DOI: 10.11817/j.ysxb.1004.0609.2020-35925

Ta-W涂层/钛合金体系大气气氛脉冲激光烧蚀行为

彭小敏1,周 凡1,高平平1,王建明1,朱耿立1,彭华凤1,夏长清2

(1. 湖南工程学院 机械工程学院,湘潭 411101;

2. 中南大学 材料科学与工程学院,长沙 410083)

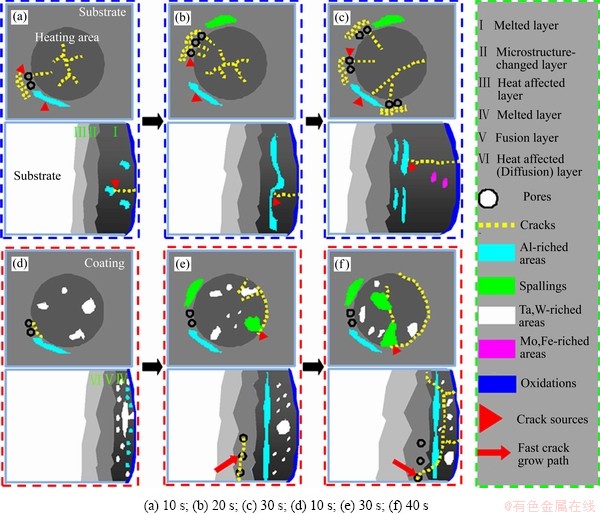

摘 要:采用电弧离子镀(AIP)在Ti-6.48Al-0.99Mo-0.91Fe(质量分数,%) 钛合金表面制备Ta-10W(质量分数,%)涂层。通过脉冲激光加热试验模拟火药气体烧蚀工况,采用有限元温度场数值模拟、X射线衍射分析 (XRD)、扫描电镜(SEM)与能谱(EDS)分析等方法,研究Ta-W涂层/钛合金体系大气气氛循环热加载烧蚀行为。结果表明:脉冲激光加热过程中,高熔点、高热导率(相比纯钛)Ta-W涂层吸收、富集热量对钛合金基体具有热障保护作用,经10~40 s加热,Ta-W涂层使加热区熔透深度从无涂层基体的190~250 μm明显减少至125~180 μm,非加热区平均温度从无涂层基体的350~900 ℃大幅降低至250~500 ℃。由于加热区边缘温度低、温差大、熔体流动性差,利于孔洞及低熔点Al元素富集区的形成,在循环热应力作用下,该区域易成为表面横向和纵向裂纹策源地。钛合金基体加热后熔化层成分偏析严重,形成富Al带、富Mo和Fe区,在循环热应力作用下,富Al带成为截面横向裂纹的策源地;Ta-W涂层试样加热后形成熔化层、熔合层、扩散层组成的微观组织,热时间延长而尺寸逐渐变小的Ta-W涂层颗粒散布于熔化层导致涂层元素富集于此而起到持续保护作用。由于涂层与基体元素互扩散在熔合层形成孔洞(带),在循环热应力作用下,孔洞(带)为起源于表面加热区边缘的截面纵向裂纹的扩展提供便捷路径,且随加热时间(热震次数)的增加,裂纹尺寸增大,并可导致富Ta-W元素层的剥落而失效。热熔化及循环热应力为Ta-W涂层/钛合金体系大气气氛脉冲激光烧蚀失效的主要因素。

关键词:Ta-W涂层;钛合金;脉冲激光加热;烧蚀行为;循环热应力

文章编号:1004-0609(2020)-09-2059-16 中图分类号:TB43 文献标志码:A

随着航空航天发动机推重比的不断提高、零部件减重以减少运行成本、武器装备减重以提高其机动性能和攻击精度等应用需求的出现,器件轻量化的需求在上述领域日渐迫切[1]。上述领域部分关键零部件,如燃气轮机叶片、枪炮身管等,往往暴露于高温、富侵蚀气体、含冲刷性高速固体颗粒流、快速热冷热震性烧蚀气氛中。高温钛合金(包括Ti-Al基金属间化合物)以其优异的比强度和良好的高温性能及抗蠕变性能,被认为是极具应用前景的轻型高温结构材料之一[2-3]。但钛合金耐烧蚀、耐磨损性能不佳的特点,限制了其在上述领域的应用[3-4]。

电镀Cr涂层体系已应用于钢基枪炮身管及其它高温压力容器表面,起到防烧蚀、冲刷作用[5]。但电镀Cr层在制备和使用中易产生裂纹,且制备过程产生的六价Cr为高污染性物质[6]。物理气相沉积(PVD)Ta、W、Ta-W等高温涂层被认为是电镀Cr层的理想替代物[4, 7-10]。钢制炮管内表面制备纯Ta层,经实弹靶试表现出优异的耐烧蚀性能[7-8]。纯Ta添加钨(W)元素有望进一步提高Ta涂层的耐烧蚀、冲刷性能,且Ta、W和Ti、Al间无脆性金属间化合物形成而影响涂层/基体体系的寿命[1, 4, 11],Ta-W涂层适合钛及其合金的高温防护。

脉冲激光加热试验可模拟不同气氛(如空气、氩气、氧气、氮气和氢气等)中枪炮发射时膛管表面极短时间内(5~10 ms)高热量输入的热环境特征,可便捷地评估材料耐烧蚀性能和失效机理[12]。SHIN等[13]和DENG等[14]认为脉冲激光加热能较好地模拟涂层循环热加载实际工况。COTE等[15]研究表明,Cr涂层/炮钢材料体系经脉冲激光加热后,可观察到大部分与实际火药气体烧蚀后产生的热破坏特征,能较好地模拟实际工况。

前期研究表明,Ta-W涂层/钛合金体系具备良好的抗热震性能[4]、界面及元素稳定性能[1],但尚未关于Ta基涂层(Ta-W涂层)/钛合金体系应用于实际烧蚀性气氛工况的报道。本文作者利用电弧离子镀在某高温钛合金表面制备了Ta-W涂层,采用脉冲激光加热模拟火药气体烧蚀工况,结合SYSWELD软件温度场数值模拟,研究了Ta-W涂层/钛合金体系大气环境中脉冲激光烧蚀行为及失效机理,为Ta-W涂层在钛合金表面高温防护的应用及材料耐烧蚀性能的评估提供理论指导。

1 实验

1.1 材料及涂层制备

选择由宝钛集团研制的某α+β型高温钛合金挤压棒材作为试样基材(名义成分Ti-6.48Al-0.99Mo-0.91Fe (质量分数,%)),试样加工成尺寸为d 35 mm×3 mm的圆片。采用电弧离子镀(AIP)技术在合金表面沉积Ta-10W(名义成分(质量分数,%))涂层,Ta-W靶材直径为100 mm。基体试样的前期准备及涂层沉积工艺参数可参考文献[1, 4]。将沉积好Ta-10W涂层及未沉积涂层的基体圆片试样切割成10 mm×10 mm×3 mm方片,以便进行后续试验。

1.2 脉冲激光加热

采用武汉楚天激光(集团)股份有限公司生产的JHM-1GXY-500型多功能激光加工机对Ta-W涂层/钛合金体系进行加热以模拟烧蚀性气氛(如火药气体等)的循环热作用。由于传统高温火药推进剂每发加热时间为5 ms,热流量约为1 J/mm2[12],因此,采用200 MW/m2激光功率和5 ms脉冲宽度以模拟每次脉冲加热基体吸收的热流量约为1 J/mm2,加热时间为5 ms。加热光斑直径为3 mm,脉冲频率为5 Hz。加热时间为10、20、30及40 s,对应循环加热次数为50、100、150和200次。期间用天平记录试样质量变化,天平称量精度为0.1 mg。

