Trans. Nonferrous Met. Soc. China 22(2012) 1855-1859

Effect of composition and sintering temperature on mechanical properties of ZrO2 particulate-reinforced titanium-matrix composite

HAN Chao1, LI Yun-cang2, LIANG Xiao-guang1, CHEN Lian-ping1, ZHAO Na1, ZHU Xin-kun1

1. Faculty of Materials Science and Engineering, Kunming University of Science and Technology;Kunming 650093, China;

2. Institute for Frontier Materials, Deakin University, Australia

Received 10 November 2011; accepted 28 April 2012

Abstract: The titanium-based composites were synthesized by powder metallurgy method. The effects of composition and sintering temperature on the microstructure and properties of the titanium-based composites were investigated by X-ray diffraction, optical microscopy, scanning electron microscopy and mechanical properties tests. The results demonstrate that adding ZrO2 particles can improve the mechanical properties of powder metallurgy (P/M) titanium-based composites. The Ti composite with 4% (mole fraction) ZrO2 sintered at 1100 ℃ for 4 h shows an appropriate mechanical property with a relative density of 93.9%, a compressive strength of 1380 MPa (570 MPa higher than pure Ti) and good plasticity (an ultimate strain above 24%).

Key words: zirconium dioxide; titanium-matrix composites; compression strength; mechanical property

1 Introduction

The attractive mechanical properties obtained by metal matrix composites such as high specific modulus, strength, and thermal stability have made the titanium-based composites promising materials for aerospace, automobile and numerous other applications [1]. The incorporation of low density, high modulus and high strength of reinforcements of titanium significantly improves the specific modulus, strength and creep resistance [2]. Particulate reinforcements are normally used to produce titanium composites. Particulate- reinforced metal composites have attracted extensive attention as a result of their relatively low cost and characteristic of isotropic properties [3-6]. Titanium and its alloys are widely used as load-bearing implants for bone tissue engineering because of the distinct mechanical properties, good biocompatibility and excellent corrosion resistance [7,8]. The Ti alloys of the first and second generation contained the noxious elements such as Al, V and Ni. Recently, the global researches of Ti have laid more attention to higher strength, stronger plasticity, better biocompatibility and elastic modulus which corresponded to human’s skeleton. Pure Ti foams with approximately 70% porosity had been successfully fabricated and showed excellent elastic modulus. Nevertheless, they were still too weak compared with cortical bone [9]. Zirconia(ZrO2) ceramics, which were studied as biomaterials in the late 1960s, are applied to orthopedic implants as ball heads in artificial hip joints currently [10,11]. After ZrO2 was surface alloyed on the NiTi alloy by laser surface alloying technique, the wearing resistance had been improved by about six times compared with the untreated one [12]. In addition, zirconia and its composites possess excellent mechanical properties. Thus, we chose ZrO2 as the strengthening phase. The elastic modulus of Ti and Ti alloys can be reduced by the introduction of a porous structure [13-15]. In this work, the influence of different compositions and sintering temperatures on mechanical properties of particulate- reinforced titanium-based composites was studied through dispersion-strengthening method, in order to fabricate a material which possesses both excellent mechanical properties and good biocompatibility.

2 Experimental

2.1 Titanium-based composites synthesized by mechanical alloying (MA)

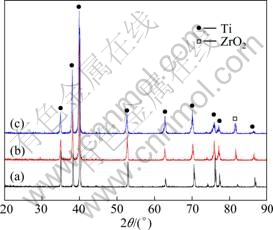

Commercially available Ti powder (99.7% purity, ≤58 μm) and ZrO2 particles (99.9 purity, ≤0.5 μm) were prepared as starting materials. The Ti and ZrO2 powders were weighed following the compositions in Table 1 and then mixed together. A QX-2 planetary ball mill with agate vials and balls were used to mix the powders. All powder handlings were performed in a glove box under argon atmosphere. The ball milling was performed at a rotation rate of 180 r/min, with 10:1 of ball-to-powder (mass ratio) and 10 g powder for each run. The milling time was 2 h.

Table 1 Nominated compositions of Ti/ZrO2 composites

2.2 Fabrication of titanium-based composites samples

The mixture was subsequently compacted into cylindrical green compacts at a pressure of 200 MPa. Then they were put in a alumina crucible and sintered in a vacuum furnace. The sintering process was carried out at 900, 1000 and 1100 ℃ respectively for 4 h with a heating-up rate of 10 ℃/min. After furnace cooling, the Ti/ZrO2 samples were obtained.

