化学镀金属薄膜与磁控溅射的关联性

唐 武1 , 邓龙江1, 徐可为2

(1. 电子科技大学 微电子与固体电子学院, 成都 610054;

2. 西安交通大学 金属材料强度国家重点实验室, 西安 710049)

摘 要: 采用原子力显微镜和X射线衍射仪研究了Al2O3基体上磁控溅射Au/NiCr/Ta多层金属膜基础上化学镀Au膜的生长形貌、 晶体取向和残余应力, 并与磁控溅射Au膜进行了对比。 结果表明: 通过化学镀工艺生长的Au膜延续了磁控溅射薄膜柱状晶结构生长的特点, 但薄膜生长颗粒出现聚合现象, 磁控溅射Au膜的颗粒尺寸约为60nm, 化学镀Au膜尺寸可增加到400nm左右; 化学镀薄膜在磁控溅射薄膜基础上表面粗糙度增大, 化学镀工艺对磁控溅射金属薄膜的晶体取向具有承继性, 并伴随有晶体取向择优生长的“放大”作用, 但对残余应力则有一定的调节作用。

关键词: 磁控溅射; 化学镀; 金属薄膜 中图分类号: TB43.1

文献标识码: A

Relationship between plating and magnetron sputtering for metallic films

TANG Wu1, DENG Long-jiang1, XU Ke-wei2

(1. School of Microelectronic and Solid State Electronics,University of Electronic Science and Technology of China, Chengdu 610054, China;

2. State Key Laboratory for Mechanical Behavior of Materials,Xian Jiaotong University, Xian 710049, China)

Abstract: Au/NiCr/Ta multi-layered metal films were deposited on Al2O3 substrate by magnetron sputtering and then Au film was chemically plated. The crystal orientation, residual stress and surface morphology were investigated, and comparison was made between plating and magnetron sputtering technology by X-ray diffractrometry and atomic force microscopy. Au grain increases from 60 to 400nm after plating. The results indicate that the plating technology can inherit the crystal orientation from magnetron sputtering, enlarge the preferred orientation, and harmonize the residual stress. The surface roughness of Au films increases after plating.

Key words: magnetron sputtering; chemical plating; metallic films

在一些特殊用途的集成电路中(如微波集成电路), 金属薄膜有时候需要用作导电带。 真空镀膜的厚度较薄, 为减少导体的损耗, 必须使导电带的厚度达到趋肤深度的3~5倍。 因此, 需将光刻好的电路及接地板用化学镀方法加厚, 使导电带达到所需的厚度。 微波集成电路中的薄膜制备工艺给薄膜力学性能和电学性能的研究提出了一个新问题, 即在磁控溅射金属薄膜基础上再化学镀一层金属薄膜, 其相关的薄膜力学性能会发生什么样的变化?这个问题似乎尚未引起人们注意, 相应的实验结果更是少见报导。 因此, 本文作者进行了相关研究, 讨论了两种薄膜制备工艺对薄膜性能的影响。

1 实验

1.1 化学镀工艺

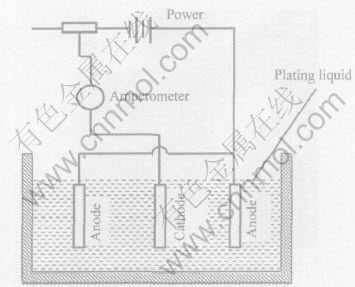

化学镀膜是指在溶液中利用化学反应或者电化学反应在基体材料表面沉积成膜的一种技术。 金属离子在溶液中还原剂作用下, 向固/液两相界面上析出和沉积, 其工作原理如图1所示。

图1 化学镀膜工作原理示意图

Fig.1 Schematic diagram of chemical plating

镀覆过程中, 溶液中的金属离子被生长着的镀层表面所催化, 并不断还原而沉积到基体表面。 显然, 基体表面的催化作用相当重要。 周期表中的Ⅷ族金属元素具有化学镀所需要的催化效应。 对无催化能力的材料, 可以人为的附加催化能力, 如塑料、 陶瓷、 玻璃等可以通过敏化处理来加以活化, 以利于化学还原沉积。

