminum alloy MMCs provide high damping and low density and allow undesirable mechanical vibration and wave propagation to be concealed [7]. Among various manufacturing processes available for discontinuous MMCs, stir casting is typically accepted as a particularly promising route. Its simplicity lies in controlling the parameters like melting temperature, stirring speed, stirring time, and cost effective process [8]. Fabrication technique plays a significant role in defining the material properties of the composites. The fabrication process was chosen depending on the type of matrix material and reinforcement. Good wetting action between matrix and reinforcement requires the pretreatment of reinforcement particles. The pretreatment of the particles improves the surface condition of the reinforcement and the properties of the composites [9]. CANAKCI et al [10] predicted the effect of reinforcement size and volume fraction using ANN on Al2014/B4C composites produced by stir casting method. They revealed that ANN is also an alternative method for determining the wear behavior of the composites. CANAKCI et al [11] also investigated the physical and mechanical properties of AA2024/B4Cp composites produced by stir casting method. They concluded that the heat-treated composites show better properties which are in agreement with Ref. [9]. The mechanical alloying process is a powder metallurgy technique used to obtain the homogeneous distribution of blended particles in a metal alloy matrix material. VAROL and CANAKCI [12] studied the effect of milling parameters on Al2024/B4C composite powders produced by the mechanical alloying method. They found that milling time and particle sizes have a greater influence on the uniform distribution of particles in the matrix materials. The reinforcement size is the most important parameter that strongly affects the particle size in a composite. Similar results have been reported in the previous study by VAROL et al [13] for Al2024/B4C composites produced by powder metallurgy technique. In recent days, extensive work has been carried out to improve the mechanical properties of functionally graded aluminium metal matrix composites. It is found that the density, hardness and bending strength of the composites, fabricated through powder metallurgy technique have been remarkably improved [14]. The powder metallurgy technique has many advantages over stir casting process, and is less expensive than stir casting process. The intention of developing HMMCs is to meet several requirements, viz, static and dynamic loading conditions and the critical demands about the phenomena of wear, erosion, and corrosion. It is hard to have such materials which satisfy these requirements. The only possible way is to manufacture by material combination or a composite design. To improve the surface property of untreated substrate, mechanical surface treatment, surface diffusion treatment, and surface overlay coatings are used [15].

Erosive wear is due to the impact of solid particles or liquid stream against the surface of an object. The liquid stream may entrain the solid particles aiding the wear process [16]. Given this, a study on the influence of processing parameters on the erosion resistance potential of Al7034-T6 composites was taken into consideration in this work. In the experimental part of this study, the impact of more than one parameter on erosion wear of the SiC/Al2O3-filled Al7034-T6 composites was experimentally analyzed. The problems associated with the fractional design can be easily overcome by implementing. Taguchi method is a statistical technique used to optimize the process parameters. The design of experiment gives more consistent outputs, irrespective of the environment in which it is used. Taguchi design uses an orthogonal array which makes the design process very easy and coherent. The inexpensive and easy experimental strategies based on Taguchi’s parameter design were adopted by many researchers [17] to study the effect of various parameters and their interactions in the wear process were studied.

2 Experimental

2.1 Materials

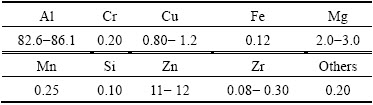

The material selected was a composite, based on an Al7034-T6 matrix, reinforced with silicon carbide (SiC) and aluminium oxide (Al2O3) particles (size 10-20 μm) in mass fraction range of 0-9% at a step of 3% each. Fenfe metallurgical provided these materials in extruded and T6 heat treatment conditions. Material composition is shown in Table 1.

2.2 Composite fabrication

This process involved melting of the Al7034-T6 alloy (matrix) carried out separately about 750 °C, and above its melting temperature using muffle furnace. Wetting action plays a significant role in the particulate reinforcement and the liquid metal. The required quantities of filler particulates (0, 3%, 6% and 9%, mass fraction), preheated to around 500 °C, were added to the molten metal and stirred continuously by using a mechanical stirrer. The uniform mixing of filler particulates in the matrix material was achieved by maintaining the stirrer at an approximate speed of 500 r/min. During stirring, to increase the wettability and degasification, small quantities of Hexo chloro ethane tablets were added to the melt. Molten metal was allowed to solidify. After solidification, the castings were taken from the mold and cut to the round shape with 20 mm in diameter and 10 mm in height for erosion test.

