冷轧法提高Mg-3Gd-1Zn合金的强度

来源期刊:中国有色金属学报(英文版)2013年第2期

论文作者:吴 迪 唐伟能 陈荣石 韩恩厚

文章页码:301 - 306

关键词:镁合金;冷轧;强度;织构

Key words:magnesium alloys; cold rolling; strength; texture

摘 要:利用大应变冷轧提高Mg-3Gd-1Zn(质量分数)合金的强度。通过单道次23%压下量的冷轧处理,可在Mg-3Gd-Zn合金热轧板材的组织中引入大量位错,使其形成基面织构,进而使其屈服强度提高150%。与Mg-3Gd-Zn合金热轧板材相比,将冷轧板材在350 °C下退火30 min,可以提高其强度,同时具有较高的塑性。由于剪切带的软化作用,多道次冷轧的Mg-3Gd-1Zn合金板材没有获得预期的强度;但是,利用多道次冷轧来制备厚度小于1 mm的薄板或箔材,可以尽可能减少道次间的回炉退火,从而提高生产效率,降低能耗。

Abstract: The severe cold rolling was employed to enhance strength of Mg-3Gd-1Zn (mass fraction, %) alloy sheet. The 0.2% yield stress of the Mg-3Gd-1Zn hot-rolled sheet can be increased by 150% through the single-pass cold rolling with the reduction of 23%, due to the high intensity of dislocation and basal texture established during cold rolling. Compared with the Mg-3Gd-1Zn hot-rolled sheet, the cold-rolled sheet annealed at 350 °C for 30 min may get an enhancement in strength without a great loss of ductility. The sheet processed by multi-pass cold rolling does not show a higher strength as expected, due to the softening effect of shear bands. However, the thin slab with the thickness less than 1 mm can be produced by the multi-pass cold rolling with the annealing treatment as few as possible.

Trans. Nonferrous Met. Soc. China 23(2013) 301-306

Di WU1, 2, Wei-neng TANG1, Rong-shi CHEN1, En-hou HAN1

1. State Key Laboratory for Corrosion and Protections, Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. University of Chinese Academy of Sciences, Beijing 100049, China

Received 12 December 2011; accepted 7 March 2012

Abstract: The severe cold rolling was employed to enhance strength of Mg-3Gd-1Zn (mass fraction, %) alloy sheet. The 0.2% yield stress of the Mg-3Gd-1Zn hot-rolled sheet can be increased by 150% through the single-pass cold rolling with the reduction of 23%, due to the high intensity of dislocation and basal texture established during cold rolling. Compared with the Mg-3Gd-1Zn hot-rolled sheet, the cold-rolled sheet annealed at 350 °C for 30 min may get an enhancement in strength without a great loss of ductility. The sheet processed by multi-pass cold rolling does not show a higher strength as expected, due to the softening effect of shear bands. However, the thin slab with the thickness less than 1 mm can be produced by the multi-pass cold rolling with the annealing treatment as few as possible.

Key words: magnesium alloys; cold rolling; strength; texture

1 Introduction

The limited room temperature formability of Mg alloys is a hindrance to the wider uptake of this metal in applications that would benefit considerably from its low density. It was recently found that magnesium alloys with rare earth additions, such as Nd and Ce, could develop a more random texture during hot extrusion [1] and conventional hot rolling [2], therefore resulting in the improvement of ductility and formability [3,4]. By the addition of Gd and optimizing the parameters of hot rolling process, we have developed a Mg-3Gd-1Zn (mass fraction, %) alloy sheet, which exhibits excellent ductility and formability at room temperature [5]. However, its strength, especially yield strength, is quite low (<130 MPa), which is not only far lower than that of Al alloy, but also inferior to AZ31 alloy sheet [6].

