Magnetic properties of multi-walled carbon nanotubes encapsulated Fe/Co particles

LI Wei-xue(李维学)1, 2, CUI Yong-fu (崔永福) 1, HAO Yuan(郝 远) 2, CHEN Ti-jun(陈体军) 2,

DAI Jian-feng (戴剑锋) 1, 2, WANG Qing (王 青) 1, 2 , WU Zhong-li(吴中立) 1, LI Yang(李 扬) 1

1. Department of Physics, Lanzhou University of Technology, Lanzhou 730050, China;

2. Gansu Key Laboratory of New Nonferrous Metal Materials, Lanzhou University of Science and Technology, Lanzhou 730050, China

Received 15 July 2007; accepted 10 September 2007

Abstract: The experimental apparatus by self-designed was used, Fe/Co particles encapsulated in multi-walled carbon nanotubes (MWCNTs) were prepared by the method of anodic arc discharging plasma. The products were characterized by transmission election microscopy, Raman spectroscopy and X-ray diffractometry. The magnetic properties of the products were characterized with vibration sample magnetometer. The TEM results show that MWCNTs have little impurity and good particles size, and Fe/Co with high continuity encapsulaties in carbon nanotubes. The saturated magnetization (σs), remanence (σm) and coercivity (Hc) of the sample are 17.30 A/(m·kg), 3.96 A/(m·kg) and 31 521.60 A/m, showing better ferromagnetism compared with the bulk Fe/Co. The optimal conditions in this case are as follows: a helium gas atmosphere of 6.0×104 Pa, an arc current of 70 A, a voltage drop of 24 V, a constant distance of about 2 mm between the anodes and cathode, metallic powder contents of Fe and Co of 15.0% (mass fraction) and 15.0%, respectively, and well cooled electrodes and collector. This process is a convenient and effective that Fe/Co particles can be encapsulated in MWCNTs.

Key words: multi-walled carbon nanotubes; Fe/Co particles; anodic arc; magnetic properties

1 Introduction

Carbon nanotubes[1-2] are attracting much interest due to their potential applications as high-performance nanoscale materials[3-4] and electronic devices[5-6]. More specifically,metal-filled carbon nanotubes may also have a variety of industrial applications[7]. Different methods of synthesis have been attempted and various materials encapsulated have been tested[8], particularly these involving the magnetic or ferromagnetic materials.

The magnetic nanocomposites have potential applications in various areas such as magnetic recording, magnetic data storage devices, toners and inks for xerography, and magnetic resonance imaging. Therefore, the studies on magnetic nanocomposites, especially on magnetic carbon nanotubes (CNTs), are rapidly expanding. Recently, Kozhuharova and his co-workers[9] have synthesized aligned Fe/Co alloy-filled MWCNTs on the silicon substrates via pyrolysis of ferrocene/cobaltocene mixtures. Stoffelbach and his co-workers have decorated MWCNTs with magnetic nanoparticles by adding a solution of positively charged Fe3O4 nanoparticles to the negatively charged MWCNTs. KORNEVA et al[10] have proposed a new method to produce magnetic tubes by filling MWCNTs with ferrofluid. SUN et al[11] have fabricated magnetic carbon nanotube composites by the decomposition of ferrocene on MWCNTs at different temperatures. Various magnetic materials including iron[12], iron oxide, nickel[13], cobalt, Co[14-15], Fe[16], Au[17]and Fe2O4 encapsulated in CNTs have been prepared. However, it is still difficult to uniformly modify CNTs with accessible cavities, which is essential for applying magnetic carbon nanotube composites in cellular delivery systems[18].

At present, MWCNTs are usually filled using post-processing steps which involve opening up and filling through either capillary action or other chemical means. Such additional filling steps are not only inefficient but also additive to the overall production cost. The present investigation focuses on the mechanism of the formation and encapsulation of metallic particles inside the nanotubes. In this paper, the results of the preparation and characterization of Fe/Co encapsulated in MWCNTs by anodic arc discharging plasma method were reported. The magnetic properties of the products were characterized by VSM, the chemical compositions of the samples by this process were characterized by XRD and TEM. The straight MWCNTs encapsulated Fe/Co particles were fabricated, and the results were discussed.

