Heat treatment and granule medium internal high-pressure forming of AA6061 tube

来源期刊:中南大学学报(英文版)2017年第5期

论文作者:董国疆 毕江 赵长财 毕蒙蒙 杜冰 陈晓华

文章页码:1040 - 1049

Key words:aluminum alloy tube; solution treatment; aging treatment; granule medium; internal high pressure forming

Abstract: The new forming process of AA6061 alloy tube, including solution treatment, granule medium internal high-pressure forming and aging treatment, was developed. The AA6061 alloy tube via heat treatment satisfied the forming requirement, and the granule medium internal high pressure forming method for AA6061 alloy tube was also realized by using convenient implementation with low requirement of equipment and flexible design of product. At a solution temperature of 560℃ and time of 120 min, the elongation of the AA6061 extruded tube increases by 300% and the strength and the hardness dramatically decrease too. Therefore, the AA6061 alloy tube meets the requirement of internal high-pressure forming because of the improvement of formability. The experiments shows that the strength and hardness of AA6061 alloy workpiece recover to that of the as-received alloy at an aging temperature of 180℃ and time of 360 min, and the strength of AA6061 alloy workpiece is equal to the base alloy. The typical parts of convex ring tube, stepped shaft tube and hexagonal tube were successfully produced in lab by using the present forming method. The forming tests show that the maximum expansion ratio (MER) of the AA6061 extruded tube increases by 25.5% and the material properties of formed AA6061 alloy tube reached the performance of as-received alloy.

Cite this article as: BI Jiang, ZHAO Chang-cai, BI Meng-meng, DU Bing, CHEN Xiao-hua, DONG Guo-jiang. Heat treatment and granule medium internal high pressure forming of AA6061 tube [J]. Journal of Central South University, 2017, 24(5): 1040-1049. DOI: 10.1007/s11771-017-3507-8.

J. Cent. South Univ. (2017) 24: 1040-1049

DOI: 10.1007/s11771-017-3507-8

BI Jiang(毕江)1, 2, ZHAO Chang-cai(赵长财)1, BI Meng-meng(毕蒙蒙)1, DU Bing(杜冰)1,

CHEN Xiao-hua(陈晓华)1, DONG Guo-jiang(董国疆)3

1. Key Laboratory of Advanced Forging & Stamping Technology and Science of Ministry of Education of China, Yanshan University, Qinhuangdao 066004, China;

2. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China;

3. College of Vehicles and Energy, Yanshan University, Qinhuangdao 066004, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Abstract: The new forming process of AA6061 alloy tube, including solution treatment, granule medium internal high-pressure forming and aging treatment, was developed. The AA6061 alloy tube via heat treatment satisfied the forming requirement, and the granule medium internal high pressure forming method for AA6061 alloy tube was also realized by using convenient implementation with low requirement of equipment and flexible design of product. At a solution temperature of 560℃ and time of 120 min, the elongation of the AA6061 extruded tube increases by 300% and the strength and the hardness dramatically decrease too. Therefore, the AA6061 alloy tube meets the requirement of internal high-pressure forming because of the improvement of formability. The experiments shows that the strength and hardness of AA6061 alloy workpiece recover to that of the as-received alloy at an aging temperature of 180℃ and time of 360 min, and the strength of AA6061 alloy workpiece is equal to the base alloy. The typical parts of convex ring tube, stepped shaft tube and hexagonal tube were successfully produced in lab by using the present forming method. The forming tests show that the maximum expansion ratio (MER) of the AA6061 extruded tube increases by 25.5% and the material properties of formed AA6061 alloy tube reached the performance of as-received alloy.

Key words: aluminum alloy tube; solution treatment; aging treatment; granule medium; internal high pressure forming

1 Introduction

AA6061 is one of the most widely used Al-Mg-Si alloys [1]. It is applied in extreme conditions such as aerospace, transportation and petrochemical for low density, high impact toughness, excellent machinability and good corrosion resistance [2, 3]. In profile preparation process of AA6061 such as extrusion and rolling, massive nano-precipitates are formed with dispersive distribution in grain inner by heat treatment, making its strength increase [4]. This material can not be formed into complex parts for its high strength and poor plasticity at room temperature. So, the application range of AA6061 is restricted seriously. Therefore, a feasible method for plastic processing in high-strength aluminum alloy like AA6061 is sought, making it a hot issue on current engineering community.