1.3 脉冲激光加热温度场数值模拟

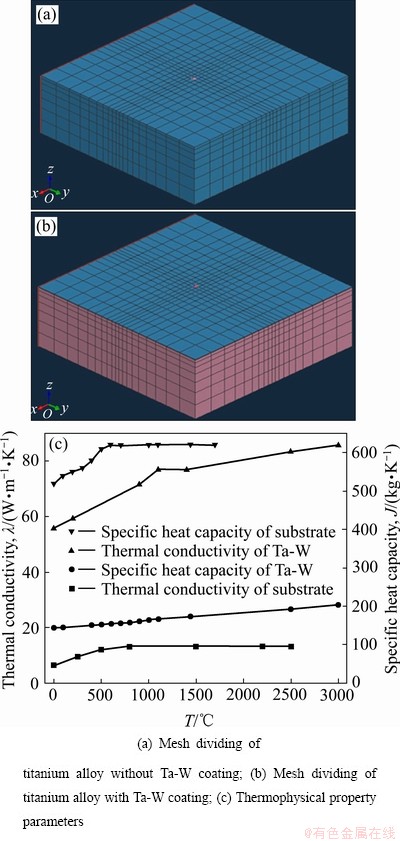

采用SYSWELD软件对脉冲激光加热过程温度场进行模拟。根据脉冲激光加热试样的实际尺寸(10 mm×10 mm×3 mm)建立有限元模型,考虑热源附近存在较大温度梯度,以Bell Curve(钟形曲线)分布形式在长度和宽度方向划分网格,节点中间密两端疏,以线性分布形式在高度方向划分网格,节点上密下疏,如图1(a)和(b)所示。选择SYSWELD激光焊接模块三维高斯热源模型,热源直径为3 mm,脉冲频率为5 Hz,脉冲宽度为5 ms。材料热物理性能参数的选择如图1(c)所示。

图1 SYSWELD有限元分析网格划分及材料热物理参数

Fig. 1 Mesh dividing and thermophysical properties parameters of SYSWELD finite element analysis

1.4 检测分析

采用Rigaku D/Max 2500型X射线衍射仪对试样相组成进行分析,使用Cu 靶Kα1射线,波长0.154056 nm,加速电压36 kV,电流30 mA,扫描速率4 (°)/min,步宽0.02°;采用Sirion200场发射扫描电镜(SEM)观察试样微观形貌,并使用其自带的GENESIS60E能谱仪(EDS)分析试样元素分布情况。

2 结果与讨论

2.1 温度场数值模拟结果

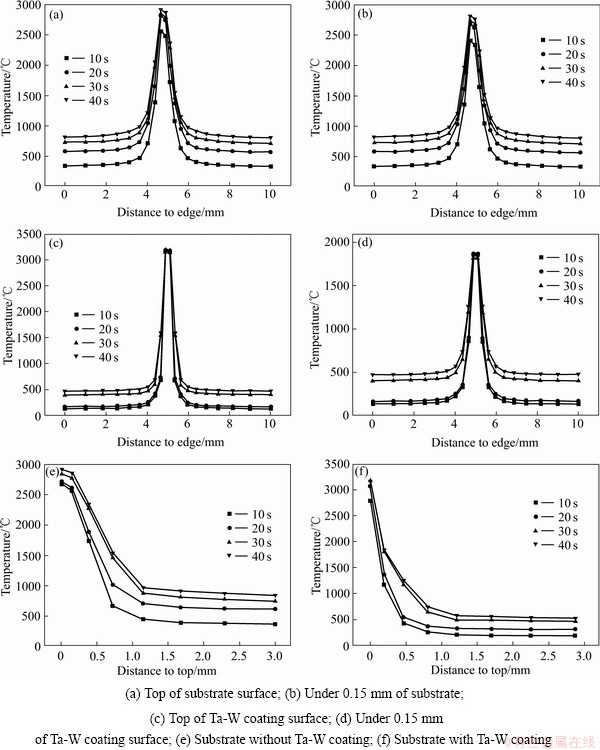

图2 钛合金基体和Ta-W涂层试样脉冲激光加热不同时间后不同位置温度曲线

Fig. 2 Temperate distribution curves of different positions of Ti alloy substrate and Ta-W coating samples after laser pulse heating for different time

图2所示为钛合金基体和Ta-W涂层试样脉冲激光加热温度场不同时间后不同位置曲线。由图2(a)可知,钛合金表面温度符合高斯分布规律,由加热区边缘至中心急剧升高至最大值,高温区集中在约3 mm直径加热区内,加热区外温度维持在较低值。随着加热时间的延长,基体表面加热区中心最高温度、非加热区表面温度均增加,中心最高温度分别为2554.3 ℃(10 s)、2826.7 ℃(20 s)、2843.2 ℃(30 s)、2920.2 ℃(40 s)。由图3(a)~(d)可知,基体非加热区整体平均温度分别为350、580、800和900 ℃。基体试样表面以下150 μm深处温度分布与表面相似,最高温度在2405.9~2816.7 ℃间,相比同一加热时间表面温度低约100~150 ℃,如图2(b)所示。若以纯钛熔点(1670 ℃[2])为参考,加热时间为10 s和20 s时,基体表面以下190 μm深处温度降至基体熔点以下(约1300 ℃),30 s和40 s时表面以下250 μm深处温度降至基体熔点以下,如图2(e)所示。

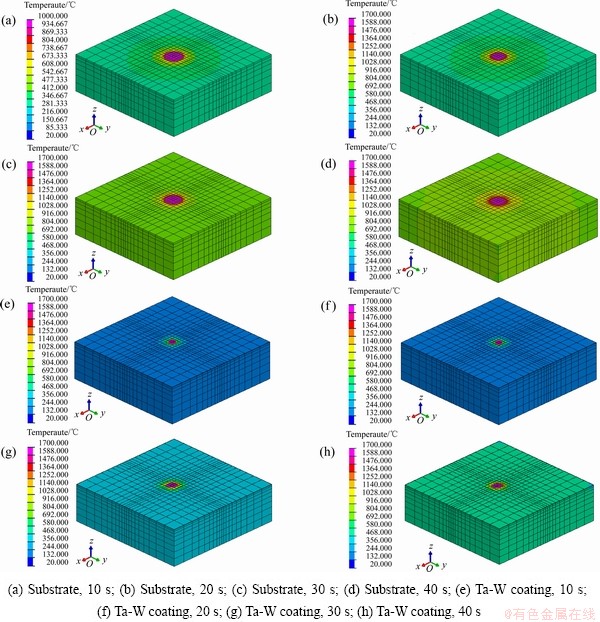

图3 钛合金基体和Ta-W涂层试样不同时间脉冲激光加热温度场有限元分析结果

Fig. 3 SYSWELD finite element analysis results of temperate field after laser pulse heating for different time of Ti alloy substrate and Ta-W coating samples

