球形石墨增强银-石墨复合材料的摩擦学行为

来源期刊:中国有色金属学报(英文版)2020年第8期

论文作者:孙阳 王艳 李云 周科朝 张雷

文章页码:2177 - 2187

关键词:银-石墨复合材料;石墨形貌;磨损性能;显微组织;磨损机制

Key words:Ag-graphite composite; graphite morphology; wear resistance; microstructure; wear mechanism

摘 要:采用粉末冶金技术分别制备球形石墨(SG)和鳞片石墨(FG)增强的银-石墨复合材料。并用销-盘式摩擦磨损仪在大气环境和3.0 N的载荷下研究石墨形貌对银-石墨复合材料(Ag-SG和Ag-FG)摩擦学行为的影响。结 果显示,Ag-FG的最低磨损率为3.5×10-5 mm3/(N·m),而Ag-SG的最低磨损率比Ag-FG低一个数量级,为1.6×10-6 mm3/(N·m)。Ag-SG和Ag-FG显著不同的摩擦学行为与亚表面裂纹的形成有关。在摩擦过程中,片状石墨的边缘容易发生应力集中,导致Ag-FG亚表面产生裂纹和严重的剥层磨损。然而,在Ag-SG中,球形石墨能有效抑制裂纹的萌生和扩展,从而使银-石墨复合材料具有优异的耐磨性能。

Abstract: Two kinds of Ag-graphite composites reinforced with spherical graphite (SG) and conventional flake graphite (FG) were prepared by powder metallurgy technology. The effect of graphite morphology on the tribological behavior for the Ag-SG and Ag-FG under the dry sliding wear was investigated with a pin-on-disk tribometer at a load of 3.0 N in atmosphere condition. The results indicated that the minimum wear rate of 3.5×10-5 mm3/(N·m) for Ag-FG was achieved and it reduced by nearly an order of magnitude, reaching 1.6×10-6 mm3/(N·m) for the Ag-SG. The obviously different tribological behaviors between the Ag-SG and Ag-FG were closely related to the formation of cracks in the sub-surface. The stress concentration tended to generate at the edges of flake graphite during sliding process, which resulted in the cracks and severe delamination wear of Ag-FG. However, no cracks were found around the spherical graphite in Ag-SG. The spherical graphite can effectively inhibit the initiation and propagation of cracks, achieving high wear resistance.

Trans. Nonferrous Met. Soc. China 30(2020) 2177-2187

Yang SUN1, Yan WANG2, Yun LI1, Ke-chao ZHOU1, Lei ZHANG1

1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Institute of Mechanical and Electrical Engineering, Zhengzhou University of Light Industry, Zhengzhou 450002, China

Received 26 August 2019; accepted 30 June 2020

Abstract: Two kinds of Ag-graphite composites reinforced with spherical graphite (SG) and conventional flake graphite (FG) were prepared by powder metallurgy technology. The effect of graphite morphology on the tribological behavior for the Ag-SG and Ag-FG under the dry sliding wear was investigated with a pin-on-disk tribometer at a load of 3.0 N in atmosphere condition. The results indicated that the minimum wear rate of 3.5×10-5 mm3/(N·m) for Ag-FG was achieved and it reduced by nearly an order of magnitude, reaching 1.6×10-6 mm3/(N·m) for the Ag-SG. The obviously different tribological behaviors between the Ag-SG and Ag-FG were closely related to the formation of cracks in the sub-surface. The stress concentration tended to generate at the edges of flake graphite during sliding process, which resulted in the cracks and severe delamination wear of Ag-FG. However, no cracks were found around the spherical graphite in Ag-SG. The spherical graphite can effectively inhibit the initiation and propagation of cracks, achieving high wear resistance.

Key words: Ag-graphite composite; graphite morphology; wear resistance; microstructure; wear mechanism

1 Introduction

Silver matrix self-lubricating composites, reinforced with graphite, have been used in many industrial applications, such as bearings, bushings as well as electrical brushes, due to their low electrical resistance, friction coefficient, and high wear resistance [1-6]. Compared with pure Ag and its alloys, the uniformly dispersed graphite is prone to adhere to the worn surface, which forms a low shear strength film to prevent the adhesion between metals and reduce the friction [7]. Therefore, graphite is the key factor affecting the friction and wear behavior of Ag-graphite composites. In order to obtain improved tribological performance and longer service life, it is becoming increasingly significant to investigate the effect of graphite on the tribological behavior of Ag-graphite composites.