Table 1 Chemical composition of Al7034-T6 alloy (mass fraction, %)

2.3 Hardness test

The ability of material to resist indentation, usually by penetration is called as hardness. A ball indenter (1/16 of 2.54 cm) was forced into the material under a load F. The position of the pointer on the selected scale, gives directly the Rockwell hardness number.

2.4 Tensile strength

The commonly used test to measure the mechanical properties of material is the tensile test. The tensile test was carried out by applying tensile load till the material failure. Stress and strain were recorded for the applied tensile load. According to ASTM E8, cylindrical specimen was prepared for the test. The specimen was loaded in the universal testing machine until the failure of the specimen occurred.

2.5 Flexural strength (three-point bending test)

Three-point bending test was used to determine the elastic modulus of the material. According to ASTM E290, the composite specimen was prepared for the bending test. The specimen was loaded at the center of the span (100 mm) through a load cell. The test was carried out until the specimen was completely broken.

2.6 Scanning electron microscope (SEM) observation

SEM was used to identify the erosive wear surface of the composite specimens. The specimens were cleaned thoroughly with acetone before SEM observation. Then, the images of the eroded and uneroded surfaces were examined at different magnifications.

2.7 Erosion test

The solid particle slurry erosion tests were carried out using a self-fabricated air-jet erosion test rig as shown in Fig. 1. This set-up mainly consisted of an air compressor unit, a particle feeder, an air-particle mixing chamber and an accelerating chamber. This set-up was also equipped with a thermocouple for preheating the compressed air. A regulating valve controlled the feed rate of the erodent particle to the mixing chamber. The compressed and dried air was mixed with the erodent particles in a chamber and allowed to pass through a convergent nozzle. The slurry was prepared for testing media by using water and sea sand particles of size approximately 10 μm. Initially, 20 L water and 6250 g of sea sand particles were mixed homogeneously. Before the specimens were subjected to wear, they were cleaned with acetone. The prepared test specimens were weighed in the electronic balance and tabulated as the initial mass of the specimen. The parameters such as impingement angle, stand-off distance (SOD) and time of exposure were varied for various experimentations. The SODs selected for experiment are 30, 40 and 50 mm, while the impinging angles are 0°-90° in the direction of erodent flow and this angle of impingement can be varied by placing the samples in different sample holders inclined faces of 0°-75° with the horizontal. The exposure time was 5, 10 and 15 min. The impact velocity of the erodent particles was determined by 1) setting the constant pressure using solenoid valve; 2) discharge Q measured using the rotometer; and 3) calculating the cross- sectional area A of the nozzle.

Q=Av (1)

v=Q/A (2)

where v is the impact velocity.

Fig. 1 Erosive wear test rig developed for erosion test

After the experimentation, the specimens were cleaned with acetone and weighed to estimate the wear rate. The mass loss method was used to compute the wear rate.

2.8 Taguchi experimental design

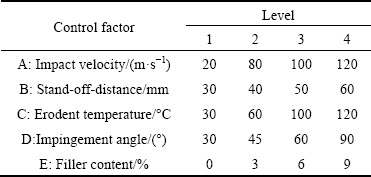

To overcome the problems associated with the traditional multifactorial experimental design, TAGUCHI and KONISHI [18] recommended the use of orthogonal arrays. The inexpensive and easy experimental strategy based on Taguchi parameter design has been adopted by many researchers, scientists, and industrialist to study the effect of various parameters and their interactions in some engineering processes. In this study, five parameters, i.e., impact velocity, impingement angle, stand-off-distance, erodent temperature and filler content were taken into consideration to study the solid particle erosion response of the composites. The experiments were conducted as per the standard L16 orthogonal array. The plan of experiments, i.e., the Taguchi method with parameter values at four levels, was used. The selection of the control factors is the most important parameter in the design of experiment (DOE). The control factors with their selected levels are shown in Table 2.