沉积Ta-W涂层试样表面温度分布与基体类似,如图2(c)所示。但涂层试样表面温度分布有以下特点:1) 最高温度明显高于无涂层基体表面温度,分别为3158.6 ℃(10 s)、3176.5 ℃(20 s)、3179.7 ℃(30 s)、3150.9 ℃(40 s),且随加热时间延长无明显变化;2) 温度分布更集中:基体1000 ℃以上温度集中在加热区中心周围约0.97 mm(10 s)、1.31 mm(20 s)、1.60 mm(30 s),2.02 mm(40 s)内,而涂层试样集中在约0.2 mm(10 s)、0.2 mm(20 s)、0.68 mm(30 s)、0.68 mm(40 s)内;3) 非加热区温度比基体试样明显降低,其整体平均温度约为250 ℃(10 s和20 s,见图3(e)和(f))和500 ℃(30 s和40 s,见图3(g)和(h))。Ta-W涂层可大幅降低基体温度,涂层试样表面以下150 μm深处最高温度在1817.5~1867.3 ℃间,比基体表面最高温度降低1300 ℃左右,如图2(d)所示。因此,涂层试样的激光熔透深度比基体试样的明显减小,加热10 s和20 s时的熔透深度为125 μm,加热30 s和40 s时的熔透深度为180 μm,如图2(f)所示。

Ta-10W合金具备高熔点(3080 ℃)、较高热导率(25 ℃,纯Ta 为54 W/(m·K),纯Ti为 15 W/(m·K))的特性[16],使加热过程中热量富集于涂层,导致涂层表面最高温度升高,热量分布更加集中,从而降低基体温度起到“热障”作用而减小激光熔透深度。

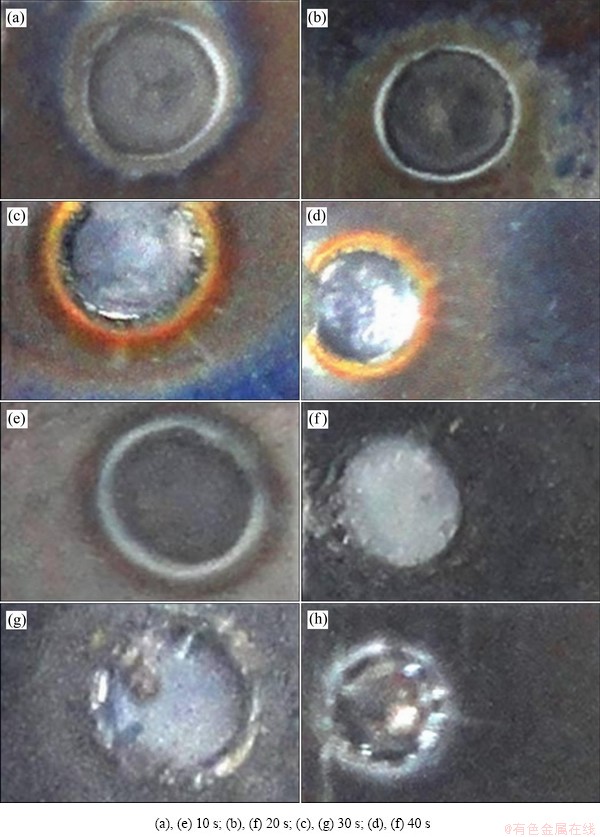

2.2 烧蚀动力学

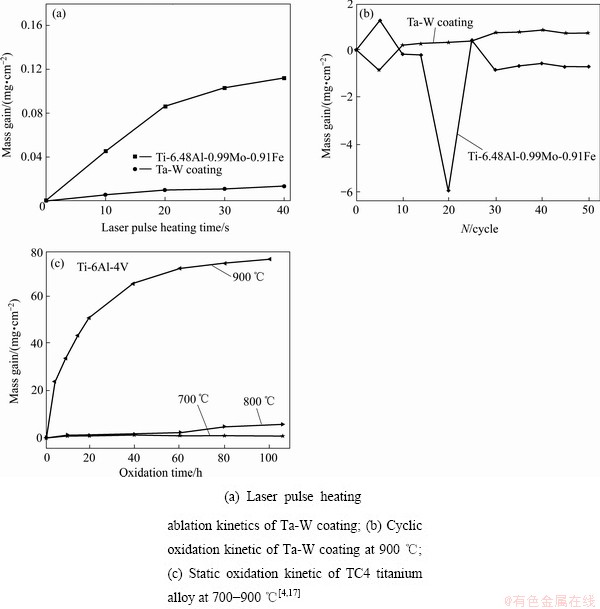

图4所示为钛合金基体和沉积Ta-W涂层试样脉冲激光加热烧蚀动力学曲线(mg/cm2~s)。由图4(a)可看出,加热10 s和20 s时试样的质量增幅呈直线变化;加热30 s和40 s时试样的质量增幅明显减小,进入稳定期。文献表明:基体钛合金在900 ℃大气气氛中循环氧化时,合金表面经15个周期循环后形成厚氧化膜,之后氧化膜严重剥落而质量明显减小[4],如图4(b)所示;TC4钛合金900 ℃静态氧化质量增加,最终增加可达76.2 mg/cm2(见图4(c)[17])。本研究中钛合金表面最高温度可达2920.2 ℃,但最终质量增加仅为0.1121 mg/cm2,且无明显剥落现象(如图5(a)~(d))。由图5(a)~(d)可知:加热30 s后基体加热区内部开始呈金属光泽,加热40 s后金属光泽明显;非加热区随时间的延长,由深蓝色氧化膜向褐色氧化物过渡,仅加热区边缘有轻微剥落。因此,基体在脉冲激光加热时的烧蚀行为主要表现为加热区的熔化和非加热区表面的氧化。涂层试样质量变化趋势与基体相似,但增幅明显小于基体试样,加热40 s时质量增加仅为0.0132 mg/cm2,约为基体的1/10。随加热时间的延长,加热区内Ta-W涂层熔化现象逐渐明显,而非加热区宏观形貌无明显变化,如图5(e)~(h)所示。上述结果说明,由于脉冲激光加热时间极短,不利于氧化过程的进行和厚氧化膜的形成,高温氧化为非主要失效形式。Ta-W涂层在大气气氛脉冲激光加热过程中表现出良好的抗热震性能和对基体的防护作用。

