碳酸盐沉淀法分离硫酸盐溶液中的锰与钙和镁

来源期刊:中国有色金属学报(英文版)2016年第4期

论文作者:林清泉 顾帼华 王晖 王重庆 刘有才 朱仁锋 符剑刚

文章页码:1118 - 1125

关键词:碳酸盐沉淀;分离;锰;钙;镁

Key words:carbonate precipitation; separation; manganese; calcium; magnesium

摘 要:以含14.59 g/L Mn2+、1.89 g/L Mg2+和1.54 g/L Ca2+的硫酸盐溶液为原料,利用碳酸盐沉淀法实现了锰与钙和镁的有效分离。热力学分析与实验结果表明,碳酸盐沉淀体系中锰对镁的选择性明显优于水解沉淀体系,而且加料方式是减少钙、镁共沉淀的主要因素。因而以硫酸锰加入碳酸氢铵的方式,研究碳酸氢铵初始浓度和用量、溶液pH值、反应温度及时间对沉淀过程的影响,并得到最优沉淀条件。结果表明:最优条件下锰、钙和镁离子的沉淀率分别为99.75%、5.62%和1.43%。另外,制得的产品经X射线衍射和能谱扫描电镜分析,结果表明该产品为菱形碳酸锰。

Abstract: The separation of manganese from sulfate solutions containing 14.59 g/L Mn2+, 1.89 g/L Mg2+ and 1.54 g/L Ca2+ was preformed successfully by carbonate precipitation. The results of thermodynamic analysis and tests indicate that carbonate precipitation holds better selectivity for manganese over magnesium than hydroxide precipitation and the feeding method is the most critical factor for minimizing the co-precipitation of calcium and magnesium. Furthermore, with adding MnSO4 solution to NH4HCO3 solution, the effects of the initial NH4HCO3 concentration, NH4HCO3 amount, solution pH value, reaction temperature and time on carbonate precipitation were evaluated and the optimum precipitation conditions were obtained. Under the optimum conditions, the precipitation rates of Mn2+, Ca2+ and Mg2+ are 99.75%, 5.62% and 1.43%, respectively. Moreover, the prepared manganese carbonate was characterized by X-ray diffraction (XRD) and scanning electron microscopy (SEM) equipped with energy-dispersive X-ray spectroscopy (EDX). The results demonstrate that the product can be indexed to the rhombohedral structure of MnCO3.

Trans. Nonferrous Met. Soc. China 26(2016) 1118-1125

Qing-quan LIN1, Guo-hua GU1, Hui WANG2, Chong-qing WANG2, You-cai LIU2, Ren-feng ZHU1, Jian-gang FU2

1. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China;

2. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China

Received 28 May 2015; accepted 10 October 2015

Abstract: The separation of manganese from sulfate solutions containing 14.59 g/L Mn2+, 1.89 g/L Mg2+ and 1.54 g/L Ca2+ was preformed successfully by carbonate precipitation. The results of thermodynamic analysis and tests indicate that carbonate precipitation holds better selectivity for manganese over magnesium than hydroxide precipitation and the feeding method is the most critical factor for minimizing the co-precipitation of calcium and magnesium. Furthermore, with adding MnSO4 solution to NH4HCO3 solution, the effects of the initial NH4HCO3 concentration, NH4HCO3 amount, solution pH value, reaction temperature and time on carbonate precipitation were evaluated and the optimum precipitation conditions were obtained. Under the optimum conditions, the precipitation rates of Mn2+, Ca2+ and Mg2+ are 99.75%, 5.62% and 1.43%, respectively. Moreover, the prepared manganese carbonate was characterized by X-ray diffraction (XRD) and scanning electron microscopy (SEM) equipped with energy-dispersive X-ray spectroscopy (EDX). The results demonstrate that the product can be indexed to the rhombohedral structure of MnCO3.

