文章编号:1004-0609(2013)S1-s0046-04

表面机械碾磨处理纯钛的显微组织和力学行为

尹雁飞1, 2,孙巧艳2,肖 林2,张鹏省1,毛小南1,孙 军2

(1. 西北有色金属研究院,西安 710016;

2. 西安交通大学 材料科学与工程学院,西安 710049)

摘 要:通过表面机械碾磨处理(SMGT)对TA2纯钛进行加工并实现表面纳米化,采用光学显微镜、扫描电镜 (SEM)和透射电镜(TEM)等技术手段观察和分析其表层剧烈变形后的组织以及心部未变形组织,并研究梯度结构表层对纯钛断裂机制和变形方式的影响。结果表明:经过SMGT处理后,TA2纯钛拉伸断口表层韧窝尺寸呈随距表层深度减小而逐渐减小的梯度结构分布;表层纵向剖面表现出与粗晶心部不同的平整剪切状形态;同时断口侧表面并没有明显的变形痕迹,颈缩变形后依然比较光滑平整。

关键词:纯钛;表面机械碾磨处理;梯度结构表层;拉伸性能;韧窝;断裂机制

中图分类号:TG146.23 文献标志码:A

Microstructure and mechanical behavior of pure titanium processed by surface mechanical grinding treatment

YIN Yan-fei1, 2, SUN Qiao-yan2, XIAO Lin2, ZHANG Peng-sheng1, MAO Xiao-nan1, SUN Jun2

(1. Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China;

2. School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an 710049, China)

Abstract: Surface mechanical grinding treatment (SMGT) was used to fabricate a gradient nano-micron-structured surface layer on commercially pure titanium TA2. The microstructures of deformed surface layer and undeformed matrix were researched by OM, SEM and TEM, and the effects of gradient nano-micron-structured surface layer on overall fracture and deformation mechanisms were discussed. The results reveal that dimple size presents a gradient tendency from 1 μm in the treated surface layer to 23 μm in the matrix. For SMGT Ti, the longitudinal section of surface layers shows smooth shear fracture surface. Different from coarse-grained samples, no obvious trace of deformation is observed on the lateral surfaces of SMGT Ti.

Key words: pure titanium; surface mechanical grinding treatment; gradient nano-micron-structured layer; tensile property; dimple; fracture mechanism

通过引入大量的晶界和晶体缺陷,使晶粒细化到亚微米和纳米尺度可以大大增加材料的强度[1-2]。然而,纳米晶(NG)/超细晶(UFG)金属的均匀塑性变形能力被极大地限制[3-5]。马恩等[6]提出适当的粗晶粒与细晶粒的双峰分布可以大大提高NG/UFG金属的应变硬化能力和延性。非均匀微观结构引起的应变硬化,可以稳定拉伸塑性变形,从而以较小的强度降低为代价拥有较大的拉伸塑性(约65%)与均匀伸长率(约30%)。另外,LU等[7-8]发现,拥有梯度纳米-微米结构表层的粗晶铜等金属材料具有优异的力学性能。他们指出:粗晶基体可以抑制纳米晶表层应变局部化的发生,使得具有高强度的梯度纳米表层表现出可与粗晶铜相比的延性。然而,对于具有密排六方结构的钛,关于非均匀结构(包括双峰和梯度组织)的研究依然较少。本文作者通过表面机械研磨处理对纯钛进行表面纳米化,研究梯度结构组织对纯钛断裂机制及变形行为的影响。

1 实验

实验原材料是西北有色金属研究院生产的直径20 mm的TA2工业纯钛棒材。实验材料原始状态为轧制态,经过700 ℃退火1 h处理后,得到平均晶粒尺寸为20~30 μm的等轴晶。采用表面机械碾磨处理(SMGT)技术[7-8],在TA2棒材表面实现纳米化。采用Olympus PMG3光学显微镜和JEM-200CX透射电子显微镜观察加工后试样表层的微观组织。对比测试了经过SMGT加工前后TA2纯钛的室温拉伸性能,实验所用仪器为Instron 1195万能电子拉伸试验机。采用Hitachi S-2700扫描电子显微镜观察拉伸断口形貌。

2 结果与分析

2.1 TA2纯钛经SMGT加工后表层组织的变化

图1所示为TA2纯钛经SMGT加工后表层组织的金相照片。在厚度约为100 μm的外表层中晶界模糊且组织细小,已很难在金相显微镜下辨认;而在距表层100~250 μm的次表层内,大量孪晶产生于变形的晶粒中;而当深度超过250 μm,组织已无明显变形,为与心部一致的粗晶组织。这是由于在SMGT加工过程中,随着距外表面深度的增加,其发生剧烈塑性变形的程度逐渐减小,因此不同深度组织呈现出从表面到心部梯度变化的现象。由图1可见,这种具有梯度结构的表层组织厚度约为250 μm。