Some important investigations have been carried out on the influence of graphite content and particle size on the tribological performance of metal-graphite composites [5,8-11]. The relationship between graphite content and tribological behavior of metal-graphite composites has been carefully investigated, and it is found that a critical concentration of graphite was present to ensure good lubrication and friction property [5,8,9]. When the graphite was below the critical content, the worn surface could not form a sufficient and effective lubricating film [5]. As the content of graphite exceeded the critical content, the mechanical property of the metal-graphite composites deteriorated and the wear was intensified. Particle size of graphite was another factor affecting the tribological behavior of metal- graphite composites. RAJKUMAR et al [10,11] showed that aluminum/copper-based composites reinforced by nano-graphite particles had a lower friction coefficient and higher wear resistance than those reinforced by micro-graphite particles.

Additionally, the graphite morphology also seriously affected the tribological property of metal-graphite composites [12,13]. However, the influence of graphite morphology on the tribological behavior of metal-graphite composites was rather limited. ZHANG et al [12] studied the tribological properties of phosphorous cast iron and suggested that the gray cast iron with flake graphite had a high friction coefficient and wear loss. In contrast, the nodular cast iron with spherical graphite possessed the better wear resistance and the lowest friction coefficient. HATATE et al [13] reported that the wear loss of the spheroidal graphite cast iron in dry slip-rolling contact was much smaller than that of flake graphite cast iron. Unfortunately, the graphite in the Ag-graphite composites mostly exhibited a flaky shape [1-6], and there was almost no work on the tribological behavior of Ag-graphite composites reinforced with spherical graphite. Therefore, it was necessary to study the effect of graphite morphology on the tribological behavior and microstructure evolution of Ag-graphite composites, which would provide a great advantage and benefit for the present work.

In this study, the Ag-flake graphite (Ag-FG) and the Ag-spherical graphite (Ag-SG) with the graphite content of 5.0, 15, 25 and 35 vol.% were successfully prepared. Then, the friction and wear properties of these two Ag-graphite composites against the AgCu10 were investigated. Particularly, the effect of graphite morphology on the wear behavior of Ag-graphite composites was explored. The microscopic morphologies of wear debris, worn surface, and sub-surface of Ag-graphite composites, especially the microstructure evolution of sub-surface, were systematically investigated.

2 Experimental

2.1 Preparation of Ag-graphite composite

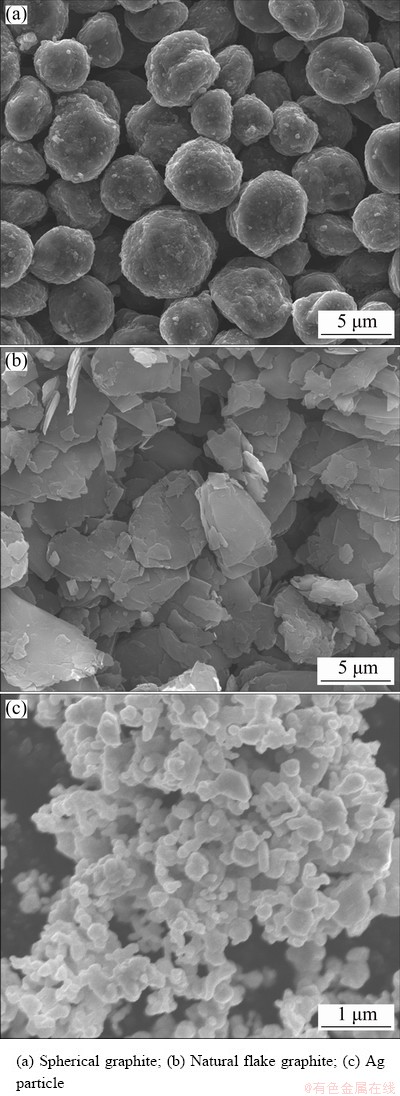

The silver powder (Ag, 99.9% pure, d50=0.5 μm), the natural flake graphite (FG, 98.0% pure, d50=8 μm) and the spherical graphite (SG, 98.0% pure, d50=8 μm) were used as the raw materials in this work. The morphologies of these three powders were completely different, in which the Ag powder, SG and FG showed irregular, spherical and flaky shapes, respectively (Fig. 1). To prepare the Ag-FG and Ag-SG, the Ag powder and the two kinds of graphite were mixed at a speed of 60 r/min for 8 h, respectively. Then, the homogeneously mixed powder was sintered under vacuum condition using the spark plasma sintering (SPS, FCT Systeme, Germany), which has been a recently developed sintering technology that could achieve rapid densification of the composites at a low temperature [14]. The sintering procedures were set as follows: (1) raising from room temperature to 750 °C with a heating rate of 100 °C/min; (2) holding at 750 °C for 10 min; (3) cooling down to room temperature. The pressure was maintained at 40 MPa throughout the sintering process. Finally, the Ag-FG and Ag-SG with the graphite contents of 5.0, 15, 25 and 35 vol.% were successfully obtained.

