Trans. Nonferrous Met. Soc. China 22(2012) 2153-2157

Influence of pyrolysis temperature on ferroelectric properties of La and Mn co-doped BiFeO3 thin films

CHENG Chuan-pin1, JIANG Bo2, TANG Ming-hua2, YANG Song-bo2,

XIAO Yong-guang2, WANG Guo-yang2, ZHOU Yi-chun2

1. Faculty of Science, Hunan Institute of Engineering, Xiangtan 411105, China;

2. Key Laboratory for Low Dimensional Materials and Application Technology of Ministry of Education,

Xiangtan University, Xiangtan 411105, China

Received 19 September 2011; accepted 1 March 2012

Abstract: Bi0.9La0.1Fe0.95Mn0.05O3 (BLFMO) ferroelectric thin films were fabricated on Pt/Ti/SiO2/Si/ substrates by the sol-gel process at different pyrolysis temperatures. The mass loss of BLFMO powder was investigated by thermo gravimetry analyser (TGA), and the polycrystalline structure and smooth surface of BLFMO thin films were characterized by X-ray diffraction (XRD) and atomic force microscopy (AFM), respectively. The remnant polarization (Pr) of the BLFMO films pyrolyzed at 420 ℃ is 21.2 μC/cm2 at the coercive field (Ec) of 99 kV/cm and the leakage current density is 7.1×10-3 A/cm2, which indicates that the BLFMO thin films display relatively good ferroelectric property at this temperature.

Key words: BLFMO thin films; thermogravimetry analysis; pyrolysis temperature; ferroelectrics

1 Introduction

Lead-free BiFeO3 (BFO) ferroelectric thin film, with a rhombohedral distorted perovskite structure, is the only thin film material that exhibits both ferroelectricity and G-type antiferromagnetism at room temperature, and possesses a giant remanent polarization and high Curie temperature (TC=1103 K), which makes itself a candidate material for high-density nonvolatile ferroelectric random access memory and other potential interesting applications [1-3]. Besides pulsed-laser deposition (PLD) and RF sputtering [4,5], large remnant polarization (Pr) in BFO thin films has also been reported in previous literatures by sol-gel preparation which has many advantages [6,7], such as easy control of stoichiometry, low processing temperature, and low cost. However, pure BFO thin films are confronted with a serious high leakage current problem resulting from poor sample quality, the charge defects such as oxygen vacancies, and the switching valence of Fe3+ between Fe2+, which hinders its practical applications. To reduce the leakage current and improve the remanent polarization of BFO [8,9], A-site is substituted by La3+, Ce3+ and Eu3+, and B-site is substituted by Mn3+, Ti4+ and Zr4+ [8-11]. Additionally, co-doping on both sites can also diminish the leakage current, even in two or three orders of magnitude [12,13].

First-principle calculation predicts that the BiFeO3 films possess a large spontaneous polarization (Ps) of ~100 μC/cm2 for rhombohedral structure and ~150 μC/cm2 for tetragonal structure [14]. SINGH et al [9] reported that Mn-doped BFO films can increase Pr value due to the increasing of the tetragonality phase transition. Their successive researches indicated that a better saturated polarization-electric field (P—E) hysteresis loop with a larger remanent polarization of 100 μC/cm2 can be obtained in 5% Mn-doped BFO film using sol-gel process [15,16].

So far, much attention has been paid to the process conditions of the BFO thin film, such as the doping, annealing temperature, annealing atmosphere, thickness, the bottom electrode and solution configuration. However, little attention is paid to the pyrolysis temperatures. Therefore, we try to obtain preferable pyrolysis temperature by TGA, and analyze the influence of different pyrolysis temperatures on the electrical properties of thin films. In this study, in order to enhance ferroelectricity and reduce leakage current, Bi0.9La0.1Fe0.95Mn0.05O3 films were fabricated on Pt/Ti/SiO2/Si substrates by sol-gel process, using sequential layer annealing (SLA) process and pyrolysis at different temperatures. Crystalline structure, surface morphology and electrical properties were investigated, respectively.

