温度对一种含Re单晶高温合金拉伸行为和变形机制的影响

来源期刊:中国有色金属学报(英文版)2011年第7期

论文作者:刘金来 于金江 金涛 孙晓峰 管恒荣 胡壮麒

文章页码:1518 - 1523

关键词:单晶高温合金;拉伸行为;屈服强度;微观组织

Key words:single crystal superalloy; tensile behavior; yield strength; microstructure

摘 要:

研究了一种含Re单晶高温合金在20~1 100 ℃的拉伸性能。结果表明:在室温至600 ℃时合金屈服强度随温度的升高轻微增大,从600至760 ℃时合金屈服强度明显降低到一个极小值,到800 ℃时急剧增至最大值。从室温至800 ℃时伸长率和面缩率缓慢降低;在800 ℃以上时,屈服强度急速下降。在600 ℃以下时,γ′被反相畴界切割而在其中留下伸长的超晶格层错;在760 ℃时,γ′被a/3<112>位错切割,这是由于层错能降低而导致强度降低;当高于800 ℃时,位错以绕越机制通过γ′。

Abstract:

Tensile properties of a Re-containing single crystal superalloy were determined within the temperature range from 20 to 1 100 ℃ with a constant strain rate of 1.67′10-4 s-1. From room temperature to 600 ℃, the yield strength increases slightly with increasing temperature. The yield strength decreases to a minimum at 760 ℃, while a maximum is reached dramatically at 800 ℃. The elongation and area reduction decrease gradually from room temperature to 800 ℃. Above 800 ℃, the yield strength decreases significantly with increasing temperature. The γ′ phase is sheared by antiphase boundary (APB) below 600 ℃, while elongated SSF (superlattice stacking fault) is left in γ′ as debris. At 760 ℃ the γ′ phase is sheared by a/3<112> superpartial dislocation, which causes decrease of yield strength due to low energy of SSF. Above 800 ℃, dislocations overcome γ′ through by-passing mechanism.

LIU Jin-lai, YU Jin-jiang, JIN Tao, SUN Xiao-feng, GUAN Heng-rong, HU Zhuang-qi

Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

Received 18 October 2010; accepted 14 March 2011

Abstract: Tensile properties of a Re-containing single crystal superalloy were determined within the temperature range from 20 to 1 100 °C with a constant strain rate of 1.67?10-4 s-1. From room temperature to 600 °C, the yield strength increases slightly with increasing temperature. The yield strength decreases to a minimum at 760 °C, while a maximum is reached dramatically at 800 °C. The elongation and area reduction decrease gradually from room temperature to 800 °C. Above 800 °C, the yield strength decreases significantly with increasing temperature. The γ′ phase is sheared by antiphase boundary (APB) below 600 °C, while elongated SSF (superlattice stacking fault) is left in γ′ as debris. At 760 °C the γ′ phase is sheared by a/3á112? superpartial dislocation, which causes decrease of yield strength due to low energy of SSF. Above 800 °C, dislocations overcome γ′ through by-passing mechanism.

Key words: single crystal superalloy; tensile behavior; yield strength; microstructure

1 Introduction

Single crystal superalloys are widely used in modern aircraft to manufacture turbine blades due to their excellent mechanical performance. The advantages of single crystal superalloy mainly arise from their unique microstructures which consist of ordered γ′ precipitates (L12 structure) coherently embedded in a fcc Ni base solid solution matrix [1-3]. The mechanical behavior of superalloy is closely related to single phase γ′. Most of the special feature of single crystal superalloy can be explained based on the corresponding character of γ′ phase. The anomalous mechanical properties of single crystal superalloy are mainly determined by intrinsic nature of γ′ phase, such as abnormal yield strength versus temperature, tension/ compression asymmetry and breakdown of Schimd’s law [4-8].

However, it should be noted that considerable differences are introduced into mechanical properties of superalloy owing to its two-phase microstructure compared with single phase γ′. For example, single crystal superalloy exhibits highly complex yield behavior [9-11]. Most single crystal superalloys display a similar peak temperature at which the yield strength achieves a maximum. Above the peak temperature, the yield strength drops rapidly with the increase of temperature. On the contrary, the relationship between yield strength and temperature varies significantly for different alloy below peak temperature. The yield strength of CMSX-4 alloy keeps constant below 600 °C and reaches a maximum at 800 °C [12]. The yield strength of SRR99 alloy almost does not change below the peak temperature of 760 °C [13]. The PWA 1480 alloy displays a minimum at 450 °C and a maximum at 760 °C in yield strength [14]. The DD98 alloy shows increasing tendency in yield strength from room temperature to peak temperature [15]. The deformation mechanism below peak temperature is well accepted that γ′ is cut by a/2á110? dislocation on octahedral slip and resultant antiphase boundary (APB) [16]. Although shearing to γ′ by a/3á112? and corresponding superlattice stack fault are observed, their influence on yield strength is not clear yet. It has been shown that both the abnormal yielding strength and deformation mechanism in a specific alloy depend closely on its composition and microstructure, e.g. size and volume fraction of γ′ as well as its misfit.