Fig. 1 SEM images of graphite and Ag powder

2.2 Tribological tests and characterization

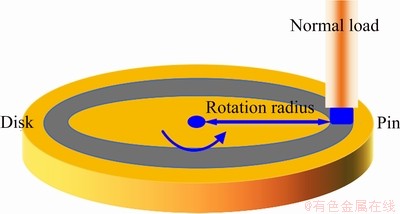

The tribological tests of Ag-graphite composites were conducted with a pin-on-disk tribometer (CSM Instruments, Switzerland). Figure 2 shows the schematic of the tribological tests. The AgCu10 alloy with a hardness of HV1 120 was used as the counter disk, which was a commonly used counterpart material in many friction tests [15]. Prior to testing, the Ag-graphite samples were cut into small cuboids of 3 mm × 4 mm × 4 mm, and the contact area was 12 mm2. Then, the Ag-graphite samples and disk were polished by SiC papers with grit size down to 6.5 μm, and the surface roughness (Ra) was approximately 0.2 μm. All tests were performed at the normal load of 3.0 N (0.25 MPa) with a sliding speed of 0.5 m/s (rotation radius R=30 mm) and a sliding distance of 20 km in an atmosphere condition ((25±3) °C, 45% relative humidity). In addition, the samples were weighed before and after testing by a sartorius (0.1 mg precision, TE214S, Germany). The wear rates were given by W=Δm/(Pρs), where W is the wear rate, Δm is the wear mass loss, P is the normal load, ρ is the density of specimens and s is the sliding distance [14]. Three parallel tests were performed, and the average value of the wear rate was used.

Fig. 2 Schematic of pin-on-disk tribological tests

Phase identification of the Ag-graphite composite was conducted by an X-ray diffractometer (XRD, D8 Advance, Bruker, Germany) with Cu Kα radiation scanning from 5° to 80°. The density was determined according to the Archimedes water displacement method and the hardness was measured by a Vickers micro- hardness tester (HV-1000, Huayin, China) at a load of 1 kg (HV1). The average of ten measurements was taken as the final value of density and hardness of the specimens. The morphologies of graphite powder, Ag-graphite composites, worn surface as well as the microstructure evolution of the sub-surfaces were analyzed by scanning electron microscope (SEM, Nova Nano SEM 230, FEI, America). Additionally, a 3D laser scanning microscope (KEYENCE, VK-X1050, Japan) was used to observe the wear tracks on the counter disk.

3 Results and discussion

3.1 Characterization of Ag-FG and Ag-SG composites

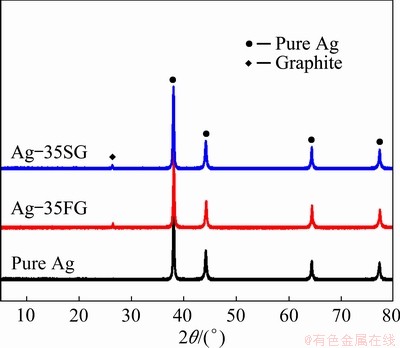

Figures 3 and 4 show the XRD patterns and microstructure of the Ag-FG and Ag-SG. Since the Ag-graphite composites with different contents of graphite have similar XRD patterns, here only the XRD patterns of pure Ag, Ag-35FG (containing 35 vol.% flake graphite) and Ag-35SG (containing 35 vol.% spherical graphite) are shown in Fig. 3. The Ag-35FG and Ag-35SG possessed five peaks, in which four belonged to the pure Ag. In addition to the peaks of Ag, a weak peak appeared around 2θ of 26.4°, which was assigned to the characteristic peak (002) of graphite.

Fig. 3 XRD patterns of pure Ag, Ag-35FG and Ag-35SG

Figure 4 shows the SEM images of Ag-FG and Ag-SG, in which the black areas are the graphite particles. It could be observed that the graphite particles were homogeneously distributed throughout the silver matrix. As the volume fraction of graphite was increased from 5 to 35 vol.%, the black regions gradually filled the entire sample surface. Additionally, the graphite presented a strip shape in the Ag-FG samples and spherical shape in the Ag-SG samples (Fig. 4). It was confirmed that the graphite morphology remained intact during the preparation process of Ag-graphite composites, which provided a good sample for studying the influence of graphite morphology on the tribological behavior of Ag-graphite composites.