Recently, warm forming processes of high-strength aluminum alloy are the main direction to solve the problem of poor formability at room temperature [5]. HE et al [6] studied the free bulging test carried out at high temperatures to evaluate the formability of AA6061 extruded tube, which reveals that the MER reaches the maximum valve of 86% at 425 °C, namely the MER at high temperature increases significantly. However, low forming efficiency, high requirement of die set and temperature control system are the main problems in warm forming processes of aluminum alloy tube. Meanwhile, the improvement of elongation in most of high-strength aluminum alloy at high temperature is less than 20%, which can not meet the requirement of tube forming [7].

6xxx series aluminum alloy is a kind of high- strength aluminum alloy which can be strengthened by heat treatment. The mechanical properties can be adjusted by solution treatment and aging treatment with the content of precipitates controlled. XIANG et al [8] studied the heat treatment process of AA6061 extruded bars and proved that Mg2Si dissolving, Cr phase and GP zone forming are the main reasons for alloy strengthening. SHANG et al [9] studied the solution and aging treatment of AA6082 extruded bars. Their result showed that the strength decreases and the plastic processing property increases after solution treatment, and the hardness and the strength rise again by subsequent aging treatment. The supersaturated solid solution, which is formed by solution treatment, can decrease strength and increase toughness; Consequently, the formability of AA6061 increases. Meanwhile, the deformation resistance of this material reduces and the requirement of equipment capacity sequentially decreases. Unfortunately, it can not meet the requirement of engineering application because the strength and the hardness of shaped tubes are very low. However, the defects can be made up through aging treatment. The second phase particles precipitate again in grain inner, causing precipitation strengthening. Due to the double effects of work hardening and precipitation strengthening, the strength and the hardness of tube increase remarkably, making the application requirements satisfied. In this respect, ZHOU et al [10] studied the spinning process of AA6061 extruded tube and found that half solution treatment before spinning makes the spinning properties better, subsequent aging treatment after forming makes the strength of spinning product meet the operating requirement of no less than 245 MPa. Therefore, the internal high-pressure forming of 6xxx series aluminum alloy at room temperature can be realized by changing mechanical properties by the method of solution treatment before manufacturing and aging treatment after forming.

In this work, the AA6061 extruded tube is selected as the research object. The formability is characterized by uniaxial test and free bulging test. The corresponding strength is measured by Vickers hardness test. The microstructure is observed by metallurgical test. The typical parts of AA6061 tube are trial-produced by the combination of heat treatment and granule medium internal high pressure forming. This study lays a basis on the preparation of high strength aluminum alloy tube.

2 Experimental

2.1 Material

The experimental material was AA6061 extruded tube produced by a domestic company with 2 mm in thickness and 100 mm in diameter. The alloy sample was tested by ADVANT X’P-381 type X-ray fluorescence spectrometer. The main chemical composition is listed in Table 1.

