新工艺制备A356铝合金半固态浆料及其流变压铸组织和性能

来源期刊:中国有色金属学报(英文版)2021年第7期

论文作者:祁明凡 康永林 徐玉昭 李静媛 刘爱森

文章页码:1868 - 1884

关键词:半固态浆料;A356铝合金;分流汇合浇道;流变压铸;显微组织;拉伸性能

Key words:semisolid slurry; A356 alloy; distributary-confluence runner; rheological die-casting; microstructure; tensile properties

摘 要:将新开发的分流汇合浇道(DCR)半固态浆料制备工艺与压铸技术结合,实现A356铝合金流变压铸成形。结合数值模拟与实验,探讨DCR工艺制备半固态浆料机理;研究DCR流变压铸和传统压铸A356铝合金的显微组织和力学性能。结果表明,DCR工艺可以制备内部含有大量初生α-Al晶粒且其平均尺寸为49 μm、形状因子为0.81的高品质半固态浆料。数值模拟结果表明,DCR工艺制备半固态浆料过程中其独特的流动状态和物理场变化有利于加速熔体温度场和成分场的均匀、晶核剥落和球状长大。和传统压铸相比,DCR流变压铸A356铝合金的抗拉强度、屈服强度和伸长率分别提高了19%、15%和107%。

Abstract: A new technique for preparing semisolid slurry, namely, distributary-confluence runner (DCR), was combined with die-casting (DC) to conduct rheological die-casting (R-DC) of A356 alloy. The mechanism of DCR for semisolid slurry preparation was determined via numerical simulations and experiments. The microstructure and mechanical properties of A356 alloys prepared via DC and R-DC were studied. High-quality slurry containing numerous primary α-Al (α1-Al) with an average size of 49 μm and a shape factor of 0.81 could be prepared via DCR. Simulation results indicated that the unique flow state and physical field changes during slurry preparation were conducive to accelerating the uniformity of melt temperature and composition fields, nucleation exfoliation, and spherical growth. Compared with the alloy prepared via DC, the tensile strength, yield strength, and elongation of A356 alloy prepared via R-DC increased by 19%, 15%, and 107%, respectively.

Trans. Nonferrous Met. Soc. China 31(2021) 1868-1884

Ming-fan QI1, Yong-lin KANG1, Yu-zhao XU1, Jing-yuan LI1, Ai-sen LIU2

1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Center International Group Co., Ltd., Beijing 100176, China

Received 6 August 2020; accepted 28 March 2021

Abstract: A new technique for preparing semisolid slurry, namely, distributary-confluence runner (DCR), was combined with die-casting (DC) to conduct rheological die-casting (R-DC) of A356 alloy. The mechanism of DCR for semisolid slurry preparation was determined via numerical simulations and experiments. The microstructure and mechanical properties of A356 alloys prepared via DC and R-DC were studied. High-quality slurry containing numerous primary α-Al (α1-Al) with an average size of 49 μm and a shape factor of 0.81 could be prepared via DCR. Simulation results indicated that the unique flow state and physical field changes during slurry preparation were conducive to accelerating the uniformity of melt temperature and composition fields, nucleation exfoliation, and spherical growth. Compared with the alloy prepared via DC, the tensile strength, yield strength, and elongation of A356 alloy prepared via R-DC increased by 19%, 15%, and 107%, respectively.

Key words: semisolid slurry; A356 alloy; distributary-confluence runner; rheological die-casting; microstructure; tensile properties

1 Introduction

As a highly productive near-net-forming process, die-casting (DC) is widely used in various fields, such as automobiles and 3C (computer, communications, and consumer electronic devices) [1,2]. However, the application of DC is hindered by the porosity of castings and their concomitant low strength [3]. Nonporous DC technologies, such as vacuum DC [4], pore-free DC [5], and rheological DC (R-DC) [6], have been developed to improve the porosity of castings. Among these technologies, R-DC has attained good results. R-DC is advantageous over conventional DC because it requires a low forming temperature, produces a stable filling, and results in small solidification shrinkage. Adopting R-DC can decrease or even eliminate cast gas pores and shrinkage. Samples prepared via R-DC have high mechanical properties [6,7]. Furthermore, R-DC combines the advantages of both semisolid forming and conventional DC; thus, it has become a research hotspot in recent years to promote its industrial application.

The preparation of semisolid slurry is the key of R-DC. Researchers have developed various semisolid slurry preparation technologies. For instance, FAN et al [3] developed the double-spiral shearing technology and prepared a semisolid slurry by using a pair of high-speed rotating screws to perform intense shear stirring on the melt. MAHATHANINWONGA et al [8] developed the gas induced semisolid (GISS) technology, which requires feeding an inert gas into the melt when the melt has solidified. Bubble disturbance is then employed to prepare a semisolid slurry. GUAN et al [9] developed the WSP technology, which involves rapidly cooling and stirring the melt on a wavy inclined plate surface to prepare a semisolid slurry. ZHU et al [10] developed the serpentine pouring channel (SCP) technology, in which a superheated melt is poured into a serpentine channel to chill, and the semisolid slurry is formed by the disturbance caused by its own gravity. WESSEN and CAO [11] developed the rapid slurry forming (RSF) technology on the basis of the principle of embedding a solid alloy block with the same composition as the alloy melts onto a stirring rod. The melt is then stirred, and a semisolid slurry is prepared during the process of controlling the enthalpy and entropy of the melt. QI et al [12] developed the air-cooled stirring rod (ACSR) technology, in which compressed air is continuously injected into the inner cavity of a stirring rod through an air guide tube during the solidification of the melt to discard large amounts of heat and accelerate the cooling of the melt. These processes promote the nucleation and rapid preparation of the slurry. DOUTRE et al [13] developed the swirling enthalpy equilibration device (SEED) technology, which involves pouring a low superheat melt into a crucible. The crucible is then rotated eccentrically to produce a shear effect inside the melt, thereby inhibiting the dendritic growth of the primary grain. Although many semisolid slurry preparation technologies have been developed, few of them have realized industrialized applications. The main problems restricting the promotion and application of semisolid slurry preparation technologies are the troublesome equipment disassembly and cleaning and unstable working conditions, which present difficulties in preparing slurry in a stable and efficient manner.