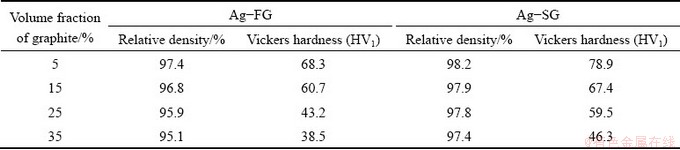

Moreover, the relative densities and Vickers hardness (HV1) of the Ag-FG and Ag-SG were also measured and the data were summarized in Table 1. The relative densities of the Ag-FG and Ag-SG showed a slight decrease with increasing graphite content, which were higher than 95.0%. At the same time, the Vickers hardness (HV1) of Ag-FG and Ag-SG rapidly decreased from 68.3 and 78.9 to 38.5 and 46.3, respectively, with the content of graphite increasing from 5 to 35 vol.%. It was worth noting that the Vickers hardness of Ag-SG was clearly higher than that of Ag-FG at the same graphite content. As the graphite content was increased from 5 to 35 vol.%, the Vickers hardness of Ag-SG significantly was improved by 15.5%, 11.0%, 37.7% and 21.0% compared with that of the Ag-FG, respectively. The Ag-SG showed higher hardness than the Ag-FG, which may help to improve the wear resistance of the material.

Fig. 4 SEM images of Ag-FG (a, b) and Ag-SG (c, d) with graphite of 5 vol.% (a, c) and 35 vol.% (b, d)

Table 1 Relative density and Vickers hardness of Ag-FG and Ag-SG

3.2 Friction and wear properties

The average friction coefficients and wear rates of Ag-FG and Ag-SG against AgCu10 alloy at the load of 3.0 N are shown in Fig. 5. As a comparison, the friction coefficient and wear rate of pure Ag are also presented in Fig. 5. As seen, the pure Ag exhibited the highest average friction coefficient (0.90) and wear rate (6.8×10-4 mm3/(N·m)), stemming from the strong adhesive bonding between two metal surfaces [7]. Compared with the pure Ag, the average friction coefficients of the two Ag-graphite composites gradually decreased with increasing graphite content in Fig. 5(a). And the friction coefficients of Ag-SG were smaller than those of Ag-FG at the same graphite content, except the Ag-5vol.% graphite composites. Besides, the difference in friction coefficient became more pronounced with increasing graphite content, as shown in Fig. 5(a). When the graphite reached 35 vol.%, the friction coefficients of Ag-graphite composites were minimized, and the minimum values were 0.16 for Ag-SG and 0.21 for Ag-FG, respectively. Figure 5(b) shows the relationship between the wear rate of Ag-graphite composites and graphite content. For the Ag-SG, the wear rates decreased as the graphite content increased. However, the wear rates of Ag-FG decreased initially, and then increased at the graphite content of 35 vol.%. It was believed that 25 vol.% was the critical content of flake graphite in Ag-FG, where the wear rate reached a minimum (Fig. 5(b)). As the graphite content increased from 5 to 35 vol.%, the wear rates of Ag-FG increased from 2.5×10-4 to 6.5×10-5 mm3/(N·m), and those of Ag-SG increased from 6.7×10-5 to 1.6×10-6 mm3/(N·m), respectively. It was worth pointing out that the wear rates of Ag-FG were significantly larger than those of Ag-SG. The experimental results indicated that the morphology of graphite particles had a great influence on the dry sliding properties, and the Ag-graphite composites with lower friction coefficients and higher wear resistances could be obtained by adding spherical graphite.

Fig. 5 Friction coefficients (a) and wear rates (b) of pure Ag, Ag-FG and Ag-SG

Fig. 6 Wear rate map of metal-graphite composites, including present results of Ag-FG and Ag-SG

Additionally, a comparison map of the wear rates of Ag-25FG, Ag-25SG and the (Ag, Cu, Al)- graphite composites added with the flake graphite is presented in Fig. 6. It was well known that the pv value consisting of contact pressure (p) and sliding velocity (v) was an important parameter in the wear process [16,17]. In order to show the degree of wear rate, all the metal-graphite composites shown in Fig. 6 were conducted at a low and similar pv value of 0.01-0.50 MPa·m/s. It can be clearly observed that the wear rates of Ag-graphite [2,3], Cu- graphite [8,9,18,19] and Al-graphite [20-22] composites were higher than 1.0×10-5 mm3/(N·m). In this study, the minimum wear rate of Ag-FG was 3.5×10-5 mm3/(N·m). However, the minimum wear rate of Ag-SG was 1.6×10-6 mm3/(N·m), which was obviously smaller than all of the listed composites. Besides, the minimum wear rate of Ag-SG was even smaller than that of the Ag- CNT-graphite composites (~3.0×10-6 mm3/(N·m)), which were reinforced by the high-strength carbon nanotubes (CNTs) [5,6]. Therefore, the replacement of spherical graphite instead of flake graphite could remarkably reduce the wear loss of Ag-graphite composites.