2.3 Microstructure and mechanical properties

After the relative density of the samples were obtained, they were sectioned, mounted, polished and etched with reagent(2%HF, 10%HNO3, 88%H2O) for metallographic observation. Phase formation was characterized by X-ray diffraction (XRD, D/max-Rc). The radiation source used was Cu Kα generated at 40 kV and 35 mA, with a scan rate of 1.5 (°)/min. The compressive test was carried out by universal testing machine (SHIMADZU AG-X, 100 kN) on the titanium-based composites samples (d8 mm×13 mm) at room temperature with an nominal strain rate of 10-3 s-1 to investigate the mechanical properties. Fracture morphology and EDAX were analyzed by SEM system (philipsXL30ESEM-TMP).

3 Result and discussion

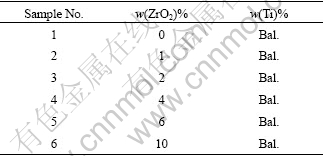

In Fig. 1, it can be concluded that after sintering at 900 ℃, the relative density of samples 1, 2 and 3 are similar. The relative density decreases with the increase of ZrO2 content above 4% (samples 5 and 6). Owing to the more ZrO2 particles added, the sintering will be more difficult. The compressive data express that the compressive strength is improved with increasing ZrO2 content. When the content is up to 4%, the compressive strength begins to decrease. The reasons are as follows: firstly, the relative density begins to decrease; secondly, when a small amount of ZrO2 is added, the particles obstruct the motion of dislocation; thirdly, when adding too much ZrO2 particles, they begin to combine together and the crack source occurs. The ultimate strain is decreased with the increase of ZrO2 content, due to the ZrO2 particles obstructing the motion of dislocation.

Fig. 1 Comparison of properties of samples (1—Pure Ti; 2—Ti+1%ZrO2; 3—Ti+2%ZrO2; 4—Ti+4%ZrO2; 5—Ti+6%ZrO2; 6—Ti+10%ZrO2)

When sintered at 1000 ℃, the relative densities of these samples are increased and reach 88.6%, 90.67%, 90.69%, 89.36%, 86.79%, 86.12% respectively compared with the ones at 900 ℃. The tendency is quite similar to the situation at 900 ℃. The compressive strength made a remarkable increase compared with 900 ℃. At 1000 ℃, with the addition of ZrO2 the compressive strength also has a notable increase compared with pure Ti. As the sintering temperature gets higher, the powder activity gets more active, the diffusion rate of ZrO2 and the contract of sintered compact increase, and the void decreases, as a result, both the relative density and the compressive strength of sintered compact increase. The addition of dispersed ZrO2 phase also enhances the bonding strength. The ultimate strain is increased a little and the exchange tendency is quite similar to the one at 900 ℃.

At 1100 ℃, the relative densities of almost all samples are increased over 93.3% except the sample 6. The compression strength is also improved a lot, and it can reach as high as 1443 MPa (615 MPa better than pure Ti). The exchange tendency is similar to the situation at 1000 ℃. As a result of the increase of the relative density, the ultimate strain is also improved, and the tendency is similar to the one at 1000 ℃. The stress—strain curves of samples 1-4 at 1100 ℃ are shown in Fig. 1(d). When the compressive stress reaches 2000 MPa which is the ultimate pressure of the machine, these samples do not fracture. So, it could be concluded that these samples have a good plasticity.