To address the abovementioned problems during slurry preparation, a non-external force stirring slurry preparation process called the distributary-confluence runner (DCR) process was developed. The process employs multiple runners to increase chilling and nucleation area and promote melt nucleation, thereby allowing the quick preparation of a semisolid slurry. The problem posed by sticky materials that complicate equipment cleaning during slurry preparation was addressed by optimizing DCR process parameters, DCR mold materials, and the cross-sectional shape of DCR molds. These factors can guarantee continuous and stable slurry preparation.

In this study, DCR was adopted to prepare a semisolid slurry of A356 aluminum alloy. The slurry was placed in the pressure chamber of a DC machine to conduct R-DC. The characteristics and evolution of the primary grains in the prepared slurry were examined under different DCR process parameters, namely, pouring temperature, tilt angle, and number of runners. The microstructure, density, and tensile properties of A356 alloys prepared via R-DC and conventional DC were compared. The mechanism of preparation of a high-quality semisolid slurry via DCR was analyzed. FLOW-3D was used to simulate the physical field changes and flow states of the melt in the DCR, as well as to determine the influence of DCR process parameters on solid fraction, temperature field, and air entrapment.

2 Experimental

2.1 DCR device

The schematic of a DCR device is displayed in Fig. 1, with outer dimensions of 480 mm × 280 mm × 50 mm, a runner depth of 22 mm, and a runner width of 20 mm. The device is mainly composed of an upper die (distributary-confluence runner), a lower die (cooling groove), a proportional integral derivative (PID) temperature controller, a heating plate, a thermocouple, and a tilt angle adjustment bracket. The bottom part of the upper mold is embedded onto the groove of the lower mold. The 5 mm-gap between the upper and lower molds can ensure the injection of cooling water. The DCR mold is placed obliquely, and the tilt angle is adjusted using the bracket. The temperature control system of the DCR device consists of a heating plate, a cooling groove, a thermocouple, and a PID temperature controller. The K-type thermocouple was placed on the upper and lower parts of the upper mold can ensure the uniformity of the DCR mold temperature. The upper and lower mold materials are made of graphite with high thermal conductivity, high strength, and high density. The graphite surface is smooth and does not react with the aluminum alloy melt, which explains why the solidification crust of the melt in the DCR can be effectively reduced during the slurry preparation process. The DCR equipment does not need to be disassembled and is easy to clean, indicating a stable and efficient technique of slurry preparation.

2.2 Material and procedures

The experimental material used in the study was a commercial A356 cast aluminum alloy with a specific chemical composition (wt.%) of 7.2% Si, 0.3% Mg, and 0.12% Fe, with the rest Al. The solidus and liquidus of the alloy were 560 and 615 °C, respectively.

The A356 alloy was placed inside a well-type resistance furnace and was heated to 720 °C. After the alloy had melted, it was refined with hexachloroethane. Then, the melt was cooled to the pouring temperature. A total of 3.2 kg of alloy melt (Fig. 2(a)) was scooped and poured onto the DCR mold (Fig. 2(b)). The specific DCR process parameters are listed in Table 1. A stainless-steel collecting crucible at room temperature was used to collect the semisolid slurry from the DCR outlet (Fig. 2(c)). After completing the slurry collection, the crucible was quickly immersed in cold water (Fig. 2(d)) to obtain the semisolid ingot (Fig. 2(e)).

This work studied not only the effect of the DCR process parameters on the microstructure of the semisolid slurry but also the microstructure and mechanical properties of the DCR R-DC alloy. Combined with the actual production of the connecting pipe of automobile steering gear, the prepared semisolid slurry was poured into the pressure chamber of a cold chamber DC machine (L.K. DCC800) with a mold temperature of 200 °C for the shaping, as presented in Figs. 3(a-c). The produced R-DC casting is shown in Fig. 3(d). A batch of conventional DC castings were also prepared using the same DC machine and DC process parameters. Figure 4 illustrates the specific process curve of the DC.

Fig. 1 Schematic of DCR device

Fig. 2 Schematic of preparing semisolid slurry via DCR process

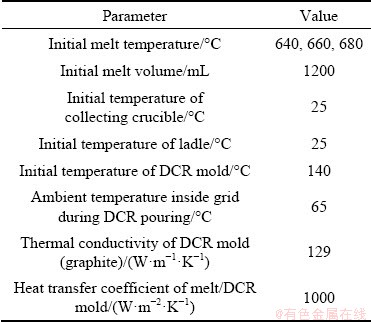

Table 1 DCR process parameters for semisolid slurry preparation

Fig. 3 Schematic of DCR R-DC process

Fig. 4 DC process curves

2.3 Microstructure observation and performance testing

The samples were cut from the center of the ingot and along Positions A and B of the casting, as shown in Fig. 3(d). After the coarse grinding, fine grinding, and polishing, the samples were eroded with a 0.5 vol.% hydrofluoric acid solution. A Neophot optical microscope and a Surpra 40 scanning electron microscope (SEM) were used to observe the microstructure of the samples. The tensile fracture was observed by SEM.