化学镀所用还原剂的电位应略低于沉积金属的电位。 常用的还原剂有次磷酸盐和甲醛, 前者用来镀镍, 后者用来镀铜。 此外, 也可以用硼氢化物以及氨基硼烷类和肼类衍生物等物质作还原剂。 无论什么还原剂, 都必须能够在自催化的条件下提供金属离子还原成元素所需要的电子。 这种反应只能在催化表面上进行, 因此, 一旦沉积开始, 沉积出来的金属就必须能够继续这种催化功能, 以便沉积过程不会因此而中断。 就这个意义而言, 化学镀必然是一种受控的自催化化学反应过程。

1.2 试样制备

Au/NiCr/Ta薄膜用美国VS-24C磁控溅射仪制作, 基体材料为A99氧化铝陶瓷片。 依次溅射Ta(50nm)、 NiCr(50nm)和Au(500nm)。 系统真空度优于10-4Pa, 溅射气体为高纯氩气。 在100~250℃内改变基体温度, 获得几组试样, 随后通过化学镀工艺将Au膜增加至7μm。

1.3 测试方法

用Rigaku/max-3C型X射线衍射仪(Cu Kα)检测薄膜的物相结构, 管压40kV, 管流35mA, 石墨单色器滤波, 扫描范围为20°~85°; 用原子力显微镜研究薄膜表面形貌; Rigaku/MSF-2M型应力测试仪测量薄膜残余应力, 采用sin2ψ法[1], Cr Kα靶, 管压30kV, 管流10mA, 滤波片为钒, 所测晶面为Au(222)。

2 结果及分析

2.1 表面形貌

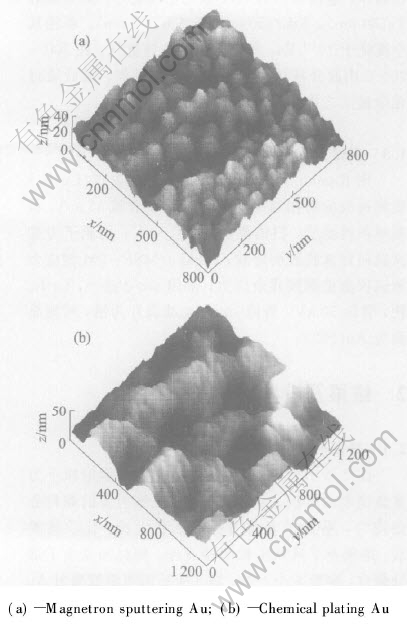

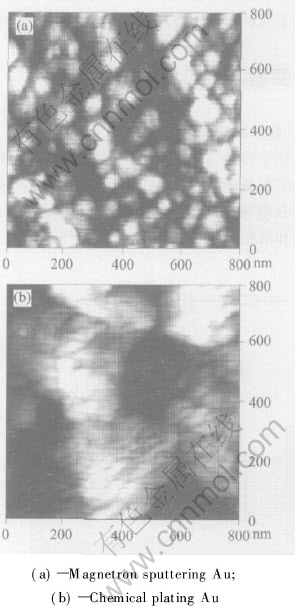

图2所示为磁控溅射和化学镀Au膜的原子力显微镜表面形貌。 可以看出, 磁控溅射膜的颗粒分布均匀, 垂直于表面向上呈柱状生长, 化学镀膜后, 除继承了柱状生长的特点外, 颗粒间发生了部分聚合, 颗粒大小不均。 图3所示表明磁控溅射Au膜的颗粒尺寸在60nm左右, 化学镀Au膜明显发生了颗粒聚合, 其尺寸可增加到400nm左右。

图2 磁控溅射和化学镀Au膜表面的三维立体形貌

Fig.2 3D morphologies of magnetron sputtering and chemical plating Au film

气相沉积薄膜的生长过程与薄膜的制备工艺有密切关系[2-5]。 文献[6-9]报道气相沉积薄膜中存在柱状晶结构。 柱状晶结构的形状相当复杂, 蒸镀膜受残余气体压力影响, 溅射膜受放电气体压力影响, 化学镀薄膜则受基体晶体取向影响。 金属蒸镀薄膜的柱状晶结构在高真空度下不再明显[10], 本实验中溅射系统真空度优于10-4Pa, 形貌中可以观察到柱状晶结构, 随后的化学镀膜在此基础上生长, 结构未见根本变化。