3.3 Microstructure of worn surface and wear debris

To further explore the reasons for the excellent tribological performance of Ag-SG, the typical worn surfaces of the two Ag-graphite composite pins are analyzed and the results are shown in Fig. 7. As seen, it exhibited the distinctly different characteristics between the Ag-25FG and Ag-25SG. The shallow grooves, delaminated regions and spalling pits appeared on the worn surfaces of Ag-25FG (Fig. 7(a)). The grooves corresponded to the abrasion wear, whereas the delaminated regions and spalling pits indicated the delamination wear [23,24]. Compared with the shallow grooves, the delaminated regions and spalling pits were the main forms of wear for Ag-25FG. Therefore, the main wear mechanism of Ag-25FG was the delamination wear. Furthermore, it can be observed that much flake graphite was concentrated in the spalling pit from the high magnification image (Fig. 7(c)), suggesting that the peeling was likely to occur at the junction between the graphite or the graphite and Ag matrix. For the Ag-25SG, the microscopic morphology was completely different, where no delaminated regions and spalling pits could be found on the worn surface (Figs. 7(b) and 7(d)). Furthermore, some shallow grooves parallel to the sliding direction on the worn surface suggested that the Ag-25SG was mainly subjected to abrasion wear.

Fig. 7 Worn surface morphologies of Ag-25FG (a) and Ag-25SG (b) pins and corresponding high magnification images (c) and (d), respectively

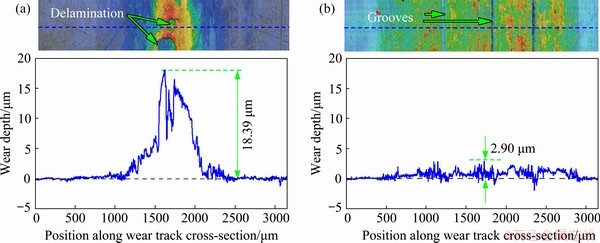

Additionally, the surface topographical area scans of wear track on the counter disk, as shown in Fig. 8, were similar to the worn surface morphology of Ag-graphite composite pins in Fig. 7. Clearly, some spalling pits appeared on the counter disk of Ag-25FG (Fig. 8(a)) and three grooves parallel to the sliding direction were seen on the counter disk of Ag-25SG (Fig. 8(b)). Moreover, the cross- sectional wear depth plots showed that the height of wear tracks was obviously higher than that of other areas, and it was believed that a graphite-rich transfer film was formed on the counter disk, which reduced the friction and wear loss [9]. On the other hand, the maximum height of the wear track for Ag-25FG reached 18.39 μm, which was only 2.90 μm for Ag-25SG. The higher wear track on the counter disk meant severer wear loss of Ag-25FG during the sliding process. Therefore, it not only indicated that the dominant wear mechanisms of Ag-25FG and Ag-25SG were the delamination wear and abrasion wear, but also confirmed a fact that the wear loss of Ag-FG was more serious than that of Ag-SG.

The wear debris morphologies of Ag-25FG and Ag-25SG are also visibly different in Fig. 9. It was evident from Fig. 9(a) that the wear debris of Ag-25FG was flake-like particles with a length from 10 to over 100 μm. Since the flake-like wear debris was the most important feature of delamination wear, the wear debris morphology suggested that Ag-25FG had been subjected to delaminated wear [23]. However, the wear debris for Ag-25SG was different, most of which had an irregular shape and was less than 10 μm (Fig. 9(b)). It has been proved that the smaller the wear debris was, the lower the wear loss was [14]. This was consistent with the results that the wear rates of Ag-FG were higher than those of Ag-SG. The EDS spectra of corresponding marked regions on the wear debris were presented in Figs. 9(c) and (d). As identified with the EDS analysis, the contents of C in the wear debris obtained from the sliding of Ag-25FG and Ag-25SG were 40.66 at.% and 30.08 at.%, respectively. The apparently higher C content in the wear debris of Ag-25FG was attributed to the fact that Ag-25FG composites were easy to peel off at the interface of flake graphites during sliding, which can be found in Fig. 7(c). The features of wear debris were well consistent with the worn surface of pins in Fig. 7 and counter disk in Fig. 8.