With reference to ASTM E8M, the tensile specimen was cut with a rectangular cross-section from Position C of the casting (Fig. 3(d)). The width, thickness, and gauge length of the sample were 12.5, 3.5, and 50 mm, respectively. According to GB/T 228—2010, a CMT41 electronic tensile machine was used for the testing of the tensile properties of the tensile specimens. The tensile speed was 1 mm/min. The average of five tensile test samples was taken as the tensile result.

In line with the Archimedes’ principle, the drainage method was employed to measure the density of the sample based on the GB/T 1423—1996. The mass of the sample was measured using an AE100 electronic balance whose accuracy can reach 1 mg. The density of each sample was taken as the average of three measurement results. The porosity is calculated by

(1)

(1)

where  is the porosity, ρ is the density of the sample measured by the Archimedes’ principle, and ρ′ is the theoretical density of the alloy.

is the porosity, ρ is the density of the sample measured by the Archimedes’ principle, and ρ′ is the theoretical density of the alloy.

The X-ray flaw detection test was performed using the Bosello SRE90 X-ray flaw detector.

2.4 Numerical simulation

Viscosity was defined in this work to address the flow problem of the semisolid slurry. The FLOW-3D software, which provides the Carreau’s model, can be used to describe the flow behavior of non-Newtonian fluids. In accordance with the previous studies [14], the relationship among the apparent viscosity (μ), temperature (T), and shear rate (γ) of the A356 aluminum alloy semisolid slurry is shown as Eqs. (2) and (3).

(2)

(2)

(3)

(3)

The process of preparing the semisolid slurry by using the DCR process is divided into alloy melt scooping, DCR pouring, and slurry collection. In the slurry preparation process, the changes in the physical fields after the melt is poured into the DCR deserve the most attention; thus, the alloy melt is assumed to have been preset in the scoop in advance. In this study, the material model of the A356 aluminum alloy was selected from the FLOW-3D material database. The scoop and the collecting crucible were both made of H13 steel, while the DCR was made of graphite. The specific parameters used in the numerical simulation of the semisolid slurry prepared via the DCR process are shown in Table 2. For the model adopted in the study, the grid width was set to be 2 mm, and the number of grids was set to be 720000.

3 Results

3.1 Effects of pouring temperature on semisolid slurry

Figure 5 displays the effects of the pouring temperatures on the temperature field, solid fraction, and air entrapment of the semisolid slurry prepared via the DCR process. When the pouring temperatures were 680, 660, and 640 °C, the temperatures of the melt after it was poured into the DCR device quickly decreased to the semisolid temperature range. This finding indicates that the DCR had a strong cooling capacity for the melt. When the melt temperatures were 680, 660, and 640 °C, the slurry temperatures at the DCR outlet were 605, 598, and 591 °C, respectively. After all of the slurry flowed into the collecting crucible, the temperatures decreased to 595, 590, and 585 °C, with solid fractions of 28%, 36%, and 39%, respectively.

Table 2 Specific parameters and initial conditions for numerical simulation of A356 aluminum alloy semisolid slurry preparation

As presented in Fig. 5, the air entrapment volume of the slurry significantly varied depending on the pouring temperature. When the pouring temperature was 660 °C, the air entrapment volume of the slurry was the lowest, as high pouring temperatures would cause serious melt gettering and violent flow in the DCR. In addition, the slurry prepared with the high pouring temperature exhibited high-temperature and low-viscosity characteristics. A slurry entering the collection crucible could easily collide with the crucible wall and cause turbulence and air entrapment. Furthermore, a pouring temperature that is excessively low could cause the subsequent slurry to flow through the solidified shell and cause the melt to fluctuate because of the rapid formation of the solidified shell in the DCR, thereby increasing the air entrapment in the slurry. At the same time, the formation of a solidified shell could prolong the flow time of the melt in the DCR, subsequently increasing the amount of air entrapment in the slurry.

Fig. 5 Temperature field, solid fraction, and air entrapment of A356 alloy semisolid slurry prepared via DCR at different pouring temperatures

Fig. 6 Microstructure and hanging material of A356 alloy semisolid slurry prepared via DCR at different pouring temperatures

Figure 6 shows the microstructure and hanging material of the slurry prepared at different pouring temperatures. Figure 7 shows the effects of pouring temperature on the average size and shape factor of the primary α-Al (α1-Al). When the pouring temperature reached 680 °C, the solid-liquid phases segregation occurred in the slurry, and a certain proportion of the α1-Al appeared with a rose structure or degenerated dendrites (Fig. 6(a)). The average size and shape factor of the α1-Al were 81 μm and 0.74, respectively (Fig. 7). The α1-Al necking shown by the arrow A in Fig. 6(a) was obvious. After dendrite necking and maturation, a part of the dendrite arms detached from the dendrite backbone and transformed into granular or nearly spherical grains, as shown by the arrow B in Fig. 6(a). This shift indicates that the formation of the spherical α1-Al is related to the necking and ripening of dendrite arms. When the pouring temperature was decreased to 660 °C, the amount of rose-shaped α1-Al in the slurry was largely reduced, whereas the amount of nearly spherical and granular α1-Al increased (Fig. 6(b)). The size of the α1-Al shrank, and its morphology became round. The average size and shape factor were 49 μm and 0.81, respectively (Fig. 7). When the pouring temperature was further decreased to 640 °C, the number of rose-shaped α1-Al in the slurry increased (Fig. 6(c)). At this time, the average size and shape factor of the α1-Al were 52 μm and 0.78, respectively (Fig. 7). For the DCR process, excessively high and low pouring temperatures were not conducive to obtaining a fine and spherical α1-Al. The melt superheat was large when the pouring temperature was high, and the number of formed free crystals was small after the melt was poured into the DCR, further resulting in a small number of crystal nuclei nucleating at the high temperature and growing into coarse rose-shaped α1-Al. The melt fluidity was poor when the pouring temperature was low, and a solidified shell was easily formed in the DCR (Fig. 6(c)). When the subsequent melt flow penetrated the high- temperature solidified shell, the chilling effect of the DCR could not be effectively exerted, and an unsatisfactory refinement effect was observed. In summary, the ideal pouring temperature of the DCR process in this study was 660 °C.