Key words: carbonate precipitation; separation; manganese; calcium; magnesium

1 Introduction

Manganese sulfate solutions derived from the hydrometallurgical process of low-grade manganese ore usually contain a certain amount of calcium and magnesium ions, which affect the subsequent recovery of manganese. Generally, it is difficult to remove calcium and magnesium ions from the MnSO4 solutions, because the chemical properties of Ca2+ and Mg2+ are similar to those of Mn2+. Till now, there are mainly three purification methods of Ca2+ and Mg2+ including variable temperature crystallization, chemical precipitation and solvent extraction. Each method has its own advantages and disadvantages. Variable temperature crystallization of manganese sulfate solutions is simple and easy to operate, but difficult to avoid the formation of the mixed crystal of MnSO4 and MgSO4 [1-3]. Chemical precipitation method is of great significance in the purification process of manganese solutions. For instance, fluoride, oxalate, phosphate and carbonate are used as precipitants of calcium and magnesium ions [4-7]. Especially, fluorides such as MnF2 and NH4F are widely used because the solubility product constants of CaF2 and MgF2 are far lower than that of MnF2 at 25 °C [8]. However, fluorination precipitation method cannot evade the drawbacks of difficult sedimentation, strong corrosion and environmental pollution. Solvent extraction can be used to separate manganese selectively from other metals and avoid above drawbacks of fluorides, but the reagent costs may limit its application for the removal of calcium and magnesium ions from manganese-bearing solutions [9-11]. Therefore, in view of today’s economic and environmental concerns, chemical precipitation method using green reagents will be a future trend in the purification processes of manganese solutions.

In recent years, studies on separation and recovery of manganese from solutions containing one or more metals such as iron, cobalt, nickel, zinc, copper, calcium and magnesium have been carried out by hydroxide precipitation, carbonate precipitation or oxidative precipitation [12-17]. Hydroxide precipitation alone is easy to cause co-precipitation of manganese and magnesium due to its poor selectivity. Oxidative precipitation with SO2/O2 (air) is highly selective for the recovery of manganese ions in the form of Mn2O3 or MnO2, but the disadvantages of this approach are the need for very precise feed control and the use of toxic and corrosive SO2 gas. As for carbonate precipitation, previous research reported the separation of manganese and magnesium ions utilizing ammonia solution and carbon dioxide or ammonium bicarbonate [18]. More recently, PAKARINEN and PAATERO [19] also reported that carbonate precipitation is a fast and effective approach for manganese recovery and iron separation from sulfate solutions, with Na2CO3 or combined CaCO3 and O2 (air) oxidation due to their relatively low prices, good filtration and leaching properties. However, to the best of our knowledge, carbonate precipitation method has not been investigated intensively for the synthesis of MnCO3 associated with the removal of calcium and magnesium ions.

In this study, ammonium bicarbonate was used to precipitate manganese ions for the preparation of manganese carbonate product while calcium and magnesium ions remained in solution. Then, the remaining solution could be used to produce ammonium sulfate fertilizer containing calcium and magnesium. Moreover, the obtained manganese carbonate is a profitable product, which can be widely used for the production of manganese zinc magnetic ferrite, non-ferrous alloys, paints, fertilizers, dietary additives, welding electrodes and other manganese compounds [20,21]. The aim of this work was to investigate the selectivity for manganese over calcium and magnesium by carbonate precipitation and effects of several experimental variables such as the initial concentration of NH4HCO3, solution pH value, feeding methods, NH4HCO3 amount, reaction temperature and time on carbonate precipitation. Then, the optimum experimental conditions for the synthesis of manganese carbonate and minimizing co-precipitation of calcium and magnesium were determined.

2 Theory

As we all know, there are two important dissociation equilibria between carbonic acid, bicarbonate ion and carbonate ion in the carbonate solution.

, K1=10-6.38 (1)

, K1=10-6.38 (1)

, K2=10-10.32 (2)

, K2=10-10.32 (2)

where K1 and K2 are the first and second dissociation constants of carbonic acid at 25 °C, respectively [8]. Then, according to the relevant knowledge of solution chemistry, the mass balance of carbon element can be expressed by the following equations:

(3)

(3)

(4)

(4)

(5)

(5)

where c(C)t represents the total concentration of carbon element in aqueous solution (mol/L),  ,

,  and

and  are the concentrations of carbonate ion, bicarbonate ion and carbonic acid, respectively, (mol/L),

are the concentrations of carbonate ion, bicarbonate ion and carbonic acid, respectively, (mol/L),  is the coefficient of total concentration of carbon element in the system and its value can be calculated by Eq. (5), pK1 and pK2 are the negative logarithms of K1 and K2, respectively [22].

is the coefficient of total concentration of carbon element in the system and its value can be calculated by Eq. (5), pK1 and pK2 are the negative logarithms of K1 and K2, respectively [22].

