Trans. Nonferrous Met. Soc. China 24(2014) 354-359

Superlubricity behaviors of Nitinol 60 alloy under oil lubrication

Qun-feng ZENG, Guang-neng DONG

Key Laboratory of Education Ministry for Modern Design and Rotor-Bearing System, Xi’an Jiaotong University, Xi’an 710049, China

Received 4 January 2013; accepted 25 February 2013

Abstract: The tribological tests were performed using Nitinol 60 alloy pin sliding over GCr15 steel disc in the tribometer system. Four kinds of oils were experimentally investigated as lubrication oils for lubricating Nitinol 60 alloy in the boundary lubrication regime. The experimental results were compared with a reference dry friction. It was found that Nitinol 60 alloy can be lubricated significantly and has shown remarkable lubrication performance. A superlubricity behavior of Nitinol 60 alloy was observed under castor oil lubrication. An ultra-low coefficient of friction of Nitinol 60 alloy about 0.008 between Nitinol 60 alloy and GCr15 steel was obtained under castor oil lubrication condition after a running-in period. Accordingly, the present study is focused on the lubrication behaviors of castor oil as potential lubrication oil for Nitinol 60 alloy. In the presence of castor oil, coefficient of friction is kept at 0.008 at steady state, corresponding to so-called superlubricity regime (when sliding is then approaching pure rolling). The mechanism of superlubricity is attributed to the triboformed OH-terminated surfaces from friction-induced dissociation of castor oil and the boundary lubrication films formed on the contact surface due to high polarity and long chain of castor oil allowing strong interactions with the lubricated surfaces.

Key words: Nitinol 60 alloy; oil lubrication; superlubricity; lubrication films

1 Introduction

TiNi alloy has attracted increasing interests to tribologists due to its high wear resistance, which is ascribed to its pseudoelastic behaviors and hardening phenomena [1,2]. The wear resistance of conventional tribo-materials strongly depends on their mechanical properties such as hardness and toughness. Based on the tribological theory, materials with high hardness exhibit high wear resistance. However, it is quite interesting to find that the hardness of TiNi alloys is so much low compared with commercial wear resistant materials, but TiNi alloys can exhibit excellent wear resistance [3]. The emergence of TiNi alloy as a novel wear-resistant tribomaterial opens new doors to the development of advanced industrial wear-resistant tribomaterials [4,5]. Nitinol 60 alloy, an intermetallic nickel titanium alloy containing 60% nickel and 40% titanium, has been extensively used due to its uniquely properties. It is hard, electrically conductive, highly corrosion resistant, less dense than steel, readily machined prior to final heat treatment, non-galling and non-magnetic, which exhibits excellent useful structural properties and offers a broad combination of properties that make it unique among bearing materials [6]. It is 26% lower in density than steel for weight sensitive applications such as aircraft, satellites and spacecraft. Based on these special characteristics, Nitinol 60 alloy is considered a promising candidate material for oil-lubricated rolling contact applications such as high-speed rolling bearings [7]. Researches indicate that coefficient of friction (COF) of Nitinol 60 alloy, not like traditional titanium alloys such as Ti-6Al-4V with poor tribological materials even under well lubricated conditions by oils and greases [8], is around 0.5 in dry sliding [9]. Clearly, researches will be required to understand the tribological properties of Nitinol 60 alloy under oil lubrication, especially when Nitinol 60 alloy is used as the bearing materials for high-speed rolling bearing. The tribological performance depends mainly on its operating parameters such as load, speed, lubrication type and lubricant oil. Our previous work showed that the lubrication properties of Nitinol 60 alloy can be improved by the appropriate lubrication oil [10]. Unfortunately, the lubrication behaviors of Nitinol 60 alloy are not well understood and more work is needed to be able to fully exploit its lubrication properties for the tribological applications.

The environmental impact of a large amount of lubricants from mineral oils has become an increasingly important issue. In recent years, energy savings have been demanding an urgent need for development in research to discover increasingly advanced lubricants as the alternatives to mineral oils, a non renewable natural source [11,12]. Vegetable oils, the products of solar energy which are recycled materials, have good biodegradability and most of the desirable lubricity properties, such as good contact lubrication and high viscosity index (i.e., the minimum changes in viscosity with temperature). Vegetable oils have been increased interest in extending the use in lubricants [13]. In the present study, the oil lubrication tests were conducted using a pin-on-disc type configuration. Castor oil, turbine oil, seed oil and paraffin oil are chosen as the lubrication oils, respectively. Friction mechanisms responsible for the unique properties of Nitinol 60 alloy are investigated. We aim to investigate the lubrication characteristics of Nitinol 60 alloy under different oils lubrication, including lubrication mechanisms and factors influencing the lubrication behaviors.