Cold rolling process is mainly employed to produce thin sheet, belt or foil, and it can solve the problems that the size of the hot rolled sheet oversteps the tolerance, and the mechanical properties in the same sheet are not uniform, due to the heat drop and non-uniform distribution of temperature during hot rolling [7]. In addition, cold-rolled sheets usually have a high surface finish quality, excellent mechanical properties and are rich in variety. The sheets with different surface roughnesses can be produced by cold rolling, and the products, produced by cold rolling with different reduction combined with the annealing treatment after cold rolling, may meet the requirement for further processing or application in a comprehensive range. Nevertheless, the cold rolling response of the common Mg alloy sheet, such as AZ31 rolled sheet, is generally poor due to its low ductility at room temperature. It is improper for the common Mg alloy sheet to be cold rolled in commercial process. Therefore, there is only a few of work concerning about cold rolling of Mg alloy [8,9], and most of them focus on the influence of cold rolling on the microstructure and texture. Few work lays stress on the improvement of mechanical properties by cold rolling.

It has been demonstrated that cold work could introduce high density of twins and dislocations [10]. Based on the high room-temperature ductility of the Mg-3Gd-1Zn sheet, the aim of this work is to enhance the mechanical properties, especially the strength, of the Mg-3Gd-1Zn sheet by cold rolling; combined with the annealing treatment after cold rolling, the Mg alloy sheet with high ductility and strength can be produced. The effects of the cold rolling and annealing treatment on its microstructure, texture and mechanical properties were investigated in detail.

2 Experimental

The alloy denoted as GZ31 was examined in the present study. The chemical composition was Mg-2.74Gd-1.06Zn (mass fraction, %). It was prepared with high purity Mg (99.9%), Zn (99.9%) and Gd (99.9%) by melting under the protection of a mixed SF6 (1% in volume fraction) and CO2 (99% in volume fraction) atmosphere. Ingots with dimensions of 75 mm×200 mm×200 mm were prepared by pouring the melt into a preheated steel mold. They were homogenized at 500 °C for 10 h, then quenched in water, and were subsequently machined to slabs with dimensions of 200 mm×70 mm×20 mm.

The slabs were rolled to sheets at 430 °C with a final thickness of 3 mm. The details of the hot rolling process were described elsewhere [5]. The hot-rolled sheets were annealed at 380 °C for 1 h after the last rolling pass. For comparison, AZ31 (Mg-3Al-1Zn- 0.2Mn, %) was selected as the counterpart since it was a popular magnesium alloy for rolled sheets. The cast ingot of the AZ31 magnesium alloy was machined to a slab with a thickness of 20 mm, and was also processed identically to the hot-rolled GZ31 sheet. Hereafter, RD, TD and ND denote the rolling, transverse and normal directions of the sheets, respectively. For cold rolling experiments, the specimens with dimensions of 40 mm×25 mm×3 mm were machined out of the hot-rolled sheets, and the surface was polished by waterproof abrasive paper. The cold rolling was carried out at room temperature on a mill with a roll diameter of 300 mm and a roll velocity of 6 m/min. No heating was carried out during the rolling schedule. The specimens were cold rolled through single-pass to different thickness reductions of 5%, 13%, 18%, 23% and 30%, respectively, or through multi-pass to a total thickness reduction of 45%, with a thickness reduction per pass of 1%-5%. Some of the cold-rolled specimens were annealed at 300 °C or 350 °C for 30 min or 1 h.

Samples were prepared for optical microscopy (OM) by sectioning and polishing the RD-ND plane. Mechanical grinding was followed by diamond and colloidal silica polishing. The etching solution was 25 mL ethanol+2 g picric acid+5 mL acetic acid + 5 mL water. The grain sizes (L) were determined by analyzing the optical micrographs with a line-intercept method (d=1.74 L).

Texture analysis of the rolled samples in the RD-TD plane was performed using the Schultz reflection method by X-ray diffraction. Calculated pole figures were obtained with the DIFFRACplus TEXEVAl software, using the measured incomplete {0002},  and

and  pole figures.

pole figures.