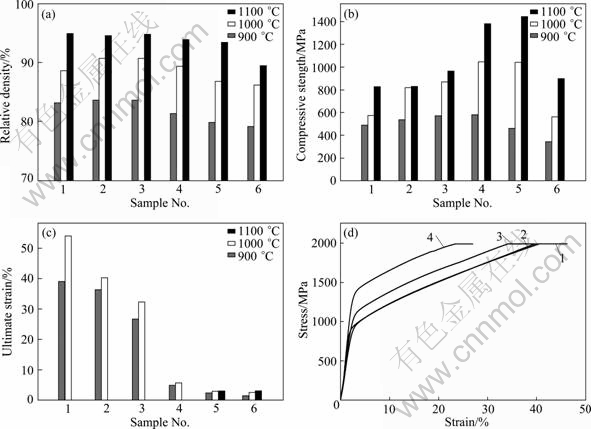

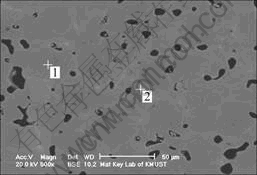

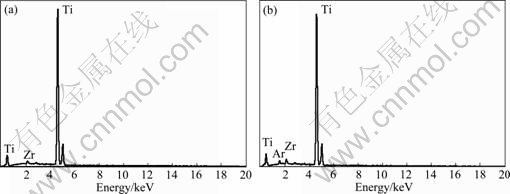

Sample 4 (Ti+4%ZrO2) was selected to be investigated by XRD with pure Ti as the comparative sample, owing to its high compression strength and good plasticity in the compressive strength data. The X-ray diffraction patterns of these samples are shown in Fig. 2. In the XRD patterns of sample 4, the sharp peaks track the elements of α-Ti and ZrO2. After ZrO2 was added, the height and the width of the peak changed. The peak became wider and moved to the left. This phenomenon indicates that the crystal lattice is changed. By EDS (Figs. 3 and Fig. 4) it turns out that the element of zirconium can be found in every grain and at grain boundary. The XRD patterns and the EDS results demonstrate that zirconium disperses in the green body of Ti in terms of molecular ZrO2 and there is no reaction between ZrO2 and Ti.

Fig. 2 XRD patterns of pure Ti sintered at 1000 ℃ (a), Ti+ 4% ZrO2 sintered at 1000 ℃ (b) and Ti+4%ZrO2 sintered at 1100 ℃ (c)

Fig. 3 SEM image of sample 4 (Ti+4%ZrO2) sintered at 1000 ℃

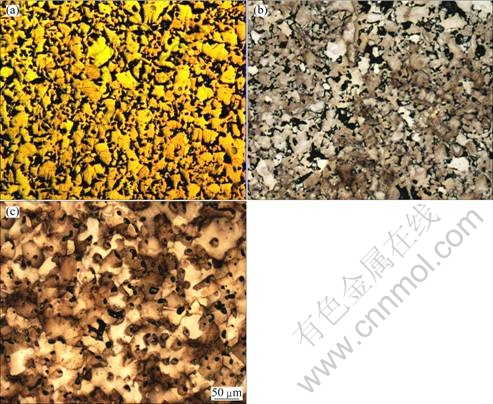

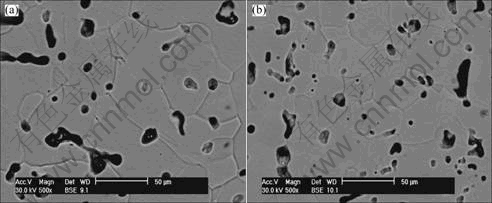

The microstructures of sample 4 (Ti+4%ZrO2) sintered at 900, 1000, 1100 ℃ in Fig. 5 display that the primary phase is α phase. With the rising of sintering temperature, the crystal becomes larger and the relative density gets higher.

As shown in Fig. 6, when 4%ZrO2 is added, the average size of the Ti crystal grain becomes smaller than others. The results illustrate that adding ZrO2 can inhibit the growth of the grain and make the grain smaller. In other words, the purpose of particle refinement is reached. Moreover, ZrO2 serves as the dispersed phase and makes the dispersion strengthened effort. That is why the compressive strength of sample 4 (Ti+4%ZrO2) is better than the others.

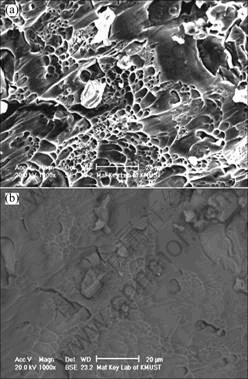

The fracture morphology of sample 3 sintered at 1000 ℃ observed by SEM is shown in Fig. 7. Many dimple fractures and some cleavage steps are found in Fig. 7(a). So the main fracture mode is plastic fracture. The backscattered electron image shown in Fig. 7(b) demonstrates that the white grains are Ti also.

Fig. 4 EDS patterns of sample 4 (Ti+4% ZrO2) sintered at 1000 ℃: (a) Point 1 in Fig. 3; (b) Point 2 in Fig. 3

Fig. 5 SEM images of sample 4 (Ti+4%ZrO2) sintered at different temperatures: (a) 900 ℃; (b) 1000 ℃; (c) 1100 ℃

Fig. 6 SEM images of samples sintered at 1100 ℃: (a) Ti+2%ZrO2; (b) Ti+4%ZrO2

Fig. 7 SEM images of fracture surface of sample 3 (Ti+2% ZrO2) after being sintered at 1000 ℃; (a) Secondary electron image; (b) Backscattered electron image

4 Conclusions

1) The mechanical property of Ti/ZrO2 composites can be improved with increasing sintering temperature.