The alloy used in present study was a Re-containing single crystal superalloy with minor C addition, which was designed for manufacturing turbine blade with high operating temperature. The tensile yielding behavior of this single crystal superalloy was studied from room temperature to 1 100 °C. The deformation mechanisms at different temperatures were analyzed with TEM.

2 Experimental

The chemical composition (mass fraction, %) of the experimental alloy used in this work was: 5Cr, 9W, 3.9Ta, 4.2Re, 6Al, 9Co, 1.5Nb, 1Mo and 0.15C. The master alloy was melted in a vacuum induction furnace as a 60 kg-ingot, then directionally solidified into [001] single crystal rods by Bridgman withdraw technique. Each mold contained 6 rods and was processed at a constant withdraw rate of 6 mm/min.

The as-cast rods were cut to short bars of about 66 mm in length, then they were heat treated by following standard scheme: (1 290 °C, 4 h, AC)+(1 280 °C, 4 h, AC)+(1 150 °C, 4 h, AC)+(870 °C, 4 h, AC). The bars were machined into tensile test specimens, the gauge length was 25 mm while the diameter was 5 mm. The tensile test was conducted at 20, 450, 600, 760, 800, 900, 980, 1 050 and 1 100 °C with a constant strain rate 1.67?10-4 s-1 to rupture. The used test machine is an AG-250KNE system equipped with a high temperature extensometer. The specimen was heated by a three-region resistance furnace with a temperature fluctuation less than 2 °C.

The metallography samples were mechanically polished and etched in a solution of 5 g CuSO4+20 mL HCl+25 mL H2O, then was examined with Shimadzu SSX-550 scanning electron microscope (SEM). The thin foils for transmission electron microscopy (TEM) were cut normal to the stress axis and 5 mm apart from the fracture, then mechanically ground to 50 μm and finally electro-polished at -20 °C in a solution of 7% perchloric acid and 93% ethanol, then were observed on PHILPS EM420 TEM operating at 200 kV.

3 Results and discussion

3.1 Microstructure

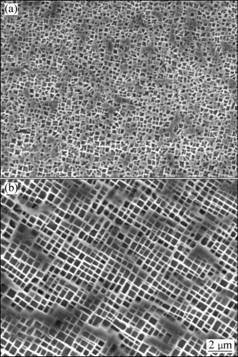

Figure 1 shows the microstructures of as-cast and heat treated samples. The γ′ particles in as-cast sample exhibit relatively small size and irregular morphology due to rapid cooling rate during directional solidification. After standard heat treatment, the segregation of alloy elements is dramatically reduced by diffusion at high solution temperature. The γ′ phase re-precipitates from the solid solution and grows into regular cuboidal morphology during ageing. The mean size of γ′ particles is 0.48 μm.

3.2 Tensile properties

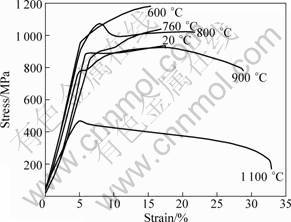

Figure 2 demonstrates stress—strain curves at the typical testing temperature. It can be seen that the alloy exhibits rather different tensile behaviors over the experimental temperature range. At room temperature, only very weak work hardening is observed after a well-defined yield point. At 600 °C, strong work hardening with near linearity is kept till rupture. At 760 °C, the flow stress shows double stages feature. At 800 °C, the alloy does not show a well-defined yield point, the flow stress drops to a platform when beyond the peak load. At 900 °C, the flow stress shows a curved feature after a well-defined yield point. At 1 100 °C, the flow stress decreases linearly after yield point.

