Trans. Nonferrous Met. Soc. China 22(2012) 60-65

Sliding wear behaviour of AZ31B magnesium alloy and nano-composite

M. SRINIVASAN1, C. LOGANATHAN2, M. KAMARAJ3, Q. B. NGUYEN4, M. GUPTA4, R. NARAYANASAMY5

1. Department of Mechanical Engineering, Saranathan College of Engineering,Tiruchirappalli, Tamilnadu 620012, India;

2. St. Jospeh’s College of Engineering and Technology, Thanjavur, Tamilnadu 613403, India;

3. Department of Metallurgical and Materials Engineering, Indian Institute of Technology Madras,Chennai, Tamilnadu 600036, India;

4. Department of Mechanical Engineering, National University of Singapore,9 Engineering Drive 1, Singapore 117576, Singapore;

5. Department of Production Engineering, National Institute of Technology,Tiruchirappalli, Tamilnadu 620015, India

Received 17 March 2011; accepted 4 July 2011

Abstract: AZ31B magnesium alloy and nano-composite were manufactured by hybrid casting process and hot extruded at 350 °C. The sliding wear behaviour of alloy and nano-composite was estimated at room temperature using the standard pin-on-disc wear test equipment. The tests were conducted under a normal load of 10 N at different sliding speeds ranging from 0.60 to 1.2 m/s for distance up to 2000 m. The wear mechanisms of the worn out surface were studied using SEM analysis. The influence of test parameters on wear rate of the pins was established using a linear regression model statistically. Compared with the AZ31B magnesium alloy, the nano-composite shows lower wear rates due to higher hardness improvement caused by the reinforcement. The wear mechanism appears to be a mix-up of ploughing, rows of furrows, delamination and oxidation.

Key words: AZ31B magnesium alloy; nano composite; wear mechanism

1 Introduction

The alloys and composites of magnesium have a 35% lower density compared with the alloys of aluminum [1-4]. These alloys and composites have a higher strength-to-mass ratio (σ/ρ) compared with the commonly used nonferrous and ferrous metallic materials [5]. In particular, magnesium based composites with discontinuous reinforcements promise high specific strength and stiffness, good damping capacities, dimensional stability and creep resistance. Composite materials have several advantages over pure metals and alloys. However, the industrial adoption of this class of materials is limited by the brittleness that almost invariably accompanies the addition of reinforcements.

The previous studies on magnesium-based composites [6-7] reinforced with nano-alumina reported that the abrasive wear and the adhesive wear were the common wear mechanisms. LIM et al [6] observed thermal softening (extrusion) of the pin surface at higher sliding speeds under a constant normal load. HABIBNEJAD-KORAYEM et al [7] reported that the oxidation is attributed to the combined effect of the higher sliding speed and higher normal stress. Reinforcing with nano-alumina (Al2O3) and calcium (Ca) is yet another attempt of improving the hardness of AZ31B magnesium [8], which influences the reduction in wear rates.

SAHIN [9] conducted wear tests on Al 2011 with SiCp reinforcement using factorial “design of experiments” to assess the contribution of load (L), distance (D), and particle size. It was reported that the wear rate increased with the increase in abrasive size and L, and decreased with the increase in D. The equations developed qualitatively hold for alloys and composites.

This work deals with the sliding wear behaviour of AZ31B magnesium alloy and nano-composite against oil hardened non-shrinking (OHNS) steel counterface. The influence of test parameters, viz., sliding distance (D) and sliding velocity (S) under a normal load on the wear rate is obtained using a linear regression model statistically and discussed in detail. SEM analysis is used to study the wear mechanism of the worn out surface. It is observed that as the sliding speed increases, the frictional heat also increases between the contact surfaces. The formed hard phase oxides enhance the resistance to wear on the pin surface.

2 Experimental

2.1 Materials

The alloy (AZ31B) and nano-composite (AZ31B- Al2O3-Ca) of magnesium used in the present investigation were synthesized by hybrid casting process (Disintegrated melt deposition) and hot extruded at 350 °C. Rods of 10 mm in diameter were obtained following the hot extrusion. The chemical composition and mechanical properties of the extruded base material are provided in Tables 1 and 2.