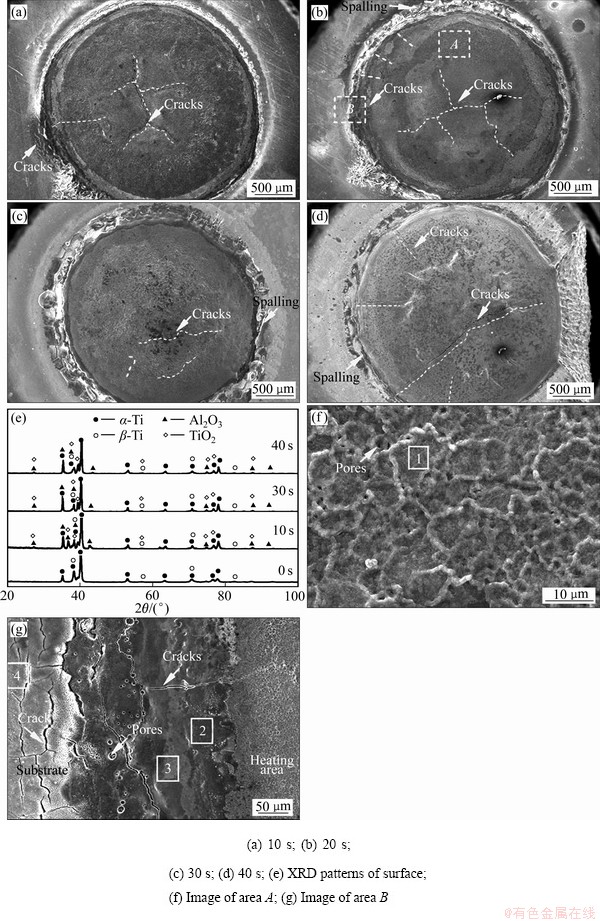

2.3 钛合金基体大气气氛脉冲激光烧蚀显微组织形貌

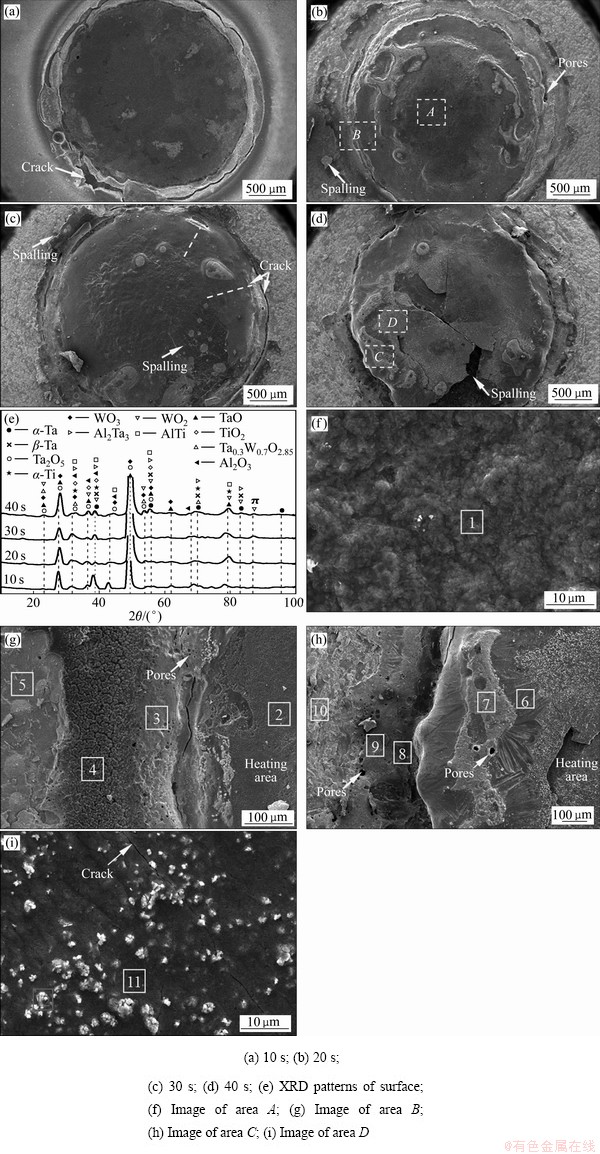

图6所示为钛合金基体脉冲激光加热后表面显微形貌和XRD谱。经10 s脉冲激光加热后,加热区粗糙度增加,呈明显的激光烧蚀(刻蚀)状态,中心形成网状裂纹,出现从加热区边缘向中间延伸的横向裂纹(黄色虚线),而非加热区基体形貌无明显变化;加热区边缘基体侧形成明显纵向裂纹,如图6(a)所示。随加热时间的延长,加热区中心网状裂纹及边缘横向裂纹(尺寸和数量)增加,加热区边缘基体侧出现剥落,如图6(b)、(c)所示。加热40 s时,随着表面熔化的进行,加热区中心呈明显的“凸台”状,加热区边缘形成了几乎贯穿该区域的横向裂纹,如图6(d)所示。由图6(e)的XRD结果可知,Ti-6.48Al-0.99Mo-0.91Fe合金由α-Ti及少量β-Ti组成,经大气气氛加热10~40 s后,合金仍主要由α-Ti及β-Ti相组成,但出现TiO2及Al2O3相,表明形成的TiO2、Al2O3混合氧化膜较薄。EDS结果可进一步说明氧化膜由TiO2、Al2O3混合物组成(表1位置1元素含量),氧化膜呈网状、疏松多孔状(如图6(f)箭头所示)。钛合金表面疏松多孔的混合氧化膜对基体的防护效果非常有限[4],可为烧蚀性气氛的侵蚀提供“快捷”通道。由于加热区边缘温度远低于中心区,低温熔体流动性差,导致低熔点Al元素在此区域富集(表1中2、3、4点Al含量分别高达45.9%、40%、11.1%(质量分数)),同时利于孔洞的形成与聚集,而形成孔洞(带),如图6(g)所示。在后续脉冲激光加热中,在循环热应力作用下,Al元素富集区及孔洞(带)极易成为裂纹的策源地,从而在加热区边缘基体侧形成纵向裂纹(箭头所示)及起源于富铝区和孔洞(带)、由加热区边缘向中间延伸的横向裂纹。

图4 钛合金基体和Ta-W涂层脉冲激光加热烧蚀动力学曲线

Fig. 4 Laser ablation kinetics of substrate and Ta-W coating

图5 钛合金基体和Ta-W涂层脉冲激光加热烧蚀宏观形貌

Fig. 5 Macrostructures of Ti alloy substrate((a)-(d)) and Ta-W coating((e)-(h))

图6 钛合金基体脉冲激光加热表面显微形貌和XRD谱

Fig. 6 Surface microstructures and XRD patterns of titanium alloy after laser pulse heating for different time