Fig. 7 Effect of pouring temperature on average size and shape factor of α1-Al

3.2 Effects of tilt angle on semisolid slurry

Figure 8 displays the effects of the tilt angles on the temperature field, solid fraction, and air entrapment of the semisolid slurry prepared via the DCR process. The contact time of the melt with the DCR was affected by the tilt angle. When the tilt angles were 30°, 45°, and 60°, the contact time of the melt with the DCR was 4.9, 4.5, and 3.8 s, respectively, starting from the time the melt came in contact with the DCR until the slurry completely flowed into the collection crucible. The melt temperature dropped faster when the melt flow time in the DCR increased. As shown in Fig. 8, the temperatures of the slurry flowing into the DCR outlet are 592, 598, and 605 °C, and then the corresponding temperatures after the slurry has completely flowed into the collection crucible are 587, 590, and 596 °C, with solid fractions of 42%, 36%, and 20%, respectively.

The tilt angle also affected the air entrapment in the slurry. When the tilt angle was increased from 30° to 45°, the air entrapment in the slurry increased slightly. When the tilt angle was further increased to 60°, the amount of slurry-entrained gas increased rapidly. Excessively high tilt angles would cause the melt to flow rapidly into the DCR, thereby increasing air entrapment. Furthermore, a slurry entering the collection crucible would collide with the crucible wall to generate turbulence, which could aggravate the gas entrapment.

Figure 9 displays the microstructure and hanging material of the A356 alloy semisolid slurry prepared with different tilt angles. Figure 10 shows the effects of tilt angle on the average size and shape factor of the α1-Al. When the tilt angle was 30°, many nearly spherical, granular, and slightly rose-shaped α1-Al were observed (Fig. 9(a)). At this time, the average size of the α1-Al was 57 μm, and the shape factor was 0.79 (Fig. 10). When the tilt angle was 45°, the α1-Al became spherical or nearly spherical, and the fine particles had an average size and shape factor of 49 μm and 0.81, respectively (Figs. 9(b) and 10). When the tilt angle was increased to 60°, rose-shaped grains appeared in the microstructure, and the α1-Al has a small roundness and a large size (Figs. 9(c) and 10). During the preparation of the slurry via the DCR process, the melt cooling and the grain nucleation both need to come in contact with the DCR for a certain time. A short contact time will lead to the insufficient heat transfer of the melt in the DCR and a small supercooling, further resulting in only a small amount of α1-Al formation. By decreasing the tilt angle, the contact time of the melt with the DCR mold increases. The cooling effect is then enhanced, and a greater supercooling can be obtained, thus considerably increasing the amount of α1-Al.

Fig. 8 Temperature field, solid fraction, and air entrapment of A356 alloy semisolid slurry prepared via DCR with different tilt angles

Fig. 9 Microstructure and hanging material of A356 alloy semisolid slurry prepared via DCR with different tilt angles

However, further lowering the tilt angle does not imply a better effect. A tilt angle that is extremely low can cause serious hanging material (Fig. 9(a)). Therefore, the tilt angle should be adjusted properly not only to ensure the quality of the slurry but also to prevent serious hanging material. The appropriate tilt angle obtained in this study is 45°.

3.3 Effects of number of runners on semisolid slurry

Figure 11 presents the effects of the number of runners on the temperature field, solid fraction, and air entrapment of the A356 alloy semisolid slurry prepared via DCR. Figure 12 shows the microstructure and hanging material of the slurry prepared with different number of runners. Figure 13 displays the effects of the number of runners on the average size and shape factor of α1-Al.

Fig. 10 Effect of tilt angle on average size and shape factor of α1-Al

Fig. 11 Temperature field, solid fraction, and air entrapment of A356 alloy semisolid slurry prepared via DCR with different number of runners

Fig. 12 Microstructure and hanging material of A356 alloy semisolid slurry prepared via DCR with different numbers of runners

Fig. 13 Effect of number of runners on average size and shape factor of α1-Al

When the number of runners was 4, the temperature at which the melt flowed into the collecting crucible was 590 °C, and the solid fraction was 36% (Fig. 11). At this point, the shape and size of α1-Al in the slurry were round and small, respectively (Fig. 12(b)). The shape factor was 0.81, and the average grain size was 49 μm (Fig. 13). When the number of runners was 2, the temperature at which the melt flowed into the collecting crucible was 598 °C, and the solid fraction was 27% (Fig. 11). The slurry contained numerous coarse rose grains, and the average size and the shape factor of α1-Al were 83 μm and 0.72, respectively (Figs. 12(a) and 13). When the number of runners was increased, both the chilling nucleation and heterogeneous nucleation of the melt in the inner wall of the DCR proceeded more easily, thereby improving the nucleation rate of the melt in the DCR. When the number of crystal nuclei was increased, the growth of dendrites was effectively inhibited. Simultaneously, the contact area between the melt and the inner wall of the DCR increased as the number of runners was increased, thereby increasing the cooling range and reducing the temperature gradient of the melt at the end of the DCR. Notably, the decrease in temperature gradient destroyed the dendrite growth environment of α1-Al. When the number of runners was increased from 2 to 4, the air entrapment in the slurry decreased. This condition could be attributed to the large number of runners, the quick melt cooling, the low temperature of the prepared slurry, and the stability of the flow. Moreover, no major differences in the hanging materials in the DCR between the 2 and 4 runners were observed (Fig. 12). Therefore, 4 runners are generally more suitable for the preparation of a high-quality semisolid slurry.

