文章编号:1004-0609(2007)05-0789-06

镁合金化学镀中预处理氟化镁膜的特征与作用

国 栋,樊占国,杨中东,赵 林,高 鹏

(东北大学 材料与冶金学院,沈阳 110004)

摘 要:对镁合金的表面前处理工艺进行研究,探讨氟化镁在化学镀层中的存在形式及作用。结果表明:酸浸使镁合金表面形成一层氧化物膜;活化过程生成的氟化镁不具备反应活性,对镁合金基体有保护作用,使之免于受镀液的过度腐蚀;对化学镀层断口进行SEM元素分布分析显示氟化镁层集中存在于镁合金基体与Ni-P镀层之间;但过度活化会导致化学镀层孔隙率升高,以3.5%NaCl溶液为介质的动电位极化测试表明,过度活化会导致化学镀层耐蚀性下降。

关键词:镁合金;化学镀;耐蚀性;氟化镁

中图分类号:TG 174.4 文献标识码:A

Effects and characteristics of MgF2 during electroless nickel plating of magnesium alloys

GUO Dong, FAN Zhan-guo, YANG Zhong-dong, ZHAO Lin, GAO Peng

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: Pretreatment of magnesium alloy surface was studied. Effects of MgF2 in Ni-P coatings were emphatically discussed. The results show that a magnesium oxide layer is formed after acid etching, and the potential differences of different phases of magnesium alloys are reduced due to the presence of oxide layer. MgF2 layer is formed after activation which can protect magnesium substrate from corrosion of plating bath. The elemental distribution of cross section of Ni-P coating was investigated by scanning electron microscopy. The MgF2 layer exists between the magnesium alloy substrate and the Ni-P coating. Excessive activation can raise the porosity of Ni-P coating, and the potentiodynamic polarization indicates that excessive activation can lead to deterioration of corrosion resistance of the Ni-P coating.

Key words: magnesium alloy; electroless nickel plating; corrosion resistance; MgF2

镁合金由于质量轻,比强度和比刚度高,还具有优良的薄壁成型性能和可再生性能,以及热传导性能高、电磁屏蔽作用好、抗电磁干扰(EMI)性能高等优点,非常适合于3Cs类产品及电动车、汽车零件的要求,在电子产品发展中具有日益重要的作用。因此可以说镁合金与现代工业紧密相连,被称为“时代金属”和“21 世纪金属”[1-2]。

镁合金耐蚀性差是制约其进一步推广使用的主要原因[3]。镁合金化学镀镍是提高其耐蚀性的有效途径,一般分为浸锌和直接化学镀镍两种方法[4-5]。浸锌法因在浸锌后采用氰化镀铜工艺,且结合效果差,工艺复杂,目前已较少使用[6-7]。近年来,不经过浸锌与氰化物预镀铜而通过在化学镀液中加入氟化物和控制pH值的直接化学镀镍方法逐渐受到重视,这一工艺最初是由Dow 公司设计的[8]。据报道,Ingram & Glass公司运用这一工艺进行直接化学镀的研究开发,取得了突破性进展,并已实现了规模化生产[9]。该方法因其形成的镀层性能良好,工艺简单,日益受到广泛关注[10-12],但是其机理仍有待深入研究。本文作者以硫酸镍为主盐进行直接化学镀镍,着重对氟元素在镀层中的存在形式以及活化工艺对镀层性能的影响进行了深入研究。

1 实验

研究所选取的镁合金型号为AZ31板材。试样大小为1.5 cm?2.5 cm。其主要成分列于表1。

表 1 AZ31镁合金的化学成分

Table 1 Chemical compositions of AZ31 magnesium alloy (mass fraction, %)