Fig. 1 Microstructures of used superalloy: (a) Irregular γ′ precipitate in as-cast sample; (b) Cuboidal γ′ precipitate in heat treated sample

Fig. 2 Typical stain—stress curves of alloys at different test temperatures

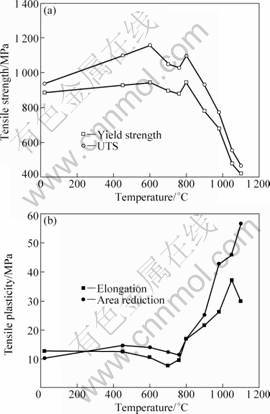

The tendencies of tensile strength and plasticity with temperature are shown in Fig. 3. The yield strength drops dramatically as temperature is above 800 °C, termed as peak temperature, which is similar to other alloys. However, it should be noted that the yield strength exhibits a complex tendency below peak temperature. The yield strength increases with increasing temperature from 20 to 600 °C, while it decreases evidently with increasing temperature from 600 to 760 °C. Then it increases rapidly in the temperature range of 760-800 °C. The ultimate tensile strength (UTS) also shows tendency rather similar to yield strength. The tensile plasticity demonstrates two temperature regimes: below the peak temperature, the elongation and area reduction do not vary but a slightly decrease near the peak temperature; above the peak temperature, these two parameters rise remarkably with temperature except a reduction of elongation at 1 100 °C.

Fig. 3 Tensile properties of alloys at various test temperatures: (a) Tensile strength; (b) Tensile plasticity

3.3 Deformation microstructure

Figure 4 shows the deformation microstructures of samples tested below 600 °C. Figure 4(a) shows the dislocation configuration formed at 20 °C. High density dislocations are present in the matrix channels, distributing parallel to each other. This indicates that only one slip system is activated, in other words, even no work hardening occurs by intersection of dislocations from another slip system. The slight increase of flow stress only stems from the geometry hardening. Another remarkable feature is the presence of elongated superlattice stacking fault (SSF) loops within γ′, which is surrounded by superpartial dislocation(marked by arrows). Their appearance differs significantly from the SSF at γ/γ′ interfaces during intermediate temperature creep. It is also observed that matrix dislocation cut into γ′ in pairs coupled by APB (marked with A). The microstructure of sample tested at 600 °C (Fig. 4(b)) is apparently similar to that at 20 °C, while some difference should be noted. High density dislocation is tangled in the matrix channel instead of parallel arrays, which indicates occurrence of multiple slip. Intersection between dislocations from different slip systems will lead to significant work hardening. This is in accordance with the linear increase of flow stress at 600 °C. Similar elongated SSF loops are also observed in γ′ with higher density (marked by arrow).

The deformation microstructures of intermediate temperature are shown in Fig. 5. Figure 5(a) shows the dislocation configuration of sample tested at 760 °C, the striking feature is presence of quantities of SSFs within γ′ in additional to dislocations tangling in matrix channel. The SSFs frequently traverse whole γ′ particle. Although this type of SSF is usually observed in samples crept at intermediate temperature [17]. It was also investigated in monotonic tensile deformation [18]. These faults are formed by the dissociation of an interfacial a/2á110? matrix dislocation via reaction a/2á110??a/3á112?+ a/6á112?. The a/3á112? superpartial enters the precipitate, creating an SISF, while the a/6á112? partial remains at the interface, pinned by the high-energy APB that would be created if it enters the precipitate. The case in the present work is in agreement with the result in Ref. [19]. The a/3á112? superpartial within γ′ is marked by arrow. The microstructure of sample tested at 800 °C (Fig. 5(b)) is significantly different to that at 760 °C. High density dislocations with curl shape are present in γ′, while SSF is only occasionally observed (marked by arrow). In addition, numerous dislocation loops with circular shape can also be observed in γ′. The decrease in amount of SSF at 800 °C indicates that the dissociation of a/2á110? interfacial dislocation is strongly restrained compared with 760 °C.

Fig. 4 Microstructure of low temperature regime: (a) Parallel dislocation array in matrix and SSF loop in γ′ at room temperature; (b) Dislocation tangling in matrix and SSF loop in γ′ at 600 °C

Fig. 5 Microstructures of intermediate temperature regime: (a) Numerous SSFs in γ′ precipitate at 760 °C; (b) Dislocation tangling and a few SSF in γ′ precipitate at 800 °C

Figure 6 shows the microstructure tensile deformed at high temperature. Figure 6(a) shows the dislocation configuration of sample tested at 900 °C. High density dislocation debris are homogeneously distributed in both matrix channel and γ′ precipitate, which demonstrates strong interaction in multiple slip systems. The dislocations entangle each other and result in irregular morphology. In addition, SSFs never occur at this temperature.