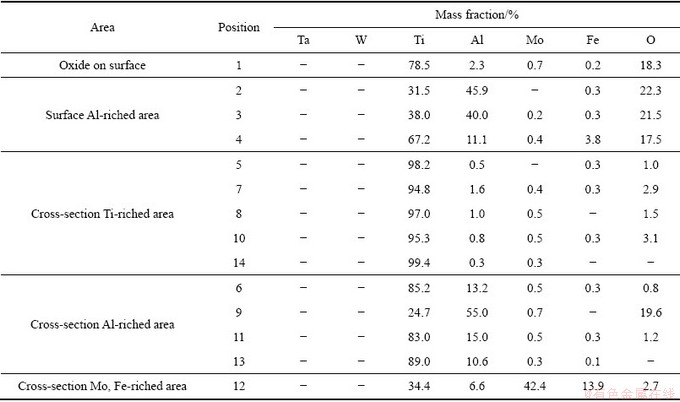

图7所示为钛合金基体脉冲激光加热后截面显微形貌。由图7(a)~(c)可知:脉冲激光加热后在基体表面形成边缘薄、中间厚“柳叶”状加热区域(黄色虚线所示)。在其他条件一定的情况下,激光加热深度主要由激光功率决定[18],因此,加热区厚度随加热时间的延长变化不明显,加热时间为10、20和30 s时其厚度分别约为190、180和220 μm,与温度场模拟结果吻合。加热10 s后,基体表层熔化、凝固后形成“黑色”富铝区(图7(a)箭头所示;表1位置6铝含量达12.1%(质量分数)),随加热时间延长至20 s,富铝区集聚成富铝带(图7(b)箭头所示,表1位置9铝含量达55.0%(质量分数));加热30 s时,富铝带显微组织更明显(图7(c)箭头所示,表1位置11铝含量达45.5%(质量分数))。由循环热应力作用下,低熔点富铝区(带)易成为裂纹的策源地,促进加热区横向裂纹的形成。因此,基体在加热10 s后便开始出现源于富铝区、向加热区扩展的横向裂纹(图7(a),约110 μm)。随加热时间延长至20 s和30 s时,加热区横向裂纹尺寸增加至120 μm(见图7(b))和220 μm(见图7(c))。基体加热区截面呈3层典型组织:Ⅰ层为熔化层,由表层树枝晶和近粗大柱状晶组成;Ⅱ层为显微组织变化区,该区域靠近熔池,温度较高,组织有重结晶长大趋势(如Ⅱ层箭头所示);Ⅲ层为热影响区,其基体组织受循环热影响呈现粗化迹象,如图7(e)所示。熔化层表层由典型树枝晶组成,树枝晶组织在加热10 s时约30 μm厚(见图7(a)红色虚线),在加热20 s时,约39 μm厚,在加热30 s时增至67 μm。由于激光快速加热、冷却,树枝晶组织成分偏析明显,枝晶中先凝固高熔点Ti元素富集(见表1位置5、7、8、10、14,钛含量偏高),晶间低熔点Al元素富集(表1位置6、9、11、13,铝含量明显偏高)。加热过程中可出现富Mo、Fe区域(见图7(h)中“白色”颗粒,表1位置12钼和铁含量分别为42.4%和13.9% (质量分数))。加热后,基体表面O含量为20.0%左右(见表1中1~4位置),内部O含量在4.0%以内(见表1中7~14位置)。因此,由于激光脉冲加热实际作用时间短,不利于氧化的进行,氧化行为集中在基体表面。高温氧化为钛合金基体在大气气氛脉冲激光烧蚀中的非主要失效因素。

图7 钛合金基体脉冲激光加热截面显微形貌

Fig. 7 Cross-section microstructures of titanium alloy after laser pulse heating for different time

表1 图7中钛合金基体脉冲激光加热试样元素分析结果

Table 1 Elements contents of titanium alloy laser pulse heating in Fig. 7

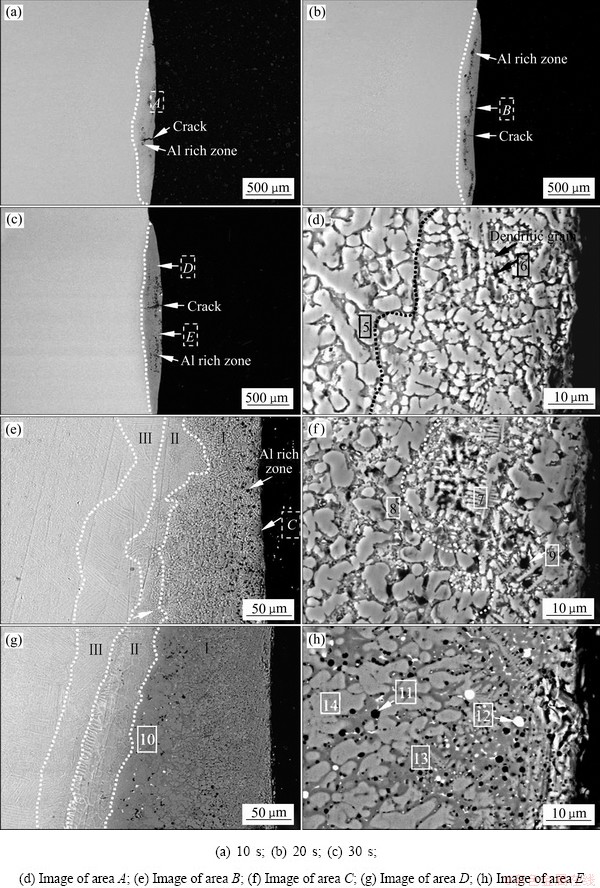

2.4 Ta-W涂层/钛合金体系大气气氛脉冲激光烧蚀显微组织形貌

图8所示为Ta-W涂层/钛合金基体脉冲激光加热表面显微形貌和XRD谱。由图8(a)~(d)可知,与基体试样不同,涂层试样脉冲激光加热初期,加热区氧化膜完整,未出现裂纹。随着加热时间延长至30 s时,由于循环热应力作用时间增加,加热区边缘处氧化膜开始出现裂纹并有轻微剥落迹象,40 s时加热区边缘处氧化膜剥落严重并向中心扩展。由图8(e)和EDS结果(表2中位置1 中Ta、W含量分别为68.6%和7.4% (质量分数))可知,氧化膜主要由β-Ta2O5、WO3、WO2、Ta0.3W0.7O2.85、[TaO]及少量TiO2、Al2O3氧化物组成,氧化膜致密、完整,可有效阻挡O等侵蚀性成分扩散[19]而对基体起到有效防护。随加热过程的进行,涂层试样表面激光烧蚀(刻蚀)形貌逐渐明显,加热区中心呈“凸台”状(见图8(b)、(d)较显著),表面出现大尺寸“未熔”富Ta-W涂层元素组织(见图8(b)~(d));随加热时间的延长,“未熔”涂层组织尺寸变小而呈颗粒状(表2中12位置,Ta含量为71%),分布于富Ti、Al(表2中11位置,Ti、Al含量分别为60.6%和4.7%(质量分数))钛合金基体中(涂层试样加热后表面XRD仍能检测到钛合金基体相α-Ti和β-Ti,如图8(e)所示),如图8(i)所示。与基体试样类似,涂层试样在加热初期,由于加热区与非加热区温差大,在加热区边缘开始形成纵向裂纹,随着加热时间的延长,该区域逐渐出现涂层剥落、孔洞(带)(图8(g)箭头所示)及低熔点Al元素富集区(表2中2、3、4点Al含量分别为10.3%、17.4%、52.1%(质量分数)),但该区域仍以涂层元素为主(表2中6~10点位置Ta含量为56%(质量分数)以上)。纵向裂纹、孔洞、富Al区易成为横向裂纹的策源地,促进表面横向裂纹的形成,如图8(c)所示。涂层试样加热后表面XRD谱仍含涂层α-Ta相,说明涂层仍有效,如图8(e)所示。

图8 Ta-W涂层/钛合金基体脉冲激光加热表面显微形貌和XRD谱

Fig. 8 Surface microstructures and XRD patterns of Ta-W coated titanium alloy after laser pulse heating for different time

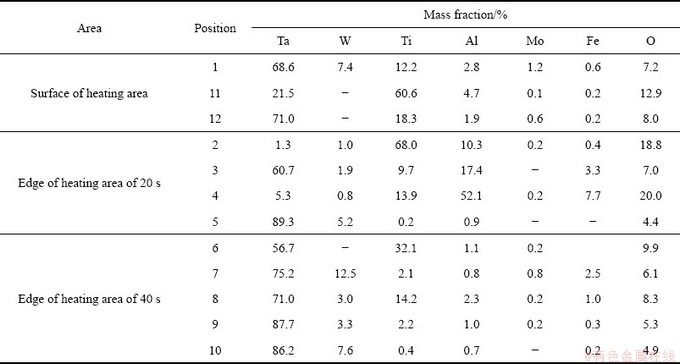

表2 图8中Ta-W涂层/钛合金基体脉冲激光加热试样元素EDS分析结果

Table 2 Elements contents of Ta-W coating after laser pulse heating of positions shown in Fig. 8

