Trans. Nonferrous Met. Soc. China 24(2014) 3372-3377

Solid-state reduction kinetics and mechanism of pre-oxidized vanadium-titanium magnetite concentrate

Shui-shi LIU, Yu-feng GUO, Guan-zhou QIU, Tao JIANG, feng CHEN

School of Minerals Processing and Bioengineering, Central South University Changsha 410083, China

Received 3 September 2013; accepted 4 March 2014

Abstract: The solid-state reduction kinetics of pre-oxidized vanadium-titanium magnetite concentrate was studied. The phase and microstructure of the reduction product were characterized by XRD, SEM and EDS methods, based on which the mechanism of the solid-state reduction was investigated. The results showed that using coal as reductant at 950-1100 °C, the solid-state reduction of the pre-oxidized vanadium-titanium magnetite concentrate was controlled by interface chemical reaction and the apparent activation energy was 67.719 kJ/mol. The mineral phase transformation during the reduction process can be described as follows: pre-oxidized vanadium-titanium magnetite concentrate → ulvospinel → ilmenite → FeTi2O5 → (FenTi1-n)Ti2O5. M3O5-type (M can be Fe, Ti, Mg, Mn, etc) solid solutions would be formed during the reduction process of the pre-oxidized vanadium-titanium magnetite concentrate at 1050 °C for 60 min. The poor reducibility of iron in M3O5 solid solutions is the main reason to limit the reduction property of pre-oxidized vanadium-titanium magnetite concentrate.

Key words: vanadium-titanium magnetite; solid-state reduction; reduction kinetics; reduction process

1 Introduction

Panxi Area of China is endowed with large reserves of vanadium-titanium magnetite, and the reserves of vanadium and titanium account for 11.6% and 35.17% of the total reserves in the world, respectively [1-4]. At present, China and Russia adopt the BF-BOF process to use the ores, while South Africa and New Zealand adopt the pre-reduction-electric furnace process, both of which can only recover the iron and vanadium [5,6]. In recent years, several metallurgy processes have been proposed to treat the vanadium-titanium magnetite concentrate, such as the reduction-magnetic separation and sodium roasting-reduction-electric furnace [7,8]. Obviously, the solid-state reduction is the key of all the technologies discussed above. The vanadium-titanium magnetite concentrate has a complicated structure, which contains minerals such as titanic magnetite, ilmenite, sulfur-bearing magnetic pyrite, gangue as well as other minerals; vanadium exists in a form of isomorphism in the titanium magnetite. Therefore, the reduction of vanadium-titanium magnetite concentrate is more complicated than other common ores, requiring higher temperature and longer reduction time to achieve a relatively high metallization ratio [9]. Hence, it is important to investigate the reduction kinetics and mechanism of the vanadium-titanium magnetite concentrate.

In recent decades, a large number of researches have been conducted to study the utilization and reduction of vanadium-titanium magnetite concentrate [10-15]. It was reported that ilmenite can be observed when ulvospinel was reduced at 500-800 °C, and the reduction of vanadium-titanium magnetite concentrate was mainly diffusion-controlled below 1050 °C, while reaction-controlled over 1050 °C [16,17]. The influencing factors of the reduction were investigated by many scholars, and the results suggested that the increase of reduction temperature, time and carbon to oxygen molar ratio could promote vanadium-titanium magnetite concentrate’s reduction, and they also found that the iron-joined crystal was formed, the size of which increased at first and then diminished with the increase of reduction time and carbon to oxygen molar ratio [18,19]. In addition, the intensification of the reduction process was also studied by scholars, which demonstrated that the addition of metal powder and sodium salt could greatly reduce the reduction temperature [20,21].

Most of the aforementioned studies mainly aimed at the gas reduction kinetics and the influencing factors of vanadium-titanium magnetite concentrate reduction. However, few researches have been conducted on the solid-state reduction kinetics and mechanism. The purpose of this work is to investigate the solid-state kinetics of pre-oxidized vanadium-titanium magnetite concentrate reduction with coal. The phase and the microstructure of the reduction product were characterized by XRD, SEM and EDS, based on which the mechanism of the solid-state reduction was studied.