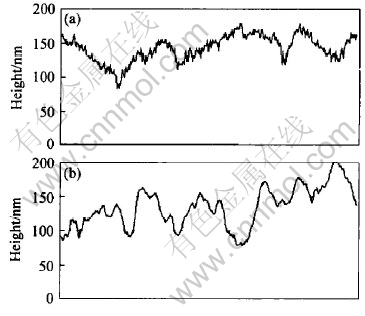

图4比较了磁控溅射和化学镀膜的表面起伏情况, 可以看出, 溅射膜的颗粒起伏在100~175nm之间; 化学镀膜的颗粒起伏在80~200nm之间, 说明化学镀膜的表面粗糙度相对较大。 当然, 这与化学镀膜的厚度远大于溅射膜有很大关系。

2.2 晶体取向

图5所示为两种工艺制备薄膜的X射线衍射谱。 由图5可知, 不管是磁控溅射薄膜, 还是在此基础上的化学镀薄膜, 都只观察到Au的衍射峰。 对所有检测的试样均发现: Au(111)取向或者Au(111)和Au(200)取向较强, Au(220)和Au(311)峰很弱, 说明薄膜存在织构, 表现为Au(111)或者Au(111)和Au(200)混合取向。

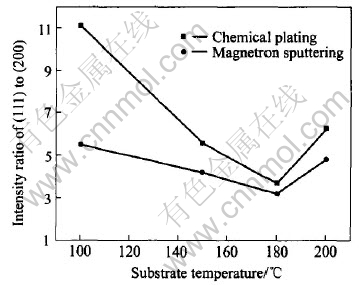

Au(111)与(200)强度比值如图6所示。 可见, 化学镀薄膜仍然保持Au(111)择优取向。 需要特别指出的是, 溅射Au膜只有0.5μm厚, 剩下增厚6.5μm的Au膜均为化学镀, 而化学镀工艺对4种样品是恒定的。 按常理推测, 4种薄膜似乎不应存在晶体取向间的显著差异。 事实上, 图6结果表明, 化学镀Au膜 (111)与(200)衍射晶面的强度比值强烈地依赖于“打底”的气相沉积Au膜。 沉积温度从100℃升高到200℃后, 化学镀Au膜衍射强度比值可从11.1变到3.6, 且气相沉积Au膜(111)与(200)强度比值越大, 在此基础上的化学镀Au膜(111)择优生长越显著。 由此可知化学镀膜的晶体取向强烈依赖于预先的溅射工艺, 晶体取向仍保留了此前溅射时基体温度的影响, 并伴随有择优生

图3 磁控溅射和化学镀Au膜的二维平面形貌

Fig.3 2D morphologies of magnetron sputtering and chemical plating Au film

图4 磁控溅射Au膜和化学镀Au膜的表面起伏状态分布图

Fig.4 Grain height distribution curves of Au film by magnetron sputtering(a) and chemical plating(b)

图5 磁控溅射和化学镀Au/NiCr/Ta薄膜的X射线衍射谱

Fig.5 XRD patterns of Au/NiCr/Ta film by magnetron sputtering(a) and chemical plating(b)