Table 2 Control factors and their selected levels

3 Results and discussion

3.1 Mechanical properties

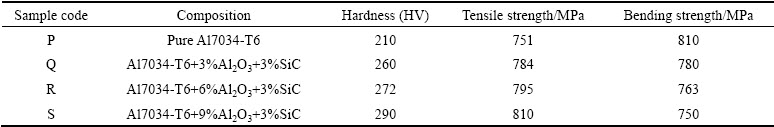

The increase in mechanical properties due to the incorporation of Al2O3 and SiC particles to the matrix alloy in varying contents was investigated in detail. Different characterization tests were conducted to evaluate various mechanical properties of the composites. The mechanical properties of the composites fabricated in this work are presented in Table 3.

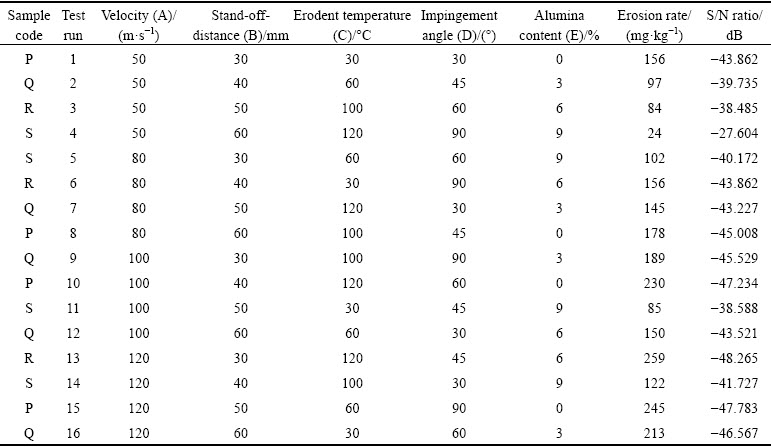

In Table 4, the erosion wear trails according to the L16 orthogonal design and their performances are shown. The output results are further transformed into the signal-to-noise (S/N) ratios. Since the minimum wear

rate is taken into consideration, S/N ratios are calculated for a minimum erosion rate under “smaller is better” characteristics as a logarithmic transformation of the loss function given below:

S/N=-10lg[1/n(Σy2)] (3)

where n represents the number of observations and y accounts for the observed data.

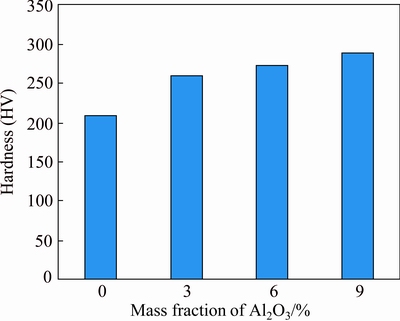

3.1.1 Hardness test

In the present investigation, hardness values of the Al7034-T6 composite with and without filler have been obtained by the Rockwell hardness tester. The hardness of composite depends on the hardness of the reinforcement and the matrix. The variation of hardness with filler content in the composites is shown in Fig. 2. Generally, Al2O3 particles are harder than the matrix alloy, which increases the hardness of the composites, and further addition of SiC particles which are even harder than the Al2O3 particles increases approximately 23% hardness of the composites. Among all the composites fabricated in this study, the maximum hardness value is observed for Al7034-T6 composite filled with 9% Al2O3 and 3% SiC. It has been found that the presence of hard ceramic particles (SiC and Al2O3) increases the hardness of Al7034-T6 composite from HV 210 to HV 290. A similar result has been proposed by AIGBODION and HASSAN [19] for the increase in hardness of the composites.  SALAZAR and BARRENA [20] found that aging of the reinforcement also enhanced the hardness of the composites. The hardness value obtained in this work is greater, compared to the similar work carried out by KIM et al [21]. Particle size is the primary cause for the increase in hardness of the composites.

SALAZAR and BARRENA [20] found that aging of the reinforcement also enhanced the hardness of the composites. The hardness value obtained in this work is greater, compared to the similar work carried out by KIM et al [21]. Particle size is the primary cause for the increase in hardness of the composites.