Flat tensile specimens with gauge dimensions of 2.5 mm×4 mm×10 mm were machined out of the rolled sheets with the tensile axis parallel to the rolling direction. Monotonic tensile tests were performed using a Sans type tensile testing machine at room temperature, with an initial strain rate of 1×10-3 s-1.

3 Results

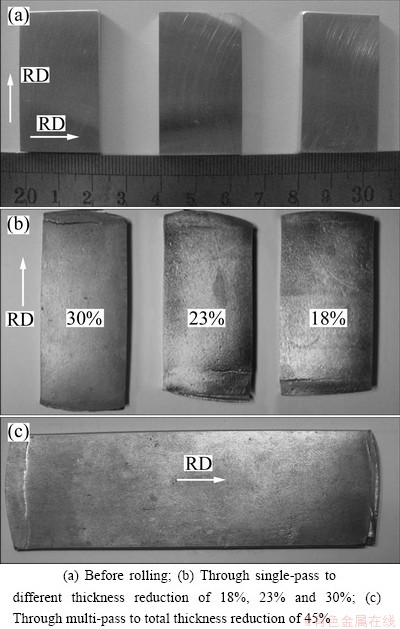

Figures 1 and 2 present the macrographs of the AZ31 and GZ31 specimens after cold rolling. With respect to rollability and surface quality, the GZ31 cold-rolled sheet is obviously better than the AZ31 cold-rolled sheet. The AZ31 cold-rolled specimen undergoes significant surface cracking due to its strong basal texture (Fig. 1), as the single-pass reduction is larger than 10%. By contrast, the GZ31 cold-rolled sheet reveals a good surface without cracks observed on the surface or side margin (except for the two ends), with the single-pass reduction as high as 30%, as shown in Fig. 2(b). By multi-pass roller with the reduction of 1%-5% in pass, the total reduction can reach 45% without the appearance of cracks (Fig. 2(c)).

Fig. 1 (0002) pole figure of AZ31 specimens before cold rolling (a) and macrographs of AZ31 specimens after cold rolling through single-pass to different thickness reductions of 5% and 13% (b)

Fig. 2 Macrographs of GZ31 specimens before (a) and after (b, c) cold rolling

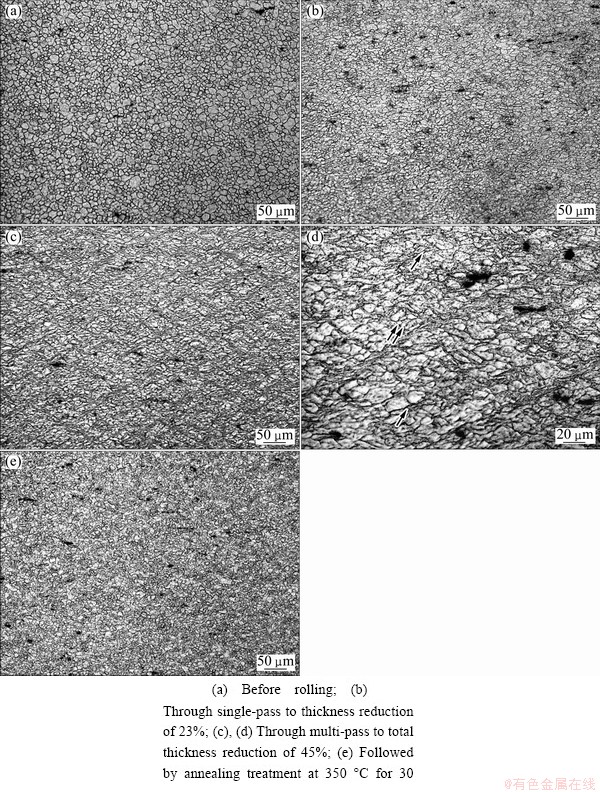

Figure 3(a) shows the optical micrograph of the GZ31 sheet before cold rolling. The hot-rolled sheet exhibits a full recrystallized microstructure with a statistical mean grain size of 12 μm. By the single-pass roller with the reduction of 23%, the grains are elongated approximately parallel to the rolling direction and the grain boundary is not so clear as that of the hot-rolled sheet, as a result of the severe cold working [11,12], as shown in Fig. 3(b). It is worth noting that there are few twins appearing, different to those in Ref. [9]. In Fig. 3(c), the microstructure of the cold-rolled GZ31 sheet through multi-pass rolling is characterized by the presence of bands diagonally inclined to the rolling plane. It was suggested that these bands were formed in regions that have undergone  twinning followed by secondary