2 Experimental

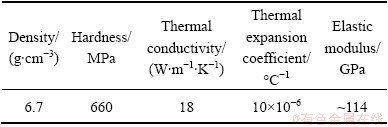

In order to characterize the lubrication behaviors of Nitinol 60 alloy, dry sliding friction and oil lubrication tests were carried out using a multifunction tribometer system (UMT-2) in a pin-on-disc configuration from CETR, respectively. The specimens were securely fastened inside the tribometer chamber. The rotation motion was GCr15 steel disc, which was used as a counterface material. Nitinol 60 alloy was manufactured by Xi’an Saite Company, China. The physical properties of Nitinol 60 alloy are shown in Table 1. Nitinol 60 alloy pin was mounted inside a pin holder which was attached directly to a suspension system, which, in turn, is attached to a load sensor that controls and records forces loaded during the friction tests. The normal load was 30 N and sliding velocity was 0.034 m/s (2 m/min) at room temperature. The environment was strictly controlled to keep humidity ranged from (30±2)% RH in ambient air and room temperature was around (24±1) °C in the laboratory. Load was uniformly applied to the top of the pin sliding the target surface at a constant velocity. The average contact pressure was around 220 MPa, assuming that the pin with 6 mm in diameter and 15 mm in length contacted the steel disc with 30 mm in diameter and 5 mm in thickness directly. Nitinol 60 alloy pin was polished in order to compare all tests under the same initial conditions before the friction tests. The procedure of polishing is described as follows. Nitinol 60 alloy pin as static specimen was fixed sliding over the abrasive paper sticking to the disc as motion specimen in UMT-2 tribometer system. The polishing conditions were the velocity 100 r/min and load 20 N. The surface of Nitinol 60 alloy pin was polished to the same surface roughness of Ra=0.22 μm approximately for each pin specimen. The surface of GCr15 steel disc was polished to surface roughness of Ra=0.006 μm approximately for each disc specimen. Before starting the friction tests, the samples were cleaned using acetone in an ultrasonic bath for 10 min, and the disc surface was pre-lubricated with 10 μL of lubricant followed by bidirectional wiping. After the friction tests, the worn surface was observed by scanning electron microscope (SEM, S-3000N, Japan Hitachi).

Table 1 Physical properties of Nitinol 60 alloy

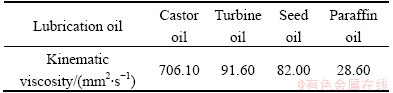

The lubrication behaviors of Nitinol 60 alloy were investigated with four kinds of different oils, namely, castor oil, turbine oil, seed oil and paraffin oil, as shown in Table 2.

Table 2 Kinematic viscosity of lubrication oil

3 Results and discussion

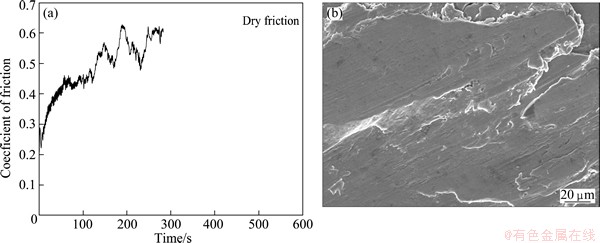

Figure 1 shows COF and SEM images of the worn surface of Nitinol 60 alloy pin sliding against GCr15 steel disc under dry friction. COF of Nitinol 60 alloy is around 0.2 at initial stage and then COF increases to 0.6 with increase of sliding time. It is found from SEM image that big hot stack and wear dent are clearly formed on the worn surfaces and some big wear debris can be found at the edges or on the wear track, which is typical adhere wear. Therefore, it is necessary to lubricate Nitinol 60 alloy with lubrication oil.