On one hand, the carbonate precipitation of divalent metal ions and the solubility product constant of related carbonate salts can be expressed by the following equations:

(6)

(6)

(7)

(7)

(8)

(8)

where c(Me2+) represents the concentration of divalent metal ion such as Ca2+, Mg2+ or Mn2+ (mol/L);  refers to the solubility product constant of CaCO3, MgCO3 or MnCO3.

refers to the solubility product constant of CaCO3, MgCO3 or MnCO3.

Applying Eqs. (4) and (5), and pK1 and pK2 values to Eq. (8), the relationship between equilibrium concentrations of divalent metal ions and the pH value in aqueous solution can be presented as follows:

(9)

(9)

where the Ksp values of CaCO3, MgCO3 and MnCO3 are 10-8.54, 10-5.17 and 10-10.63, respectively [8].

On the other hand, hydroxide precipitation of divalent metal ions may occur with the solution pH value increasing according to the following equations:

(10)

(10)

(11)

(11)

where the Ksp values of Ca(OH)2, Mg(OH)2 and Mn(OH)2 are 10-5.26, 10-11.25 and 10-12.72, respectively [8], pKW refers to the negative logarithm of the ionic activity product constant of water and its value is 14 at 25 °C.

3 Experimental

3.1 Materials

The main material of experiments was manganese sulfate solution obtained by acid leaching of low-grade manganese carbonate ores and removal of iron and heavy metals from leaching solution [23,24]. Table 1 lists the major compositions of the solution, indicating that 1.54 g/L Ca2+ and 1.89 g/L Mg2+ were the principal impurities and needed to be removed. In addition, other chemicals in the experiments such as ammonium bicarbonate, ammonia water (28%) and barium chloride were analytical reagent grade and de-ionized (DI) water was used in dissolution and washing.

Table 1 Major metal ions and their contents in manganese sulfate solution (g/L)

3.2 Experimental procedure

All the tests were carried out in 500 mL three-necked flack provided with a mechanical stirrer. In the typical precipitation procedure, 200 mL manganese sulfate solution was added to 117 mL ammonium bicarbonate solution at a flow rate of 2 mL/min with agitating at 300 r/min. The temperature of reaction system was maintained by water circulation from a thermostatic water bath through the water jacket. The solution pH value was monitored by a thermo pH probe and adjusted to 7.0-7.5 by dropping ammonia water. After feeding, the solution continued to be stirred for a predefined time. When the reaction was completed, the slurry was cooled to room temperature naturally for 3 h. After the slurry was filtered, the filter cake was collected and washed with 1000 mL de-ionized water five times until the filtrate was not precipitated by adding 5% BaCl2 solution (mass fraction). Finally, the manganese carbonate product was dried in a vacuum at 90 °C for 2 h.

3.3 Analysis methods

The manganese contents of the aqueous samples and solid products were detected by titration with the normality ammonium ferrous sulfate solution. The contents of Ca and Mg were analyzed by inductively coupled plasma atomic emission spectroscopy (ICP-AES). Moreover, the crystal purity of products under optimal conditions was determined by X-ray diffraction (XRD). XRD analysis was performed using a Rigaku D/max 2500V diffractometer equipped with a Cu target and a graphite monochromator. Particle morphologies were characterized by scanning electron microscopy (SEM) equipped with an energy-dispersive X-ray spectroscopy (EDX).

4 Results and discussion

According to Eqs. (9) and (11), at ammonium bicarbonate concentration of 1.0 mol/L (c(C)t=1.0 mol/L) and 25 °C, the diagram of metal ions equilibrium concentration versus pH value is shown in Fig. 1.

Fig. 1 Diagram of metal ions equilibrium concentration vs pH value at ammonium bicarbonate concentration of 1.0 mol/L and 25 °C