镁合金化学镀镍工艺流程为:预磨试样→化学除油→碱性除油→酸性浸蚀→活化→化学镀镍(各步间水洗)[13-14]。预处理步骤及工艺参数见图1。

图 1 镁合金的预处理工艺

Fig.1 Pretreatment process and parameters of magnesium alloys

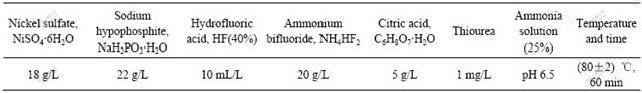

预处理完毕后的试样迅速放入化学镀镍溶液中,化学镀溶液成分及操作参数见表2。

表 2 镁合金化学镀镍工艺

Table 2 Compositions of bath and operating conditions of nickel deposition

用附带能谱仪(EDS)的扫描电子显微镜(日本岛津公司,SSX-550)观察试样的表面以及冲击断口形貌和元素成分的分布。用Princeton PARSTAT 2273电化学测试系统检测镀层耐腐蚀性能,腐蚀介质为3.5%NaCl溶液,测试温度为室温,采用标准三电极系统,参比电极为饱和甘汞电极,辅助电极为铂电极,工作电极为样品。用样品做工作电极时,仅留出工作面,其它表面以石蜡封固。

为证实MgF2是否具有反应活性,以丙酮为溶剂分散MgF2(分析纯)粉末成糊状,涂覆在未经活化的塑料片上,固化后在上述镀液及操作条件下施镀。

2 结果与讨论

2.1 前处理各步骤对镁合金的影响

2.1.1 酸浸

AZ系列镁合金由不同的金属相组成,主体为α相,金属间化合物β相(Mg17Al12)沿晶界呈网状分布,腐蚀电位分别接近-1.73和-1.0 V(0.1 mol/L Calomel electrode)。样品因表面电位不等形成微电池是镁合金难于施镀的主要原因[15]。

酸浸后试样表面形貌见图2。经酸浸处理的镁合金表面呈疏松结构,由能谱分析可知其表面成分(质量分数,下同)为Mg 87.974%,O 7.054%,Al 3.728%,Cr 1.244%。与未经酸浸时相比,新增了Cr元素和O元素。这表明酸浸过程中,在强氧化性酸HNO3和CrO3作用下,镁合金表面被氧化,形成一层均匀的氧化膜,该膜在酸性镀液中会逐渐溶解,因此单独的氧化膜不能保护镁合金不被镀液过度腐蚀。酸浸可洗去基体上松散附着的污垢和金属屑,另外可使基体表面形成一弱浸蚀层,增加基体的表面粗糙度,有利于镀层的机械楔入效果[11]。

图2 AZ31镁合金酸浸处理后的表面形貌

Fig.2 Etched surface morphology of AZ31 magnesium alloy

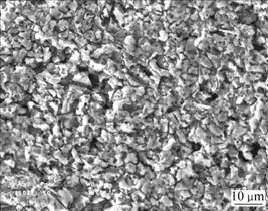

2.1.2 活化

活化后试样表面形貌见图3。经活化处理的镁合金表面呈疏松结构,由能谱分析可知其表面成分(质量分数,以下同)为Mg 73.266%,O 5.536%,F 16.668%,Al 3.525%,Cr 1.005%,与酸浸后相比,Mg、O、Al、Cr 4种元素含量均有不同程度的下降,其中Cr对于化学镀来说是一种有害物质,微量的Cr可能会造成漏镀等镀层缺陷,因此Cr在活化后含量大幅下降有利于后续的化学镀过程[16]。而新增了一定量的F元素,主要形成了MgF2,这是由于在酸性镀液中,MgO膜发生溶解,形成Mg2+,溶液中的F-与之发生如下反应

(1)

(1)

图 3 AZ31镁合金活化处理后的表面形貌

Fig.3 Activation surface morphology of AZ31 magnesium alloy

生成物的MgF2为极难溶的物质,通过原位生成作用沉积于基体表面,这对减缓化学镀液对Mg基体的腐蚀起到一定的作用。

2.1.3 F元素在镀层中的存在形式

对镁合金化学镀镍初始沉积机制进行研究发 现[17],直接进行化学镀时,由于MgO在酸性溶液中会溶解,裸露的Mg基体与溶液中的Ni2+发生置换反应。Ni的初始沉积是在活化中形成的MgF2膜下面。这样,随着镀层的不断生长,势必将MgF2膜顶破,即随着化学镀的进行,MgF2就不能作为整体存在,而会呈弥散状存在于镀层之中。