2 Experimental

2.1 Materials

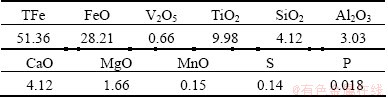

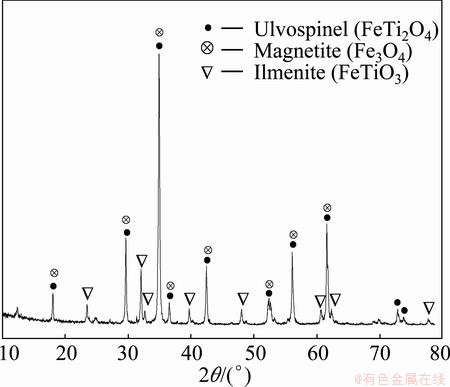

The vanadium-titanium magnetite concentrate (73% of concentrate less than 74 μm) used in this study was obtained from Panzhihua Iron & Steel Company (Sichuan province, China). The main chemical compositions and phases are shown in Table 1 and Fig. 1, respectively. The oxidized samples (TFe 50.76%; FeO 15.03%) were prepared by oxidizing vanadium-titanium magnetite concentrate, and the specific operation is described in section 2.2.2. The reduction coal was a soft coal obtained from Inner Mongolia, China (Fixed carbon 57.07%, volatile matter 33.83%, ash 4.52%, size <1 mm). The pelletizing binder was a multifunctional composite binder developed by Central South University [22].

Table 1 Chemical composition of vanadium-titanium magnetite concentrate (mass fraction, %)

Fig. 1 XRD pattern of vanadium-titanium magnetite concentrate

2.2 Procedure

2.2.1 Preparation of pellets

Vanadium-titanium magnetite concentrate was thoroughly mixed with 1% binder, and then pelletized to d10-15 mm in a disc pelletizer (d1000 mm). The wet pellets were dried at the temperature of (105±5) °C for 4 h.

2.2.2 Preparation of pre-oxidized

The pre-oxidation was carried out in a horizontal resistance furnace (d60 mm) with an automatic temperature control system. When the furnace temperature reached 900 °C, the corundum crucible filled with pellet samples was located into the furnace to oxidize for 6 min, and then removed, cooled to the room temperature in the air. The sample obtained would be used as the reduction sample.

2.2.3 Reduction

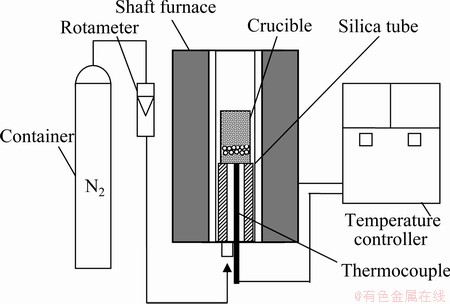

The reduction was carried out in a vertical resistance furnace (d60 mm) with an automatic temperature control system. 10 g of pre-oxidized pellets and 20 g of coal were loaded in a heat-resistant steel retort (d50 mm×100 mm). When the furnace was heated to the required temperature, the heat-resistant steel retort was put into the furnace. After a period of time, power supply was cut off and the reduction was stopped; the resort was take out quickly and the samples were poured into a container with nitrogen to cool down to the room temperature. The contents of total iron, ferrous and metallic iron were analyzed to calculate the reduction degree of iron. The microstructure and the phase of the reduction products were characterized by X-ray diffraction (Cu Kα radiation, λ=1.54056  , D/Max2200, Rigaku, Japan) and scanning electron microscope (SEM, Quanta200, FEI, Holland) equipped with energy dispersive analysis of X-ray (EDAX). Figure 2 illustrates the reduction experimental apparatus.

, D/Max2200, Rigaku, Japan) and scanning electron microscope (SEM, Quanta200, FEI, Holland) equipped with energy dispersive analysis of X-ray (EDAX). Figure 2 illustrates the reduction experimental apparatus.