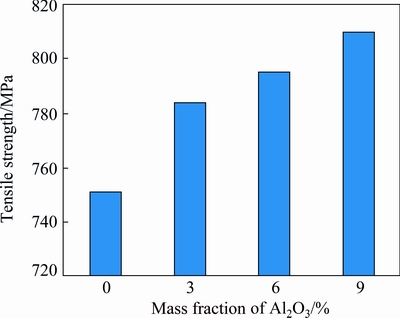

3.1.2 Tensile test

Failure of the composite materials in tension is a serious problem for structural applications. Therefore, the development of new composite materials with improved tensile strength is a challenging task. Figure 3 shows the relation between tensile strength and mass fraction of Al2O3 and SiC reinforcements in composites. It is observed from the tensile test that, the tensile strength of Al7034-T6 composites is higher than the unreinforced alloy due to the strong interface between the reinforcement and the matrix alloy [22]. From Fig. 3, one can observe the increase in tensile strength with the increase in contents of Al2O3 and SiC in composites due to strong interfacial bonding. The addition of harder (SiC) and stiffer (Al2O3) reinforcements results in a direct strengthening of composites [23]. The presence of magnesium in the Al7034-T6 composites increases the wetting capability of the reinforcement in the composites, thereby increasing the tensile strength of the composites. This is in agreement with KUMAR et al [24]. Moreover, the addition of harder reinforcement gives resistance to the plastic deformation but leads to the increase in the porosity at the interface of the composites. A similar result has been presented by WAHAB et al [25] that tensile strength and ductility decrease due to the increase in the porosity.

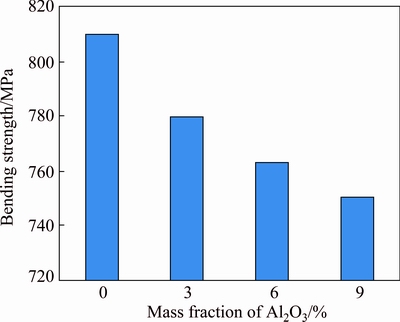

3.1.3 Flexural test

Table 3 Mechanical properties of composites

Table 4 Experimental design (L16 orthogonal array) with output and S/N ratio

Fig. 2 Variation of composite hardness with mass fraction of Al2O3 at 3% SiC

Fig. 3 Variation of composite tensile strength with mass fraction of Al2O3 at 3% SiC

The test results for bending strengths of the composites with Al2O3 and SiC are shown in Fig. 4. It can be observed in all the samples that the bending strength decreases with the increase in filler content, irrespective of the type of reinforcement. It is quite evident that the increase in the reinforcement content enhances the hardness of the composites, thereby increasing the brittleness of the composites and decreasing the bending strength of the composites [26]. ALTINKOK and  [27] predicted the bending strength of the composites using neural network technique. They concluded that particle size is the primary influencing parameter for decreasing the bending strength of the composites.

[27] predicted the bending strength of the composites using neural network technique. They concluded that particle size is the primary influencing parameter for decreasing the bending strength of the composites.

3.2 Surface morphology

Fig. 4 Variation of composite bending strength with mass fraction of Al2O3 at 3% SiC