3.4 Comparison of microstructure between DCR and conventional casting

Figure 14 presents a comparison of the edge, half radius (R/2), and center microstructures of the A356 alloy ingots prepared via the DCR and conventional casting (CC). Table 3 summarizes the average grain sizes and shape factors of the different positions of the A356 alloy ingots prepared via the CC and DCR processes. For the CC pouring, the α1-Al was coarse, with well-developed dendrites at the edge and R/2 of the

Fig. 14 Comparison of microstructures at edge, half radius (R/2), and center of A356 alloy ingots prepared via CC (a, c, e) and DCR (b, d, f)

Table 3 Average size and shape factor of α1-Al of different positions of A356 alloy ingots prepared by CC and DCR processes

sample. The secondary dendrite arms were coarse with slight gaps, and the sizes of some of the dendrites exceeded 200 μm (Figs. 14(a) and (c)). The center of the sample was composed of developed dendrites, rose grains, and a small number of irregularly shaped polygonal grains. The dendrites showed a certain rosification (Fig. 14(e)). In the normal solidification process, the grains developed in the form of dendrites, and a small number of irregular polygonal grains appeared. This condition can be attributed to the solidified melt that was disturbed to a certain extent during the pouring process. Furthermore, the pouring time was about 4 s, which had a short-term heat preservation and maturation effect on the microstructure of the center area. For the DCR pouring, the α1-Al at the edge of the ingot mainly consisted of nearly spherical and a few rose α1-Al particles (Fig. 14(b)). The α1-Al in the R/2 part was mainly composed of nearly spherical and a few granular particles (Fig. 14(d)), whereas the α1-Al in the center was composed of numerous nearly spherical particles (Fig. 14(f)). The sample microstructure was gradually rounded from the edge to the center, and the grain size and shape factor increased gradually. The edge of the collecting crucible had a faster cooling rate, and the slurry was first solidified in this area. As the slurry flowed into the crucible, it was further stirred and mixed under the action of the gravity field; thus, the primary crystal nuclei, which had initially spheroidized and matured, became evenly dispersed inside the slurry [15]. At the same time, the stirring and mixing were also conducive to the formation of uniform slurry composition and temperature fields in the crucible. The cooling rate of the crucible core was slow, and the α1-Al had enough time to spheroidize and ripen; thus, the shape of the α1-Al grains at the center became more rounded. The nearly spherical α1-Al particles at the center were the likely result of further spheroidization and maturation after the initial spheroidization of the α1-Al in the DCR upon entering the collection crucible.

3.5 Microstructure and properties of A356 alloy prepared by DC and DCR R-DC

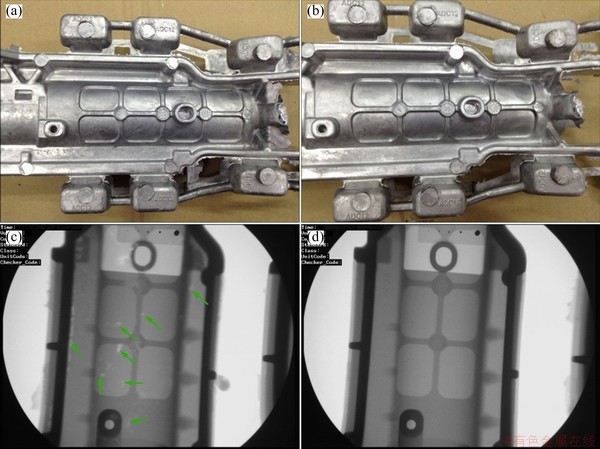

Fig. 15 Physical pictures (a, b) and X-ray inspections (c, d) of A356 alloy castings prepared via conventional DC (a, c) and DCR R-DC (b, d)

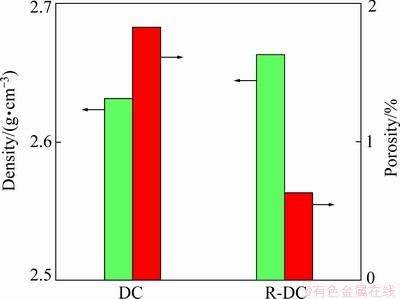

Figure 15 shows the physical pictures and X-ray inspections of the A356 alloy castings prepared via the conventional DC and DCR R-DC processes. The specific DCR process parameters were tilt angle, pouring temperature, and the number of runners, which were 45°, 660 °C, and 4, respectively. The castings prepared via the two technologies had a fine surface quality (Figs. 15(a) and (b)). The X-ray inspection results indicated that the DC alloy had serious casting defects, such as gas pores and shrinkage porosities, whereas no obvious defects in the R-DC alloy were observed (Figs. 15(c) and (d)). The densities of the A356 alloys prepared via DC and R-DC were 2.631 and 2.663 g/cm3, with porosities of 1.83% and 0.63%, respectively (Fig. 16). This result demonstrated that the DCR R-DC process can greatly reduce the alloy’s porosity and improve its casting defects.

Fig. 16 Density and porosity of A356 alloy castings prepared via DC and R-DC processes

Figures 17(a-c) and (d-f) present the micro- structures at Positions A and B (Fig. 3) of the A356 alloys prepared via conventional DC and DCR R-DC, respectively. The microstructural characteristic values of the A356 aluminum alloy prepared via the two processes are shown in Fig. 18.

