文章编号:1004-0609(2010)S1-s0242-06

时效热处理对α挤压态TiAl合金显微组织的影响

刘 冬,刘仁慈,崔玉友,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:研究了不同时效热处理后挤压态γ-TiAl合金在高温期间显微组织的稳定性。结果表明:在1 330 ℃将Ti-47Al-2Cr-2Nb-0.15B合金挤压得到近片层组织,将α单相区热处理后得到全片层组织,在700~1 000 ℃停留不同时间后进行时效处理,从平行挤压方向上观察,在全片层晶界处出现细小γ晶粒,随着时效时间的延长,γ晶粒增大,其体积分数增加;全片层晶粒晶界处的非连续界面处首先发生不连续粗化,最终转变为拉长的γ晶粒,然后层片晶团内部各片层之间的连续界面处发生连续粗化,具有小曲率的薄α2片层开始以逐步变薄的方式断开和溶解,γ片层得到粗化。

关键词:TiAl;时效热处理;显微组织;片层

中图分类号:TG 146.2 文献标志码:A

Effect of aged-heat treatment on microstructure of

α extruded TiAl alloy

LIU Dong, LIU Ren-ci, CUI Yu-you, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The stability of the microstructure of extruded γ-TiAl alloy in high temperature was studied after different aged-heat treatment. The results show that Ti-47Al-2Cr-2Nb-0.15B alloy is extruded in 1 330 ℃ and the deformed near full lamellar (NFL) microstructure is obtained. Full lamellar (FL) microstructure forms after single α phase is heat treated. Observing from parallel extruding direction, the fine γ grain appears in FL grain boundary after being held at 700- 1 000 ℃ for different times. As the aged-time prolongs, the γ grain grows up and the volume fraction of γ grain increases. Discontinuous coarsening happens in the discontinuous boundary of FL grains firstly, which transforms the extended γ grain eventually, and then the continuous interface thickens continuously among lamellars in inner grain, the thin and small curvature α2 lamellar starts to disconnect and melt and the γ lamellar is thickened.

Key words: TiAl; aged-heat treatment; microstructure; lamellar

γ-TiAl 合金密度低、比强度和比模量高,具有较好的抗氧化性和较高的蠕变抗力,在航空航天和汽车等应用领域具有很大的应用前景,近年来受到研究者的广泛重视[1-3]。作为高温应用材料的TiAl合金,在高温服役时,组织的稳定性对其应用特别重要,显微组织的改变会引起材料性能的显著变化。本文作者以挤压变形态γ-TiAl合金为实验材料,通过调整时效热处理制度来研究Ti-47Al-2Cr-2Nb-0.15B合金的高温显微组织的稳定性。

1 实验

TiAl合金的名义成分为Ti-47Al-2Cr-2Nb-0.15B (摩尔分数,%),TiAl合金电极经真空自耗电弧炉一次熔炼后制备母合金,然后通过水冷铜坩锅感应炉重熔经离心铸造成d 75 mm×150 mm的棒材。挤压实验在630 t的垂直式挤压机上进行,挤压比为6?1。挤压 温度(tα)为1 330 ℃。挤压后得到直径为30 mm的棒材。沿挤压方向从棒材中抽取试样(d 8 mm×10 mm)放入充氩气的石英管中封装,在KSS-1600马福炉进行热处理。金相样品经2000#砂纸研磨、抛光后在Kroll腐蚀液中刻蚀。热处理后试样利用Axiovert200MAT型光学显微镜和FEI-TECNAIG型透射电镜进行显微组织分析。时效热处理具体制度如下:

1) 样品加热至900 ℃,加热速度为20 ℃/min,保温持续时间分别为2、8、24、48 h,然后空冷到室温。

2) 样品加热至1 340 ℃,加热速度为20 ℃/min,保温10 min后,然后空冷到室温。样品重新加热至900 ℃,保温持续时间分别为2、8、24、48 h,然后空冷到室温。

3) 样品加热至1 340 ℃,加热速度为20 ℃/min,保温10 min后,然后空冷到室温。样品重新加热至700、800、900、1 000 ℃,保温8 h后,空冷至室温。