The graph of equilibrium concentration versus pH value suggests that the precipitation laws of Ca2+, Mg2+ and Mn2+ in hydroxide precipitation system are different from those in carbonate precipitation system. With the solution pH value increasing from 2 to 13, the equilibrium concentrations of Ca2+, Mg2+ and Mn2+ drop linearly by hydroxide precipitation. However, in the carbonate precipitation system, the metal ions equilibrium concentrations decrease gradually with the increase of solution pH value and then remain nearly unchanged when the solution pH value exceeds 11. Figure 1 also shows that at the same pH value, the precipitation potentialities of Ca2+, Mg2+ and Mn2+ decrease in the order: MnCO3>CaCO3>MgCO3> Mn(OH)2>Mg(OH)2>Ca(OH)2. When the solution pH value is 7, the difference of lg[c(Me2+)] between Mg(OH)2 and Mn(OH)2 is 1.47 while those are 5.46 between MgCO3 and MnCO3 and 2.09 between CaCO3 and MnCO3. Therefore, from the view of thermodynamics, carbonate precipitation is more feasible to separate manganese from magnesium and calcium than hydroxide precipitation due to its better selectivity for manganese over magnesium. Furthermore, the precipitation of manganese carbonate is more thermodynamically favorable for magnesium-manganese separation than calcium-manganese separation. This is important for obtaining better quality manganese deposition product from manganese sulfate solution containing higher concentration of magnesium and lower concentration of calcium [13].

In fact, the reactions of metal ions with carbonate ions are essentially the crystallization processes of metal carbonates. Generally, the growth process of crystals can be separated into two steps, an initial nucleating stage and a subsequent crystal growth process. Both the nucleating speed and crystal growth speed can influence the particle size of crystals and further influence the impurity content in crystals or products. Furthermore, the nucleating speed and crystal growth speed are governed by the supersaturation of the solution and crystallization temperature [25]. Therefore, in order to obtain manganese carbonate product with extremely few impurities, several factors of crystallization process such as the initial concentration of ammonium bicarbonate, solution pH value, feeding methods, reaction temperature and time should be considered and optimized.

4.1 Effects of initial concentration of ammonium bicarbonate and solution pH value

According to Eqs. (9) and (11), the curves of Mn2+ equilibrium concentration versus pH value with different initial concentrations of ammonium bicarbonate at 25 °C are shown in Fig. 2.

Fig. 2 Curves of Mn2+ equilibrium concentration vs pH value under different initial concentrations of ammonium bicarbonate at 25 °C

With increasing the initial concentration of ammonium bicarbonate from 0.1 to 1.0 mol/L, the equilibrium concentration of Mn2+ at a certain pH value tends to decrease, indicating that high concentration of bicarbonate ion or carbonate ion can contribute to the carbonate precipitation of Mn2+. This generally agrees to the precipitation-dissolution equilibrium law as indicated by Eq. (6). When the carbonate ion concentration in solution augments, the precipitation- dissolution equilibrium moves towards the formation of carbonate deposition. Therefore, in consideration of maximizing the precipitation of Mn2+ and minimizing the co-precipitation of Mg2+ and Ca2+, the initial concentration of ammonium bicarbonate of 1.0 mol/L is recommended.

On the other hand, the solution pH value plays a critical role in precipitation reactions as indicated by Figs. 1 and 2. The Mn2+ equilibrium concentration under a certain concentration of carbonate ions decreases with the increase of solution pH value from 2 to 13. When the solution pH value is in the range of 7.0-8.0, the carbonate precipitation of Mn2+ occupies an obvious advantage. However, when the solution pH value exceeds the demarcation point such as 12.5, the hydroxide precipitation of Mn2+ holds an advantage with respect to carbonate precipitation, and consequently, Mn(OH)2 can contaminate the manganese carbonate product. Hence, the formation of Mn(OH)2 should be avoided and the solution pH value of 7.0-7.5 is adequate for the carbonate precipitation process.

4.2 Effect of feeding methods

Generally speaking, there are three feeding methods in the carbonate precipitation process, such as adding NH4HCO3 solution to MnSO4 solution or adding MnSO4 solution to NH4HCO3 solution or feeding simultaneously. Hence, carbonate precipitations with three feeding methods were investigated under the conditions of the initial concentration of ammonium bicarbonate of 1.0 mol/L, ammonium bicarbonate amount of 110% of the theoretical value, solution pH values of 7.0-7.5, temperature of 40 °C and reaction time of 4 h. The experimental results are shown in Table 2.