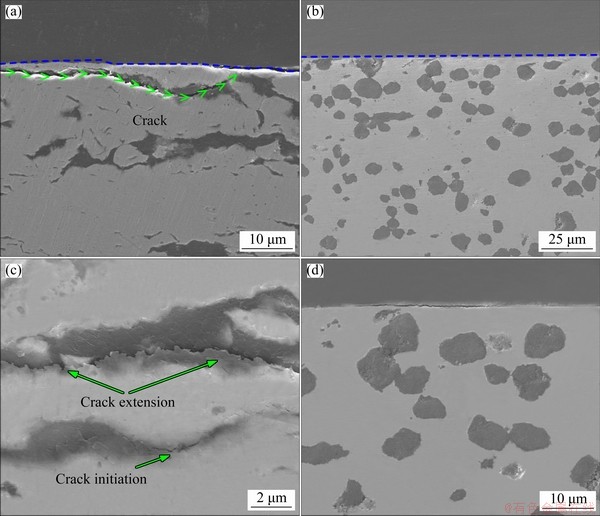

3.4 Microstructure evolution of sub-surface

In general, the layer underneath the worn surface underwent repeated deformation, fragmentation and compaction during dry sliding, and it dominated the frictional behaviors of the materials [23-26]. To study the microstructure evolution behavior of the sub-surface, the sub- surface morphologies of Ag-25FG and Ag-25SG after sliding against AgCu10 are shown in Fig. 10. Apparently, some cracks were displayed underneath the worn surface of Ag-25FG in Figs. 10(a) and (c). It was also observed that the cracks tended to initiate on the graphite tip and then extended along the graphite sheet (Fig. 9(c)). When the cracks reached the worn surface, as shown in Fig. 10(a), a part of the materials would peel off from the surface, resulting in the delamination wear and the formation of flaky wear debris [27,28]. However, the sub-surfaces of Ag-SG showed a different microstructure that no visible cracks can be observed from Fig. 10(b) and the corresponding high magnification image in Fig. 10(d). It indicated that the addition of spherical graphite in the Ag-25SG effectively prevented the initiation and expansion of the cracks in the sub-surface during sliding, which reduced the delaminated wear and resulted in a lower wear rate (Figs. 5 and 6).

Fig. 8 Surface topographical area scans and cross-sectional wear depth plots of counter disk after sliding with Ag-25FG (a) and Ag-25SG (b)

Fig. 9 SEM images of wear debris from sliding of Ag-25FG (a) and Ag-25SG (b), and corresponding EDS spectra of marked regions (c, d)

Fig. 10 Cross-sectional morphologies underneath worn surface of Ag-25FG (a, c) and Ag-25SG (b, d)

3.5 Effect of graphite morphology on wear behavior of Ag-graphite composites

Based on the above analysis, a number of interesting results have also been obtained from the tribological studies of Ag-25FG and Ag-25SG. The severe delamination wear occurred only in the Ag-25FG during sliding operation, which indicated that the particle morphology of graphite strongly affected the wear behavior of Ag-graphite composites. Finite element analysis of metal-matrix composites had revealed that the morphology of particles strongly influenced the strain fields in the matrix, and the severe stress concentration in the regions was close to the sharp corners of angular particles [29,30]. Besides, the high level of stress concentration often promoted the formation of micro-cracks in the matrix [25,31]. For the Ag-25FG, a large amount of flake graphite was embedded in the silver matrix and the stress concentration was prone to appear at the edges of flake graphite particles. Under the cyclic stress (mainly friction force), the cracks began to initiate on the flake graphite tip during the sliding process, as shown in Fig. 10(c). Furthermore, the graphite had a laminar structure and each layer was connected by weak van der Waals force, which allowed the crack to propagate along the interlayer (Figs. 10(a) and (c)). When these cracks were joined together and reached the worn surface of Ag-25FG, the materials would peel off from the surface, resulting in the delamination wear (Figs. 7(a), 7(c) and 8(a)). The spherical shape of graphite greatly modified the stress concentration behaviors around the graphite particles, thereby inhibiting crack initiation and delaminated wear. It was well consistent with the crack evolution behavior in the sub-surface of Ag-graphite composites in Fig. 10.

Additionally, many studies have reported that the delamination wear was the main form of mass loss of metal self-lubricating composites (MMSCs) during the process of friction [11,15,23,32]. It could be attributed to the fact that the solid lubricant particles (graphite, MoS2 and WS2) generally exhibited a flaky shape, and the stress concentration was easy to create at the edges of these solid lubricant particles. Combined the study of microstructural evolution of sub-surface, the matrix damage accumulation at stress concentration sites provided an opportunity for the initiation and propagation of cracks and ultimately led to the delamination wear. At present, the wear rates of MMSCs (including Ag-graphite [1-3], Cu- graphite [8,9], Al-graphite [20-22], Ag-MoS2 [15], Cu-MoS2 [32], Cu-WS2 [14,23]) are generally higher than 1.0×10-5 mm3/(N·m). Therefore, it is very important and meaningful to find a way to inhibit the delamination wear, which can effectively reduce the wear rate of the MMSCs. In this study, the replacement of spherical graphite with the flake graphite in the Ag-graphite composites can effectively improve the ability to resist delamination wear, and the wear rate of Ag-SG was greatly reduced to 1.6×10-6 mm3/(N·m), which was nearly an order of magnitude lower than that of most MMSCs (Fig. 6). This finding also provided an effective method for preparing other low-wear MMSCs.