Table 1 Chemical composition of AZ31B magnesium alloy from Ref. [8]

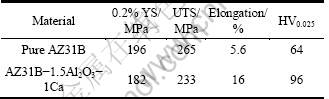

Table 2 Mechanical properties of pin specimens used in this study from Ref. [8]

2.2 Wear testing

Dry sliding wear tests were conducted using the standard pin-on-disc tester. The pin specimens with diameter of 8 mm and length of 15 mm were machined from the as-extruded rods of 10 mm in diameter. The contact surfaces were prepared by grinding against 600-grit silicon carbide (SiC) paper and cleaning with acetone. A pin holder loaded the stationary pins vertically onto a rotating OHNS steel disc, which had been oil-hardened to 62HRC. All experiments were conducted in air at temperature 22-25 °C under a normal load of 10 N at different sliding speeds ranging from 0.60 to 1.2 m/s for distance up to 2000 m. Prior to sliding, the disc was ground against 600-grit SiC paper for a few minutes to remove accumulated debris on the wear track, followed by cleaning with acetone. At the end of every sliding distance, the pins were carefully cleaned with acetone. The pins were weighed using a sensitive electronic balance with an accuracy of ±0.1 mg to determine the mass loss. On certain pins, material had been extruded from the pin surface and later re-solidified around the periphery. Since these extruded layers should rightly be considered material worn out, they were carefully filed off prior to weighing so as not to add falsely to the weight. The wear rate was analyzed using a linear regression model. Using scanning electron microscopy (SEM), the worn out pin surfaces were examined for the mechanism of the wear.

2.3 Statistical analysis

Linear regression technique was used to study the wear rate of A31B magnesium alloy and nano-composite. The wear rate for both the materials is the response (dependent) variable. The factors that are independent and influence the response variables are S and D. The generalized linear regression equation for these experiments can be written as:

Y=a0+a1x1+a2x2+a3x1x2 (1)

where Y is the wear rate; independent variables x1 and x2 represent S and D, respectively; a1 and a2 are coefficients of x1 and x2, respectively; a3 is the interaction coefficient between x1 and x2 within the selected levels of each variable. The true values of a0 to a3 are unknown and must be estimated from least-squares analysis [9-11].

3 Results and discussion

3.1 Wear rates

The volumetric wear rates obtained from the experimental results are fitted into the following equations (2) and (3) for AZ31B magnesium alloy (Y1) and nano-composite (Y2), respectively.

Y1=1.03×10-5-1.49×10-6S+3.67×10-9D-1.17×10-9SD (2)

Y2=9.80×10-6-1.54×10-6S+3.03×10-9D-1.67×10-9SD (3)

The correlation coefficients of determination (R2) for the alloy and composite are 93.2% and 90.8%, respectively. This is an expected result because the metal matrix composite has a multiphase microstructure, and the wear data are usually scattered. From the individual linear regression results, the wear behavior of alloy can be described more accurately than that of the composite. The maximum deviations of the experimental values from the calculated values for the alloy and the nano-composite are 4%, and 5%, respectively.

The values of a0 for the alloy and nano-composite are 1.03×10-5 and 9.80×10-6, respectively. The value of a0 is the intercept of the plane and is a mean response value for all the experiments conducted. The value of a0 depends not only on the major parameters S and D, which are considered in this study, but also on experimental irregularities like machine vibrations, environmental conditions, and the surface finish of both the pin and the disc. The experiments were repeated twice to minimize the possible experimental errors. It is very clear from the experimental results that the wear rate is less for the composite compared with the alloy as shown in Fig. 1.

Fig. 1 Variation of wear rate with sliding distance at different sliding speeds: (a) Alloy; (b) Nano-composite

The wear rates can be calculated from Eq. (2) and Eq. (3). The positive values of the coefficients suggest that the wear rate increases with the increase in the associated variables, whereas the negative values of the coefficients indicate an opposite effect. The magnitude of the variables indicates the relative weight of each of these factors. It is observed from Eq. (2) and Eq. (3) that S has a greater effect on the wear rate followed by D. The interactions among the factors are not significant in the case of composite compared with the alloy.