Figure 6(b) shows the dislocation configuration of sample deformed at 1 100 °C. It can be seen that regular hexagonal dislocation networks have formed at γ/γ′ interface through dislocation reaction between different slip systems. These dislocation networks cover almost all γ′ particles. It is also noted that some segments of dislocation networks have sheared into γ′ precipitate (marked by arrow).

Fig. 6 Microstructure of high temperature regime: (a) High density dislocation debris in two-phase at 900 °C; (b) Regular hexagonal dislocation networks at γ/γ′ interface at 1100 °C

3.4 Temperature dependence of SSF formation

In single crystal superalloys, the matrix dislocations have to overcome the precipitate particles by one of the following mechanisms: 1) by-passing the precipitates by Orowan mechanism; 2) cutting to precipitates; 3) climbing over the precipitates. All of these deformation mechanisms have been observed in nickel-based superalloys under different conditions. In the present work, SSFs are observed below 800 °C, but their appearance and quantity vary remarkably with temperature. This phenomenon has also been observed in PWA 1480 single crystal superalloy. The SSFs are divided into two types according to their appearances, i.e. elongated SSF as low temperature type and isolate SSF as high temperature type [20]. They attribute the reduction of SSF quantity of low temperature type with temperature to increase of SSF energy.

The SSF is postulated to be formed through decomposition of the trailing dislocation of a/2á110? pairs cutting into γ′. The coexisting of a/2á110? pairs and SSF loop in one γ′ (Fig. 4(a)) confirms the mechanism of SSF formation in this study is consistent to that proposed in PWA 1480 alloy. In contrast to the reference, the quantity of SSF loops increase from 20 to 600 °C. The possible reason to this difference is that the number of operative slip systems at 600 °C is larger than that at room temperature. Consequently, the number of a/2á110? pairs is increased in γ′, resulting in higher probability of SSF formation at 600 °C.

As mentioned above, when temperature is higher than 600 °C, the morphology of SSF is changed from elongated loop to isolated plane. The corresponding mechanism is changed from dislocation dissociation within γ′ to dissociation at γ/γ′ interface. The later reaction a/2á110??a/3á112?+a/6á112? is not favorable from the viewpoint of energy because the Burgers vector of a/3á112? superpartial is greater than that of a/2á110? regardless of a/6á112? partial dislocation. It needs some necessary assistances to keep the balance of energy during dislocation reaction, while the misfit between two phases just can supply this energy due to relaxation to misfit strain to some extent by a/6á112? partial. Usually, the misfit of a superalloy becomes more negative with increase of temperature because of higher thermal expansion coefficient of matrix [21]. Thus, the decomposition of matrix dislocation at interface occurred from 600 °C when enough misfit strain energy is supplied. On the other hand, it has been reported that the stacking fault energy of many disordered face-centered cubic materials increases by about a factor of 2 as the temperature increases from zero to 350 °C [22]. The case for γ′ should be same to that in FCC materials owing to a similar crystal structure. The SSF energy serves as resistance to dislocation reaction at interface. Consequently, the quantity of SSF achieves the maximum at 760 °C and decreases at 800 °C.

3.5 Correlation of microstructure and tensile behavior

As aforementioned, only one slip system is activated at room temperature, no work hardening takes place, so the flow stress almost keeps constant. At 600 °C, multiple slip occurs due to thermal activation, then linear work hardening behavior is exhibited. Below 600 °C, the γ′ is sheared by a/2á110? pairs coupled by APB at first, although the APB energy is assumed to be constant within certain temperature range, the misfit strain hardening is enhanced with the increase of temperature. Thus, the yield strength increases slightly between room temperature and 600 °C.

At 760 °C, the increase of misfit can compensate the energy difference of dislocation decomposition at interface, then the shearing mechanism transforms from high energy APB to low energy SSF, in other words, the shearing to γ? is facilitated with assistance of this change of mechanism, so the yield strength decreases evidently compared with 600 °C. With the proceeding of deformation, the glissile dislocations in primary slip system are exhausted gradually, then the flow stress exhibits a steeple but a small rise. Once the second slip system is activated under help of lattice rotation, flow stress reaches the second platform on stress—strain curve. The tensile behavior at 760 °C is in good agreement with the microstructure observation to SSF fringes with two directions.