4 Conclusions

(1) The graphite morphology (spherical and flake) seriously affects the tribological behavior of Ag-graphite composites. Ag-graphite composites reinforced with spherical graphite (Ag-SG) possessed a lower friction coefficient and wear loss than Ag-graphite composites reinforced with flake graphite (Ag-FG). And the minimum wear rate was 3.5×10-5 mm3/(N·m) for Ag-FG, which dramatically reduced to 1.6×10-6 mm3/(N·m) for Ag-SG.

(2) The microstructure evolution of sub- surface revealed the mechanism of high wear resistance for Ag-SG. Cracks were easily generated along the flake graphite particles in the sub-surface of Ag-FG, leading to severe delamination wear. However, the initiation and propagation of the crack were effectively suppressed by the spherical graphite, and the wear resistance of Ag-SG was remarkably improved.

(3) The effective method of achieving high wear resistance of Ag-graphite composites by adding spherical graphite also supported the preparation of other metal self-lubricating composites with excellent tribological performance.

References

[1] CHEN F Y, FENG Y, SHAO H, LI B, QIAN G, LIU Y F, ZHANG X B. Tribological behaviour of silver based self- lubricating composite [J]. Powder Metall, 2013, 56: 397-404.

[2] PARDEE R P. Moisture dependence of silver-graphite brushes in air, nitrogen, helium, and carbon dioxide [J]. IEEE Transactions on Power Apparatus and Systems, 1967, 86: 616-625.

[3] BRATERSKAYA G N, ZATOVSKII V G. Wear resistance of sliding electrical contacts of silver-base composite materials [J]. Soviet Powder Metallurgy and Metal Ceramics, 1984, 23: 397-401.

[4] FENG Y, ZHANG M, XU Y. Effect of the electric current on the friction and wear properties of the CNT-Ag-G composites [J]. Carbon, 2005, 43: 2685-2692.

[5] WANG J, FENG Y, LI S, LIN S. Influence of graphite content on sliding wear characteristics of CNTs-Ag-G electrical contact materials [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 113-118.

[6] FENG Y, WANG J, ZHANG M, XU Y, The influence of pressure on the electrical tribology of carbon nanotube- silver-graphite composite [J]. Journal of Materials Science, 2007, 42: 9700-9706.

[7] SCHARF T W, PRASAD S V. Solid lubricants: A review [J]. Journal of Materials Science, 2012, 48: 511-531.

[8] KOVACIK J, EMMER S, BIELEK J, KELESI L U. Effect of composition on friction coefficient of Cu-graphite composites [J]. Wear, 2008, 265: 417-421.

[9] GRANDIN M, WIKLUND U. Wear phenomena and tribofilm formation of copper/copper-graphite sliding electrical contact materials [J]. Wear, 2018, 398-399: 227-235.

[10] RAJKUMAR K, SANTOSH S. Effect of nano and micro graphite particle on tribological performance of aluminium metal matrix composites [J]. Applied Mechanics and Materials, 2014, 592-594: 917-921.

[11] RAJKUMAR K, ARAVINDAN S. Tribological behavior of microwave processed copper-nanographite composites [J]. Tribology International, 2013, 57: 282-296.

[12] ZHANG Y M, CHEN Y, HE R T, SHEN B L. Investigation of tribological properties of brake shoe materials- phosphorous cast irons with different graphite morphologies [J]. Wear, 1993, 166: 179-186.

[13] HATATE M, SHIOTA T, TAKAHASHI N, SHIMIZU K. Influences of graphite shapes on wear characteristics of austempered cast iron [J]. Wear, 2001, 251: 885-889.

[14] ZHOU J, MA C, KANG X, ZHANG L, LIU X L. Effect of WS2 particle size on mechanical properties and tribological behaviors of Cu-WS2 composites sintered by SPS [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 1176-1185.

[15] ZHANG L, XIAO J K, ZHOU K C. Sliding wear behavior of silver-molybdenum disulfide composite [J]. Tribology Transactions, 2012, 55: 473-480.

[16] WANG Y A, LI J X, YAN Y, QIAO L J. Effect of pv factor on sliding friction and wear of copper-impregnated metallized carbon [J]. Wear, 2012, 289: 119-123.

[17] HU Z L, CHEN Z H, XIA J T, DING G Y. Effect of PV factor on the wear of carbon brushes for micromotors [J]. Wear, 2008, 265: 336-340.