Fig. 17 Microstructures of A356 aluminum alloy at Positions A (a, d) and B (b, c, e, f) prepared via conventional DC (a-c) and DCR R-DC (d-f)

Numerous fine non-dendritic α1-Al were observed in the DCR R-DC castings. The average size and shape factor of the α1-Al were 43 μm and 0.82, respectively. By contrast, numerous coarse dendrites could be observed in the conventional DC castings, with an average size and shape factor of 128 μm and 0.46, respectively. Numerous gas pores and shrinkage porosities could also be observed in the microstructure of the conventional DC castings. Normally, the solid fraction of the R-DC alloy was less than 45 vol.%. Hence, the secondary solidification of the remaining liquid phase may have also played a key role in the performance of the alloy. As shown in Figs. 17(c, f) and 18(b), as the preparation process was replaced by traditional DC with DCR R-DC, the average size of the secondary α-Al (α2-Al) was decreased from 16.5 to 8.9 μm, and the length of the eutectic silicon was reduced from 14.6 to 8.7 μm. These results could be attributed to the primary phase that had an effect on the morphology of the eutectic silicon. Furthermore, the spherical primary phase divided the remaining liquid phase into many small areas where the eutectic reaction would be subsequently confined. As a result, the supercooling of the eutectic silicon front was changed, further affecting the nucleation of the eutectic silicon and causing it to grow isotropically [14]. The growth of the eutectic silicon was considerably limited with a higher solid fraction.

Fig. 18 α1-Al (a), α2-Al and eutectic silicon (b) characteristic values of A356 aluminum alloy prepared via two processes

The tensile properties of the A356 alloys prepared via the conventional DC and DCR R-DC processes are displayed in Table 4. The tensile strength, yield strength, and elongation of the R-DC alloy were 271 MPa, 174 MPa, and 8.9%, respectively, and higher than those of the DC alloy by 19%, 15%, and 107%, respectively. The comparative results of the A356 alloys prepared via the DCR R-DC process and other R-DC processes indicated that the alloy prepared via the DCR R-DC process had better mechanical properties, as displayed in Fig. 19.

Table 4 Tensile properties of A356 alloy prepared via DC and DCR R-DC processes

Fig. 19 Comparison of mechanical properties for A356 alloys prepared via DCR R-DC technique and other R-DC processes

4 Discussion

4.1 Mechanism of semisolid slurry preparation via DCR process

As the A356 alloy melt is poured into the DCR, the DCR quickly absorbs the superheat and generates a supercooling temperature boundary layer between the DCR surface and the melt. The heterogeneous nucleation work reduces owing to the good wettability between the graphite wall and the melt. Subsequently, the heterogeneous nuclei grow quickly and vertically on the DCR surface. The solute segregation restricts the growth of crystal roots and forms a necking after the nucleation of the mold wall [19]. In addition, LEE et al [20] believed that solute atoms on the countercurrent side of the grain are taken away by liquid when chilled crystals nucleated on the mold walls growing in the liquid flow, resulting in the lower concentration; meanwhile, the adsorption of solute atoms on the downstream side increases the concentration. The shape of the interface gradually develops into a cellular shape and grows preferentially along the countercurrent direction until the adjacent grains connect to form a solidified shell. However, the chance of the liquid flow infiltrating into the root is reduced when the density of the mold wall chilled crystals is increased. Subsequently, the solute mass of the liquid flow transfer is reduced, and the grain growth is slowed down, resulting in necking.

Figure 20 simulates the shear rate of the A356 alloy melt flowing in DCR. When the melt was flowed into the DCR, the shear rate at the inner wall of each runner was the largest, which was conducive to scour down the necked crystal nuclei growing on the inner wall of the runner and dissociated in the melt in the form of secondary nuclei. This condition could avoid the grains that were connected with each other to produce solidification shell. In addition, Fig. 21 shows the cross-sectional velocity vector diagram of the melt flowing into the DCR. The velocity vectors of the melt at the upper and lower parts of the DCR are opposite to one another, as shown in Figs. 21(a) and (b), and the change in the velocity vector is conducive to the uniformity of the melt temperature and composition fields [15,21]. At the confluence of the DCR, the melt converges and collides to produce convection, as shown in Fig. 21(c). This phenomenon further promotes the uniformity of the melt temperature and composition fields while promoting the spallation of the nuclei and suppressing the generation of dendrites.

Fig. 20 Simulation of shear rate of A356 alloy melt flowing in DCR

Fig. 21 Simulation of cross-sectional velocity vector of A356 alloy melt flow during preparation of semisolid slurry via DCR process

It can be found from Figs. 5, 8 and 11 that the chilling effect of the DCR causes the melt poured into the DCR to quickly reach the overall supercooling state. The temperature gradient inside the melt is small, which constitutes the conditions for burst heterogeneous nucleation. In addition, the melt is poured into the DCR within a few seconds. It will inevitably produce a large number of chilling crystals inside the flowing melt that can break away from the wall surface to form free crystals. They act as secondary nuclei that induce grain proliferation and provide the conditions for refining the semisolid microstructures.

When the slurry prepared via the DCR flows into the collecting crucible, the velocity vector of the slurry in the crucible is shown in Fig. 22. It can be observed that the slurry has a downward axial movement after flowing into the crucible due to the action of the gravity field. After the slurry comes in contact with the crucible wall, it moves upward along the wall due to the reaction force, and a convection is formed to promote the further spheroidization of the α1-Al. This condition explains why the α1-Al in the slurry within the crucible mainly consists of uniformly distributed nearly spherical and spherical particles. In summary, for the slurry prepared via the DCR, the melt is simultaneously subjected to the rapid chilling and convection mixing of multiple runners. This phenomenon fundamentally changes the physical fields of the melt during conventional solidification, and the high quality slurry can be quickly prepared.