邵忠财等[18]认为在施镀过程中,MgF2膜不会消失,而是仍作为一个整体夹杂在镀层与基体之间。但是MgF2膜性质稳定,不参与氧化还原反应,也不与镀镍层发生化学键合作用,因此MgF2层的存在对镀层性能有一定的影响。

图4所示为对化学镀层断口做面扫描分析得到的各元素分布。图4(a)所示为断口组织形貌。由左至右分别为镁合金基体(A),MgF2层(B),Ni-P镀层(C);图4(b)、(c)、(d)、(e)依次为图4(a)中Mg、F、Ni、P 4种元素的分布,即图中深色部分代表该元素在该区域的分布。从各元素分布位置可以看到F元素在Mg元素与Ni和P元素(化学镀层)之间集中分布,证明MgF2膜并未在化学镀过程中被破坏,而始终存在于镁合金基体与镀层之间。

图 4 镁合金化学镀层断口的元素分布

Fig.4 SEM micrographs and elements distributions of cross section of Ni-P coating on magnesium alloy: (a) Cross section of Ni-P coating; (b) Distribution of Mg; (c) Distribution of F; (d) Distribution of Ni; (e) Distribution of P

2.2 MgF2是否具有反应活性

活化后试样表面存在一定含量的O,说明活化后形成的MgF2膜是不完整的、疏松的,加上试样在活化取出后与空气接触形成MgO,同时由能谱分析可知,活化后镁合金表面基本是由MgO和MgF2组成的。以下列实验验证MgF2是否具有反应活性。

涂覆在塑料片上的MgF2膜在化学镀操作条件下进行施镀,结果无反应发生,证实了MgF2本身是不具有反应活性的。

2.3 MgF2膜所占面积比例对化学镀的影响

活化液中[F-]越高,形成的MgF2膜占总面积的比例越大,对试样在镀液中的保护作用就越强。在试样放入镀液初期,MgO在酸性镀液作用下发生溶解,裸露在镀液中的Mg与Ni2+发生置换反应,即

(2)

(2)

有了置换出的Ni为催化中心,镀液中Ni2+快速催化还原,化学镀过程开始。镁合金前处理工艺的活化步骤形成的MgF2在镀液条件下溶解度极小,一定面积的MgF2膜可起到保护镁合金免于被酸性镀液过度腐蚀的作用。

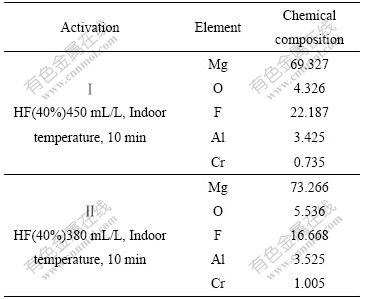

为了进一步研究MgF2对化学镀过程的影响,分析比较了两种活化工艺(见表3)。由能谱分析可知,活化工艺Ⅰ与工艺Ⅱ相比,前者使Mg、O、Al、Cr 4种元素含量均有不同程度的下降,而F元素含量增加,表示MgF2膜面积所占比例较后者有所增加。

表 3 活化工艺及能谱分析结果

Table 3 Chemical compositions of samples after activation (mass fraction, %)

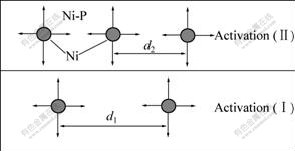

MgF2面积越大,露出的MgO面积就越小,可以用来与Ni2+发生置换反应的Mg面积就越小,置换生成的Ni就越少。图5中圆圈部分表示置换生成的Ni核,d1、d2分别表示经过活化工艺Ⅰ、Ⅱ处理的试样在化学镀初期所得相邻Ni核间的距离,箭头表示Ni-P镀层由Ni核向四周平面二维生长的过程。结合表3所列能谱分析结果可知,MgF2面积所占比例越大,则单位面积内生成Ni核就越多,即活化工艺Ⅱ条件下得到单位面积内Ni核数量多于活化工艺Ⅰ所得Ni核数