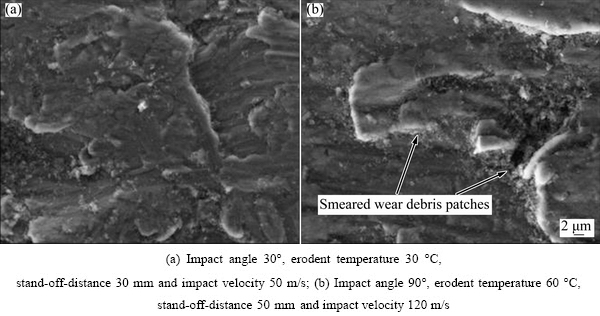

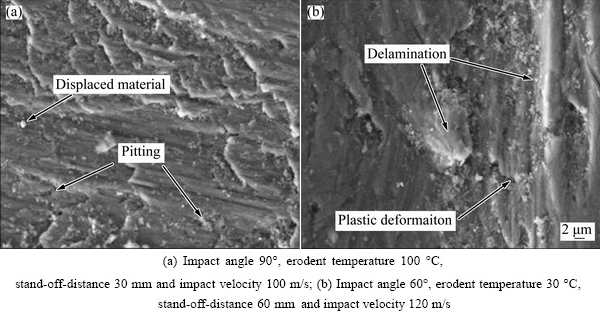

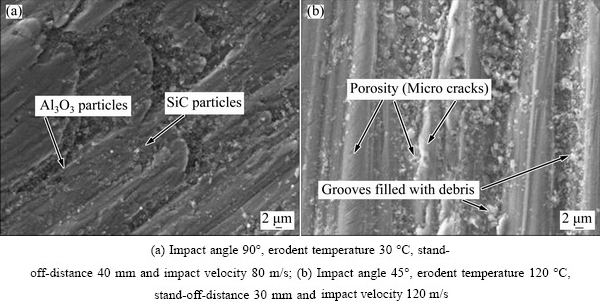

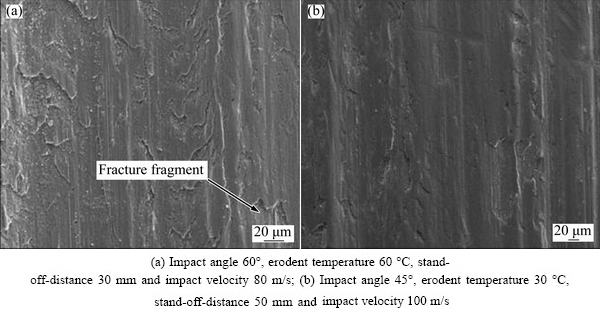

SEM images of the worn surface of Al7034-T6

composites with different contents of Al2O3 and SiC can be seen from Figs. (5)-(8). Figure 5 shows the worn surface of pure Al7034-T6 composites. From Fig. 5(a), it is observed that little amount of material appears at an impact velocity of 50 m/s. As the velocity increases to 120 m/s, a significant amount of substance appears from the surface of the matrix material. One can observe the formation of wear debris patches on the surface of composites as shown in Fig. 5(b). Figure 6(a) shows the fracture surface of Al7034-T6 with 3% Al2O3 and 3% SiC at 100 m/s, which reveals that the particle is pulled out. This fracture is due to the cutting action of the particles at 90°, causing pitting action and displacement of material. The extent of deformation thus increases with the increase in impact velocity to 120 m/s, leading to the delamination and plastic deformation of material as shown in Fig. 6(b). Figure 7(a) indicates the portion of Al7034-T6 with 6% Al2O3 and 3% SiC composite materials eroded at 90° and 80 m/s. One can observe that exposure of materials (Al2O3 and SiC), due to repeated impact of eroded particles and thus craters are formed, especially in higher contact angles. The impingement of the erodent at higher contact angles causes the roughening of the surface of the material [28]. Figure 7(b) shows wear damage eroded at 45° and 120 m/s, characterized by wear debris filled the grooves and pits on the surface. The erosion scar at this incident angle was slightly deeper than that at 90° and showed micro cracks (porosity) on the surface of the composite material due to the pre-heat treatment of reinforcement particles. Many other researchers [29,30] previously reported different types of hard reinforcements with metal matrix composites. They found that increasing the impact velocity substantially increased the wear removal rate from the surface of the composites. In contrast to this, in the present study it is found that the increase in the velocity stabilizes the wear resistance of the composites due to increasing in the filler content. Figure 8 shows the portion of Al7034-T6 with 9% Al2O3 and 3% SiC composite materials eroded at 60° and 80 m/s. It is observed from Fig. 8(a) that, with the increase in content of reinforcement, the pre-treatment of particles leads to substantial increase in the hardness of the material and good interfacial bonding between the matrix and reinforcement. The surface eroded under this condition is very less compared with that under other conditions. Also, very less fracture fragment is observed in Fig. 8(b).