Fig. 22 Cross-sectional velocity vector of semisolid slurry flowing into collecting crucible

4.2 Mechanical properties enhancement of DCR R-DC alloy

Fig. 23 Tensile fracture morphologies of A356 aluminum alloys prepared via conventional DC (a, b) and DCR R-DC (c, d) processes

The tensile fractures of the conventional DC A356 alloy are shown in Figs. 23(a) and (b). Many casting defects, such as gas pores and shrinkage porosities, appear in the fracture. These defects can accelerate the fracture process when the specimen is stretched [22]. In non-defective areas, cleavage planes, tearing edges, secondary cracks, and a few dimples can be observed in the fracture of the DC alloy, indicating that the fracture mode of the DC alloy has a quasi-cleavage fracture. As shown in Figs. 23(c) and (d), many tearing edges and dimples, as well as a few cleavage planes, appear in the tensile fracture of the R-DC alloy. Therefore, the fracture mode of the R-DC alloy is in a mixed fracture mode, in which quasi-cleavage and local plastic fractures are included. In addition, compared with the dimples in the fracture of the DC alloy, the dimples in the fracture of the R-DC alloy are more in number, smaller in size, and larger in depth, which supports the higher strength and plasticity of the R-DC alloy.

The maximum stress (σmax) experienced by the tensile specimen during loading is expressed as [23]

(4)

(4)

where α is the stress concentration coefficient of the pore, S0 is the cross-sectional area of the specimen, F is the tensile force, and μ is the fraction of the pore area. Compared with the DC alloy, the DCR R-DC alloys have an extremely small amount of internal pore defects, and μ is almost 0. Hence, the σmax experienced by the R-DC alloy during stretching is smaller, which is beneficial to improving their tensile properties. In addition, the microstructure of the R-DC alloy is fine and distributed evenly, which can also improve their tensile properties [24,25].

The DCR R-DC A356 alloy had better mechanical properties than the A356 alloy prepared via the other processes (Fig. 19). The main reasons that explain this result can be summarized as follows: (1) Multiple runners were employed in DCR to enhance the chilling effect and promote nucleation, and the α1-Al in the prepared was considerably finer and rounder; (2) The DCR process does not adopt mechanical stirring and thus can greatly avoid gas entrapment during slurry preparation; (3) Compared with the other processes, DCR took a shorter time (3 to 5 s) to prepare the slurry, thereby effectively inhibiting the growth of α1-Al, as well as the oxidation and gettering of the slurry, while substantially improving production efficiency.

5 Conclusions

(1) The suitable pouring temperature, number of runners, and tilt angle of the A356 alloy semisolid slurry prepared via the DCR process were 660 °C, 4, and 45°, respectively. High-quality slurry could be prepared under these conditions. The volume fraction, average size, and shape factor of α1-Al were 36%, 49 μm, and 0.81, respectively.

(2) The DCR process utilizes the chilling of multiple runners to increase the nucleation area and promote melt nucleation. The self-stirring action generated during the flow of the melt in the DCR produces a large number of free primary crystal nuclei inside the melt.

(3) The melt has opposite velocity vectors at the upper and lower parts of DCR. The intersection and collision occur at the confluence to produce convection, which is conducive to accelerating the uniformity of the melt temperature field and composition field, the exfoliation of the crystal nuclei, and the spherical growth of α1-Al.

(4) Compared with the A356 alloys produced via the conventional DC and other R-DC processes, the DCR R-DC A356 alloy not only had finer and rounder α1-Al particles, fewer air pores, and less shrinkage porosities but also had better tensile properties. The tensile strength, yield strength, and elongation of the DCR R-DC A356 alloy were increased by 19%, 15%, and 107%, respectively, compared with those of the conventional DC alloy.

Acknowledgments

The authors are grateful for the financial supports from the National Natural Science Foundation of China (Nos. 52005034, 52027805), the Beijing Postdoctoral Research Foundation (No. 2021-ZZ-073), the China Postdoctoral Science Foundation Funded Project (2021M691860), the Fundamental Research Funds for the Central Universities (No. FRF-TP-18-043A1), and the Zhuhai Industry-University-Research Cooperation Project (No. ZH22017001200176PWC).

References

[1] OUTMANI I, FOUILLAND-PAILLE L, ISSELIN J, MANSORI M E. Effect of Si, Cu and processing parameters on Al-Si-Cu HPDC castings [J]. Journal of Materials Processing Technology, 2017, 249: 559-569.

[2] HAGHAYEGHI R. Effect of external forces on microstructural evolution and mechanical properties of high pressure die cast AA5754 alloy [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(2): 282-288.

[3] FAN Z, FANG X, JI S. Microstructure and mechanical properties of rheo-diecast (RDC) aluminum alloys [J]. Materials Science and Engineering A, 2005, 412: 298-306.

[4] DONG X X, ZHU X Z, JI S X. Effect of super vacuum assisted high pressure die casting on the repeatability of mechanical properties of Al-Si-Mg-Mn die-cast alloys [J]. Journal of Materials Processing Technology, 2019, 266: 105-113.

[5] LAI Hua-qing, XU Xiang, FAN Hong-xun. Pore-free die casting and its application [J]. Metal Forming Technology, 2004, 22(2): 12-14. (in Chinese)

[6] QI Ming-fan, KANG Yong-lin, ZHU Guo-ming. Microstructure and properties of rheo-HPDC Al-8Si alloy prepared by air-cooled stirring rod process [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(9): 1939-1946.

[7] HU Zhao-hua, PENG Xiang, WU Guo-hua, CHENG Da-qiang, LIU Wen-cai, ZHANG Liang, DING Wen-jiang. Microstructure evolution and mechanical properties of rheo-processed ADC12 alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(12): 3070-3080.