图 5 2种活化工艺下的化学镀初期行为示意图

Fig.5 Sketch maps of initial behavior of electroless plating under different activations

量。因此,d2<d1,即工艺Ⅱ处理后相邻Ni核间距短,Ni-P镀层生长搭界所经距离短,在最终生成Ni-P化学镀层中形成孔隙的概率就越低;反之则Ni-P化学镀层形成孔隙的概率越高。但MgF2膜面积所占比例过小,则镁合金基体可能会被镀液过度腐蚀。因此,活化工艺对于最终的化学镀层孔隙率大小有很大影响。

图6所示为样品经活化工艺处理后进行化学镀镍的表面形貌。可明显看到活化工艺Ⅰ较活化工艺Ⅱ存在较多的孔隙。

图 6 2种不同活化工艺下镁合金化学镀层的表面形貌

Fig.6 Surface morphologies of Ni-P coating on different active formulas of AZ31 magnesium alloys

图7所示为对上述两种镀层所作的电化学极化曲线,介质为3.5%NaCl溶液。由电化学极化曲线可知,镁合金基体自腐蚀电位约在-1.4 V左右,进入阳极极化以后,腐蚀电流急剧增大,样品发生溶解,肉眼可观察到样品表面上产生大量气泡;在活化工艺Ⅰ后进

图 7 AZ31镁合金及不同活化工艺后化学镀镍动电位极化曲线

Fig.7 Potentiodynamic polarization curves for bare alloy, specimens with different process parameters of activation

行化学镀的样品的自腐蚀电位约为-0.57 V,腐蚀的倾向大幅度降低,动电位扫描进入阳极区以后,表面Ni-P镀层产生钝化,钝化区间约为300 mV;而在活化工艺Ⅱ后进行化学镀的样品的自腐蚀电位约为-0.48 V,腐蚀的倾向较前者有所降低,动电位扫描进入阳极区以后,表面Ni-P镀层产生钝化,钝化区间约为300 mV。总体来说,活化工艺Ⅱ得到化学镀层较在活化工艺Ⅰ得到的化学镀层耐蚀性好一些。

3 结论

1) 经酸浸处理的镁合金表面形成一层氧化物膜;活化处理可消除酸浸工序中在镁合金表面残存的大部分Cr元素,为后续的化学镀做好准备。活化处理可使镁合金表面形成一定面积的MgF2膜,而MgF2本身是不具有反应活性的,可使镁合金免于被镀液过度腐蚀。

2) MgF2膜并未在化学镀过程中被破坏,而以整体形式存在于镁合金基体与镀层之间,而非以弥散形式存在于镀层之中。

3) 不同活化工艺的选择对最终的化学镀层耐蚀性能有一定影响。

REFERENCES

[1] 余 刚,刘跃龙,李 瑛, 等. Mg 合金的腐蚀与防护[J]. 中国有色金属学报, 2002, 12(6): 1087-1098.

YU Gang, LIU Yue-long, LI Ying, et al. Corrosion and protection of magnesium alloys[J]. The Chinese Journal of Nonferrous Metal, 2002, 12(6): 1087-1098.

[2] 曾荣昌,柯 伟,徐永波. Mg合金的最新发展及应用前景[J]. 金属学报, 2001, 37(7): 673-681.

ZENG Rong-chang, KE Wei, XU Yong-bo. Recent development and application of magnesium alloys[J]. Acata Metallurgica Sinica, 2001, 37(7): 673-681.

[3] 李 瑛,宋光铃,林海潮,等. 金属镁在腐蚀介质中界面结构特征与负差数效应关系研究[J]. 腐蚀科学与防护技术, 1999, 11(4): 202-208.