2 结果与讨论

2.1 时效时间对α挤压态TiAl合金显微组织的影响

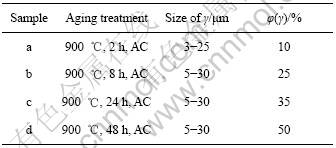

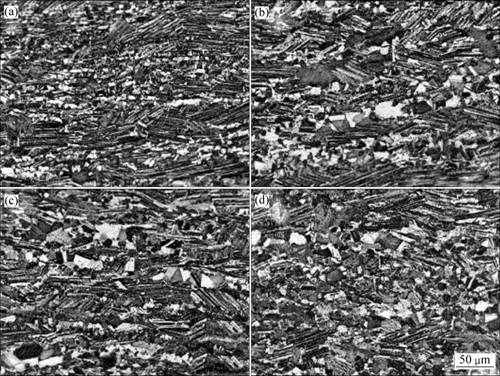

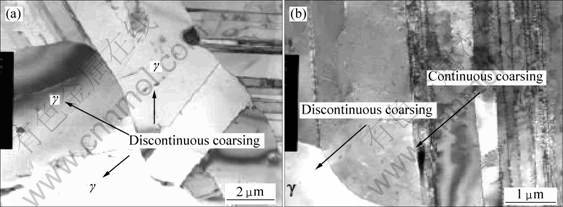

Ti-47Al-2Cr-2Nb-0.15B合金在1 330 ℃挤压得到片层组织,直接在900 ℃停留2、8、24、48 h,然后空冷至室温,其结果如图1所示。在平行挤压方向上可以观察到经过900 ℃,2 h时效后,在片层的晶界处出现细小γ晶粒(见图1(a)),随着时效时间的延长,γ晶粒逐渐增大,体积分数也逐渐增大,其结果如表1所列。片层晶界之间的非连续界面处开始发生不连续粗化,并最终转变为拉长的γ晶粒(见图1(b))。在透射电镜下可以观察到Ti-47Al-2Cr-2Nb-0.15B合金细小片层界面间位错堆积及经900 ℃,24 h时效后片层晶粒内部的片层之间的连续界面处发生连续粗化,具有小曲率的薄α2片层开始以逐步变薄的方式断开和溶解,γ片层得到粗化(见图2)。总体来看,与挤压态相比,通过900 ℃时效不同时间段后的显微组织发生2个显著变化:1) 带状组织中局部富Al的地方,首先发生γ晶粒再结晶,并随时间的延长,晶粒度和体积分数都在增加(见图1);2) 层片晶团内部α2片层溶解,γ片层得到粗化(见图2(b));

表1 挤压γ-TiAl合金经不同时效处理后的晶粒参数统计

Table 1 Statistic of grain parameters of extruded γ-TiAl after different aging treatments

图1 Ti-47Al-2Cr-2Nb-0.15B合金在900 ℃挤压时效后不同时间的金相照片

Fig.1 Metallographs of Ti-47Al-2Cr-2Nb-0.15B alloy extruded then aged at 900 ℃ for different times: (a) 2 h; (b) 8 h; (c) 24 h; (d) 48 h

Ti-47Al-2Cr-2Nb-0.15B合金在1 330 ℃挤压得到的片层组织是由挤压热变形过程中发生动态再结晶和随后空冷静态再结晶二者结合的结果。因为2个再结晶过程都比较短暂,在挤压变形过程中,储存的畸变能得不到释放,晶粒内部存在着大量位错(见图2(a)),为时效热处理中提供了形核和驱动力。

图2 TiAl合金挤压态及时效处理(900 ℃,24 h)后片层界面组织

Fig.2 Dislocation accumulating in interface of fine lamellar of TiAl alloy(a) and α2 lamellar dissolution and γ lamellar coarsening after aged at 900 ℃ for 24 h(b)

另一方面,挤压态带状组织的存在也为组织转变提供了化学梯度,片层晶带间Al富集的地方首先再结晶为γ晶粒,使全片层组织发生分解。热变形片层组织(TMPL)虽然具有优良的室温性能[4-5](σ0.2=678 MPa,σb=729 MPa,δ=3.6%),但是由于组织中储存大量的形变能,使其显微组织在时效过程中很不稳定,全片层很快就分解了。为了稳定其组织,合金需要经过α单相区短时间的固溶处理。