Fig. 5 SEM images of pure Al7034-T6 composites without SiC and Al2O3

Fig. 6 SEM images of Al7034-T6 composites with 3% Al2O3 and 3% SiC

Fig. 7 SEM images of Al7034-T6 composites with 6% Al2O3 and 3% SiC

Fig. 8 SEM images of Al7034-T6 composites with 9% Al2O3 and 3% SiC

3.3 Wear behavior and Taguchi analysis

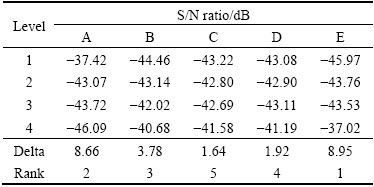

The erosion wear behaviors of Al2O3 and SiC reinforced Al7034-T6 composites under different operating conditions are given in Table 4. MINITAB 17 was used to analyze the design of experiments. An attempt was made to predict the measure of performance, the possible interactions between the control factors must be considered. The combination of factors producing minimum wear of the composites is presented in Table 5. The experimental data are transformed into signal-to- noise (S/N) ratios. The last column in Table 5 represents the S/N ratio of the erosion rate. The overall mean for the S/N ratio of the erosion rate is found to be 42.5681 dB. Table 5 clearly indicates that filler content is the most significant factor among all the parameters. The effect of impact velocity is very much closer to filler content on erosion rate of these Al2O3 and SiC-filled Al 7034-T6 metal matrix composites. MISHRA et al [31] found that the impingement angle was the most influential parameter which affected the erosion wear rate of the composites.

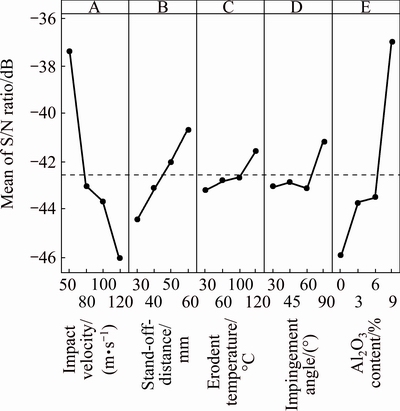

The effect of individual control factor on the S/N ratio shown in Fig. 9 also leads to the conclusion that the factor combination of A1, B4, C2, D4, and E4 gives the minimum erosion wear rate. Various studies [32-34] have proved that impact velocity is the most significant factor, which is followed by filler content. However, in our study, we have found that the effects of filler content and impact velocity are almost the same.

Table 5 Signal-to-noise ratio response for erosion test (smaller is better)

Fig. 9 Effect of individual control factor on S/N ratio

4 Conclusions

1) Successful fabrication of hybrid composites using stir casting technique, using Al2O3 and SiC as reinforcement material ranging from 0 to 9% at step of 3% is possible. This process improves the physical performance of the fabricated composites. Stir casting method is the most simple, flexible and economical compared with other methods available.

2) These hybrid composites with improved hardness, tensile strength and excellent wear resistance are potential candidates for the erosive environment. This can be determined by the stability of reinforcement and matrix material. It is evident from the above result that properties of hybrid composites depend on the size of the reinforcement and strong bonding between reinforcement with the matrix material.

3) Taguchi experimental design, as the most simple, efficient and systematic method of design, is successfully employed for determining the erosion characteristics of these composites. Al7034-T6+9%Al2O3+3%SiC composite shows good wear resistance compared to other specimens.

4) The effect of significant factors on the erosion rate of composites is identified through successful implementation of signal-to-noise response approach. Signal-to-noise ratio, smaller is better, is found to be the filler content.

5) Among all factors, filler content and impact velocity are found to be the most significant factors on the erosion rate of Al7034-T6 metal matrix composites filled with Al2O3 and SiC.

6) The erodent temperature is identified as the least significant parameter as far as the wear of such composites is concerned. At the elevated temperature of the erosive environment, target surface may undergo corrosive wear.

7) Due to the pretreatment of reinforcement and strong interaction between reinforcement and matrix material, the fracture fragments for Al7034-T6 metal matrix composites are much smaller than those for pure Al7034-T6 matrix.

References

[1] VAMSI KRISHNA M, XAVIOR M. An investigation on the mechanical properties of hybrid metal matrix composites [J]. Procedia Engineering, 2014, 97: 918-924.

[2] RESHETNYAK H, KUYBARSEPP J. Mechanical properties of hard metals resistance [J]. Wear, 1994, 177: 185-193.

[3] REIDENBACH F. Surface engineering [M]. 10th ed. Ohio: ASM International, 1994.

[4] CHAWLA N, WILLIAMS J J, SAHA R. Mechanical behavior and microstructure characterization of sinter-forged SiC particle reinforced aluminum matrix composites [J]. Journal of Light Metals, 2002, 2: 215-227.