2 Experimental

To prepare Bi0.9La0.1Fe0.95Mn0.05O3 (BLFMO) precursor solution, bismuth nitrate, lanthanum nitrate, iron nitrate and manganese acetate were dissolved into 2-methoxyethanol, ethylene glycol and acetic anhydride, stirred at 110 ℃ for 1 h, and then adjusted solution to 0.2 mol/L BLFMO. After ageing for 48 h, the solution was filtered by pinhole membrane filter of 0.22 μm in diameter, and was spin-coated on the Pt/Ti/SiO2/Si substrates at 4000 r/min, pyrolyzed at 350, 400 and 420 ℃, and annealed at 550 ℃ for 5 min. These processes were repeated 9 times until the thickness of the film approached about 300 nm, and then the final annealing was conducted at 550 ℃ for 20 min in O2.

The mass loss of BLFMO powder was estimated by TGA, the crystalline structure and surface morphology of BLFMO thin films were investigated by XRD and AFM, respectively. For the measurement of electrical properties, Pt top electrodes were deposited through a shadow mask by RF sputtering. The ferroelectric property and leakage current behavior of the films were measured using a Radiant technologies precision workstation ferroelectric test system. All measurements were implemented at room temperature.

3 Results and discussion

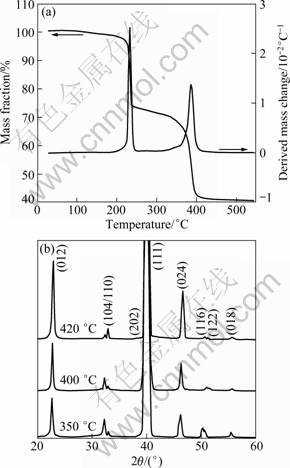

Figure 1(a) shows the TG curve of Bi0.9La0.1Fe0.95Mn0.05O3 power at a heating rate of 10 ℃/min. There is a fall in sample mass of ~23% between 180 ℃ and 240 ℃, due to the volatile substances. Another fall in sample mass of ~28% appears between 360 ℃ and 420 ℃ because of the precursor decomposition. We recognize that pyrolysis temperature may be determined by volatile organic compounds. If the sample is pyrolyzed below the temperature of the precursor decomposition, some organic compositions in the films were volatile in the annealing process, resulting in inferior quality films. Therefore, based on the analysis of the TG curves, we intended to choose three temperatures (350 ℃, 400 ℃ and 420 ℃) as the pyrolysis temperatures, among which, 350 oC is usually adopted as a pyrolysis temperature in other papers [9,13,14]. Figure 1(b) exhibits the XRD patterns of BLFMO thin films pyrolyzed at various temperatures, and indicates that BLFMO thin films are polycrystalline and crystallized. Besides the relatively strong (012), (024) and (104/110) diffraction peaks, there are also (202), (116/122) and (018) peaks. As the pyrolysis temperature grows, crystallinity of films overall increases, especially the (012) diffraction peaks enhance significantly, while (104/110) diffraction peaks decline. Due to the release of other elements before annealing, the density of the thin films ascends, and the activation energy of crystallization of thin films lessens [17]. We can choose a suitable temperature to pyrolyze the films to get the crystallization enhanced while the annealing temperature unchanged.

Fig. 1 TG curve of BLFMO powder (a) and XRD patterns of BLFMO thin films (b)