2 Experimental

The schematic diagram of the experimental installation designed for obtaining MWCNTs encapsulated magnetic Fe, Co, and Fe/Co metal nano- particles is presented in Fig.1. The experimental apparatus self-designed and fabricated mainly consists of the stainless steel vacuum chamber, the gas supply device, the DC power supply current source (idle voltage (U) 24 V, continuously adjustable current (I ) in the range of 70 A, DC), the plasma generator with high frequency initiator, the vacuum-pump, the water-cooled collection cylinder, the fixed water-cooled copper anode crucible and plumb moveable tungsten cathode in a vacuum chamber and connected to a power supply. The bulk raw material was coarse-grained electrolytic polycrystalline Fe/Co and graphite (purity 99.9%) to be evaporated was placed on the anode.

Fig.1 Schematic diagram of experimental installation

In the preparation process, the vacuum chamber was pumped to 6.6×10-3 Pa and was then back filled with inert helium (purity 99.99%) to near 6.0×104 Pa. The electric arc in the helium environment is automatically ignited between the graphite anode and the graphite cathode(well cooled), and it is maintained by the current source at the pre-established values U and I. Under helium pressure and electric discharge current (I), the ionized gas was driven from the plasma jet. The bulk metal Fe/Co and graphite anode was heated and melted by the high temperature of the plasma. The melt detached from the metal surface when the plasma jet kinetic energy exceeded the melt superficial energy. The metal atoms diffusing around and colliding with inert gas atoms decreased the germ forming energy, and then the products were formed by collision between the metal atoms[19]. Finally, the reactor was slowly cooled down to room temperature in an He working gas.

To investigate the structure of the samples, the samples were analyzed by Rigaku D/max-Ⅲ X-ray powder diffraction (XRD). The XRD patterns were collected in the diffraction angle range of 0?–60? at room temperature. The scanning rate was 0.005 (?)/s, the step size was 0.02?. The shape of the samples we reexamined by transmission electron microscopy with JEM1200EX. The samples were placed in a vacuum oven to dry at ambient temperature before examining. The magnetic properties of the products were characterized with vibration sample magnetometer (VSM)(LakeShore7304).

3 Results and discussion

3.1 TEM results

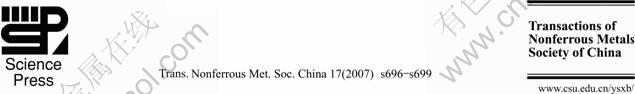

Figs.2(a) and (b) show the representative TEM micrographs of Fe/Co encapsulated MWCNTs prepared

Fig.2 TEM micrographs of MWCNTs before(a) and after(b) HCL oxidation treatment

by this process. The samples are scanned in all zones before the picture is taken. It can be seen from Fig.2 that all of the MWCNTs are fairly homogeneous, the size of the Fe/Co encapsulated MWCNTs ranges from 20 nm to 60 nm, and the median diameter (taken as average diameter) is about 25 nm by calculation.

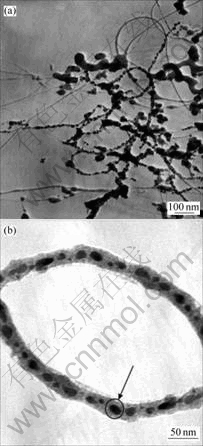

3.2 EDS results

As we know that the encapsulated Fe/Co particles can not be discerned in the MWNTs. Fig.3 shows the samples EDS pattern for the samples, the peak is the metal Fe, Co and Cu, which explains that the carbon nanotubes are filled with Fe, Co. The metallic Cu formed may be because of the floor.

Fig.3 EDS pattern of MWCNTs encapsulated metal particles after HCL oxidation treatment

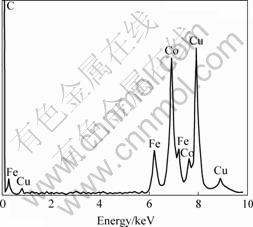

3.3 XRD results

Although TEM may give us direct information of their microstructures, statistically the XRD method can provide us more reliable knowledge about the microstructures of the samples. Fig.4 shows the XRD pattern of the samples. All the peaks with 2θ values of 26.1? and 43? correspond to the (002), (100) planes of the bulk metallic Fe, Co, Cu and carbon nanotubes, respectively. This shows that the physical phases of the sample synthesized in this work have high purity.