Fig. 2 Schematic diagram of reduction apparatus

The reduction degree of iron is calculated by the following formula [23]:

where R is the reduction degree of iron; w(TFe) is the total iron content in the reduced sample; w(Fe) is the metallic iron content in the reduced sample; w(FeO) is the ferrous content in the reduced sample; w(TFe0) is the total iron content in the pre-oxidized sample; w(FeO0) is the ferrous content in the pre-oxidized sample.

3 Results and discussion

3.1 Solid-state reduction kinetics

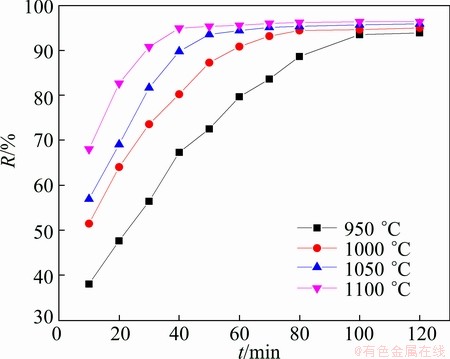

The isothermal reduction result of the pre-oxidized vanadium-titanium magnetite concentrate with coal reduced at 950-1100 °C is shown in Fig. 3, and R is the reduction degree of iron.

Fig. 3 Isothermal reduction curves of pre-oxidized vanadium-titanium magnetite concentrate

Figure 3 shows that the reduction degree of the iron is greatly affected by reduction temperature when the vanadium-titanium magnetite concentrates are reduced at relatively low temperature. However, the increase of the reduction degree slowed down when the degree was close to 95%.

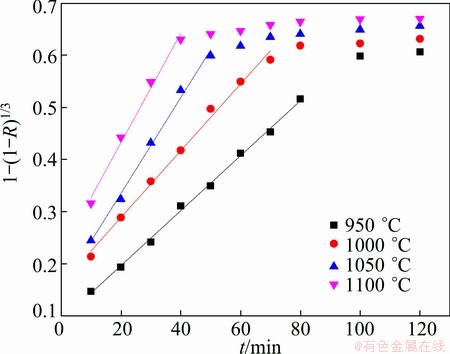

The unreacted shrinking core model was used to analyze the results and a graphic of the relationship between the reduction degree and the reduction time t was made, namely 1-(1-R)1/3 vs t and 1-2R/3-(1-R)2/3 vs t. At the test temperature, there is a better linear relationship between 1-(1-R)1/3 and t. Figure 4 shows that the solid-state reduction of the pre-oxidized vanadium-titanium magnetite concentrate with coal at 950-1100 °C is controlled by interface chemical reaction. From the slopes of the lines in Fig. 4, the speed constant k under different temperatures and the apparent activation energy can be calculated by adopting the Arrhenius equation, namely,

(1)

(1)

Taking the logarithm of both sides in the above equitation yields:

(2)

(2)

where E is the activation energy; k0 is the coefficient; k is the reaction rate constant; R is the molar gas constant, 8.314×10-3; T is the temperature.

Fig. 4 Relationship between 1-(1-R)1/3 and t at 950-1100 °C

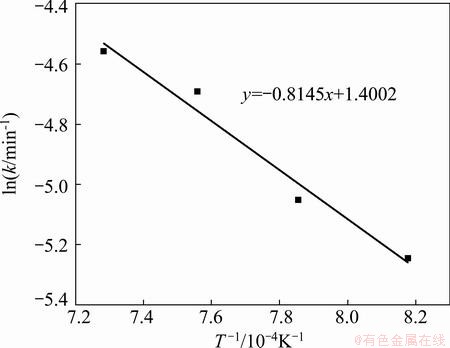

Figure 5 shows the Arrhenius curve of reaction rate constant k and temperature. As shown in Fig. 5, ln k has a linear relationship with 1/T. From the slope (-E/R), it can be calculated that the apparent activation energy of the solid-state reduction of the pre-oxidized vanadium- titanium magnetite concentrate is 67.719 kJ/mol.