As indicated in Table 2, the Mn precipitation rates with three feeding methods are similar while the contents of Ca and Mg in the carbonate product are greatly different. The obtained products by adding NH4HCO3 solution to MnSO4 solution and feeding simultaneously have higher contents of Ca and Mg with respect to the feeding method of adding MnSO4 solution to NH4HCO3 solution. The reason could be that during the process of adding NH4HCO3 solution to MnSO4 solution, the co-precipitation of Ca2+ and Mg2+ generates largely due to the high initial concentrations of Ca2+ and Mg2+ in the solution. As for the synchronous feeding way of NH4HCO3 and MnSO4 solutions, carbonate precipitate tends to form large diameter crystal which is easy to parcel the impurity ions such as Ca2+ and Mg2+ [26]. However, in the carbonate deposition process with adding MnSO4 solution to NH4HCO3 solution, the initial concentrations of Mg2+ and Ca2+ are lower, which contributes to decreasing the precipitation of Ca2+ and Mg2+. Therefore, in order to obtain high quality carbonate product, the feeding method of adding MnSO4 solution to NH4HCO3 solution is adopted.

Table 2 Effects of feeding methods on carbonate precipitation

4.3 Effect of ammonium bicarbonate amount

With other conditions fixed (the initial concentration of NH4HCO3 of 1.0 mol/L, solution pH values of 7.0-7.5, reaction temperature of 25 °C, reaction time of 4 h), the effects of NH4HCO3 amount on the metals precipitation rates and manganese grade of product were examined with the results shown in Fig. 3.

Figure 3 illustrates that an increase of NH4HCO3 amount from 100% to 130% of the theoretical dose significantly promotes the carbonate precipitation of Mn, Ca and Mg. When the NH4HCO3 amount equals the theoretical dose, the Mn precipitated in the carbonate deposition process is only 86.99% because a certain amount of carbonate ions in solution can be consumed by Ca2+ and Mg2+ ions. When the NH4HCO3 amount rises to 110% of the theoretical dose, the precipitation rate of Mn reaches 98.13% and the precipitation rates of Ca and Mg are 10.10% and 4.29%, respectively. Then, with increasing the NH4HCO3 amount from 110% to 130% of the theoretical dose, the precipitation rate of Mn nearly reaches a high platform while the precipitation rates of Ca and Mg augment markedly from 10.10% and 4.29% to 24.15% and 13.30%, respectively. That is a result of great excess bicarbonate ions accelerating the deposition of Ca2+ and Mg2+ ions. Moreover, Fig. 3 also suggests that the more the NH4HCO3 amount is, the higher the precipitation rates of Ca and Mg are and the lower the manganese grade of carbonate product is. Therefore, in order to precipitate Mn2+ in solution as completely as possible and minimize the co-precipitation of Ca2+ and Mg2+ ions, the optimal NH4HCO3 amount should be 110% of the theoretical dose.

Fig. 3 Effect of NH4HCO3 amount on carbonate precipitation

4.4 Effect of reaction temperature

To optimize the effect of reaction temperature on the carbonate precipitation, the tests at different temperatures were carried out by keeping other conditions the same (the initial concentration of NH4HCO3 of 1.0 mol/L, NH4HCO3 amount of 110% of the theoretical dose, solution pH values of 7.0-7.5, reaction time of 4 h). The results are shown in Fig. 4.

Fig. 4 Effect of reaction temperature on carbonate precipitation

As shown in Fig. 4, with the reaction temperature rising from 25 to 40 °C, the Mn precipitation rate increases slightly from 98.13% to 99.53% and the Mn grade of carbonate product rises from 44.18% to 44.67%, but the precipitation rates of Ca and Mg decrease significantly from 10.10% and 4.29% to 6.33% and 1.72%, respectively. It suggests that an appropriate increase of reaction temperature is beneficial to reducing the co-precipitation of Ca and Mg. However, with continuing to raise temperature from 40 to 60 °C, the precipitation rates of Ca and Mg have an upward trend, and conversely, that of Mn shows a significant downward trend. Apparently, at higher reaction temperatures, the solubility of carbonic acid in solution becomes lower and the decomposition of ammonium bicarbonate performs faster. Consequently, the carbonate ions amount in solution at 60 °C is insufficient to deposit most of Mn2+ ions. Thus, taking selective carbonate precipitation into consideration, the optimal reaction temperature should be 40 °C.

4.5 Effect of reaction time

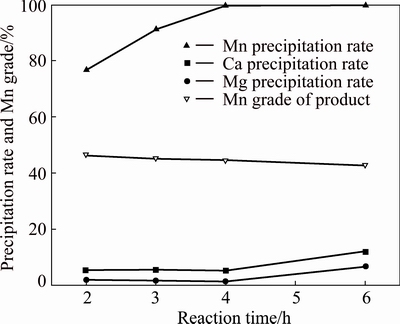

Fixing the initial concentration of NH4HCO3 at 1.0 mol/L, NH4HCO3 amount at 110% of the theoretical dose, solution pH values at 7.0-7.5 and temperature at 40 °C, the effect of reaction time on carbonate precipitation was studied and is shown in Fig. 5.