twinning followed by secondary  twinning [13]. These structures are interpreted here as shear bands. Interestingly, many of the shear bands shown in Fig. 3(d) contain some very fine grains with grain size smaller than 5 μm (indicated by the arrows), which appear to be recrystallized grains. Room temperature recrystallization of pure Mg has been reported elsewhere [14], which lends some support to this interpretation. Owing to a large amount of fine precipitates in the matrix of the GZ31 sheet [5], which can pin the grain boundary and hinder the movement of dislocation. No obvious recrystallization occurs when the GZ31 cold rolled sheet is annealed at 300 °C for 1 h. As the annealing temperature increases to 350 °C, recrystallization takes place substantially, a great deal of recrystallized grains can be detected clearly in Fig. 3(e), and the size of the new grains is obviously smaller than that of the GZ31 hot-rolled sheet.

twinning [13]. These structures are interpreted here as shear bands. Interestingly, many of the shear bands shown in Fig. 3(d) contain some very fine grains with grain size smaller than 5 μm (indicated by the arrows), which appear to be recrystallized grains. Room temperature recrystallization of pure Mg has been reported elsewhere [14], which lends some support to this interpretation. Owing to a large amount of fine precipitates in the matrix of the GZ31 sheet [5], which can pin the grain boundary and hinder the movement of dislocation. No obvious recrystallization occurs when the GZ31 cold rolled sheet is annealed at 300 °C for 1 h. As the annealing temperature increases to 350 °C, recrystallization takes place substantially, a great deal of recrystallized grains can be detected clearly in Fig. 3(e), and the size of the new grains is obviously smaller than that of the GZ31 hot-rolled sheet.

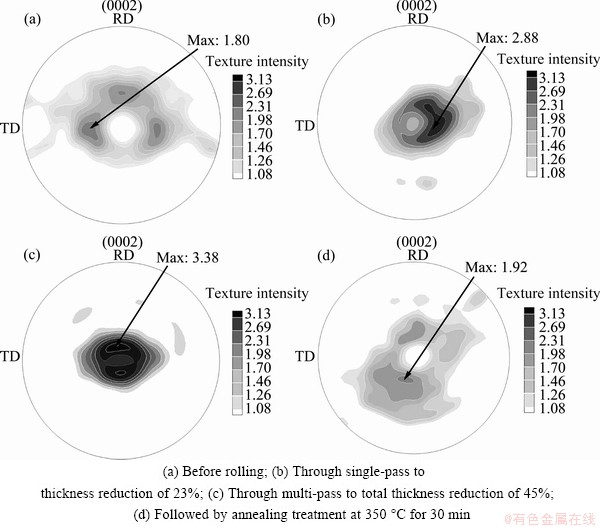

As shown in Fig. 4(a), the (0002) pole figure of GZ31 hot-rolled sheet shows a non-basal texture with basal poles tilting about 30° from the ND towards RD and TD, and the (0002) plane texture intensity is far lower than that of the AZ31 sheet in Fig. 1(a). However, by the single-pass cold rolling with the reduction of 23%, the basal poles of the GZ31 cold-rolled sheet switch back to ND, almost turning into a basal texture, and the texture intensity increases to ~3 m.r.d. (multiples of random distribution), as seen in Fig. 4(b). The (0002) pole figure of the GZ31 sheet processed by multi-pass cold rolling (Fig. 4(c)) is very similar to that of the single-pass cold-rolled specimen, except that it approaches to a basal texture more, with a higher texture intensity. It is interesting that, the basal texture turns back into non-basal texture, and the texture intensity drops to 1.9 m.r.d, as the cold-rolled specimen is annealed at 350 °C for 30 min (Fig. 4(d)).