Fig. 5 Arrhenius curve of reaction rate constant k and temperature

3.2 Phase transformation during reduction

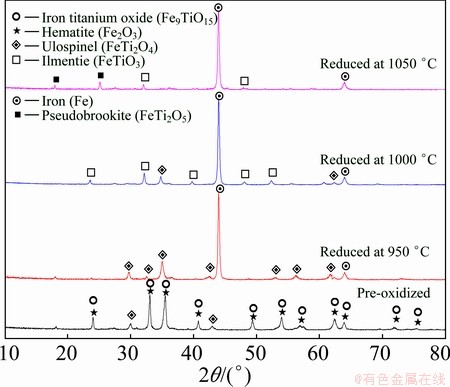

Phase transformation during reduction was investigated to find out the reaction mechanism of the solid-state reduction. Samples were reduced with coal at a given temperature for 60 min, and their XRD patterns are shown in Fig. 6.

Fig. 6 Phase transformation of reduction products

As shown in Fig. 6, the main phases of the pre-oxidized vanadium-titanium magnetite concentrate before reduction are Fe9TiO15 and Fe2O3. It should be noted that Ca, Mg, Al and other impurties were not detected by XRD. This is probably because the concentrations of these impurties are below the detection limit of the XRD technique.

When the reduction temperature was 950 °C, the phasese of Fe2O3 and Fe9TiO15 disappeared and the main phases of the reduction products were Fe and Fe2TiO4, suggesting that the following reactions occurred:

Fe2O3+C=2FeO+CO (3)

FeO+C=Fe+CO (4)

Fe9TiO15+11C=7Fe+Fe2TiO4+11CO (5)

When the reduction temperature was 1000 °C, the diffractive peaks of Fe2TiO4 weakened and that of FeTiO3 appeared, suggesting that the following reaction occurred:

Fe2TiO4+C=Fe+FeTiO3+CO (6)

When the reduction temperature was 1050 °C, the diffractive peaks of Fe2TiO4 disappeared, the specific diffractive peaks of FeTiO3 weakened and that of FeTi2O5 appeared, suggesting that the following reaction occurred:

2FeTiO3+C=Fe+FeTi2O5+CO (7)

According to the results of the isothermal reduction in Fig. 3, the reduction degree of iron is 94.41% after the pre-oxidized vanadium-titanium magnetite concentrate was reduced at 1050 °C for 60 min. Assuming that FeTi2O5 was the only unreduced iron-bearing and Ti-bearing mineral in the end, and TiO2 grade did not change after reduction, the reduction degree of iron could be calculated theoretically according to the definition, i.e., the loss of oxygen in the reduction.

The total oxygen in iron oxide: w(OT)= [15.03×(16/72)+39.78×(48/160)]×100%=16.91%; the remaining oxygen in iron oxide: w(ORemaining)=9.98× [16/(79.88×2)]×100%=1%. So, R=(16.91-1)/16.91= 94.08%.

Obviously, the actual reduction degree is approximately equal to the theoretical reduction degree, which means that iron oxide is almost reduced to FeTi2O5. GUO [23] reported that FeTi2O5 can be further reduced according to the following reaction:

(3-n)FeTi2O5+5(1-n)C=3(1-n)Fe+2(FenTi1-n)Ti2O5+5(1-n)CO, 0<N<1 (8)

For a lack of XRD characteristic spectral line data of (FenTi1-n)Ti2O5, this phase can not be found in the XRD detection results.

According to the earlier research [24], in the stage of generating float by magnetite iron reduction, the new phase of Fe2TiO4 was generated, which was further reduced to FeTiO3, and finally vanadium-titanium magnetite concentrate is reduced into Fe and (Fe,Mg)Ti2O5. The reduction process discussed in this work is consistent with the results obtained by the earlier researchers.