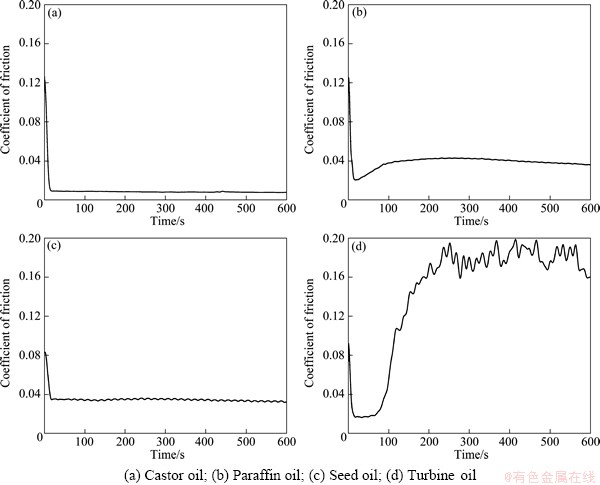

For metals, it is well known that the lubrication behaviors are strongly dependent on the lubrication oil. Figure 2 shows COF of Nitinol 60 alloy under castor oil, turbine oil, seed oil and paraffin oil lubrication, respectively. The tendency of COF varied with sliding time is that COF decreased firstly and then kept this value or increased. It is seen in Fig. 2 that the initial values of COF are high because an effective oil film has not been formed yet and the static friction is effective at the initial stage. After some sliding distances, the decrease of COF was observed. COF was around 0.12 at the initial stage, and then decreased to 0.008 after 15 s and kept it finally at the steady stage under castor oil lubrication. Apparently, castor oil is beneficial to the tribological behaviors of Nitinol 60 alloy under oil lubrication. COF was around 0.13 at the initial stage, and then decreased to 0.02 in a short time and increased to 0.04 under paraffin oil lubrication. COF was around 0.08 at the initial stage, and then decreased to 0.04 and kept this value under seed oil lubrication. COF was around 0.09 at the initial stage, and then decreased to 0.02 and finally increased to 0.2 under turbine oil lubrication. Table 3 shows COF at the initial stage and average COF at the steady stage.

Fig. 1 COF (a) and SEM image (b) of worn surface of Nitinol 60 alloy under dry friction

Fig. 2 COF of Nitinol 60 alloy vs sliding time under different oil lubrications

Table 3 COF of Nitinol 60 alloy under different oil lubrications

Lubricants reduce energy loss and wear and avoid the sticking at the interface of two solid surfaces. Generally, liquid lubricants are expected to form an oil film between the mating surfaces and avoid the direct contact of pin and disc. Low and stable COF is maintained because it results from the lubrication effect of the oil films. COF is low and stable under castor oil lubrication; however, COF is a little high even failure under other oils lubrication. For castor oil lubrication, COF is super low and there is no visible wear scar on the worn surface. This is probably due to the formation of lubricating films on the contact surface. The status of lubrication is boundary lubrication. The boundary lubricating films can reduce the adhesion and ploughing effect. Castor oil has an higher viscosity index than other oils. The higher viscosity index of castor oil can be explained due to the fact that oil contains triglycerides that maintain stronger intermolecular interactions. These factors could contribute to the better lubricating hence could reduce COF. Under seed oil lubrication, the oil film is also formed easily on the contact surface. COF is about 0.04 under paraffin oil with the lowest viscosity lubrication.