[8] MAHATHANINWONGA N, PLOOKPHOL T, WANNASINA J, WISUTMETHANGOON S. T6 heat treatment of rheocasting 7075 Al alloy [J]. Materials Science and Engineering A, 2012, 532: 91-99.

[9] GUAN R G, ZHAO Z Y, LEE C S, ZHANG Q S, LIU C M. Effect of wavelike sloping plate rheocasting on microstructures of hypereutectic Al-18pctSi-5pctFe alloys [J]. Metallurgical and Materials Transactions B, 2012, 43: 337-343.

[10] ZHU Wen-zhi, MAO Wei-min, TU Qin. Preparation of semi-solid 7075 aluminum alloy slurry by serpentine pouring channel [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 954-960.

[11] WESSEN M, CAO H P. The RSF technology-a possible breakthrough for semi-solid casting processes [C]//Proceedings of the 3rd International Conference on High Tech Die Casting. Vicenza, Italy: AIM, 2006: 22-28.

[12] QI M F, KANG Y L, LI J Y, Shang B Y. Improvement in mechanical, thermal conductivity and corrosion performances of a new high-thermally conductive Al-Si-Fe alloy through a novel R-HPDC process [J]. Journal of Materials Processing Technology, 2020, 279: 116586.

[13] DOUTRE D, HAY G, WALES P, GABATHULER P. SEED: a new process for semi-solid forming [J]. Canadian Metallurgical Quarterly, 2004, 43(2): 265-272.

[14] QI M F, KANG Y L, ZHOU B, LIAO W N, ZHU G M, LI Y D, LI W R. A forced convection stirring process for Rheo-HPDC aluminum and magnesium alloys [J]. Journal of Materials Processing Technology, 2016, 234: 353-367.

[15] LIU Zhi-yong, MAO Wei-min, WANG Wei-pan, ZHENG Zhi-kai. Preparation of semi-solid A380 aluminum alloy slurry by serpentine channel [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1419-1426.

[16] WU S S, LV S L, AN P, NAKAE H. Microstructure and property of rheocasting aluminum alloy made with indirect ultrasonic vibration process [J]. Materials Letters, 2012, 73: 150-153.

[17] THANABUMRUNGKUL S, JANUDOM S, BURAPA R, DULYAPRAPHANT P, WANNASIN J. Industrial development of gas induced semi-solid process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(3): 1016-1021.

[18] LI Lu, ZHOU Rong-feng, CEN Qi-hong, LI Zhen-hua, JIANG Ye-hua, ZHOU Rong. Die casting semi-solid ZL101 alloy prepared by inclined slope cooling-transferring method and its properties [J]. Special Casting & Nonferrous Alloys, 2011, 31(10): 907-910. (in Chinese)

[19] LI Yuan-dong, XING Bo, MA Ying, HAO Yuan. Effect of cooling channel on AM60 Mg alloy semi solid slurry prepared by self- inoculation method (III) [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 22-32. (in Chinese)

[20] LEE S Y, LEE S M, HONG C P. Numerical modeling of deflected columnar dendritic grain solidified in a flowing melt and its experimental verification [J]. ISIJ International, 2000, 40(1): 48-57.

[21] LIU Zhi-yong, MAO Wei-min, WANG Wei-pan, ZHENG Zhi-kai. Microstructure evolution of A380 aluminum alloy semi-solid slurry during solidification [J]. The Chinese Journal of Nonferrous Metals, 2015, 25(5): 1153-1162. (in Chinese)

[22] QI M F, KANG Y L, XU Y Z, ZHUMABIEKE W, LI J Y. A novel rheological high pressure die-casting process for preparing large thin-walled Al-Si-Fe-Mg-Sr alloy with high heat conductivity, high plasticity and medium strength [J]. Materials Science and Engineering A, 2020, 776: 139040.

[23] ZUO L J, YE B, FENG J, KONG X Y, JIANG H Y, DING W J. Microstructure, tensile properties and creep behavior of Al-12Si-3.5Cu-2Ni-0.8Mg alloy produced by different casting technologies [J]. Journal of Materials Science & Technology, 2018, 34: 1222-1228.

[24] WANG Yong-fei, ZHAO Sheng-dun, ZHANG Chen-yang. Microstructures and mechanical properties of semi-solid squeeze casting ZL104 connecting rod [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(2): 235-243.

[25] SAFFARI S, AKHLAGHI F. Microstructure and mechanical properties of Al-Mg2Si composite fabricated in-situ by vibrating cooling slope [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(4): 604-612.

祁明凡1,康永林1,徐玉昭1,李静媛1,刘爱森2

1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 森特士兴集团股份有限公司,北京 100176

摘 要:将新开发的分流汇合浇道(DCR)半固态浆料制备工艺与压铸技术结合,实现A356铝合金流变压铸成形。结合数值模拟与实验,探讨DCR工艺制备半固态浆料机理;研究DCR流变压铸和传统压铸A356铝合金的显微组织和力学性能。结果表明,DCR工艺可以制备内部含有大量初生α-Al晶粒且其平均尺寸为49 μm、形状因子为0.81的高品质半固态浆料。数值模拟结果表明,DCR工艺制备半固态浆料过程中其独特的流动状态和物理场变化有利于加速熔体温度场和成分场的均匀、晶核剥落和球状长大。和传统压铸相比,DCR流变压铸A356铝合金的抗拉强度、屈服强度和伸长率分别提高了19%、15%和107%。

关键词:半固态浆料;A356铝合金;分流汇合浇道;流变压铸;显微组织;拉伸性能

(Edited by Xiang-qun LI)

Corresponding author: Jing-yuan LI, Tel: +86-10-82738653, E-mail: lijy@ustb.edu.cn

DOI: 10.1016/S1003-6326(21)65623-6

1003-6326/  2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press