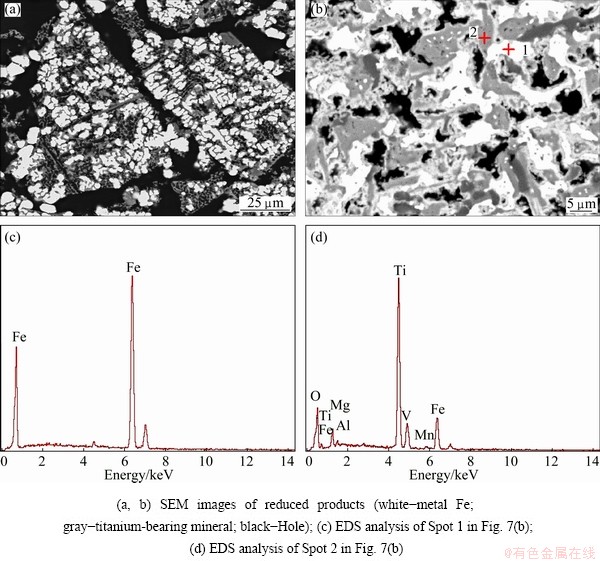

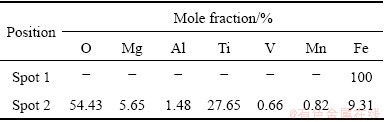

3.3 Microstructure of reduction products

Figure 7 shows the SEM and EDS analyses of the reduction products, which were obtained by reducing the pre-oxidized samples at 1050 °C for 60 min. As shown in Fig. 7, most of the metallic iron is located in the edges or cracks of the particles. From the result of EDS analysis (Spot 2), it can be inferred that part of iron oxide in pre-oxidized vanadium-titanium magnetite concentrate was not reduced and this part of iron oxide usually combined with Ti, Mg, Al, V, Mn, etc. The atomic number ratio suggested that these substances existed in the form of M3O5-type (M can be Fe, Ti, Mg, Mn etc).

To sum up, M3O5-type solid solution will be formed in the reduction of pre-oxidized vanadium-titanium magnetite concentrate. GUO et al [2] demonstrated that FeTi2O5 solid solution would be stable in the presence of MgO and MnO, and the iron ionic activity would be reduced. The vanadium-titanium magnetite concentrate used in this work has higher MgO content (1.66%), in which the iron in the M3O5 solid solution is hard to be completely reduced. Additionally, it is easy for the FeTi2O5 and the low-valence-state titanic oxide to be mutually soluble to the un-reacted ilmenite, which will reduce the iron ionic activity in the newly-formed ilmenite. Therefore, the poor reducibility of the iron in M3O5 solid solution is the main reason to limit the reduction property of pre-oxidized vanadium-titanium magnetite concentrate.

Fig. 7 SEM images and EDS analysis of reduced products

Table 2 EDS analyses of Spot 1 and Spot 2

4 Conclusions

1) The kinetics study indicated that, with coal reducing at 950-1100 °C, the solid-state reduction of the pre-oxidized vanadium-titanium magnetite concentrate was controlled by interface chemical reaction and the apparent activation energy was 67.719 kJ/mol.

2) The analyese on phases transformation of the reduced products suggested that, with coal reducing at 950-1050 °C, its reduction process was: pre-oxidized vanadium-titanium magnetite concentrate→ ulvospinel→ilmenite→ FeTi2O5→ (FenTi1-n)Ti2O5.

3) SEM and EDS analyses of the reduced products show that M3O5-type (M can be Fe, Ti, Mg, Mn, etc) solid solutions would be formed in the reduced products when the pre-oxidized vanadium-titanium magnetite concentrate was reduced at 1050 °C for 60 min, and the poor reducibility of iron in M3O5 solid solution is the main reason to limit the reduction property of pre-oxidized vanadium-titanium magnetite concentrate.

References

[1] WANG Ming-yu, WANG Xue-wen, HE Yue-hui, LOU Tai-ping, SUI Zhi-tong. Isothermal precipitation and growth process of perovskite phase in oxidized titanium bearing slag [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 459-462.