[5] DAS S, SARASWATHI Y L, MONDAL D P. Erosive–corrosive wear of aluminum alloy composites: Influence of slurry composition and speed [J]. Wear, 2006, 261: 180-190.

[6] HUANG Z, LI Z Z, YUAN X. The effect of reinforcing particles on the erosive wear behavior of particles reinforced silicone matrix composite coating [J]. Wear, 2001, 249: 1046-1050.

[7] LI Y, NGAI T L, XIA W, ZHANG W. Effects of Mn content on the tribological behaviors of Zn-27%A1-2%Cu alloy [J]. Wear, 1996, 198: 129-35.

[8] HASHIM J, LOONEY L, HASHIM M S J. Metal matrix composites: Production by the stir casting method [J]. Journal of Material Processing Technology, 1993, 92-93: 1-7.

[9] CANAKCI A, ARSLAN F, VAROL T. Effect of volume fraction and size of B4C particles on production and microstructure properties of B4C reinforced aluminum alloy composites [J]. Materials Science and Technology, 2013, 29: 954-960.

[10] CANAKCI A, OZSAHIN S, VAROL T. Prediction of effect of reinforcement size and volume fraction on the abrasive wear behavior of AA2014/B4Cp MMCs using artificial neural network [J]. Arabian Journal for Science and Engineering, 2014, 39: 6351-6361.

[11] CANAKCI A, ARSLAN F, VAROL T. Physical and mechanical properties of stir-casting processed AA2024/B4Cp composites [J]. Science and Engineering of Composite Materials, 2014, 21: 505-515.

[12] VAROL T, CANAKCI A. Synthesi and characterization of nanocrystalline Al2024-B4C composite powders by mechanical alloying [J]. Philosophical Magazine Letters, 2013, 93: 339-345.

[13] VAROL T, CANAKCI A, OZSAHIN S. Prediction of the influence of processing parameters on synthesis of Al2024-B4C composite powders in a planetary mill using an artificial neural network [J]. Science and Engineering of Composite Materials, 2014, 21: 411-420.

[14] ERDEMIR F, CANAKCI A, VAROL T. Microstructural characterization and mechanical properties of functionally graded Al2024/SiC composites prepared by powder metallurgy techniques [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3569-3577.

[15] RAJMOHAN T, PALANIKUMAR K, KATHIRVEL M. Optimization of machining parameters in drilling hybrid aluminium metal matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1286-1297.

[16] RICHMAN R H, MCNAUGHTON W P. Correlation of cavitation erosion behavior with mechanical properties of metals [J]. Wear, 1990, 140: 63-82.

[17] DHARMALINGAM S, SUBRAMANIAN R, SOMASUNDARA V K. Analysis of dry sliding friction and wear behavior of aluminum–alumina composites using Taguchi’s techniques [J]. Journal of Composite Materials, 2010, 44(18): 2161-2177.

[18] TAGUCHI G, KONISHI S. Taguchi methods: Orthogonal arrays and linear graphs; tools for quality engineering [M]. Dearborn, MI: American Supplier Institute Inc, 1987.

[19] AIGBODION V S, HASSAN S B. Effects of silicon carbide reinforcement on microstructure and properties of cast Al-Si-Fe/SiC particulate composites [J]. Materials Science and Engineering A, 2007, 447: 355-360.

[20] de  SALAZAR J M, BARRENA M I. Influence of heat treatments on the wear behavior of an AA6092/SiC25p composite [J]. Wear, 2004, 256: 286-293.

SALAZAR J M, BARRENA M I. Influence of heat treatments on the wear behavior of an AA6092/SiC25p composite [J]. Wear, 2004, 256: 286-293.

[21] KIM J H, NA K S, KIM G G, YOON C S, KIM S J. Effect of manganese on the cavitation erosion resistance of iron–chromium– carbon–silicon alloys for replacing cobalt-base stellite [J]. Journal of Nuclear Materials, 2006, 352: 85-89.

[22] CHEN R, LWABUCHI A, SHIMIZU T, SHIN H S, MIFUNE H. The sliding wear resistance behavior of NiAI and SiC particles reinforced aluminum alloy matrix composites [J]. Wear, 1997, 213(1-2): 175-84.