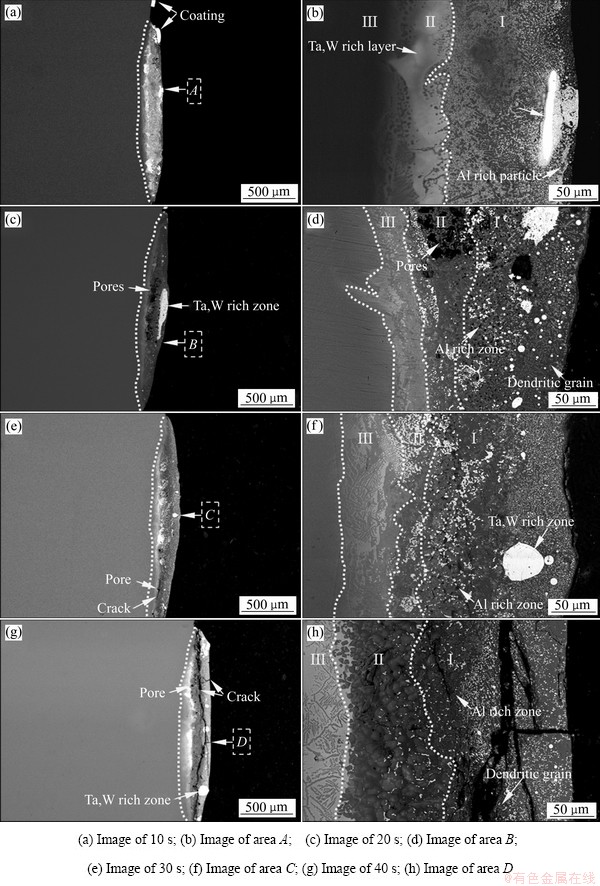

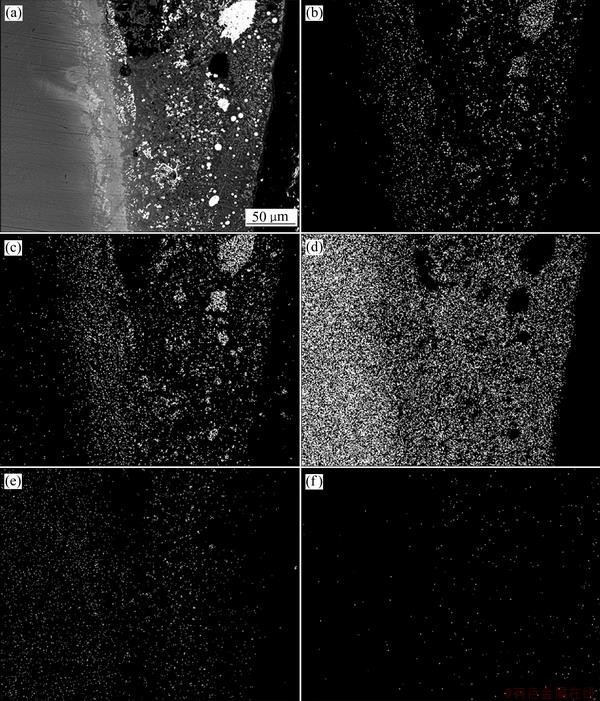

图9所示为Ta-W涂层/钛合金基体脉冲激光加热截面显微形貌。由图9(a)、(c)、(e)和(g)可知,经脉冲激光加热后试样表面形成边缘薄,中间厚“柳叶”状加热区域,厚度分别约为218 μm(10 s)、248 μm(20 s)、227 μm(30 s)和294 μm(40 s)。与基体加热试样对比,涂层试样表面形貌有以下不同:1) 加热初期(10 s、20 s),加热区无明显横向裂纹形成,说明加热区具备良好的抗热震性能;2) 加热区与基体界面处形成涂层与基体元素互扩散层;3) 由于剧烈的元素互扩散,在加热区与基体界面处可形成孔洞(带)(如图9(c)、(e)、(g)箭头所示);4) 孔洞(带)可成为裂纹发展的“便捷”途径,即在试样表面加热区边缘纵向裂纹、孔洞带、富Al区的策源下,促成截面纵向裂纹的形成,并导致加热30 s后开始出现始于加热区边缘,沿孔洞(带)扩展的截面纵向裂纹(如图9(e)箭头所示),加热40 s后纵向裂纹则贯穿整个加热区(见图9(g))。由图9(b)、(d)、(f)和(h)可知,Ta-W涂层试样加热后形成3个典型组织层:Ⅰ层为熔化层,即熔化的涂层与基体材料混合层;Ⅱ层为熔合层(区),即固态基体与熔池交界区,由于该区域温度较高,晶粒呈长大趋势;Ⅲ层为扩散层,由涂层和基体元素经熔合区互扩散而形成。熔化层厚度分别约为145 μm(10 s)、123 μm(20 s)、190 μm(30 s)和171 μm(40 s),与温度场模拟分布大致吻合(加热10 s和20 s时,高于基体熔点区厚度约为125 μm,加热30 s和40 s时约为180 μm),表明高熔点Ta-W涂层自身吸热熔化,可有效缓解脉冲激光对基体的烧蚀。由图10可知,熔化层由Ta-W涂层和基体元素组成,绝大部分Ta、W元素富集于此,并含有“未熔化”的大尺寸涂层颗粒(见图9(b)、(d)、(f)和(h)中“白色”颗粒组织)。随加热时间的延长,涂层颗粒逐渐熔化,尺寸变小,而散布于熔化层(如图9(h))。加热过程中,低熔点、低密度Al元素先熔化、后凝固,在熔化层逐渐形成富Al区(带),如图9(d)和(f)所示“黑色”颗粒状组织。熔合区位于熔池与基体界面处,温度低于基体材料熔点,该区域基体组织呈长大趋势(见图9(h)),元素经该区域互扩散可形成孔洞(带)(见图9(d))。熔合区形成的孔洞(带)在循环热应力作用下可为该处裂纹扩展提供“便捷”途径,从而加速截面纵向裂纹的形成(见图9(e)),且随着循环热应力作用时间的延长,纵向裂纹可扩展至整个截面加热区域(见图8(h))。热影响区为富Ta、W元素扩散层,加热过程中涂层元素向基体方向扩散,若该区域温度高于钛合金α相 β 相转变温度[1],将加速元素的扩散。

β 相转变温度[1],将加速元素的扩散。

2.5 Ta-W涂层/钛合金体系大气气氛脉冲激光烧蚀行为

Ta-W合金的高熔点(3080 ℃)、较高热传导率(54 W/(m·K),对比纯钛热导率15 W/(m·K))的特性[16],使涂层在加热过程中吸收、富集热量,起到“热障”作用而保护基体。因此,由温度场有限元分析结果可知,在加热过程中,涂层试样的表面最高温度高于无涂层基体的,但涂层试样的温度分布更集中,其非加热区平均温度比无涂层基体试样的大幅降低(加热 40 s时,非加热区整体温度最高可降低400 ℃),熔透深度从无涂层基体的约190~250 μm减小至涂层试样的125~180 μm。

图9 Ta-W涂层/钛合金基体激光脉冲加热截面显微形貌

Fig. 9 Cross-section microstructures of Ta-W coated titanium alloy after laser pulse heating

图10 Ta-W涂层/钛合金基体脉冲激光加热截面显微形貌及元素分布

Fig. 10 Cross-section microstructure (a) and element section-distributions of Ta (b), W (c), Ti (d), Al (e) and O (f) after 20 s laser pulse heating