Fig. 5 Effect of reaction time on carbonate precipitation

Figure 5 demonstrates that the precipitation rate of Mn augments sharply from 76.68% to 99.79% with prolonging the reaction time from 2 to 4 h. Although the precipitation rates of Ca and Mg at 2, 3 and 4 h are almost the same, the precipitation rates of Mn at 3 and 4 h are above 91% while the precipitation rate of Mn at 2 h is only 76.68%. Furthermore, when the reaction time exceeds 4 h, the precipitation rate of Mn becomes almost independent of the reaction time while the precipitation rates of Ca and Mg start to rise, and this gradually influences the Mn grade of carbonate product.

As we know, the growth process of crystals includes an initial nucleating stage and a subsequent crystal growth process. The crystal growth stage strongly governs the final architecture of the crystals through the delicate balance between the kinetic growth and thermodynamic growth regimes [27]. Based on the precipitation rates of Mn2+, Ca2+ and Mg2+ at different reaction time, the products prepared by crystallizing for 3 and 4 h were characterized by scanning electron microscopy (SEM).

Fig. 6 SEM images of manganese carbonate product prepared by crystallizing for 3 h (a) and 4 h (b), EDX image (c) and XRD pattern (d) of final product

Figures 6(a) and (b) show the SEM images of manganese carbonate products obtained at 3 and 4 h, respectively. The manganese carbonate product obtained by crystallizing for 3 h seems coarse and fuzzy. It could be attributed to the lack of crystallization time and the immature of crystal growth. However, the product obtained by crystallizing for 4 h has a smooth morphology, indicating that 4 h is sufficient to accomplish the total crystallization process. Therefore, the most favorable reaction time is 4 h, corresponding to precipitation rates of 99.79% for Mn, 5.30% for Ca and 1.38% for Mg and manganese grade of 44.62% in product.

4.6 Reproducibility tests under optimum conditions

Based on the above test results, the optimized processing conditions of carbonate precipitation are considered as the initial NH4HCO3 concentration of 1.0 mol/L, solution pH values of 7.0-7.5, feeding method of adding MnSO4 solution to NH4HCO3 solution, reaction temperature of 40 °C, reaction time of 4 h. In order to further examine the reproducibility of the test results, repeated tests of carbonate precipitation were conducted under the optimum conditions. The results are shown in Table 3, which indicates that the reproducibility of test results is good and satisfactory. Table 3 also shows that the average precipitation rates of Mn, Ca and Mg are 99.75%, 5.62% and 1.43%, respectively.

Table 3 Results of repeated tests under optimum conditions

4.7 Identification of manganese carbonate product

The prepared manganese carbonate product under the optimum conditions was analyzed chemically with the quality of product shown in Table 4, which indicates that the product conforms to the III grade standard of HG/T 2836-2011. Moreover, the generated product under the optimum conditions was also characterized by EDX and XRD for evaluating its composition and purity. The EDX image (Fig. 6(c)) shows that the product is pure manganese carbonate. Besides, all the diffraction peaks in the XRD pattern (Fig. 6(d)) can be perfectly indexed to the rhombohedral structure of MnCO3 from JPCDS card 83-1763.

Table 4 Quality of manganese carbonate product prepared under optimum conditions (mass fraction, %)

5 Conclusions

1) Ammonium bicarbonate was used to effectively precipitate manganese from sulfate solutions, due to its low price, reaction process of being easy to control and not introducing impurities except ammonium ions. Moreover, with ammonium bicarbonate and ammonia water as the precipitant and pH regulator, respectively, carbonate precipitation method has a significant advantage that manganese carbonate is obtained as a main product, meanwhile, the byproduct of ammonium sulfate solution containing Ca and Mg is also obtained for the production of ammonium fertilizer. Besides, carbonate precipitation offers better selectivity for manganese over magnesium than hydroxide precipitation.