The important factor which affects the wear rate is S, because the coefficient value is negative. This suggests that the wear rate decreases with increasing speed for the range of parameters tested. This can be attributed to the increased extent of oxidation of the magnesium alloy as a result of higher interfacial temperatures, resulting in a thicker oxide film, which protects the sliding interfaces, thereby lowering the wear rate [12]. This may be the reason for the decrease in wear rate with increased S in the present case. As the speed increases the pin surface ploughs the surface of the counterface. In the case of composite, the projected Al2O3 particles are crushed, leading to third-body abrasion between the pin and the counterface. When the speed increases further, the ploughed surface of the counterface (Fe) will react to form Fe3O4. The Fe3O4, Fe, minute fractured particles of Al2O3p, and the oxide film form a layer between the work-hardened pin and the counterface. This layer, called the mechanical mixed layer (MML) [12], reduces the wear rate.

In general, the positive value of the D coefficient in both alloy and composite indicates that as the distance increases, the wear rate also increases. In the case of composite, this may be attributed to the ploughing ability of the fractured Al2O3 particles between the pin and the counterface. Further ploughing of nano-composite is prevented due to the presence of nano-alumina in dispersed form.

3.2 Analysis of worn surface using SEM

3.2.1 Abrasion

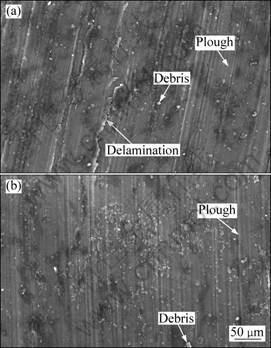

The worn out surfaces of the specimens under sliding were covered with grooves parallel to the sliding direction as shown in Fig. 2 to Fig. 4. The following are typical features associated with abrasive wear: hard

Fig. 2 SEM images of alloy (a) and nano-composite (b) sliding at 0.6 m/s for distance to 500 m

asperities on the steel counterface, or hard particles between the pin and disc, plough or cut into the pin, causing wear by the removal of small fragments or ribbon-like strips of material [13]. As suggested by ARCHARD [14], the harder composites are better able to resist wear by abrasion. From Fig. 2 to Fig. 4, it is suggested that the primary wear mechanisms under these conditions are abrasive wear. Surface projections or asperities present in the contact surface are plastically deformed and eventually welded together by high local

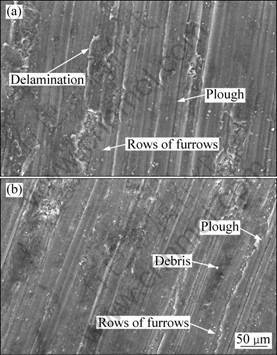

Fig. 3 SEM images of alloy (a) and nano-composite (b) sliding at 0.9 m/s for distance to 500 m

Fig. 4 SEM images of alloy (a) and nano-composite (b) sliding at 1.2 m/s for distance to 500 m

pressure during the relative motion between the contact surfaces.

Differences in the extent of grooving are observed with the variation in sliding speed as shown in Fig. 2 to Fig. 4. The well-defined deep grooves at the lower speed changing to shallower scratches are due to plastic deformation sliding at higher speeds. The deeper grooves indicate a higher degree of penetration by hard asperities, which, together with the minimal displacement of material on both sides of the grooves, suggests a primarily cutting mode of abrasion at the lower speeds. As speed increases, frictional heating leads to a rise in the temperature of the pin surface. Thus, it might be reasonable to conclude that at higher sliding speeds, an increased plastic deformation of the matrix leads to a transition from cutting to ploughing or wedge formation during abrasive. In ploughing, material is displaced on either side of the abrasion groove without being removed. While in wedge forming, tiny wedge-shaped fragments are worn only during the initial contact with an abrasive particle [13]. This could account for the shallower scratches and reduction in wear rates as sliding speed increases.