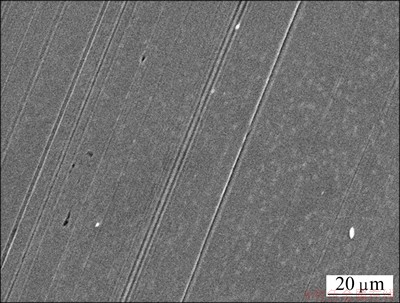

Vegetable oils are investigated as a potential source of environmentally favorable lubricants friendly, due to a combination of biodegradability, renewability and excellent lubrication performance. The triglyceride structure of vegetable oils provides qualities desirable in a lubricant. Vegetable oils are particularly effective as boundary lubricants because the high polarity of the oil allows strong interactions with the lubricated surfaces [14]. Boundary lubrication performance is affected by the attraction of the lubricant molecules to the surface. The antifriction characteristic increases because the depth of the boundary films attached to the metal increases with increasing the length of carbon chain. Polarity and chain length are critical factors for their wear/friction behaviors. The low polarity and short chain length of these volatile compounds mean that they are unlikely to have any impact on lubrication performance. The 12, 14 and 16-carbon chain fatty acids all provide similar improvements of wear resistance. The 18-carbon chain fatty acid provides the greatest improvement out those tested. Most vegetable oils have the triglyceride structure, as tri-esters derived from glycerol and fatty, carboxylic, acids. Differences in the physical and chemical properties of vegetable oils are largely dependent on the degree of unsaturation of the constituent fatty acids. Castor oil is a triglyceride with a very high (~90%) content of an 18-carbon monounsaturated fatty acid, ricinoleic acid, an unusual fatty acid, containing one double bond and a hydroxyl (—OH) group [15]. Castor oil displays the properties quite distinct to all other vegetable oils due to the quirks in structure. Long, polar fatty acid chains of castor oil provide high strength lubricant films [16], which is beneficial for improving the lubrication behaviors of Nitinol 60 alloy. Figure 3 shows SEM image of worn surface of Nitinol 60 alloy after 12 h wear test. There are only few shallow grooves on the worn surface. The reason why COF of Nitinol 60 alloy under castor oil lubrication is ultra low and wear-resistance is high may be that castor oil has long and polar fatty acid chains to form high strength lubricant films. The viscosity of castor oil is high and the oiliness is good in all used oils, therefore, the oil films are formed easily and the load capacity is the highest, which exhibited the best lubrication behaviors. Moreover, the higher viscosity of castor oil ensures that it will provide more stable lubricity during the lubrication tests and helps to flow easily into the contact zone at a minimal quantity. This ensures the reduction of friction between pin and disc.

Fig. 3 SEM image of worn surface of Nitinol 60 alloy pin after 12 h wear test

Superlubricity was already obtained experimentally with some systems. It is the ultimate goal of tribology researchers to realize an ideal friction-free machinery system with zero energy consumption. MATTA et al [17] reported the example of superlubricity for such lubrication regime obtained with DLC films in the presence of polyhydric alcohols containing additives. The proposed mechanism of super-low friction of DLC films under boundary lubrication conditions is attributed to gliding on triboformed OH-terminated surfaces and could also be associated with triboinduced degradation of glycerol, producing a nanometer-thick film containing organic acids and water. The main component of castor oil is 12-hydroxyl oleic acid. —OH group is dissociated under high friction heat and high pressure on the contact surface. The free hydroxyl group in ricinoleic acid is able to interact with polar groups on metal surfaces, thereby giving superior lubricity. The castor oil molecules adsorb on the two contacting OH-terminated surfaces [18]. Super-low friction is attributed to easy sliding on triboformed OH-terminated surface. LI et al [19] found that the achievement of superlubricity is closely related to two important conditions. One is the positively charged surfaces, actually there is OH-terminated surface, induced by the attached hydrogen ions via a protonation reaction. The superlubricity mechanism is mainly attributed to the hydrogen bond effect that forms a hydrated water layer with a low shearing strength, and the dipole-dipole effects that form an interfacial Coulomb repulsion force also make some contributions to low friction between the friction pair under acid solutions lubrication.

Generally, castor oil can make COF of Nitinol 60 alloy remain stable at very low level. The lubricating effect is superior to other lubricating oils. Therefore, castor oil can be used as a potential green lubricant for the improvement of the lubrication behaviors about Nitinol 60 alloy.

4 Conclusions

1) Nitinol 60 alloy has excellent lubrication behaviors under oil lubrications. Especially for castor oil, Nitinol 60 alloy exhibits superlubricity characteristics with the COF value of 0.008.

2) The superlubricity mechanism of Nitinol 60 alloy under castor oil lubrication is attributed to the boundary wear-protective films formed on the contact surface due to high polarity and long chain of castor oil allowing strong interactions with the lubricated surfaces and the triboformed OH-terminated surfaces from friction- induced dissociation of castor oil.

References

[1] WU S, LIN H, YEH C. A comparison of the cavitation erosion resistance of TiNi alloys, SUS304 stainless steel and Ni-based self-fluxing alloy [J]. Wear, 2000, 244(1-2): 85-93.

[2] DONG G, ZHANG J, ZHANG D, YANG H, CHEN W, XIE Y. Tribological performance of molded micro-cratered surface of superelasticity TiNi alloy [J]. Rare Metals and Engineering, 2011, 40(8): 1334-1338.

[3] GAO F, WANG H. Abrasive wear property of laser melting/deposited Ti2Ni/TiNi intermetallic alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 1358-1362.

[4] LI D, LIU R. The mechanism responsible for high wear resistance of pseudo-elastic TiNi alloy—A novel tribo-material [J]. Wear, 1999, 225-229: 777-783.