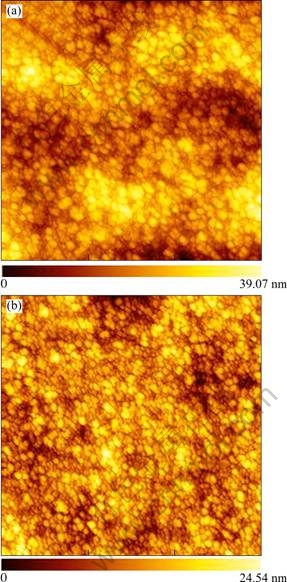

Figure 2 shows the surface morphology of the BLFMO thin films characterized using atomic force microscopy (AFM). BLFMO thin film pyrolyzed at 350 ℃ (Fig. 2(a)) has larger grain size with a few tiny interstices, while the thin film pyrolyzed at 420 ℃ (Fig. 2(b)) presents dense, crack-free and smooth surface and small grain size. With the increase of pyrolysis temperature, the interstices of BLFMO thin films diminish, and the density, smoothness and crystallization improve as well. We predict that the dense and crack-free microstructure contributes much more to improving ferroelectric performance.

Fig. 2 AFM images of BLFMO thin films under pyrolysis temperature: (a) 350 ℃; (b) 420 ℃

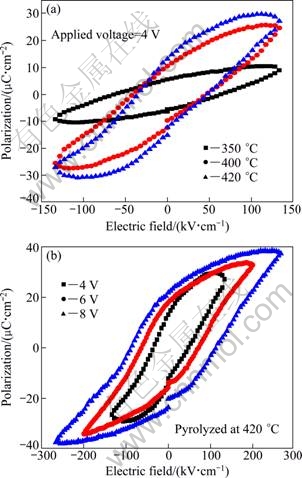

Figure 3(a) displays the typical P—E hysteresis loops of BLFMO thin films at different pyrolysis temperatures. One can see that the ferroelectric properties (the remanent polarization and the coercive electric field) become better as the pyrolysis temperature increases. The sample pyrolyzed at 350 ℃ is not well saturated under the coercire field (Ec) of 63 kV/cm and the ferroelectric performance is not obvious, due to its high leakage current and low crystallization. When the pyrolysis temperature goes up to 420 ℃, the Pr is 12 μC/cm2 and the Ec is 42 kV/cm. LI et al [18] reported that different preferred orientations have different spontaneous polarizations (Ps), and the Ps value of (012) peak is theoretically smaller than that of (104/110) peak. In our study, due to the higher crystallization and relatively good film quality, the film pyrolyzed at 420 ℃ with (012) preferred orientation gets higher Pr value than the one pyrolyzed at 350 ℃ with (104/110) preferred orientation. Figure 3(b) shows the P—E loops with different operation electric fields at the pyrolysis temperature of 420 ℃. Under the condition of 267 kV/cm electric field and 10 kHz frequency, the largest Pr value comes to be 21.2 μC/cm2 with a low coercive field (Ec=99 kV/cm).

Fig. 3 P—E loops of BLFMO thin films at different pyrolysis temperatures (a) and at different operating electric fields pyrolyzed at 420 ℃ (b)

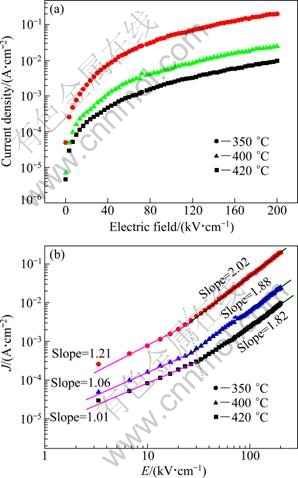

Figure 4(a) illustrates the leakage current density—voltage (J—V) curves of BLFMO thin films. One can see that the current density value decreases as the pyrolysis temperature increases. The leakage current density of the sample pyrolyzed at 420 ℃ is less than 7.1 mA/cm2 at the maximum applied electric field of 200 kV/cm. Large leakage current mainly results from the oxygen vacancies and iron valence (Fe2+, Fe3+), as well as from various defects such as stoichiometry, pores, cracks and interstices in films. In this work, besides by means of substitution and annealing in O2, we try to decrease the leakage current by improving the quality of thin films and reducing its defects. We can see from the XRD patterns that the enhancement of crystallinity is one of the improvements for the thin film quality. And a higher pyrolysis temperature can reduce unwanted content of thin films before annealing, and make thin films lessen the cracks and pores, etc.