[2] GUO Yu-feng, YOU Gao, JIANG Tao, QIU Guan-zhou. Solid-state reduction behavior of Panzhihua ilmenite [J]. Journal of Central South University: Science and Technology, 2010, 41(5): 1639-1644. (in Chinese)

[3] TAN Ping, HU Hui-ping, ZHANG Li. Effects of mechanical activation and oxidation-reduction on hydrochloric acid leaching of Panxi ilmenite concentration [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6): 1414-1421.

[4] WANG Yu-ming, YUAN Zhang-fu, GUO Zhan-cheng, TAN Qiang-qiang, LI Zhao-yi, JIANG Wei-zhong. Reduction mechanism of natural ilmenite with graphite [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 962-968.

[5] HAN Gui-hong, JIANG Tao, ZHANG Yuan-bo, HUANG Yan-fang, LI Guang-hui. High-temperature oxidation behavior of vanadium, titanium-bearing magnetite pellet [J]. Journal of Iron and Steel Research, International, 2011, 18(8): 14-19.

[6] ZHU De-qing, GUO Yu-feng, QIU Guan-zhou, JIANG Tao. Catalyzing the direct reduction of cold-bound pellets from titanomagnetite concentrate [J]. Journal of Central South University: Science and Technology, 2000, 31(3): 208-211. (in Chinese)

[7] LIU Xiao-hua, GAI Guo-sheng, YANG Yu-fen, SUI Zhi-tong, LI Li, FU Jian-xia. Kinetics of the leaching of TiO2 from Ti-bearing blast furnace slag [J]. Journal of China University of Mining and Technology, 2008, 18(2): 275-278.

[8] LI Jing, ZHANG Zuo-tai, ZHANG Mei, GUO Min, WANG Xi-dong. The influence of SiO2 on the extraction of Ti element from Ti-bearing blast furnace slag [J]. Steel Research International, 2011, 82(6): 607-614.

[9] FU Wei-guo, WEN Yong-cai, XIE Hong-en. Development of intensified technologies of vanadium-bearing titanomagnetite smelting [J]. Journal of Iron and Steel Research, International, 2011, 18(4): 7-18.

[10] CHEN De-sheng, SONG Bo, WANG Li-na, QI Tao, WANG Yong, WANG Wei-jing. Solid state reduction of Panzhihua titanomagnetite concentrates with pulverized coal [J]. Minerals Engineering, 2011, 24(8): 864-869.

[11] ZHANG Wen-sheng, ZHU Zhao-wu, CHENG Chu-yong. A literature review of titanium metallurgical processes [J]. Hydrometallurgy, 2011, 108(3-4): 177-188.

[12] CHEN De-sheng, ZHAO Long-sheng, LIU Ya-hui, QI Tao, WANG Jian-chong, WANG Li-na. A novel process for recovery of iron, titanium, and vanadium from titanomagnetite concentrates: NaOH molten salt roasting and water leaching processes [J]. Journal of Hazardous Materials, 2013, 244-245(1): 588-595.

[13] HUKKANEN E, WALDEN H. The production of vanadium and steel from titanomagnetites [J]. International Journal of Mineral Processing, 1985, 15(1-2): 89-102.

[14] GONZALEZ L M, FORSSBERG K. Utilization of a vanadium- containing titanomagnetite: Possibilities of a beneficiation-based approach [J]. Mineral Processing and Extractive Metallurgy, 2001, 110(2): 63-72.

[15] TAYLOR P R, SHUEY S A, VIDAL E E, GOMEZ J C. Extractive metallurgy of vanadium-containing titaniferous magnetite ores: A review [J]. Minerals and Metallurgical Processing, 2006, 23(2): 80-86.