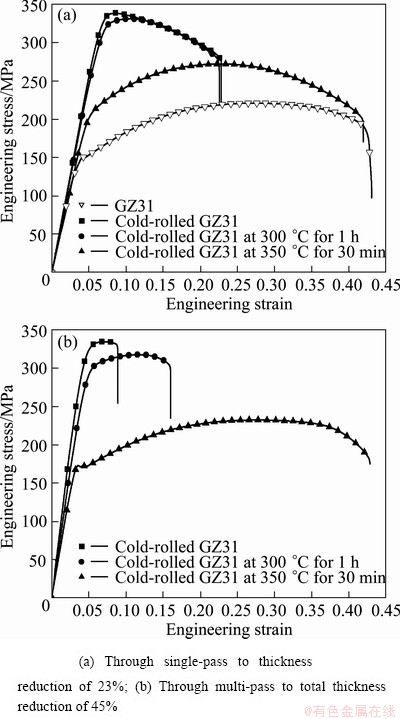

The typical engineering stress—strain curves of the GZ31 cold-rolled and annealed sheets are presented in Fig. 5, and the hot-rolled sheet is also included. It is evident from these curves that there is a significant increase in the strength of the cold-rolled sheet through single-pass with the reduction of 23%, as compared with the GZ31 hot-rolled sheet. The 0.2% yield stress increases from 120 MPa to 300 MPa, which is far higher than that of the AZ31 sheet [15], and the elongation-to-failure can reach 16%. The tensile curve changes little, as the single-pass cold-rolled sheet is annealed at 300 °C for 1 h, and the 0.2% yield stress only drops by ~25 MPa. However, as it is annealed at 350 °C for 30 min, the strength drops sharply. The 0.2% yield stress decreases to ~200 MPa, but still comparable with that of the AZ31 sheet. It is worth noting that the annealed sheet exhibits an excellent tensile ductility. The elongation to failure is ~35%, which is far larger than that of the AZ31 sheet, though it is still a little lower than that of the hot-rolled GZ31 sheet. The strengthening effect of the multi-pass cold rolling on the hot-rolled GZ31 sheet is very similar to that of the single-pass cold rolling, and the annealed sheet (at 350 °C for 30 min) likewise exhibits strength comparable with that of the AZ31 sheet and a high ductility at room temperature.

Fig. 3 Optical micrographs of GZ31 specimens before (a) and after (b, c, d, e) cold rolling

Fig. 4 (0002) pole figures of GZ31 specimens before (a) and after (b, c, d) cold rolling

Fig. 5 Engineering stress—strain curves of GZ31 cold-rolled and annealed sheet

4 Discussion

Due to the high room-temperature ductility of the GZ31 hot-rolled sheet, a large thickness reduction (>20%) can be applied to it by the single-pass cold rolling. The results from the tensile tests demonstrate conclusively that the severe cold rolling is very effective in improving the strength of the GZ31 hot-rolled sheet. The 0.2% yield stress can increase by 150% through the single-pass cold rolling with the reduction of 23%. As it is known that, cold work can introduce high density of twins and dislocations [10], therefore the strength of the processed workpiece can be enhanced. Nevertheless, in this work, the strengthening results seem to be independent of the high density of twins, since few twins can be detected in the cold-rolling microstructure (Fig. 3(b)). Twinning can be affected by a decrease in grain size. It has been shown that a transition from twinning- to slip-dominated flow occurs in compression tests with decreasing grain size [16]. The hot-rolled GZ31 sheet shows a fine and homogeneous microstructure with a grain size of ~12 μm, so it exhibits a slip-dominated flow during single-pass cold rolling. In addition, texture evolution also plays a role in the strengthening effect. Single-pass cold rolling with the reduction of 23% results in an obvious transition from non-basal texture to basal texture and an increase in texture intensity, which means that the majority of the grains are rotated to an orientation unfavorable for both basal slip and tensile twinning because of a low Schmid factor, and therefore leads to an increase in the 0.2% yield stress.