2) Adding ZrO2 can inhibit the growth of the grain and make the grain smaller than the one without any addition. What’s more, ZrO2 serves as the dispersed phase and improves the compressive strength. The best sample can reach a compressive strength of 1443 MPa.

3) After ZrO2 is doped, the particulate-reinforced titanium-based composites exhibit high strength, at the same time, the plasticity is preserved. The compressive strength of the composite with 4% ZrO2 sintered at 1100 ℃ is 1280 MPa, meanwhile the ultimate strain is over 24%.

References

[1] LIU B, LIU Y, HE X Y, TANG H P, CHEN L F, HUANG B Y. Preparation and mechanical properties of particulate-reinforced powder metallurgy titanium matrix composites [J]. Metallurgical and Materials Transactions A, 2007, 38(11): 2825-2831.

[2] RANGANATH S. A review on particulate-reinforced titanium matrix composites [J]. Journal of Materials Science, 1997, 32(1): 1-16.

[3] HELSEN J A, BREME H J. Metals as biomaterials [M]. 1st ed. Chichester: John Wiley & Sons, 1998: 73-100.

[4] IBRAHIM I A, MOHAMED F A, LAVERNIA E J. Particulate reinforced metal matrix composites—A review [J]. Journal of Materials Science, 1991, 26(5): 1137-1156.

[5] KACZMAR J W, PIETRZAK K, WLOSINSKI W. The production and application of metal matrix composite materials [J]. Journal of Materials Processing Technology, 2000, 106(1-3): 58-67.

[6] LIU Y, CHEN L F, TANG H P, LIU C T, LIU B, HUANG B Y. Design of powder metallurgy titanium alloys and composites [J]. Materials Science and Engineering A, 2006, 418(1-2): 25-35.

[7] POLMEAR I J. Titanium alloys light alloys [M]. 4st ed. Oxford: Butterworth-Heinemann, 2005: 299-365.

[8] RACK H J, QAZI J I. Titanium alloys for biomedical applications [J]. Materials Science and Engineering C, 2006, 26: 1269-1277.

[9] WEN C E, YAMADA Y, SHIMOJIMA K, SHIMOJIMA, CHINO Y, HOSOKAWA H, MABUCH. Novel titanium foam for bone tissue engineering [J]. Journal of Materials Research, 2002, 17: 2633-2639.

[10] PICONI C, MACCAURO G. Zirconia as a ceramic biomaterial [J]. Biomaterials, 1999, 20: 1-25.

[11] ADOLFSSON E, HERMANSSON L. Zirconia-fluorapatite materials produced by HIP [J]. Biomaterials, 1999, 20: 1263-1267.

[12] NG K W, MAN H C, YUE T M. Corrosion and wear properties of laser surface modified NiTi with Mo and ZrO2 [J]. Applied Surface Science, 2008, 254: 6725-6730.

[13] WEN C E, MABUCHI M, YAMADA Y, SHIMOJIMA K, CHINO Y, ASAHINA T. Processing of biocompatible porous Ti and Mg [J]. Scr Mater, 2001, 45: 1147-1153.

[14] GIBSON L G, ASHBY M F. Cellular solids: Structure and properties [M]. Cambridge, U K: Cambridge University Press, 1997: 54-65.

[15] BANNO T, LI Y C, WEN C E, YAMADA Y. Mechanical properties of micro-porous metals produced by space-holding sintering [J]. Advanced Materials Research, 2007, 29-30: 75-78.

成分和烧结温度对ZrO2颗粒增强型钛基

复合材料力学性能的影响

韩 超1,李云苍2,梁晓光1,程莲萍1,赵 娜1,朱心昆1

1. 昆明理工大学 材料科学与工程学院,昆明 650093;2. 迪肯大学 前沿材料研究所,澳大利亚

摘 要:钛利用粉末冶金方法制备钛基复合材料。采用X射线衍射仪、金相显微镜、扫描电镜及力学性能测试仪研究材料成分和烧结温度对显微结构及性能的影响。结果表明:加入ZrO2颗粒能够提高粉末冶金钛基复合材料的力学性能。加入4% ZrO2,在1100 ℃下烧结4 h,得到的钛基复合材料的相对密度为93.9%,屈服强度能达到1380 MPa(比纯钛高570 MPa),并且具有良好的塑性(极限应变超过24%)。

关键词:二氧化锆;钛基复合材料;屈服强度;力学性能

(Edited by LI Xiang-qun)

Corresponding author: ZHU Xiu-kun; Tel: +86-871-5109952; E-mail: xk_zhu@hotmail.com

DOI: 10.1016/S1003-6326(11)61397-6