2) The process of carbonate precipitation can be affected by the initial concentration of ammonium bicarbonate, solution pH value, feeding methods, reaction temperature and time. The optimum conditions of carbonate precipitation are determined as the feeding method of adding MnSO4 solution to NH4HCO3 solution, initial NH4HCO3 concentration of 1.0 mol/L, NH4HCO3 amount of 110% of the theoretical dose, solution pH values of 7.0-7.5, reaction temperature of 40 °C and time of 4 h. The precipitation rates of Mn2+, Ca2+ and Mg2+ under the optimal conditions are 99.75%, 5.62% and 1.43%, respectively.

3) The prepared manganese carbonate product contains 44.62% Mn, 0.25% Ca and 0.08% Mg and conforms to the III grade standard of HG/T 2836-2011. This separation process would be promising to recover manganese from sulfate solution containing calcium and magnesium due to high recovery of manganese, good availability and simplicity of operation.

References

[1] YUAN Ming-liang, QIU Guan-zhou. Study on the removing of MgSO4 from MnSO4 solution based on the aqueous system phase diagram [J]. Journal of Central South University of Technology, 2000, 31(3): 212-214. (in Chinese)

[2] PAGNANELLI F, GARAVINI M, VEGLIO F, TORO L. Preliminary screening of purification processes of liquor leach solutions obtained from reductive leaching of low grade manganese ores [J]. Hydrometallurgy, 2004, 71(3): 319-327.

[3] FARRAH H E, LAWRANCEL G A, WANLESS E J. Solubility of calcium sulfate salts in acidic manganese sulfate solutions from 30 to 105 °C [J]. Hydrometallurgy, 2007, 86(4): 13-21.

[4] PENG Chang-hong, TANG Mo-tang, HUANG Hong. Primary and deep purification of complex system of MeSO4 [J]. The Chinese Journal of Process Engineering, 2006, 6(6): 894-898. (in Chinese)

[5] LIU Hong-gang, ZHU Guo-cai. Removal of Ca(II), Mg(II) from leaching solution of low-grade manganese ore by precipitation with fluoride [J]. Mining & Metallurgy, 2007, 16(4): 25-28. (in Chinese)

[6] HE Gui-xiang, HE Li-hua, ZHAO Zhong-wei, CHEN Xing-yu, GAO Li-li, LIU Xu-heng. Thermodynamic study on phosphorous removal from tungstate solution via magnesium salt precipitation method [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3440-3447.

[7] YAN Sheng, QIU Yun-ren. Preparation of electronic grade manganese sulfate from leaching solution of ferromanganese slag [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3716-3721.

[8] SPEIGHT J G. Lange’s handbook of chemistry [M]. 16th ed. New York: McGraw-Hill, Inc, 2005.

[9] CHENG C Y. Purification of synthetic laterite leach solution by solvent extraction using D2EHPA [J]. Hydrometallurgy, 2000, 56(3): 369-386.

[10] PAKARINEN J, PAATERO E. Effect of temperature on Mn-Ca selectivity with organophosphorus acid extractants [J]. Hydrometallurgy, 2011, 106(3): 159-164.

[11] HAGHIGHI H K, MORADKHANI D, SALARIRAD M M. Separation of zinc from manganese, magnesium, calcium and cadmium using batch countercurrent extraction simulation followed by scrubbing and stripping [J]. Hydrometallurgy, 2015, 154: 9-16.

[12] ZHANG W, SINGH P, MUIR D. Oxidative precipitation of manganese with SO2/O2 and separation from cobalt and nickel [J]. Hydrometallurgy, 2002, 63(2): 127-135.

[13] ZHANG W, CHENG C Y, PRANOLO Y. Investigation of methods for removal and recovery of manganese in hydrometallurgical process [J]. Hydrometallurgy, 2010, 101(1-2): 58-63.

[14] ZHANG W, CHENG C Y. Manganese metallurgy review. Part I: leaching of ores/secondary materials and recovery of electrolytic/ chemical manganese dioxide [J]. Hydrometallurgy, 2007, 89(3-4): 137-159.

[15] ZHANG W, CHENG C Y. Manganese metallurgy review. Part II: manganese separation and recovery from solution [J]. Hydrometallurgy, 2007, 89(3-4): 160-177.

[16] ZHANG W, CHENG C Y. Manganese metallurgy review. Part III: manganese control in zinc and copper electrolytes [J]. Hydrometallurgy, 2007, 89(3-4): 178-188.