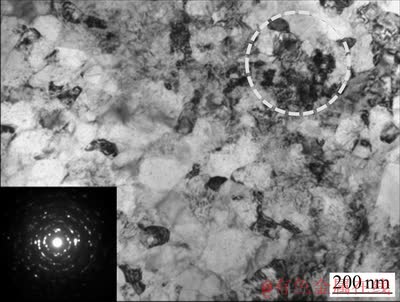

图2所示为经过SMGT加工的TA2纯钛试样距表层20 μm处组织的TEM形貌。其中左下角为与右上角标识区域相对应的选区衍射花样,约成环状的衍射环表明表层晶粒得到了有效的细化,平均晶粒尺寸约为100 nm。这与ZHU等[9]通过表面机械研磨处理(SMAT)以及YANG等[10]通过冷轧获得的超细晶纯钛的最终细化效果相似。综上所述,通过表面机械碾磨处理,TA2纯钛表面实现了纳米化,获得了由纳米晶(100 nm)到粗晶(30 μm)分布的具有梯度结构的表层组织。

图1 TA2纯钛经SMGT加工后从表层到心部的金相组织

Fig. 1 OM microstructure of pure titanium after SMGT

图2 SMGT纯钛距表层20 μm处明场TEM形貌及选区电子衍射花样

Fig. 2 Bright field TEM image and selected-area electron diffraction pattern of SMGT Ti at 20 μm depth from surface

2.2 梯度结构表层对TA2纯钛力学性能的影响

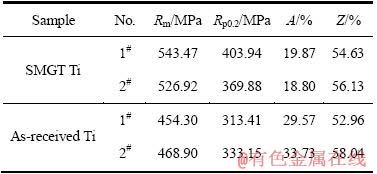

为了研究梯度结构表层对TA2纯钛力学性能的影响,对经SMGT加工的纯钛与未经加工的对比试样进行了拉伸性能测试,结果见表1。对比分析发现:TA2纯钛经过SMGT处理后,其抗拉强度和屈服强度得到明显提高,分别提高约16%和20%;其伸长率降低约38%,断面收缩率基本保持不变。其中强度的增加相较于LU等[11]通过SMAT制备的具有表面梯度组织的纯钛要略低一些。这是不同的制备方法以及细化得到的纳米表层厚度不同所致。而伸长率虽然明显降低,但相比于通过剧烈塑形变形(SPD)制备的超细晶纯钛,SMGT纯钛的伸长率还是很可观的。

表1 SMGT纯钛和对比试样的拉伸力学性能

Table 1 Mechanical properties of SMGT Ti and as-recevied Ti

2.3 梯度结构表层对TA2纯钛断裂机制与变形方式的影响

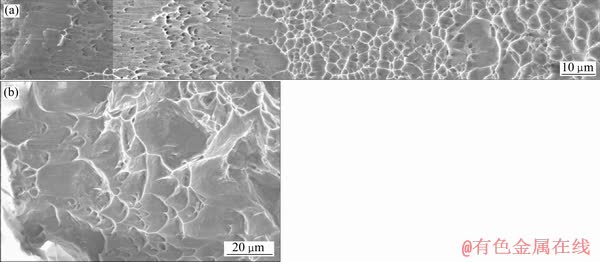

图3所示为SMGT纯钛及粗晶对比试样拉伸断口的SEM形貌。SMGT纯钛与粗晶纯钛均表现出韧性断裂的特征,断裂面分布有大量的韧窝。其中粗晶对比试样韧窝的尺寸较大,平均韧窝尺寸约为25 μm;而SMGT纯钛断裂面的韧窝尺寸从表面的约1 μm到心部的23 μm呈现梯度分布,这与其表层纳米-微米梯度结构相对应。同样,这与通过其他SPD方法制备的纯钛组织相类似[11-12]。进一步观察发现,在断口外表面约20 μm范围内,韧窝形态呈抛物线状,且断口较为平坦。这是由于SMGT纯钛在拉伸过程中外表面受剪切应力的作用而形成的。

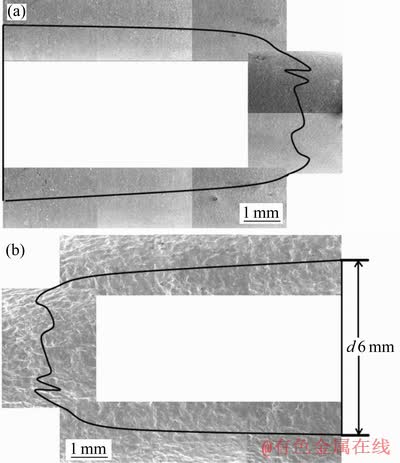

图4所示为SMGT纯钛试样拉伸断口的纵向剖面金相形貌。由图4可知,随着试样颈缩变形的增大,表层组织变形均匀,厚度并没有明显改变,同时表层断口平整呈剪切状(见图4(a)左侧圆形区域)。而粗晶 基体中晶粒拉长并伴有大量孪晶,断口呈峰峦状,这与粗晶对比试样类似(见图4(b))。