图6 不同基体温度的Au(111)/(200)强度比值

Fig.6 Intensity ratio of Au(111) to (200) at different substrate temperatures

长的“放大”作用。 气相沉积薄膜基础上的化学镀膜具有很强的组织(如织构)承继性, 这种组织承继性对表面材料合成与表征的影响值得给予特别关注。

2.3 残余应力

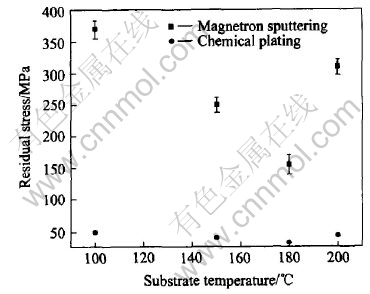

磁控溅射和此基础的化学镀Au膜残余应力分布如图7所示。

图7 磁控溅射和化学镀Au膜的残余应力

Fig.7 Residual stress of Au film by magnetron sputtering and plating

由图7可见, 磁控溅射薄膜的残余应力在150~400MPa间, 化学镀薄膜的残余应力维持在40MPa左右, 且随基体温度变化不大。 国际上对磁控溅射金属薄膜的残余应力也有相关报导[11-15], 数量级一般在几百MPa。 化学镀薄膜残余应力随基体温度变化不大, 本文作者认为其原因可能不是因为温度范围变化有限, 毕竟晶体取向已经出现了急剧的变化, 可能的推论是化学镀过程中薄膜生长较磁控溅射温和, 从而改变了在整个厚度上的平均应力状态。 对比残余应力和晶体取向的结果可以认为, 化学镀对溅射薄膜的晶体取向有较强的承继性, 对内应力则有一定的调节作用, 因为内应力必须在整个膜/基体系上达到平衡。 事实上, 根据文献和经验, 单独用磁控溅射获取7μm的Au膜并非易事, 此时薄膜残余应力将远远超出现有测量值, 在制备过程中并有可能使薄膜发生剥落或开裂。

3 结论

1) 化学镀Au膜在磁控溅射柱状晶生长的基础上其结构未见根本变化。

2) 化学镀工艺对磁控溅射金属薄膜的晶体取向具有承继性, 对择优生长具有“放大”作用。

3) 化学镀工艺对磁控溅射薄膜残余应力有一定的调节作用。

REFERENCES

[1]Cullity B D. Elements of X-ray Diffraction[M]. Reagin: Addison-Wesley, 1978. 456-468.

[2]Mitsui A, Masumo K. Effect of a zirconium oxide undercoat on microstructure and properties of tin-doped indium oxide films for organic light emitting devices[J]. Thin Solid Films, 2003, 442(1-2): 140-144.

[3]Laha A, Bhattacharyya S, Krupanidhi S B. Impact of microstructure on dielectric properties of Pb(Mg1/3-Nb2/3)O3-PbTiO3 thin films[J]. Mater Sci Eng B, 2004, B106: 111-119.

[4]Cheng H E, Wen Y W. Correlation between process parameters, microstructure and hardness of titanium nitride films by chemical vapor deposition[J]. Surf Coat Technol, 2004, 179: 103-109.

[5]Brinkiene K, Kezelis R. Correlations between processing parameters and microstructure for YSZ films produced by plasma spray technique[J]. Journal of the European Ceramic Society, 2004, 24: 1095-1099.

[6]Wójcik W, Janczuk B, Bruque J M, The destruction time of the sediment column structure as a method for studying the dispersion system[J]. Powder Technol, 2000, 113: 1-8.

[7]Jobin M, Burdet B, Escudeiro S A, et al. AFM of ion-etched cross-sections: a method for analyzing the morphology of dense hard coatings[J]. Thin Solid Films, 2004, 469-470: 398-403.

[8]Santana A E, Karimi A, Derflinger V H, et al. Microstructure and mechanical behavior of TiAlCrN multilayer thin films[J]. Surf Coat Technol, 2004, 177-178: 334-340.

[9]Kim G, Lee S, Hahn J. Properties of TiAlN coatings synthesized by closed-field unbalanced magnetron sputtering[J]. Surf Coat Technol, 2005, 193: 213-218.

[10]Mayadas A F, Shatzkes M. Electrical resistivity model for polycrystalline films: the case of arbitrary reflection at external surface[J]. Phys Rev B, 1970, B1: 1382-1387.

[11]Nix W D. Mechanical properties of thin films[J]. Metal Trans A, 1989, A20: 2217-2249.

[12]Koski K, Holsa J, Juliet P. Properties of zirconium oxide thin films deposited by pulsed reactive magnetron sputtering[J]. Surf Coat Technol, 1999, 120-121: 303-312.

[13]Gillet M, Assaban A, Mikaelian G. Stress in thin Au films on γ alumina[J]. Vacuum, 1998, 50: 73-78.

[14]Pauleau Y. Generation and evolution of residual stresses in physical vapor-deposited thin films[J]. Vacuum, 2001, 61: 175-181.

[15]Tang W, Xu K, Wang P, et al. Residual stress and crystal orientation in magnetron sputtering Au films[J]. Mater Lett, 2003, 57: 3101-3106.

(编辑龙怀中)

基金项目: 国家自然科学基金重点资助项目(59931010); 科技部中法先进研究计划资助项目(PRA MX9906)

收稿日期: 2005-07-15; 修订日期: 2005-08-20

作者简介: 唐 武(1975-), 男, 副教授, 博士

通讯作者: 唐 武; 电话: 028-83204938; E-mail: tangwu@mailst.xjtu.edu.cn