[16] ZHANG Guo-hua, YAN Zheng, FENG Ying-jie, ZHANG Mei, GUO Min, WANG Xi-dong, LI Li-fen, ZHOU Guo-zhi. Reduction kinetics study on Panzhihua vanadic titanomagnetite [C]//2008 National Conference of Metallurgical Physical Chemistry. Beijing: Beijing General Research Institute of Nonferrous Metals, 2008: 210-216. ( in Chinese)

[17] QI Da-guang, YAN gen-nian, ZHANG Gui-xin, FAN Zhong-zheng. The reduction mechanism study of vanadium-titanium magnetite [J]. Chemical Engineering and Metallurgy, 1980(2): 16-30. (in Chinese)

[18] ZHANG Jian-liang, WANG Chun-long, LIU Zheng-jian, WANG Jie, CAO Ming-ming. Influencing factors of the reduction of vanadium titano-magnetite carbon composite pellets [J]. Journal of University of Science and Technology Beijing, 2012, 34(5): 512-518. (in Chinese)

[19] CAO Ming-ming, ZHANG Jian-liang, XING Xiang-dong, WEN Yong-cai, WANG Chun-long. Study on direct reduction of carbon-containing pellet made of vanadium-bearing titaniferous magnetite [J]. Iron Steel Vanadium Titanium, 2012, 33(4): 28-33. (in Chinese)

[20] ZHOU Lan-hua, WANG Jun, GOU Shu-yun, CHEN Lv-ying, LI Ze-rong. Development of utilization of vanadic titanomagnetite [J]. Applied Mechanics and Materials, 2012, 184: 949-953.

[21] ZHOU Lan-hua, TAO Dong-ping, FANG Min-xian, ZENG Fu-hong, PU Xia. Carbothermic reduction of V-Ti magnetite ore [J]. Chinese Journal of Rare Metals, 2009, 33(3): 406-410. (in Chinese)

[22] XU Jing-cang, YANG You-yu, LIU Zhong-hui, FU Bo-yi, YU Ke-ting, CAI Ru-zhuo, LIU Yi-yan, ZHANG Qing-cen, LI Shu-geng, LIAO Chen-ying, DAI Bai-hong. New technology of coal-based direct reduction of cold bond pellets with complex binders: China, CN92111782.5 [P]. 1994-06-29. (in Chinese)

[23] GUO Yu-feng. Study on strenthening of solid-state reduction and comprehensive utilization of vanadiferous titanomagnetite [D]. Changsha: Central South University, 2007. (in Chinese)

[24] LIU Song-li, BAI Chen-guang, HU Tu, LV Xue-wei, QIU Gui-bao. Quick and direct reduction process of vanadium and titanium iron concentrate with carborrcontainin pellets at high temperature [J]. Journal of Chongqing University, 2011, 34(1): 60-64. (in Chinese).

预氧化钒钛磁铁精矿的固态还原动力学及其机理

刘水石,郭宇峰,邱冠周,姜 涛,陈 凤

中南大学 资源加工与生物工程学院,长沙 410083

摘 要:研究预氧化钒钛磁铁精矿固态还原反应的动力学,采用XRD、SEM和EDS等手段研究还原产物的显微结构和物相变化,在此基础上,对其固态还原机理进行研究。结果表明:以煤为还原剂,在还原温度为950~1100 °C时,预氧化钒钛磁铁精矿的固态还原受界面化学反应控制,反应的表观活化能为67.719 kJ/mol;预氧化钒钛磁铁精矿的还原历程可描述为:预氧化钒钛磁铁精矿→钛铁晶石→钛铁矿→亚铁板钛矿(FeTi2O5)→ (FenTi1-n)Ti2O5。预氧化钒钛磁铁精矿在1050 °C还原60 min后,还原产物中会形成M3O5型(M为Fe、Ti、Mg、Mn等)固溶体,存在于M3O5固溶体中铁的难还原性是限制预氧化钒钛磁铁矿还原的主要原因。

关键词:钒钛磁铁矿;固态还原;还原动力学;还原过程

(Edited by Hua YANG)

Foundation item: Project (NCET-10-0834) supported by the Program for New Century Excellent Talents in University, China

Corresponding author: Yu-feng GUO; Tel: +86-731-88830542; E-mail: guo.yf@126.com

DOI: 10.1016/S1003-6326(14)63479-8