图5所示为SMGT纯钛及其对比试样拉伸断口的侧表面SEM形貌。可以看出,经过SMGT加工的纯钛试样其断口侧表面形貌要明显较未加工试样更平滑。在相同的放大倍数下,前者的侧表面并没有明显的撕裂变形的痕迹,而后者有很多,同时越靠近断口,这种变形痕迹越密集。对于粗晶纯钛,在塑性变形过程中,需要启动滑移系或者孪晶系以承担塑性变形,在其表面会形成尺寸较大的滑移台阶和孪晶,所以可以观察到明显的变形痕迹。而且越靠近断口附近,颈缩越严重,塑性变形量越大,所以这种变形痕迹会越密集。而对于SMGT纯钛,其表层是纳米晶粒,由于纳米晶金属的变形方式与粗晶粒不同,主要为晶粒旋转、晶界滑移以及机械驱动的晶粒长大等方式[8, 13-14],所以其断口颈缩处的变形痕迹并不明显,整体形貌比较光滑。

图3 SMGT纯钛以及对比试样的拉伸断口SEM形貌

Fig. 3 SEM images of fracture surfaces in SMGT Ti (a) and as-received Ti (b)

图4 SMGT纯钛拉伸断口纵向剖面金相形貌

Fig. 4 OM images of longitudinal sections in SMGT Ti from surface (a) to matrix (b)

图5 SMGT纯钛及对比试样拉伸断口的侧表面SEM形貌

Fig. 5 SEM images of lateral surfaces in SMGT Ti (a) and as-received Ti sample (b)

3 结论

1) 具有梯度结构表层的纯钛拉伸断口呈韧性断裂特征并伴有大量韧窝,其表层韧窝尺寸呈随距表层深度减小而逐渐减小的梯度结构分布。

2) SMGT Ti断口表层纵向剖面表现出与粗晶心部不同的形态,为平整的剪切状,而心部呈峰峦状。

3) 由于表层晶粒得到有效细化,SMGT Ti断口侧表面并没有明显的变形痕迹,颈缩变形后侧表面依然比较光滑。

REFERENCES

[1] VINOGRADOV A Y, STOLYAROV V V, HASHIMOTO S, VALIEV R Z. Cyclic behavior of ultrafine-grain titanium produced by severe plastic deformation[J]. Materials Science and Engineering A, 2001, 318(1/2): 163-173.

[2] UEJI R, TSUJI N, MINAMINO Y, KOIZUMI Y. Ultragrain refinement of plain low carbon steel by cold-rolling and annealing of martensite[J]. Acta Materialia, 2002, 50(16): 4177-4189.

[3] CHEN X H, LU J, LU L, LU K. Tensile properties of a nanocrystalline 316L austenitic stainless steel[J]. Scripta Materialia, 2005, 52(10): 1039-1044.

[4] XIAO Shu-long, TIAN Jing, XU Li-juan, CHEN Yu-yong, YU Hong-bao, HAN Jie-cai. Microstructures and mechanical properties of TiAl alloy prepared by spark plasma sintering[J]. TransactionsofNonferrous MetalsSocietyof China, 2009, 19(6): 1423-1427.

[5] HASE K, TSUJI N. Effect of initial microstructure on ultrafine grain formation through warm deformation in medium-carbon steels[J]. Scripta Materialia, 2011, 65(5): 404-407.

[6] WANG Y M, CHEN M W, ZHOU F H, MA E. High tensile ductility in a nanostructured metal[J]. Nature, 2002, 419(6910): 912-915.

[7] LI W L, TAO N R, LU K. Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment[J]. Scripta Materialia, 2008, 59(5): 546-549.

[8] FANG T H, LI W L, TAO N R, LU K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper[J]. Science, 2011, 331(6024): 1587-1590.

[9] ZHU K Y, VASSEL A, BRISSET F, LU K, LU J. Nanostructure formation mechanism of α-titanium using SMAT[J]. Acta Materialia, 2004, 52(14): 4101-4110.

[10] YANG D K, CIZEK P, HODGSON P D, WEN C E. Microstructure evolution and nanograin formation during shear localization in cold-rolled titanium[J]. Acta Materialia, 2010, 58(13): 4536-4548.

[11] WEN M, LIU G, GU J F, GUAN W M, LU J. The tensile properties of titanium processed by surface mechanical attrition treatment[J]. Surface and Coatings Technology, 2008, 202(19): 4728-4733.

[12] ZHU Y T, HUANG J Y, GUBICZA J, UNGAR T, WANG Y M, MA E, VALIEV R Z. Nanostructures in Ti processed by severe plastic deformation[J]. Journal of Materials Research, 2003, 18(8): 1908-1917.

[13] ZHANG K, WEERTMAN J R. Microstructural changes produced by fatigue in high-purity copper severely deformed by cryogenic rolling[J]. Metallurgical and Materials Transactions A, 2009, 40(10): 2255-2263.

[14] PAN D, KUWANO S, FUJITA T, INOUE A, CHEN M W. Ultra-large room-temperature compressive plasticity of a nanocrystalline metal[J]. Nano Letters, 2007, 7(7): 2108-2111.

(编辑 袁赛前)

基金项目:国家自然科学基金资助项目(51071118, 50771080);国家重点基础研究发展计划项目(2010CB631003)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:孙巧艳,教授,博士;电话:029-82665125;E-mail: qysun@mail.xjtu.edu.cn