Since there present a great deal of fine particles in the matrix, pining the dislocations and blocking their movement, the cold-rolled sheets are annealed at a lower temperature (300 °C) without recrystallization occurring. The annealed sheets exhibit a similar microstructure and mechanical properties to the cold-rolled one. So it should be the recovery taking place during the annealing treatment at a lower temperature. The movement of point defects dominates the recovery process; they can move to grain boundary or dislocation and then disappear [17]. Because the mechanical properties are insensitive to the density of point defects and the residual stress in the cold-rolled sheets can be removed, the strength of sheets at a lower temperature only drops a little.

As the GZ31 cold-rolled sheets are annealed at 350 °C for 30 min, the recrystallization takes place by virtue of a higher driving force at higher annealing temperatures. Thus, the strength of the annealed sheets drops sharply, yet still higher than that of the hot-rolled sheets and comparable with that of the AZ31 sheet, due to a smaller size of the new recrystallized grains. However, it shows an excellent room-temperature ductility with the elongation-to-failure of ~35%, far higher than that of the AZ31 sheet, as a result of the finer microstructure and the weak and non-basal texture formed during recrystallization. Compared with the GZ31 hot-rolled sheet, the sheets annealed at higher temperatures keep a weak and non-basal texture and show a finer microstructure, therefore leading to an enhancement in strength without a great loss of ductility.

Additionally, compared with the sheet processed by single-pass cold rolling, the sheet processed by multi-pass cold rolling does not show a higher strength as expected, though it experiences a larger total thickness reduction. The major difference between the sheets processed by the two kinds of cold rolling is the shear bands established during multi-pass cold rolling, which may contribute to lower its tensile strength to some degree. BARNETT et al [9] suggested that the shear bands are indeed soft because the easy glide basal planes in the banded material are more favourably aligned for shear. The increase in the fraction of bands with increasing strain has been used elsewhere to explain the drop in tensile yield stress with increasing rolling reduction [13]. However, if the shin slab is required to be produced with the annealing treatment as few as possible, the multi-pass cold rolling is a nice choice. Figure 6 shows the macrographs of the thin slab with the thickness of 0.8 mm, which was produced by the multi-pass cold rolling with the total thickness reduction of 45%, annealing treatment at 350 °C for 30 min, and the multi-pass cold rolling one again.

Fig. 6 Macrographs of thin slab produced by multi-pass cold rolling and annealing treatment

5 Conclusions

1) The 0.2% yield stress of the hot-rolled GZ31 sheet can be increased by 150% through the single-pass cold rolling with the reduction of 23%, due to the high intensity of dislocation and basal texture.

2) Compared with the hot-rolled GZ31 sheet, the cold rolled sheet annealed at 350 °C for 30 min may get an enhancement in strength without a great loss of ductility.

3) Although it experiences a large total thickness reduction, the sheet processed by multi-pass cold rolling does not show a higher strength as expected, due to the softening effect of shear bands.

References

[1] BALL E A, PRANGNELL P B. Tensile-compressive yield asymmetries in high strength wrought magnesium alloys [J]. Scripta Metallurgica et Materialia, 1994, 31: 111-116.

[2] BOHLEN J, NURNBERG M R, SENN J W, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium–zinc–rare earth alloy sheets [J]. Acta Materialia, 2007, 55: 2101-2112.

[3] CHINO Y, KADO M, MABUCHI M. Enhancement of tensile ductility and stretch formability of magnesium by addition of 0.2 wt%(0.035 at%)Ce [J]. Materials Science and Engineering A, 2008, 494: 343-349.

[4] STANFORD N, BARNETT M R. The origin of “rare earth” texture development in extruded Mg-based alloys and its effect on tensile ductility [J]. Materials Science and Engineering A, 2008, 496: 399-408.