At 800 °C, the SSF energy increases slightly compared with 760 °C, which causes the difficulty of generation of SSF. So the matrix dislocations cut into γ′ directly with higher energy APB at yield point to maintain the applied strain rate. Thus, the yield strength retains the level compared with 600 °C. With the accumulation of deformation, the density of matrix dislocation increases significantly, the probability of decomposition of a/2á110? dislocation and resultant SSF become large reasonably. Therefore, the flow stress at 800 °C drops remarkably with the onset of SSF formation after yield point.

At 900 °C, the SSF does not appear over entire deformation due to the decrease of order of γ′ superlattice and the resultant APB energy, so the yield strength lowers considerably in comparison with 800 °C. In addition, occurrence of several slip systems with assistance of thermal activation leads to significant work hardening. Thus, the flow stress increases to a maximum much higher than yield strength, then decreases gradually after the maximum. At 1 100 °C, the γ′ dissolves to matrix to some extent, then the matrix channel are broadened, the dislocations overcome γ′ particles through by-passing mechanism because lower Orowan resistance is caused by decrease of line energy of dislocation and increase of matrix channel width. Moreover, regular dislocation networks are located at γ/γ′ interface, which can only cause very weak resistance to matrix dislocation, while the cutting to γ′ by segment of dislocation networks lead to further softening. Therefore, the flow stress at 1 100 °C decreases gradually after yield point.

4 Conclusions

1) The peak temperature of the studied single crystal superalloy is around 800 °C where the yield strength attains the maximum. Above the peak temperature, the yield strength drops rapidly, while the tensile plasticity rises steeply with temperature. Below the peak temperature, the yield strength increases slightly between room temperature and 600 °C, then decreases evidently at 760 °C, after that rises again from 760 to 800 °C.

2) Below 600 °C, there are numerous elongated SSF loops remaining in γ′ particles, which are formed by decomposition of dislocation pairs coupled by APB within γ′. In other words, the γ′ is sheared by a/2á110? dislocation and resultant APB firstly, so the yield strength keeps almost constant. At 760 °C, the γ′ is sheared by a/3á112? superpartials formed by dissociation of a/2á110? dislocation at γ/γ′ interface, so the yield decreases due to low energy of SSF. Above 900 °C, the dominating deformation mechanism changes from shearing γ′ to by-passing process.

3) Below peak temperature, the transformation of shearing mechanism around 600 °C is attributed to the increase of misfit which facilitates the decomposition of a/2á110? dislocation at interface. Above peak temperature, the broadening of matrix channel as well as decreasing of line energy of dislocation energy takes place. Therefore the γ′ particles are overcome by dislocation in Orowan mode.

References

[1] JACKSON M P, REED R C. Heat treatment of UDIMET 720Li: The effect of microstructure on properties [J]. Mater Sci Eng A, 1999, 259(1): 85-97.

[2] WALSTON S, CETEL A, MACKAY R. Joint development of a fourth generation single crystal superalloy [C]//Superalloys 2004. Seven Spring, Pennsylvania: TMS, 2004: 15-24.

[3] TIN S, ZHANG L, HOBBS R A. Linking the properties, processing and chemistry of advanced single crystal Ni-base superalloys [C]// Superalloys 2008. TMS, 2008: 81-90.

[4] NITZ A, LAGERPUSCH U, NEMBACH E. CRSS anisotropy and tension/compression asymmetry of a commercial superalloy [J]. Acta Mater, 1998, 46(13): 4769-4779.

[5] OSTERLE W, BETTGE D, FEDLICH B, KLINGELOFFER H. Modelling the orientation and direction dependence of the critical resolved shear stress of nickel-base superalloy single crystals[J]. Acta Mater, 2000, 48(3): 689-670.

[6] WESTBROOKE E F, FORERO L E, EBRAHIMI F. Slip analysis in a Ni-base superalloy [J]. Acta Mater, 2005, 53(7): 2137-2147.

[7] UMAKOSHI Y, POPE D P, VITEK V. The asymmetry of the flow stress in Ni3(Al,Ta) single crystals[J]. Acta Metall, 1984, 32(3): 449-456.

[8] NITZ A, NEMBACH E. Critical resolved shear stress anomalies of the L12-long-range ordered γ′-phase of the superalloy NIMONIC 105[J]. Mater Sci Eng A, 1999, 263(1): 15-22.

[9] SHAH L D M, DUHL D N. The effect of orientation, temperature and gamma prime size on the yield strength of a single crystal nickel base superalloy [C]//Superalloys 1984. Warrendale, PA: AIME, 1984: 105-114.