[23] THAKUR S K, DHINDAW B K. The influence of interfacial characteristics between SiCp and Mg/Al metal matrix on wear, coefficient of friction and microhardness [J]. Wear, 2001, 247(2): 191-201.

[24] KUMAR A, LAL S, KUMAR S. Fabrication and characterization of A359/Al2O3 metal matrix composite using electromagnetic stir casting method [J]. Journal of Material Research Technology, 2013, 2(3): 250-254.

[25] WAHAB M N, DAUD A R, GHAZALI M J. Preparation and characterization of stir cast-aluminium nitride reinforced aluminium metal matrix composites [J]. International Journal of Mechanical and Materials Engineering, 2009, 4(2): 115-117.

[26] ABDULLAH Y, DAUD A R, SHAMSUDIN R, MOHD HARUN B. Flexural strength and fracture studies of Al-Si/SiCp composites [J]. International Journal of Mechanical and Materials Engineering, 2009, 4: 109-114.

[27] ALTINKOK N,  R. Neural network approach to prediction of bending strength and hardening behaviour of particulate reinforced (Al-Si-Mg)-aluminium matrix composites [J]. Materials and Design, 2004, 25(7): 595-602.

R. Neural network approach to prediction of bending strength and hardening behaviour of particulate reinforced (Al-Si-Mg)-aluminium matrix composites [J]. Materials and Design, 2004, 25(7): 595-602.

[28] KAUNDAL R, PATNAIK A, SATAPATHY A. Solid particle erosion of short glass fiber reinforced polyester composite [J]. American Journal of Materials Science, 2012, 2(2): 22-27.

[29] SARAVANAN A, SURAPPA B M K, PRAMILA B N. Erosion of A356 Al-SiCp composites due to multiple impact [J]. Wear, 1997, 202: 154-164.

[30] SETSUO A, SHOJI G, YOSHINARI K, LIU W, LIU C M. Slurry erosion of Fe-15%/25%Cr-C-B eutectic alloys [J]. Wear, 1999, 233-235: 160-176.

[31] MISHRA S C, SATYABATI D, ALOK S, ANAN- THAPADMANABHAN P V, SREEKUMAR K P. Erosion wear analysis of plasma sprayed ceramic coating using the Taguchi technique [J]. Tribology Transactions, 2009, 52(3): 401-404.

[32] MAHAPATRA S S, PATNAIK A. Study on mechanical and erosion wear behavior of hybrid composites using Taguchi experimental design [J]. Materials and Design, 2009, 30: 2791-2801.

[33] PATNAIK A, SATAPATHY A, MAHAPATRA S S, DASH R R. Tribo-performance of polyster hybrid composites: Damage assessment and parameter optimization using Taguchi design [J]. Materials and Design, 2009, 30: 57-67.

[34] SAHIN Y. Optimization of testing parameters on the wear behavior of metal matrix composites based on the Taguchi method [J]. Materials Science and Engineering A, 2005, 408: 1-8.

B. A. MUDASAR PASHA1, Kaleemulla MOHAMED2

1. Department of Mechanical Engineering, GMIT, Davanagere 577004, Karnataka, India;

2. Department of Mechanical Engineering, UBDTCE, Davanagere 577004, Karnataka, India

摘 要:采用Taguchi法预测工艺参数对不同含量SiC和Al2O3增强Al7034-T6复合材料冲蚀磨损行为的影响。用一种简单的工艺即搅拌铸造技术制备此混合金属基复合材料。用扫描电镜研究复合材料的表面形貌及其随加工时间的演变规律。利用基于Taguchi法的L16正交实验法进行冲蚀磨损实验以确定影响磨损率的关键因素。结果表明,相对于其他参数,增强剂含量和冲击速度对此复合材料的冲击磨损速率的影响最大,且其抗磨损性能随增强剂SiC和Al2O3含量的增加而增强。

关键词:混合金属基复合材料;冲蚀腐蚀;搅拌铸造;SiC;Al2O3;Taguchi法

(Edited by Wei-ping CHEN)

Corresponding author: B. A. MUDASAR PASHA; E-mail: mudasarpasha@gmail.com

DOI: 10.1016/S1003-6326(17)60242-5