3.2.2 Adhesion

The rows of furrows and delamination are the signs of plastic deformation, as seen in Fig. 2(a), Fig 3 and Fig. 4. At the same time, the wear track on the disc was covered with a visible layer of transferred material, the thickness of which grew with increasing sliding speed. These features suggest that adhesive wear was operative, and its severity intensified with sliding speed. However, adhesion appeared to be less significant for the nano-composite than for the alloy. In the case of abrasive wear, this observation is in accordance with Archard’s proposal that the wear rate of a material is inversely proportional to its hardness [14]. The onset of adhesive wear supports the aforementioned suggestion that the ductility of the magnesium matrix increased at this sliding speed due to the sudden activation of additional slip planes, thus promoting the plastic deformation that is associated with this wear mechanism. As sliding speed was raised, frictional heating led to a gradual softening of the pin surface, and thus, more extensive adhesion between pin and disc. Due to the frictional heat the active slip planes increase, which will increase the plastic deformation and hence wear rate.

3.2.3 Thermal softening

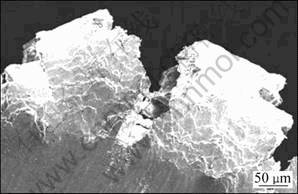

On pins tested at sliding distance of 1500 m, layers of material were seen to protrude slightly on the contact surface as shown in Fig. 5. The worn pin surfaces also appeared relatively featureless, and extensive material transfer to the disc was noted. These observations are associated with softening and localized melting of the matrix material caused by frictional heating at the sliding interface. Once again, the composites showed only slight extrusion compared with the monolithic magnesium. Therefore, the wear rate was found to be less in the case of nano-composite compared with AZ31B Mg alloy.

Fig. 5 Protruded layers on pin surface of alloy at sliding distance of 1500 m (1.2 m/s)

Previous investigations of magnesium and aluminium composites had found the presence of particulate reinforcements beneficial to lowering wear rates [6, 7, 15-17]. This was linked to the higher thermal stability of the nano-composite, which allowed them to retain their strengths to higher temperatures. Likewise, the nano-sized alumina reinforcements in the present case appear to promote resistance to thermal softening in the nano-composite.

3.2.4 Oxidation

The SEM images of the worn surface of the alloy and nano-composite are shown in Fig. 4. The wear track shows clearly the presence of oxide film, which suggests that the relative motion between pins and OHNS disc surface generates frictional heat, which significantly affects the wear rate of pins. QUINN et al [18] stated the dominance of oxidative wear at ambient temperature. These are distributed evenly throughout the worn surface and eventually broke off to become debris. The frictional heat during the wear contributes to oxidation of the finer debris more easily than the coarser ones. The oxide layer prevents metal-to-metal contact. The oxide growth in the wear track appears to be present to a much higher degree compared with alloy owing to its content of Al2O3 reinforcement, and there is small fracture on the oxide film. There is a clear evidence of fracturing of oxides on the surface, which is also reported by QUINN et al [18].

4 Conclusions

The sliding wear behaviour of the AZ31B magnesium alloy and nano-composite are investigated. Empirical linear regression equations are developed for predicting the wear rate under the selected experimental conditions. The equations illustrate that the composite exhibits higher wear resistance compared with the alloy. The wear rate decreases with an increase in the sliding speed for both the alloy and nano-composite, but increases with sliding distance. From the SEM analysis the wear mechanisms of the alloy and nano-composite are characterized by ploughing groove, adhesion and oxidation. Abrasion and adhesion are the dominant wear mechanisms with a transition to thermal softening only under the sliding distances above 1500 m.

References

[1] GOH C S, WEI J, LEE L C, GUPTA M. Development of novel carbon nanotube reinforced magnesium nanocomposites using the powder metallurgy technique [J]. Nano Technology, 2006, 17: 7-12.

[2] AVEDESIAN M M, BAKER H. Magnesium and magnesium alloys—ASM specialty handbook [M]. Materials Park, OH: ASM International, 1999: 87.

[3] HASSAN S F, GUPTA M. Enhancing physical and mechanical properties of Mg using nano-sized Al2O3 particulates as reinforcement [J]. Metallurgical and Materials Transactions A, 2005, 36: 2253-2258.

[4] MORDIKE B L, EBERT T. Magnesium properties—applications— potentials [J]. Material Science Engineering A, 2001, 302: 37-45.

[5] SRIVATSAN T S, SUDARSHAN T S, LAVERNIA E. Processing of discontinuously-reinforced metal matrix composites by rapid solidification [J]. Progress in Material Science, 1995, 39: 317-409.