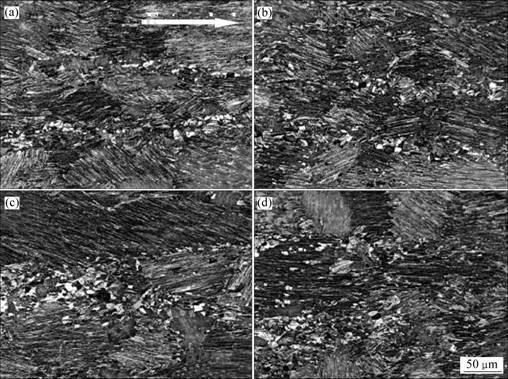

2.2 时效时间对α单相区固溶热处理TiAl合金显微组织的影响

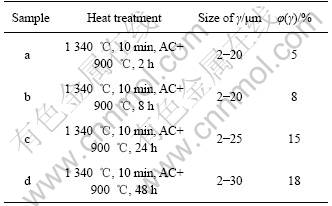

在1 330 ℃挤压的Ti-47Al-2Cr-2Nb-0.15B合金经α单相区热处理(1 340 ℃,10 min,AC)后形成沿挤压方向取向的全片层组织(TMTL)。这些热处理得到的片层组织明显带有挤压组织痕迹,几乎所有片层晶粒都沿挤压方向被拉长,而且片层方向大部分与挤压方向相一致或呈小角度偏差(见图3(a)),经900 ℃时效不同时间后,在晶界处开始不连续粗化形核形成细小的γ晶粒。但是合金即使时效48 h后,这些γ晶粒也没有如挤压态TiAl合金那样明显长大,γ晶粒大小一直保持在30 μm以下,体积分数在18%以内(见表2)。

表2 γ-TiAl合金α单相区经900 ℃热处理不同时间后的晶粒参数统计

Table 2 Statistic of grain parameters of single α phase region of extruded γ-TiAl after heat treated at 900 ℃ for different times

合金通过1 340 ℃,10 min热处理,在α单相区充分静态再结晶,畸变能得到释放,但是随后空冷条件下由于冷却速度过快,得到的片层组织片层间距较小、界面上台阶较多、界面位错和晶内位错密度相对较高,因此组织也远离平衡态。在这种情况下,组织不稳定主要是由各种非平衡的微结构和亚结构引起的。首先在片层晶界处发生不连续粗化,造成片层边缘溶解(见图3(a)、(b)和图4(a))。时效时间大于8 h后,在全片层晶粒内部观察到连续粗化现象(见图4(b)),造成细α2片层溶解,γ片层变宽,部分最终转变为γ晶粒。但是相比TMPL组织,γ晶粒的晶粒粒径和体积分数上都要小得多。因为经α单相区固溶处理后,挤压态片层组织发生静态再结晶使位错、台阶和孪晶的密度大为减少,片层也相比以前略厚,界面减少,所以发生在片层内部的连续粗化的几率也减小。

图3 Ti-47Al-2Cr-2Nb-0.15B合金经α单相区热处理和时效后的显微组织

Fig.3 Microstructures of Ti-47Al-2Cr-2Nb-0.15B alloy after single α phase heat treatment and different ageing conditions: (a) 900 ℃, 2 h; (b) 900 ℃, 8 h; (c) 900 ℃, 24 h; (d) 900 ℃, 48 h

图4 固溶处理和900 ℃,48 h时效后TiAl合金的显微组织

Fig.4 Microstructures of TiAl alloy after solution treatment and ageing at subject to heat treatment of 900 ℃ for 48 h: (a) Discontinuous coarsening and γ grains forming in interface of lamellar; (b) Continuous coarsening on lamellar dissolution and γ lamellar coarsening in grain

2.3 时效温度对α单相区固溶热处理TiAl合金显微组织的影响

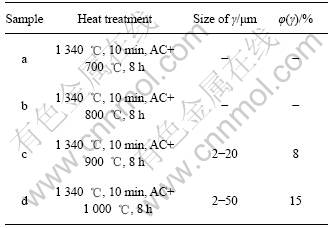

在1 330 ℃下挤压的Ti-47Al-2Cr-2Nb-0.15B合金经α单相区固熔热处理(1 340 ℃,10 min,AC),然后分别经700、800、900和1 000 ℃时效处理8 h (见表3),以考察Ti-47Al-2Cr-2Nb-0.15B合金在各个温度段的组织稳定性。