[17] BELLO-TEODORO S, PEREZ-GARIBAY R, URIBE-SALAS A. The controlled oxidative precipitation of manganese oxides from Mn(II) leach liquors using SO2/air gas mixtures [J]. Minerals Engineering, 2011, 24(15): 1658-1663.

[18] XIE Lan-xiang, OUYANG Chang-lun. Study on separation of magnesium and manganese from manganese sulfate mother solution containing rich magnesium ions [J]. China’s Manganese Industry, 1989(1): 35-37. (in Chinese)

[19] PAKARINEN J, PAATERO E. Recovery of manganese from iron containing sulfate solutions by precipitation [J]. Minerals Engineering, 2011, 24(13): 1421-1429.

[20] LEI S, LIANG Z, ZHOU L, TANG K. Synthesis and morphological control of MnCO3 and Mn(OH)2 by a complex homogeneous precipitation method [J]. Materials Chemistry and Physics, 2009, 113: 445-450.

[21] POURMORTAZAVI S M, RAHIMI-NASRABADI M, DAVOUDI-DEHAGHANI A A, JAVIDAN A, ZAHEDI M M, HAJIMIRSADEGHI S S. Statistical optimization of experimental parameters for synthesis of manganese carbonate and manganese oxide nanoparticles [J]. Materials Research Bulletin, 2012, 47: 1045-1050.

[22] LI Zhi-qiang, HE Liang-hui. Diagrams of chemical potential and application in aqueous solutions [M]. Chengdu: Chengdu University of Science and Technology Press, 1991. (in Chinese)

[23] LIU You-cai, LIN Qing-quan, LI Li-feng, FU Jian-gang, ZHU Zhong-si, WANG Chong-qing, QIAN Dong. Study on hydrometallurgical process and kinetics of manganese extraction from low-grade manganese carbonate ores [J]. International Journal of Mining Science and Technology, 2014, 24(4): 567-571.

[24] LIN Qing-quan, LIU You-cai, LI Li-feng, WANG Yun-qiu, WANG Jia-yi, XU Jing-yan, PENG Bin-jiang, ZHU Zhong-si. Study on technology of preparing high purity manganese sulfate with low-grade manganese carbonate ores [J]. Inorganic Chemicals Industry, 2014, 46(11): 35-38. (in Chinese)

[25] YUAN Ming-liang, QIU Guan-zhou. Controlling of the particle size in the preparation process of manganese carbonate and its effect on the product quality [J]. Journal of Central South University of Technology, 2001, 32(5): 473-476. (in Chinese)

[26] HU Guo-rong, ZHOU Yu-lin, PENG Zhong-dong. A study of the preparation of manganese carbonate with high purity by the use of industry manganese [J]. China’s Manganese Industry, 2007, 25(2): 14-17. (in Chinese)

[27] DUAN X, LIAN J, MA J, KIM T, ZHENG W. Shape-controlled synthesis of metal carbonate nanostructure via ionic liquid-assisted hydrothermal route: The case of manganese carbonate [J]. Crystal Growth & Design, 2010, 10(10): 4449-4455.

林清泉1,顾帼华1,王 晖2,王重庆2,刘有才2,朱仁锋1,符剑刚2

1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 中南大学 化学化工学院,长沙 410083

摘 要:以含14.59 g/L Mn2+、1.89 g/L Mg2+和1.54 g/L Ca2+的硫酸盐溶液为原料,利用碳酸盐沉淀法实现了锰与钙和镁的有效分离。热力学分析与实验结果表明,碳酸盐沉淀体系中锰对镁的选择性明显优于水解沉淀体系,而且加料方式是减少钙、镁共沉淀的主要因素。因而以硫酸锰加入碳酸氢铵的方式,研究碳酸氢铵初始浓度和用量、溶液pH值、反应温度及时间对沉淀过程的影响,并得到最优沉淀条件。结果表明:最优条件下锰、钙和镁离子的沉淀率分别为99.75%、5.62%和1.43%。另外,制得的产品经X射线衍射和能谱扫描电镜分析,结果表明该产品为菱形碳酸锰。

关键词:碳酸盐沉淀;分离;锰;钙;镁

(Edited by Mu-lan QIN)

Foundation item: Project (51374249) supported by the National Natural Science Foundation of China

Corresponding author: Guo-hua GU; Tel: +86-13975151469; E-mail: guguohua@126.com

DOI: 10.1016/S1003-6326(16)64210-3