[6] LIM C Y H, LEO D K, ANG J J S, GUPTA M. Wear of magnesium composites reinforced with nano-sized alumina particulates [J]. Wear, 2005, 259: 620-625.

[7] HABIBNEJAD-KORAYEM M, MAHMUDI R, GHASEMIA H M, POOLE W J. Tribological behaviour of pure Mg and AZ31 magnesium alloy strengthened by Al2O3 nano-particles [J]. Wear, 2009, 268: 405-412.

[8] NGUYEN Q B, GUPTA M. Microstructure and mechanical characteristics of AZ31B/Al2O3 nanocomposite with addition of Ca [J]. Journal of Composite Materials, 2009, 43: 5-17.

[9] SAHIN Y. Wear behavior of aluminium alloy and its composites reinforced by SiC particles using statistical analysis [J]. Materials and Design, 2003, 24: 95-103.

[10] MONTGOMERY D C, RUNGER G C. Applied statistics and probability for engineers [M]. 2nd ed. New York: John Wiley & Sons, 1999.

[11] BARNES J W. Statistical analysis for engineers and scientists: a computer based approach [M]. New York: Mc Graw-Hill, 1994.

[12] GUL F, ACILAR M. Effect of reinforcement volume fraction on dry sliding wear behavior of Al-10Si/SiCp composites produced by vacuum infiltration technique [J]. Composite Science and Technology, 2004, 64: 1959-1970.

[13] HOKKIRIGAWA K, KATO K. An experimental and theoretical investigation of ploughing, cutting and wedge formation during abrasive wear [J]. Tribology International, 1988, 21: 151-158.

[14] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics, 1953, 24: 981-988.

[15] ZHANG J, ALPAS A T. Wear regimes and transitions in Al2O3 particulate-reinforced aluminum alloys [J]. Material Science Engineering A, 1993, 161: 273-284.

[16] PRAMILA BAI B N, RAMASESH B S, SURAPPA M K. Dry sliding wear of A356-Al-SiCp composites [J]. Wear, 1992, 157: 295-304.

[17] WILSON S, ALPAS A T. Wear mechanism maps for metal matrix composites [J]. Wear, 1997, 212: 41-49.

[18] QUINN T F J, SULLIVAN J L, ROWSON D M. Origins and development of oxidational wear at low ambient temperatures [J]. Wear, 1984, 94: 175-191.

AZ31B镁合金及其纳米复合材料的滑动磨损行为

M. SRINIVASAN1, C. LOGANATHAN2, M. KAMARAJ3, Q. B. NGUYEN4,

M. GUPTA4, R. NARAYANASAMY5

1. Department of Mechanical Engineering, Saranathan College of Engineering,Tiruchirappalli, Tamilnadu 620012, India;

2. St. Jospeh’s College of Engineering and Technology, Thanjavur, Tamilnadu 613403, India;

3. Department of Metallurgical and Materials Engineering, Indian Institute of Technology Madras,Chennai, Tamilnadu 600036, India;

4. Department of Mechanical Engineering, National University of Singapore,9 Engineering Drive 1, Singapore 117576, Singapore;

5. Department of Production Engineering, National Institute of Technology,Tiruchirappalli, Tamilnadu 620015, India

摘 要:采用复合铸造工艺制备AZ31B镁合金及其纳米复合材料,再对所得材料在350 °C进行热挤压。采用标准的销-盘式摩擦磨损试验机对AZ31B镁合金及其纳米复合材料的室温滑动磨损行为进行研究。实验条件为法向载荷10 N、滑移速度0.60~1.2 m/s、滑移距离2000 m。采用SEM观察来研究磨损表面的磨损机理。通过构建一个线性回归模型来研究试验参数对磨销磨损率的影响。与AZ31B镁合金相比,由于增强体的作用而导致的硬度增强使复合材料表现出低的磨损率。犁削、犁沟、分层和氧化构成混合的磨损机理。

关键词:AZ31B镁合金;纳米复合材料;磨损机理

(Edited by YANG Hua)

Corresponding author: M. SRINIVASAN; Mobile: +91-94435-48564; Tel/Fax: +91-431-2473684; E-mail: srini.janu@gmail.com; srinivasanm@ saranathan.ac.in

DOI: 10.1016/S1003-6326(11)61140-0