[18] CUI G J, NIU M Y, ZHU S Y, YANG J, BI Q L. Dry-sliding tribological properties of bronze-graphite composites [J]. Tribology Letters, 2012, 48: 111-122.

[19] MA W L, LU J J, WANG B. Sliding friction and wear of Cu-graphite against 2024, AZ91D and Ti6Al4V at different speeds [J]. Wear, 2009, 266: 1072-1081.

[20] SHARMA P, PALIWAL K, GARG R K, SHARMA S, KHANDUJA D. A study on wear behaviour of Al/6101/ graphite composites [J]. Journal of Asian Ceramic Societies, 2018, 5: 42-48.

[21] BARADESWARAN A, PERUMAL A E. Wear and mechanical characteristics of Al7075/graphite composites [J]. Composites (Part B): Engineering, 2014, 56: 472-476.

[22] AKHLAGHI F, ZARE-BIDAKI A. Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024-graphite composites produced by in situ powder metallurgy method [J]. Wear, 2009, 266: 37-45.

[23] XIAO J K, ZHANG W, ZHANG C. Microstructure evolution and tribological performance of Cu-WS2 self-lubricating composites [J]. Wear, 2018, 412-413: 109-119.

[24] ROUHI M, MOAZAMI-GOUDARZI M, ARDESTANI M. Comparison of effect of SiC and MoS2 on wear behavior of Al matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 1169-1183.

[25] SHOCKLEY J M, DESCARTES S, VO P, IRISSOU E, CHROMIK R R. The influence of Al2O3 particle morphology on the coating formation and dry sliding wear behavior of cold sprayed Al-Al2O3 composites [J]. Surf Coat Technol, 2015, 270: 324-333.

[26] WANG P, ZHANG H, YIN J, XIONG X, TAN C, DENG C Y, YAN Z Q. Wear and friction behaviours of copper mesh and flaky graphite-modified carbon/carbon composite for sliding contact material under electric current [J]. Wear, 2017, 380-381: 59-65.

[27] SUH N P. An overview of the delamination theory of wear [J]. Wear, 1977, 44: 1-16.

[28] FLEMING J R, SUH N P. Mechanics of crack propagation in delamination wear [J]. Wear, 1977, 44: 39-56.

[29] LIU X, CAO D F, MEI H, LEI Z T, LIU L S. Effect of particle shapes on effective strain gradient of SiC particle reinforced aluminum composites [J]. Journal of Physics: Conference Series, 2013, 419: 012042.

[30] CHEN C R, QIN S Y, LI S X, WEN J L. Finite element analysis about effects of particle morphology on mechanical response of composites [J]. Materials Science and Engineering A, 2000, 278: 96-105.

[31] MICHAEL SHOCKLEY J, DESRAYAUD C, CHROMIK R R, DESCARTES S. Significance of Al2O3 particle morphology in the microstructure evolution of cold-sprayed Al-Al2O3 during unconstrained high-pressure torsion [J]. Materials Science and Engineering A, 2017, 684: 510-516.

[32] MOAZAMI-GOUDARZI M, NEMATI A. Tribological behavior of self lubricating Cu/MoS2 composites fabricated by powder metallurgy [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 946-956.

孙 阳1,王 艳2,李 云1,周科朝1,张 雷1

1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 郑州轻工业大学 机电工程学院,郑州 450002

摘 要:采用粉末冶金技术分别制备球形石墨(SG)和鳞片石墨(FG)增强的银-石墨复合材料。并用销-盘式摩擦磨损仪在大气环境和3.0 N的载荷下研究石墨形貌对银-石墨复合材料(Ag-SG和Ag-FG)摩擦学行为的影响。结果显示,Ag-FG的最低磨损率为3.5×10-5 mm3/(N·m),而Ag-SG的最低磨损率比Ag-FG低一个数量级,为1.6×10-6 mm3/(N·m)。Ag-SG和Ag-FG显著不同的摩擦学行为与亚表面裂纹的形成有关。在摩擦过程中,片状石墨的边缘容易发生应力集中,导致Ag-FG亚表面产生裂纹和严重的剥层磨损。然而,在Ag-SG中,球形石墨能有效抑制裂纹的萌生和扩展,从而使银-石墨复合材料具有优异的耐磨性能。

关键词:银-石墨复合材料;石墨形貌;磨损性能;显微组织;磨损机制

(Edited by Xiang-qun LI)

Foundation item: Project (51674304) supported by the National Natural Science Foundation of China; Project (2018JJ3677) supported by Natural Science Foundation of Hunan Province, China

Corresponding author: Lei ZHANG; Tel: +86-731-88830408; E-mail: zhanglei@csu.edu.cn

DOI: 10.1016/S1003-6326(20)65370-5