LI Ying, SONG Guang-ling, LIN Hai-chao, et al. Study on the relationship between the corrosion interface structure and negative difference effect for pure magnesium[J]. Corrosion Science and Protection Technology, 1999, 11(4): 202-208.

[4] Ambat R, Zhou W. Electroless nickel-plating on AZ91D magnesium alloy: Effect of substrate microstructure and plating parameters[J]. Surface and Coatings Technology, 2004, 179(223): 124-134.

[5] Gray J E, Luan B. Protective coatings on magnesium and its alloys—A critical review[J]. Journal of Alloys and Compounds, 2002, 336(122): 88-113.

[6] Chen J H, Chang C C, Lee T S. Pretreatment for plating on magnesium alloys[A]. AESF SUR/FIN91[C]. Toronto, Canada, 1991: 754-759.

[7] Olsen A L. Plating of magnesium high pressure die castings[J]. Trans IMF, 1980, 58: 29-32.

[8] Delong H K. Electroless Nickel Plating[P]. U S Patent, 3152009, 1964-10-06.

[9] Brown L. UK company leads the way in magnesium plating[J]. Finishing, 1994, 18(11): 22-23.

[10] Mallory G O, Hajdu J B. Electroless plating: fundamentals and applications[M]. Orlando, FL: AESF Publishing, 1990: 261-265.

[11] Fairweather W A. Electroless nickel plating of magnesium[J]. Trans IMF, 1997, 75(3): 113-117.

[12] 胡波年,陈珏伶,余 刚,等. 镁合金在镀液中的腐蚀行为[J]. 中国有色金属学报,2005,15(3): 463-470.

HU Bo-nian, CHEN Jue-ling, YU Gang, et al. Corrosion behavior of magnesium alloy in electroless plating bath[J]. The Chinese Journal of Nonferrous Metal, 2005,15(3): 463-470.

[13] 姜晓霞,沈 伟. 化学镀理论及实践[M]. 北京:国防工业出版社, 2000: 26.

JIANG Xiao-xia, SHEN Wei. The Fundamentals and Practice of Electroless Plating[M]. Beijing: National Defense Industry Press, 2000: 26.

[14] Sharma A K, Suresh M R, Bhojraj H, et al. Electroless nickel plating on magnesium alloy[J]. Metal Finishing, 1998, 96(3): 10-18.

[15] Sakata Y. Electroless nickel plating directly on magnesium alloy die castings[A]. The proceedings of the 74th AESF Annual Technical Conference[C]. Orlando: AESF, 1987: 6.

[16] 胡文彬,向阳辉,刘新宽,等. 镁合金化学镀镍预处理过程表面状况的研究[J] . 中国腐蚀与防护学报, 2001, 21(6): 340-344.

HU Wen-bin, XIANG Yang-hui, LIU Xin-kuan, et al. A study on surface state during the pretreatment of electroless nickel plating on magnesium alloys[J]. Journal of Chinese Society for Corrosion and Protection, 2001, 21(6): 340-344.

[17] 向阳辉,胡文彬,沈 彬,等. 镁合金直接化学镀镍的初始沉积机制[J]. 上海交通大学学报,2000, 34(12): 1638-1644.

XIANG Yang-hui, HU Wen-bin, SHEN Bin, et al. Initial deposition mechanism of direct electroless nickel plating on magnesium alloy[J]. Journal of Shanghai Jiao Tong University, 2000, 34(12): 1638-1644.

[18] 邵忠财,李建中,康凤娣,等. 镁合金化学镀镍层的生长过程[J]. 化工学报,2005, 56(2): 301-305.

SHAO Zhong-cai, LI Jian-zhong, KANG Feng-di, et al. Deposition process of electroless nickel plating on magnesium alloy[J]. Journal of Chemical Industry and Engineering, 2005, 56(2): 301-305.

收稿日期:2006-07-20;修订日期:2007-02-27

通讯作者:樊占国,教授;电话:024-83687727;E-mail: fanzg@smm.neu.edu.cn

(编辑 陈爱华)