虽然钛合金基体脉冲激光加热后,表面将形成保护作用欠佳的网状、疏松多孔的TiO2、Al2O3混合氧化膜,但由于加热时间短、升温和降温速度快,不利于O的扩散及氧化的进行,因此氧化仅限于试样表面,高温氧化失效为基体脉冲激光加热烧蚀的非主要失效因素。加热区边缘温度相对较低,熔体流动性差,而易在基体侧形成富Al区和孔洞(带)。由于加热区边缘温度差大,基体侧在降温过程中承受较大的拉应力,形成纵向裂纹,如图6(g)所示。富Al区和孔洞(带)易成为向加热区中心扩展裂纹的策源地,促成表面横向裂纹的形成,如图6(a)~(d)所示。由于试验激光功率保持不变,基体加热区厚度随加热时间的变化不明显,主要由熔化层、显微组织变化层、热影响层组成。钛合金热导率低、激光能量密度高、快速升降温等因素易造成熔化层过热,利于粗大柱状晶的形成[20]。熔合区靠近熔池而温度较高,其组织有长大、粗化的趋势。熔化层元素偏析现象明显:先凝固的树枝晶富Ti、贫Al,枝晶间富Al并可能聚集成富Al带,甚至可以形成富Mo、Fe组织。在循环热应力作用下,低熔点富Al带可成为裂纹策源地,促成截面横向裂纹(基体表面中心网状裂纹)的形成。加热区裂纹的形成可为侵蚀性气氛提供“快捷”路径[5-6, 12],可预测钛合金基体并不具备直接暴露于热震、侵蚀性气氛中的能力。

经脉冲激光加热后,Ta-W涂层试样表面温度升高,但温度分布更加集中,非加热区温度大幅降低,熔化层厚度明显减小,涂层在加热过程中能起“热障”作用而保护基体材料。涂层试样加热后,表面形成致密、完整氧化膜;氧化膜以富涂层元素氧化物为主,可有效阻挡O向基体扩散,使高温氧化行为受限。涂层试样表面加热区边缘形成的富Al区、孔洞带可成为该区域纵向裂纹的策源地,进而促成该区域纵向裂纹的形成。经加热10~30 s,涂层表现出良好的抗热震性能,加热区表面未形成明显裂纹,但加热40 s后,随着热震次数的增加,起源于表面加热区边缘孔洞带、富Al区的纵向裂纹快速扩展,氧化膜剥落明显。涂层试样加热后截面形成3个区域,即熔化区、熔合区和热影响区。高熔点Ta-W涂层在短时间内加热未完全熔化,形成“未熔化”大尺寸Ta-W涂层颗粒分布于熔化层,但随加热时间的延长,涂层颗粒逐渐熔化变小而散布于熔化层。绝大部分Ta、W涂层元素富集于熔化层,可认为高熔点涂层元素依然可起到防护作用。涂层试样加热后在熔化层易形成富Al区(带)。熔合区基体组织呈长大趋势,在此区域涂层与基体元素互扩散可形成孔洞。虽然Ti和Ta的热膨胀系数相差不大,但富Ta、W元素熔化层与非加热区钛合金基体间温差大,从而导致循环热应力的存在。在上述循环热应力作用下,截面纵向裂纹可起源于涂层试样表面加热区边缘的富Al区、孔洞带及表面纵向裂纹,并沿熔合区孔洞快速扩展并可导致试样表层部分剥落。

Ta-W涂层/钛合金体系大气环境脉冲激光加热烧蚀行为如图11所示。

3 结论

1) 随脉冲激光加热时间从10 s增加至40 s,钛合金表面最高温度在从2554.3 ℃增加至2920.2 ℃,非加热区温度从350 ℃增加至900 ℃,基体熔透深度约为190~250 μm;Ta-W涂层表面最高温度虽升至3150 ℃左右,但非加热区温度却大幅降低至250~ 500 ℃,熔透深度明显减少至125~180 μm,高熔点Ta-W涂层具备 “热障”作用保护作用。

2) 大气环境脉冲激光加热后,钛合金基体表面形成疏松多孔的网状TiO2和Al2O3混合氧化膜,而Ta-W涂层试样形成致密、完整的以β-Ta2O5等氧化物为主的富Ta、W氧化膜。由于累计加热时间短,基体及涂层试样增重分别仅为0.1121 mg/cm2和0.0132 mg/cm2,无大气静态、热震氧化的明显剥落行为,氧元素仅富集试样表面,高温氧化非主要失效因素。

图11 Ta-W涂层/钛合金基体体系脉冲激光加热烧蚀示意图

Fig. 11 Schematic diagram of ablation behavior under pulse laser heating of titanium alloy((a)-(c)) and Ta-W coating((d)-(f)) for different time

3) Ta-W涂层能对钛合金基体起到有效防护作用,脉冲激光加热熔化层厚度从基体的约190 μm (10 s)、180 μm (20 s)、220μm (30 s) 减少至涂层试样的约145 μm (10 s)、123 μm (20 s)、190 μm (30 s)及171 μm (40 s);循环热应力作用下,试样表面加热区边缘形成的富Al区、孔洞(带)及熔化层形成的富Al带为裂纹策源地,易促成横向和纵向裂纹的形成,并可导试样表层的剥落;绝大部分Ta、W涂层元素以未熔颗粒状富集于熔化层可起到持续防护作用;热熔化、循环热应力为试样脉冲激光烧蚀失效的主要因素。

REFERENCES

[1] 彭小敏, 董丽君, 孙小刚, 吴安如, 夏长清. 纯热暴露下Ta-W涂层/钛合金体系稳定性[J]. 中国有色金属学报, 2019, 29(6): 1198-1209.

PENG Xiao-min, DONG Li-jun, SUN Xiao-gang, WU An-ru, XIA Chang-qing. Stability of Ta-W coating/titanium alloy under pure thermal exposure[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1198-1209.

[2] LEYENS C, PETERS M. Titanium and titanium alloys: Fundamentals and applications[M]. Weinheim: Wiley-VCH, 2006.

[3] 彭超群, 黄伯云, 贺跃辉, 王健农. TiAl基合金的抗氧化性及其改善[J]. 稀有金属材料与工程, 1999, 28(2): 93-96.

PENG Chao-qun, HUANG Bai-yun, HE Yue-hui, WANG Jian-nong. Oxidation resistance and its improvement of the Ti-Al based alloys[J]. Rare Metal Materials and Engineering, 1999, 28(2): 93-96.

[4] 彭小敏, 夏长清, 吴安如, 董丽君, 李东锋, 谭季秋. 钛合金表面Ta-W涂层的制备及循环氧化行为[J]. 中国有色金属学报, 2015, 25(6): 1567-1578.

PENG Xiao-min, XIA Chang-qing, WU An-ru, DONG Li-jun, LI Dong-feng, TAN Ji-qiu. Preparation of Ta-W coating on titanium alloy and its oxidation behavior[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1567-1578.

[5] UNDERWOOD J H, VIGILANTE G N, MULLIGAN C P, TODARO M E. Thermomechanically controlled erosion in army cannons: A review[J]. Journal of Pressure Vessel Technology, Transactions of the ASME, 2006, 128(2): 168-172.

[6] UNDERWOOD J H, VIGILANTE G N, MULLIGAN C P. Review of thermo-mechanical cracking and wear mechanisms in large caliber guns[J]. Wear, 2007, 263(7/12): 1616-1621.