Figure 4(b) shows the double logarithmic plots of the leakage current curve of BLFMO films pyrolyzed at different temperatures. In all samples, the leakage current density was in proportion to the electric field. The slope 1.21 under a low electric field for the films pyrolyzed at 350 ℃ is transitional region. The slopes of films pyrolyzed at 400 and 420 ℃ are approximately 1 under a low electric field, and turn to 2 when electric field increases, indicating that the leakage current predominantly depends on Ohmic conduction.

Fig. 4 J—V curves of BLFMO thin films pyrolyzed at various temperatures (a) and double logarithmic plots of leakage current curve for BLMO films at various temperatures (b)

4 Conclusions

BLFMO ferroelectric thin films were fabricated at different pyrolysis temperatures. When the pyrolysis temperature was increased, relatively high quality thin films with higher crystallization, better density and smoothness, larger remnant polarization, and lower leakage current density were obtained. At the electric field of 133 kV/cm, the Pr ranges from 6.2 μC/cm2 to 12 μC/cm2 with coercive electric field varying from 63 kV/cm to 42 kV/cm at various temperatures in the range of 350-420 ℃. At the electric field of 267 kV/cm, thin film pyrolyzed at 420 ℃ exhibits a saturate ferroelectric hysteresis loop with the remanent polarization of 21.2 μC/cm2 at coercive electric field of 99 kV/cm and leakage current density of 7.1 mA/cm2.

References

[1] SCOTT J F, ARAUJO C A. Ferroelectric memories [J]. Science, 1989, 246: 1400-1405.

[2] FIEBIG M, LOTTERMOSER T, GOLTSEV A V, PISAREV R V. Observation of coupled magnetic and electric domains [J]. Nature, 2002, 419: 818-820.

[3] WANG J, NEATON J B, ZHENG H, NAGARAJAN V, OGALE S B, LIU B, VIEHLAND D, VAITHYANAATHAN V, SCHLOM D G, WAGHMARE U V, SPALDIN N A, RABE K M, WUTTIG M, RAMESH R. Epitaxial BiFeO3 multiferroic thin film heterostructures [J]. Science, 2003, 299: 1719-1722.

[4] LIU H J, YANG P, YAO K, WANG J. Twinning rotation and ferroelectric behavior of epitaxial BiFeO3 (001) thin film [J]. Appl Phys Lett, 2010, 96: 012901-1-3.

[5] WU J G, WAN J. Improved ferroelectric behavior in (110) oriented BiFeO3 thin films [J]. J Appl Phys, 2010, 107: 034103-1-4.

[6] MUKHERJEE S, GUPTA R, GARG A, BANSAL V, BHARGAVA S. Influence of Zr doping on the structure and ferroelectric properties of BiFeO3 thin films [J]. J Appl Phys, 2010, 107: 123535-1-5.

[7] KIM K, SONG Y J. Integration technology for ferroelectric memory devices [J]. Microelectronics Reliability, 2003, 43: 385-398.

[8] KHOMCHENKO V A, KARPINSKY D V, KHOLKIN A L, SOBOLEV N A, KAKAZEI G N, ARAUJO J P, TROYANCHUK I O, COSTA B F O, PAIXAO J A. Rhombohedral-to-orthorhombic transition and multiferroic properties of dy-substituted BiFeO3 [J]. J Appl Phys, 2010, 108: 074109-1-5.

[9] SINGH S K, MENOU N, FUNAKUBO H, MARUYAMA K, ISHIWARA H. (111)-textured Mn-substituted BiFeO3 thin films on SrRuO3/Pt/Ti/SiO2/Si structures [J]. Appl Phys Lett, 2007, 90: 242914-1-3.

[10] UNIYAL P, YADAVA K L. Room temperature multiferroic properties of Eu doped BiFeO3 [J]. J Appl Phys, 2009, 105: 07D914-1-3.