3.4 Magnetic properties of Fe/Co encapsulated in MWCNTs

The magnetic properties of the Fe/Co-filled MWCNTs were characterized by VSM at room temperature. Fig.5 shows the magnetic hysteresis loops for samples with Fe/Co encapsulated in MWCNTs, respectively, which are the typical loops of soft magnet.

In order to characterize the macroscopic anisotropy of the sample, which is an average anisotropy of the individual Fe/Co-filled MWCNTs, the magnetic field (H) was applied in two different directions: i.e. H in the filmplane and perpendicular to the MWCNTs. The magnetic hysteresis loops were measured at room temperature, which shows the ferromagnetic behavior of the Fe/Co-filled MWCNTs. The uniform filling of ferromagnetic metals inside the MWCNTs is a difficult task and few researchers have succeeded in obtaining uniform, continuous long metal filling inside MWCNTs. Although a number of papers were published about the deposition of filled CNTs using different methods, reports on the magnetic properties of ferromagnetic metal-filled MWCNTs which are important for potential applications in key areas of nanotechnology, are very limited. LEONHARDT et al[20] have studied the magnetic properties of Fe-filled CNTs deposited by CVD. They have found that the Fe filling inside the CNTs enhances the ferromagnetic properties, compared with the bulk Fe material.

Fig.4 XRD pattern of MWCNTs encapsulated metal particles after HCL oxidation treatment

Fig.5 Hysteresis loops of Fe/Co filled MWCNTs

There are no papers published, to the knowledge of the authors, reporting the magnetic properties of Fe/Co encapsulated in MWCNTs deposited using arc discharging plasma. In this investigation, the uniform filling of Fe/Co inside MWCNTs by arc discharging plasma was obtained. The saturated magnetization (σs), remanence (σm) of the sample are 17.30 A/(m·kg) and 3.96 A/(m·kg), respectively. The coercivity (Hc) is 31 521.60 A/m, which is higher than that of bulk Fe (around 20-100 A/m). The high magnetization and protection against the oxidation is the advantage of using Fe/Co as filling material in the MWCNTs.

3.5 Theory of MWCNTs encapsulated Fe/Co by anode-arc discharge method

The schematic diagram of CNTs encapsulated magnetic Fe, Co metal nanoparticles is presented in Fig.6. The magnetic field comes into being when DC power switch on between two poles. And the compound catenary of graphite is produced because of anode-arc. The piece of graphite crinkles in the magnetic field because of the electric power and magnetic force, Fe, Co metal nanoparticles is encapsulated in CNTS for magnetic shrinkage.

Fig.6 Schematic diagram of hysteresis construction

4 Conclusions

1) The deposition of MWCNTs using the anodic arc discharged plasma approach was carried out. The as-grown MWCNTs are both filled and unfilled with Fe/Co, a ferromagnetic material, which is essential in the growth of MWCNTs as it plays the role of a metallic catalyst.

2) The optimal conditions are as follows: helium gas atmosphere of both 6.0×104 Pa, arc current of 70 A, voltage drop of 24 V, the metallic powder contents (mass fraction) of Fe and Co of 15.0%.

3) The MWCNTs and other particle size distribution of the powders range from 20 to 60 nm, the average particle size is about 25 nm. The coercivity (Hc) is 31 521.60 A/m, which is higher than that of bulk Fe.

References

[1] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature, 1991, 354: 56-58.

[2] SHAO Ming-wang, LI Min, BAN Hui-zhao, NIU Li-ling, WANG Hong, PAN Shi-yan. Synthesis and electrochemical application of carbon nanotubes obtained from hexachloroethane[J]. J Mater Sci, 2007, 42: 6961-6964

[3] KEAR B H, SKANDAN G. Thermal spray processing of nanoscale materials[J]. Nanostruct Mater, 1997, 8: 765-769.

[4] CARLSON C M, RIVKIN T V, PARILLA P A, et al. Large dielectric constant Ba0.4Sr0.6TiO3 thin films for high-performance microwave phase shifters[J]. Appl Phys Lett, 2000, 76: 1920-1922.