[5] CHENG X, LI Z, XIANG G. Dry sliding wear behavior of TiNi alloy processed by equal channel angular extrusion [J]. Materials and Design, 2007, 28: 2218-2223.

[6] KHAMEI A, DEHGHANI K. A study on the mechanical behavior and microstructural evolution of Ni60wt%-Ti40wt% (Nitinol 60) intermetallic compound during hot deformation [J]. Materials Chemical and Physics, 2010, 123: 269-277.

[7] CIVJAN S, HUGET E, DESIMON L. Potential applications of certain nickel-titanium [J]. Journal of Dental Research, 1975, 54: 89-96.

[8] BANSAL D, ERYILMAZ L, BLAU P. Surface engineering to improve the durability and lubricity of Ti-6Al-4V alloy [J]. Wear, 2011, 271: 2006-2015.

[9] PEPPER S, DELLA CORTE C. Lubrication of Nitinol 60 [J]. NASA/TM-2010: 215331-01-08.

[10] ZENG Q, ZHAO X, DONG G, WU H. Study on lubrication properties of Nitinol 60 alloy used as high-speed rolling bearing and numerical simulation of flow pattern of oil-air lubrication [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2431-2438.

[11] HAQ I, FAROOQ M, MUHAMMD N. Some studies on the use of vegetable oils as environmentally friendly lubricants [J]. Tribology Online, 2011, 6(5): 230-234.

[12] SHASHIDHARA Y, JAYARAM S. Vegetable oils as a potential cutting fluid—An evolution [J]. Tribology International, 2010, 43: 1073-1081.

[13] NIZAM M, BARI H. The use of vegetable oil in lubricant as base oil: A review [C]//National Conference on Postgraduate Research. Malaysia, 2009: 123-127.

[14] CHUA W, STACHOWIAK G. The growth of thin lubricating films of plant oils [J]. Tribology Letter, 2011, 41: 451-462.

[15] SINGH A. Castor oil-based lubricant reduces smoke emission in two-stroke engines [J]. Industrial Crops and Products, 2011, 33: 287-295.

[16] BERMAN P, NIZRI S, WIESMAN Z. Castor oil biodiesel and its blends as alternative fuel [J]. Biomass and Bioenergy, 2011, 41: 451-462.

[17] MATTA C, POTTUZ L, de BARROS BOUCHET M, MARTIN J, KANO M, ZHANG Q, GODDARD W. Superlubricity and tribochemistry of polyhydric alcohols [J]. Physical Review B, 2008, 78: 085436-01-08.

[18] de BARROS BOUCHET M, MATTA C, MARTIN J, ZHANG Q, GODDARD W, KANO M, YE J. Superlubricity mechanism of diamond-like carbon with glycerol-coupling of experimental and simulation studies [J]. Journal of Physics: Conference Series, 2007, 89: 012003-01-14.

[19] LI J, ZHANG C, MA L, LIU Y, LUO J. Superlubricity achieved with mixtures of acids and glycerol [J]. Langmuir, 2013; 29: 271-275.

TiNi60合金在油润滑下的超滑行为

曾群锋,董光能

西安交通大学 现代设计及转子轴承系统教育部重点实验室,西安 710049

摘 要:研究了4种润滑油(蓖麻油、菜籽油、透平油、石蜡油)对TiNi60合金润滑性能的影响。研究发现,TiNi60合金在可再生蓖麻油润滑下呈现出摩擦因数为0.008的超滑现象。TiNi60合金在干摩擦及4种润滑油下的销-盘摩擦磨损实验研究表明:TiNi60合金在油润滑下具有优异的摩擦学性能,蓖麻油的润滑性能最优,摩擦因数最小,长时间摩擦后摩擦副表面无可测磨损。超滑机理归纳为极性高、碳链长的蓖麻油在TiNi60合金表面形成了边界润滑膜以及摩擦诱发的解离—OH基团形成屏蔽表面有关。

关键词:钛镍60合金;油润滑;超滑;润滑膜

(Edited by Hua YANG)

Foundation item: Project (51305331) supported by the National Natural Science Foundation of China; Project (2012M511993) supported by China Postdoctoral Science Foundation; Project (TPL1202) supported by the Open Fund Program of the State Key Laboratory of Traction Power, Southwest Jiaotong University, China

Corresponding author: Qun-feng ZENG; Tel: +86-29-82667520; E-mail: qzeng@mail.xjtu.edu.cn

DOI: 10.1016/S1003-6326(14)63068-5