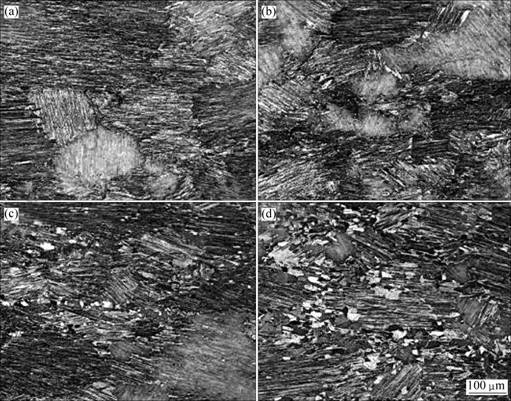

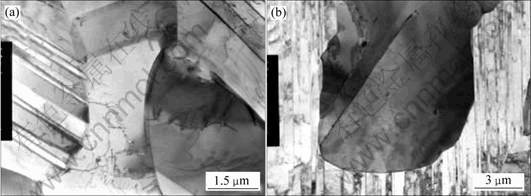

图5所示为Ti-47Al-2Cr-2Nb-0.1B合金经α单相区热处理和时效的显微组织。由图5(a)可以看出,α单相区处理得到的全片层组织经700 ℃,8 h时效未发生任何变化;经过800 ℃,8 h时效后,发现在晶界处开始不连续粗化(见图5(b)),但是γ晶粒没有形核长大,全片层晶粒组织虽还保留着全片层形貌,但已经出现连续粗化现象;经900 ℃,8 h时效后,晶界出现细小等轴γ晶粒,且在晶界内部也观察到γ小晶粒的出现(见图5(c));经1 000 ℃时效,晶界处γ晶粒得到迅速长大达50 μm(见图5(d)和图6(a)),在晶粒内部片层间发生连续粗化,α板条消溶,γ板条粗化和球化,在层片晶粒内部形成与片层方向相一致的长条形γ晶粒(见图6(b)),γ相体积分数随之增大。

表3 γ-TiAl合经α单相区热处理和不同温度时效后的晶粒参数统计

Table 3 Statistic of grain parameters of γ-TiAl alloy after α phase region heat treatment and aging at different temperatures

挤压态Ti-47Al-2Cr-2Nb-0.15B合金经α单相区短时间保温以较快速率冷却至室温得到的全片层组织,一般晶粒尺寸和片层间距较小,片层组织中存在各种非平衡亚结构,界面上台阶数目较多,界面位错和晶内位错密度比较高,还有位错攀移造成的亚晶界[6]。这些片层组织由α2、γ和γ孪晶片层构成,其中α2片层较细,γ片层较粗,片层界面微结构会对热稳定性产生影响。在时效温度大于900 ℃时,界面的微结构促使片层断开。α2片层的断开始于片层的缩颈化,然后缩颈逐步发展到断开,再进一步球化。所有的转变都是因为片层之间界面相交点要保持表面张力平衡所致,界面相交点一侧的α2/γ界面局部发生倾转,导致在界面相交处发生缩颈化,然后缩颈化进一步发生致片层断开。因而非平衡界面,孪晶都能促使α2片层断开分解。同时,在晶界处有新的γ晶粒形成,它将不断吞食原片层组织而长大。

图5 Ti-47Al-2Cr-2Nb-0.15B合金经α单相区热处理和时效的显微组织

Fig.5 Microstructures of TiAl alloy after α phase region heat treatment and different aging treatments: (a) 700 ℃, 8 h; (b) 800 ℃, 8 h; (c) 900 ℃, 8 h; (d) 1 000 ℃, 8 h

图6 片层晶界边缘的γ晶粒和晶粒内部连续粗化后形成拉长的γ晶粒的形貌

Fig.6 Microstructures of γ grain appearing at boundary of lamellar grain(a) and elongated γ grain inner of lamellar grain due to continuous coarsening(b)

3 结论

1) 针对细小全片层组织,研究时效时间和时效温度对组织稳定性的影响,发现在1 330 ℃挤压得到的TiAl合金因为在挤压过程中储存的畸变能为热处理提供了形核的驱动力。在片层晶带间Al富集处很快就再结晶为γ晶粒,随着时效时间的延长,γ晶粒体积分数最大增至50%。

2) 在900~1 000 ℃温度范围内,TiAl合金具有非平衡结构的组织,在随后的时效过程中很不稳定。这些非平衡态条件为片层组织中的结构转变提供驱动力。片层的热稳定性与片间距有关,一般来说,片层越细越不稳定,越容易球化。

REFERENCES

[1] HUANG Shyh-chin, HALL ERNEST L. Plastic deformation and fracture of binary TiAl-base alloys[J]. Metallurgical Transaction A, 1991, 22: 427-439.

[2] LIPSITT H A. In high-temperature ordered intermetallic alloys[C]//KOCH C C. MRS, Pittsburgh, PA, 1985: 351-364.

[3] MAZIASZ P J, LIU C T. Development of ultrafine lamellar structure in two-phase γ-TiAl alloys[J]. Metallurgical and Materials Transaction A, 1998, 29: 105-117.

[4] SEMIATIN S L, SEETHARAMAN V, JAIN V K. Microstructure development during conventional and isothermal hot-forging of a near-gamma titanium aluminide[J]. Metall Mater Trans, 1994, 25: 2753-2768.

[5] JAIN V K, GOETZ R L, SEMIATIN S L. Can design for nonisothermal pancake forging of gamma titanium aluminide alloys[J]. Eng Industry, 1996, 118: 155-160.

[6] TANB Jian-cheng, HUANG Bai-yun, ZHOU Ke-chao. Factors affecting the lamellar spacing in two-phase TiAl alloys with fully lamellar microstructures[J]. Mater Res Bull, 2001, 36: 1737-1742.

(编辑 龙怀中)

通信作者:刘 冬;电话:024-83970951;E-mail: dliu@imr.ac.cn