[7] LEE S L, WINDOVER D, AUDINO M. MATSON D W, MCCLANAHAN E D. High-rate sputter deposited tantalum coating on steel for wear and erosion mitigation[J]. Surface Coatings and Technology, 2002, 149(1): 62-69.

[8] LEE S L, CIPOLLO M, WINDOVER D, RICKARD C. Analysis of magnetron-sputtered tantalum coatings versus electrochemically deposited tantalum from molten salt[J]. Surface Coatings and Technology, 1999, 120/121: 44-52.

[9] COLIN J J, ABADIAS G, MICHEL A, JAOUEN C. On the origin of the metastable β-Ta phase stabilization in tantalum sputtered thin films[J]. Acta Materialia, 2017, 126: 481-493.

[10] NIU Y S, CHEN M H, WANG J L, YANG L X, GUO C, ZHU S L, WANG F H. Preparation and thermal shock performance of thick α-Ta coatings by direct current magnetron sputtering (DCMS)[J]. Surface Coatings and Technology, 2017, 321: 19-25.

[11] 祁小红, 胡昌义, 蔡宏中, 郑 旭, 魏 燕. CVD Ta/W复合材料的力学性能及影响因素[J]. 稀有金属材料与工程, 2016, 45(1): 197-200.

QI Xiao-hong, HU Chang-yi, CAI Hong-zhong, ZHENG Xu, WEI Yan. Mechanical properties of the Ta/W composite prepared by CVD and their influencing factors[J]. Rare Metal Materials and Engineering, 2016, 45(1): 197-201.

[12] COTE P J, TODARO M E, KENDALL G, WITHERELL M. Gun bore erosion mechanisms revisited with laser pulse heating[J]. Surface Coatings and Technology, 2003, 163/164: 478-483.

[13] SHIN H G, JEON S, CHOI Y, SONG J K, LEE H. Degradation behaviour of TiN and TiCNcoatings after laser ablation[J]. Surface Engineering, 2014, 30(2): 142-147.

[14] DENG J, LI S, XING Y, LI Y. Studies on thermal shock resistance of TiN and TiAlN coatings under pulsed laser irradiation[J]. Surface Engineering, 2014, 30(3): 195-203.

[15] COTE P J, KENDALL G, TODARO M E. Laser pulse heating of gun bore coatings[J]. Surface and Coatings Technology, 2001, 146/147: 65-69.

[16] SHABALIN I L. Ultra-high temperature materials Ⅰ[M]. Berlin: Springer-Verlag, 2014.

[17] 彭小敏, 夏长清, 王金惠, 刘莹颖, 刘 娟. TC4 钛合金沉积 NiCrAlY涂层的氧化行为[J]. 中国有色金属学报, 2008, 18(4): 601-607.

PENG Xiao-min, XIA Chang-qing, WANG Jin-hui, LIU Ying-ying, LIU Juan. Oxidation behavior of TC4 titanium alloy with NiCrAlY coating[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 601-607.

[18] YILBAS B S, AL-DWEIK A Y, AL-AQEELI N, AL-QAHTANI H M. Laser Pulse Heating of Surfaces and Thermal Stress Analysis[M]. Berlin: Springer-Verlag, 2014.

[19] CHANELIERE C, AUTRAN J L, DEVINE R A B, BALLAND B. Tantalum pentoxide(Ta2O5) thin films for advanced dielectric applications[J]. Materials Science and Engineering R, 1998, 22: 269-322

[20] 虞鸿江, 范如意, 黄 坚, 潘丽华, 王 勇. TC11高强钛合金激光焊接接头的显微组织与力学性能[J]. 中国有色金属学报, 2015, 25(1): 1-8.

YU Hong- jiang, FAN Ru- yi, HUANG Jian, PAN Li -hua, WANG Yong. Microstructure and mechanical properties of high- strength TC11 titanium alloy joints welded by laser beam[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 1-8.

Ablation behavior of Ta-W coating/titanium alloy under laser pulse heating in ambient atmosphere

PENG Xiao-min1, ZHOU Fan1, GAO Ping-ping1, WANG Jian-ming1, ZHU Geng-li1, PENG Hua-feng1, XIA Chang-qing2

(1. School of Mechanical Engineering, Hunan Institute of Engineering, Xiangtan 411101, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Ta-10W (mass fraction, %) coating was deposited on Ti-6.48Al-0.99Mo-0.91Fe (mass fraction, %) titanium alloy by arc ion plating (AIP). Laser pulse heating was used to simulate the heat input and duration in a gun barrel during firing. Finite element analysis of temperate field, XRD, SEM and EDS analysis were carried out to study the behavior of the Ta-W coating/titanium alloy system during laser pulse heating in atmosphere. The results show that Ta-W coating absorbs and gathers heat during heating process for high melting point and thermal conductivity (comparing with the substrate), Ta-W coating can work as thermal barrier to the substrate for absorbing and gathering heat. During 10-40 s heating, the fusion depth obviously decreases from 190-250 μm of the substrate to 125-180 μm of the coating in heated zone and the average temperature sharply drops from 350-900 ℃ of the substrate to 250-500 ℃ in unheated zone after depositing Ta-W coating. Porous and reticular TiO2 and Al2O3 mixed oxides film forms on the substrate surface, but integrated, compact, mainly consisted of β-Ta2O5 and Ta, W-riched oxides film forms on the coated sample. Unlike the static and cyclic oxidation in atmosphere, there are no obviously spalling of the laser pulse heated oxides film for the short heating time. High temperature oxidation is not the main failure factor of laser pulse heated Ta-W coating/titanium alloy system. For lower temperature, large temperature difference and poor fusant fluidity at the edge of heating zone, pores and Al-riched zone, which may be the sources of the transverse and longitudinal cracks under thermal cycling stress, form easily in this zone. Composition segregation is obvious in melted layer of the substrate, which leads to the formation of Al-riched belt and Mo, Fe-riched zone. The Al-riched belt may become the source of the transverse cracks in the cross section under thermal cycling stress. The cross section of Ta-W coated sample is made up of melted layer, fusion layer and inter-diffusion layer after heating. Ta-W coating particles sizes decrease with the heating time increasing, intersperse in the melted layer. Then, the melted layer is rich in Ta and W elements, which maintains the protective effect of the coating during the heating. The pore belts, forming during the inter-diffusion of coating and substrate elements, provid convenient paths for the longitudinal cracks in the cross section under thermal cycling stress. The size of the cracks increases with the heating time, which leads to the spalling of the Ta, W-riched layer. Heat fusing and thermal cycling stress are the main failure factors of laser pulse heated Ta-W coating/titanium alloy system.

Key words: Ta-W coating; titanium alloy; laser pulse heating; ablation behavior; thermal cycling stress

Foundation item: Projects(51671085, 51101054) supported by National Natural Science Foundation of China; Projects (2020JJ5100, 14JJ3132) supported by the Hunan Provincial Natural Science Foundation of China; Project(16B058) supported by the Scientific Research Fund of the Hunan Provincial Education Department, China

Received date: 2020-04-03; Accepted date: 2020-06-18

Corresponding author: PENG Xiao-min; Tel: +86-731-58688521; E-mail: xmpeng@hnie.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51671085,51101054);湖南省自然科学基金资助项目(2020JJ5100,14JJ3132);湖南省教育厅资助科研项目(16B058)

收稿日期:2020-04-03;修订日期:2020-06-18

通信作者:彭小敏,副教授,博士;电话:0731-58688521;E-mail:xmpeng@hnie.edu.cn