[11] WEN Z, HU G D, FAN S H, YANG C H, WU W B, ZHOU Y, CHEN X M, CUI S G. Effects of annealing process and Mn substitution on structure and ferroelectric properties of BiFeO3 films [J]. Thin Solid Films, 2009, 517: 4497-4501.

[12] EDERER C, SPALDIN N A. Effect of epitaxial strain on the spontaneous polarization of thin film ferroelectrics [J]. Phys Rev Lett, 2005, 95: 257601-1-4.

[13] SINGH S K, ISHIWARA H, SATO K, MARUYAMA K. Microstructure and frequency dependent electrical properties of Mn-substituted BiFeO3 thin films [J]. J Appl Phys, 2007, 102: 094109-1-5.

[14] SINGH S K, ISHIWARA H, MARUYAMA K. Room temperature ferroelectric properties of Mn-substituted BiFeO3 thin films deposited on Pt electrodes using chemical solution deposition [J]. Appl Phys Lett, 2006, 88: 262908-1-3.

[15] WU J G, WANG J, XIAO D Q, ZHU J G. Combined effects of bilayer structure and ion substitutions on bismuth ferrite thin films [J]. J Appl Phys, 2011, 109: 074101-1-4.

[16] YANG K G, ZHANG Y L, YANG S H, WANG B. Structural, electrical, and magnetic properties of multiferroic Bi1-xLaxFe1-yCoyO3 thin films [J]. J Appl Phys, 2010, 107: 124109-1-6.

[17] HU G D, WILSON I H, XU J B, CHEUNG W Y, WONG S P, WONG H K. Structure control and characterization of SrBi2Ta2O9 thin films by a modified annealing method [J]. Appl Phys Lett, 1999, 74: 1221-1223.

[18] LI J, WANG J, WUTTIG M, RAMESH R, WANG N, RUETTE B, PYATAKOV A P, ZVEZDIN A K, VIEHLAND D. Dramatically enhanced polarization in (001), (101), and (111) BiFeO3 thin films due to epitiaxial-induced transitions [J]. Appl Phys Lett, 2004, 84: 5261-5263.

热解温度对镧、锰共掺杂铁酸铋薄膜铁电性能的影响

成传品1,蒋 波2,唐明华2,杨松波2,肖永光2,王国阳2,周益春2

1. 湖南工程学院 理学院,湘潭 411105;

2. 湘潭大学 低维材料与应用技术教育部重点实验室,湘潭 411105

摘 要:在不同热解温度下,采用溶胶-凝胶法在Pt/Ti/SiO2/Si衬底上制备镧、锰共掺杂铁酸铋铁电薄膜Bi0.9La0.1Fe0.95Mn0.05O3(BLFMO)。利用热失重仪(TGA)分析BLFMO原粉的质量损失,用X射线衍射仪(XRD)和原子力显微镜(AFM)分析BLFMO薄膜的晶体结构和表面形貌。在热解温度为420 ℃时,得到BLMFO薄膜的剩余极化值为21.2 μC/cm2,矫顽场为99 kV/cm,漏电流密度为7.1×10-3 A/cm2,说明薄膜在此热解温度下具有较好的铁电性能。

关键词:BLFMO薄膜;热重分析;热解温度;铁电

(Edited by YANG Hua)

Foundation item: Project (11032010) supported by Key Project of National Natural Science Foundation of China; Projects (51072171, 61274107, 61176093, 11275163) supported by the National Natural Science Foundation of China; Project (IRT1080) supported by Program for Changjiang Scholars and Innovation Research Team in University; Project (2012CB326404) supported by National Basic Research Program of China; Project (CX2011B248) supported by Hunan Provincial Innovation Foundation for Postgraduate; Project (20104301110001) supported by the Doctoral Program of Higher Education of China

Corresponding author: TANG Ming-hua; Tel: +86-731-58292200; Fax: +86-731-58292468; E-mail: mhtang@xtu.edu.cn

DOI: 10.1016/S1003-6326(11)61442-8