[5] AVOURIS P, HERTEL T, MARTEL R, et al. Carbon nanotubes: nanomechanics, manipulation, and electronic devices[J]. Applied Surface Science, 1999, 141: 201-209.

[6] COLLINS PG, BRADLEY K, ISHIGAMI M, et al. Extreme oxygen sensitivity of electronic properties of carbon nanotubes[J]. Science, 2000, 287: 1801-1804.

[7] MING C, CHAO H, LIN H, CHANG H L, et al. Growth of the large area horizontally-aligned carbon nanotubes by ECR-CVD[J]. Thin Solid Films, 2002, 420: 225-229

[8] ZHANG Y, GAO XP, HU H, et al. Electrochemical performance of carbon nanotubes filled with Fe2O3 as anode materials for Li-ion batteries[J]. Chinese Journal of Inorganic Chemistry, 2004, 20: 1013-1017.

[9] KOZHUHAROVA R, RITSCHEL M, ELEFANT D, et al. Well-aligned Co-filled carbon nanotubes: preparation and magnetic properties[J]. Applied Surface Science, 2004, 238: 355-359.

[10] KORNEVA G, YE H H, GOGOTSI Y, HALVERSON D, FRIEDMAN G, BRADLEY J G, et al. Carbon nanotubes loaded with magnetic particles[J]. Nano Lett, 2005, 5: 879-884.

[11] SUN Yan-yi, FEI Jun-jie, WU Kang-bing, HU Sheng-shui. Simultaneous electrochemical determination of xanthine and uric acid at a nanoparticle film electrode[J]. Analytical and Bioanalytical Chemistry, 2003, 375(4): 544-549.

[12] GUPTA A K, CURTIS A S G. Surface modified superparamagnetic nanoparticles for drug delivery: Interaction studies with human fibroblasts in culture[J]. Materials in Medicine, 2004, 15: 493-496

[13] TYAGI P K, SINGH M K, MISRA A, PALNITKAR U, MISRA D S, TITUS E, ALI N, CABRAL G, GRACIO J, ROY M, KULSHRESHTH S K. Preparation of Ni-filled carbon nanotubes for key potential applications in nanotechnology[J]. Thin Solid Films, 2004, 469:127-130.

[14] MA Xi-cheng, CAI Yuan-hua, LUN Ning, AO Qing, LI Shen-li, LI Feng-zhao, WEN Shu-lin. Microstructural features of Co-filled carbon nanotubes[J]. Materials Letters, 2003, 57: 2879-2884.

[15] MA Xi-cheng, CAI Yuan-hua, LI Xia, WEN Shu-lin. Growth and microstructure of Co-filled carbon nanotubes[J]. Mater Sci Eng A, 2003, 357: 308-313.

[16] LIU Bao-yu, WEI Li-wa, DING Qi-min, YAO Jin-lei. Synthesis and magnetic study for Fe-doped carbon nanotubes (CNTs)[J]. Journal of Crystal Growth, 2005, 277: 293-297.

[17] LEE S Y, YAMADA M, MIYAKE M. Synthesis of carbon nanotubes over gold nanoparticle supported catalysts[J]. Carbon, 2005, 43: 2654-2663.

[18] PORTNEY N G, OZKAN M. Nano-oncology: drug delivery, imaging, and sensing[J]. Analytical and Bioanalytical Chemistry, 2006, 384: 620-630.

[19] JOE A, KWAN W. Arc-discharge ion sources for heavy ion fusion[J]. Nuclear Instruments and Methods in Physics Research, 2001, A464: 569-575.

[20] LEONHARDT A, RITSCHEL M, KOZHUHAROVA R, GRAFF A, MUHL T, HUHLE R, MONCH I, ELEFANT D, SCHNEIDER C M. Synthesis and properties of filled carbon nanotubes[J]. Diamond Relat Mater, 2003, 12: 790.

(Edited by LONG Huai-zhong)

Foundation item: Project (ZS-011-A25-007) supported by the Natural Science Foundation of Gansu province, China

Corresponding author: LI Wei-xue; Tel: +86-931-3327289; E-mail: lwx@lut.cn