[5] WU D, CHEN R S, HAN E H. Room-temperature ductility and formability of Mg-Gd-Zn alloy sheets [J]. Journal of Alloys and Compounds, 2011, 509: 2856-2863.

[6] YI S, BOHLEN J, FEINEMANN F, LETZIG D. Mechanical anisotropy and deep drawing behaviour of AZ31 and ZE10 magnesium alloy sheets [J]. Acta Materialia, 2010, 58: 592-605.

[7] ROBERTS, WILLIAM L. Cold rolling of steel [M]. New York: Marcel Dekker, 1978.

[8] STYCZYNSKI A, HARTIG C, BOHLEN J, LETZIG D. Cold rolling textures in AZ31 wrought magnesium alloy [J]. Scripta Materialia, 2004, 50: 943-947.

[9] BARNETT M R, NAVEA M D, BETTLES C J. Deformation microstructures and textures of some cold rolled Mg alloys [J]. Materials Science and Engineering A, 2004, 386: 205-211.

[10] HILDITCH T, NIE J F, MUDDLE B C. The effect of cold work on precipitation in alloy WE54 [C]//MORDIKE B L, KAINER K U. Proceedings of Magnesium Alloys and Their Applications. Frankfurt: Viley-VCH, 1998: 339-344.

[11] MASOUMI M, HOSEINI M, PEKGULERYUZ M. The influence of Ce on the microstructure and rolling texture of Mg-1%Mn alloy [J]. Materials Science and Engineering A, 2011, 528: 3122-3129.

[12] BULAIN W, FAHRENHORST E. Metallography of magnesium and its alloys [M]. London: F. A. Hughes & Co Limited Abbey House, 1994.

[13] COULING S L, PASHAK J F, STURKEY L. Unique deformation and aging characteristics of certain magnesium-based alloys [J]. Trans ASM, 1959, 51: 94-107.

[14] WONSIEWICZ B C, BACKOFEN W A. Plasticity of magnesium crystals [J]. Trans Metall Soc AIME, 1967, 239: 1422-1431.

[15] HUANG X, SUZUKI K, WATAZU A, SHIGEMATSU I, SAITO N. Mechanical properties of Mg-Al-Zn alloy with a titled basal texture obtained by differential speed rolling [J]. Materials Science and Engineering A, 2008, 488: 214-220.

[16] BARNETT M R, KESHAVARZ Z, BEER A G, ATWELL D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn [J]. Acta Materialia, 2004, 52: 5093-5103.

[17] HAASEN, PETER. Physical metallurgy [M]. Cambridge: Cambridge University Press, 1986.

吴 迪1, 2,唐伟能1,陈荣石1,韩恩厚1

1. 中国科学院金属研究所 腐蚀与防护国家重点实验室,沈阳 110016;

2. 中国科学院大学,北京 100049

摘 要:利用大应变冷轧提高Mg-3Gd-1Zn(质量分数)合金的强度。通过单道次23%压下量的冷轧处理,可在Mg-3Gd-Zn合金热轧板材的组织中引入大量位错,使其形成基面织构,进而使其屈服强度提高150%。与Mg-3Gd-Zn合金热轧板材相比,将冷轧板材在350 °C下退火30 min,可以提高其强度,同时具有较高的塑性。由于剪切带的软化作用,多道次冷轧的Mg-3Gd-1Zn合金板材没有获得预期的强度;但是,利用多道次冷轧来制备厚度小于1 mm的薄板或箔材,可以尽可能减少道次间的回炉退火,从而提高生产效率,降低能耗。

关键词:镁合金;冷轧;强度;织构

(Edited by Xiang-qun LI)

Foundation item: Project (2013CB632202) supported by the National Basic Research Program of China; Project (51105350) supported by the National Natural Science Foundation of China

Corresponding author: Rong-shi CHEN; Tel: +86-24-23926646; Fax: +86-24-23894149; E-mail: rschen@imr.ac.cn

DOI: 10.1016/S1003-6326(13)62461-9