[10] LEVERANT G R, GELL M, HOPKINS S W. The effect of strain rate on the flow stress and dislocation behavior of a precipitation-hardened nickel-base alloy [J]. Mater Sci Eng, 1971, 8(3): 125-133.

[11] LUO Z P, WU Z T, MILLER D J. The dislocation microstructure of a nickel-base single-crystal superalloy after tensile fracture [J]. Mater Sci Eng A, 2003, 354(1): 358-368.

[12] SENGUPTA A, PUTATUNDA S K, BARTOSIEWICZ L, HANGAS. Tensile behavior of a new single crystal nickel-based superalloy (CMSX-4) at room and elevated temperatures [J]. J Mater Eng Perf, 1994, 3(5): 664-672.

[13] FELLER-KNIEPMEIER M, LINK T, POSCHMANN I, SCHEUNEMANN-FREKER G, SCHULZE C. Temperature dependence of deformation mechanisms in a single crystal nickel-base alloy with high volume fraction of γ′ phase[J]. Acta Mater, 1996, 44(6): 2397-2407.

[14] DOLLAR M, BERNSTEIN I M. The effect of temperature on the deformation structure of single crystal nickel base superalloys [C]//Superalloys 1988. Seven Spring, Pennsylvania: TMS, 1988: 275-284.

[15] LIU Jin-lai, JIN Tao, ZHANG Jing-hua, SUN Xiao-feng, GUAN Heng-rong, HU Zhuang-qi. Tensile properties and deformation feature of a Ni base single crystal superalloy [C]//The Proceeding of 11th Superalloy Conference of China. Shanghai: MIP, 2007: 458-462. (in Chinese)

[16] SCHEUNEMANN-FRERKER G, GABRISCH G, FELLER- KNIEPMEIER M. Dislocation microstructure in a single-crystal nickel-based superalloy after tensile testing at 823 K in the [001] direction[J]. Phil Mag A, 1992, 65(6): 1353-1368.

[17] DIOLOGENT F, CARON P. On the creep behavior at 1033K of new generation single-crystal superalloys[J]. Mater Sci Eng A, 2004, 385(1): 245-257.

[18] MILLIGAN W W, ANTOLOVICH S D. Yielding and deformation behavior of the single crystal superalloy PWA 1480[J]. Metall Trans A, 1987, 18(1): 85-95.

[19] BONNET R, ATI A. Observation par met d'interactions de dislocations aux interfaces γ/γ′ d'un superalliage biphase[J]. Acta Metall, 1989, 37(8): 2153-2169.

[20] MILLIGAN W W, ANTOLOVICH S D. The mechanisms and temperature dependence of superlattice stacking fault formation in the single-crystal superalloy PWA 1480[J]. Metall Trans A, 1991, 22(10): 2309-2318.

[21] MULLER L, LINK T, FELLER-KNIEPMEIER M. Temperature dependence of the thermal lattice mismatch in a single crystal nickel-base superalloy measured by neutron diffraction [J]. Scrip Metall Mater, 1992, 26(8): 1297-1302.

[22] REMY L, PINEAU A, THOMAS B. Temperature dependence of stacking fault energy in close-packed metals and alloys[J]. Mater Sci Eng, 1978, 36(1): 47-63.

刘金来,于金江,金 涛,孙晓峰,管恒荣,胡壮麒

中国科学院 金属研究所,沈阳 110016

摘 要:研究了一种含Re单晶高温合金在20~1 100 °C的拉伸性能。结果表明:在室温至600 °C时合金屈服强度随温度的升高轻微增大,从600至760 °C时合金屈服强度明显降低到一个极小值,到800 °C时急剧增至最大值。从室温至800 °C时伸长率和面缩率缓慢降低;在800 °C以上时,屈服强度急速下降。在600 °C以下时,γ′被反相畴界切割而在其中留下伸长的超晶格层错;在760 °C时,γ′被a/3á112?位错切割,这是由于层错能降低而导致强度降低;当高于800 °C时,位错以绕越机制通过γ′。

关键词:单晶高温合金;拉伸行为;屈服强度;微观组织

(Edited by YANG Hua)

Foundation item: Project (2010CB631206) supported by the National Basic Research Program of China; Project (50931004) supported by the National Natural Science Foundation of China

Corresponding author: LIU Jin-lai; Tel: +86-24-23971713; E-mail: jlliu@imr.ac.cn

DOI: 10.1016/S1003-6326(11)60890-X