Table 1 Chemical composition of as-received material

2.2 Experimental methods

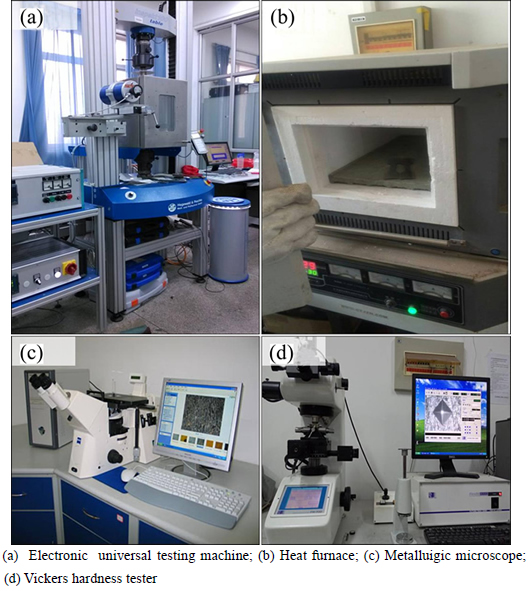

1) Heat treatment process steps. AA6061 tubes were cut into axial tensile specimens, ring tensile specimens and metallographic specimens by line cutting machine. The solution treatment was carried out in SX-G16103 type heat furnace. Solution temperatures (TS) were 530, 540, 550, 560 and 570 °C respectively and holding time (tS) was 30, 60, 90, 120 and 150 min respectively. The specimens were put into furnace at specified temperature. The temperature was fluctuant in this process. Begin timing when the temperature stabilised again. Quenching was carried out in HH-2 type constant temperature water bath pot. In this process, the transfer time was less than 5 s and the water temperature was lower than 25 °C. After solution treatment, all the AA6061 specimens were kept in a freezer. It is very important to avoid the natural aging of the alloy at room temperature.

Following the solution treatment, the specimens were artificially age hardened in DHG-9070A type thermostatic air-blower-driven drying closet and subsequently cooled in air. Aging temperature (TA) was 180 °C. Aging time (tA) was 0.5, 1, 2, 4, 6 and 8 h.

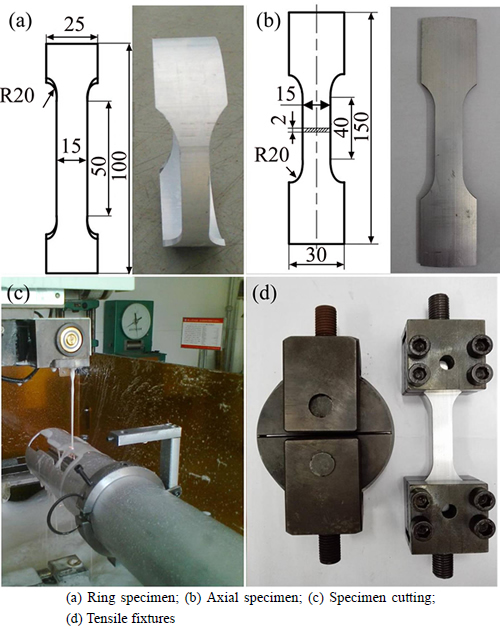

2) Tube performance test. Axial tensile specimens and ring tensile specimens were clamped by different fixtures. Three samples were performed in one state and the values were averaged. The sizes of axial tensile specimen and ring tensile specimen were determined by the international standard of tensile specimen and the accuracy of experimental equipment (See Fig. 1 and Fig. 2). A kind of fixture, which was designed for tube with 96 mm inner diameter, was applied to this research to ensure the integrity of the specimen, as shown in Fig. 1(d). The clamped part of the axial tensile fixture is circular-arc. Compared with traditional fixture, the experiment result is more accurate by using this fixture. The working principle of ring specimen fixture is conducted through deformation produced by the relative motion of D shaped blocks after two D shaped blocks inserted into ring specimen. HE et al [11] believe that in the process of hoop tension test, radial normal force, tangent tension force and tangent friction distribute regularly. In order to reduce the influence of friction and make deformation focus on the gauge length, the gauge length of ring specimen was located at the top point of D shaped block with lubrication. The mechanical properties were tested by Inspekt-Table100 type electronic universal testing machine and the strain rate was 0.001 s-1. Microhardness measurements tests were also carried out to investigate the mechanisms responible for solution treatment and artificial aging. The samples were ground with SiC paper and hardness measurements were carried out using a micro vickers hardness (HMV) instrument with 100 g load and a dwell time of 15 s. Five hardness readings were performed per sample and they were averaged.

Fig. 1 Specimen sizes and experimental fixtures (Unit: mm):

Fig. 2 Experimental equipments:

3) The microstructure observation. Different treatments on metallographic samples were carried out as follows: grinding with SiC paper, mechanical polishing, electrolytic polishing, coating anodic film. The mixed solution for electrolytic polishing was 10% HClO4 and 90% C2H5OH. The voltage was 30 V and the time was 30 s. The solution for anodic film was 5% HBF4. The voltage was 28 V and the time was 3 min. Metallographic samples were observed by Axiovert 200 MAT type metallurgical microscope.

3 Solution and aging treatment

3.1 Effect of solution treatment process parameters on mechanical properties of AA6061

3.1.1 True stress-strain curves of AA6061 in different solution treatment processes

Through material extending test, it is concluded that the strain rate has little effect on mechanical properties of AA6061 extruded tube at room temperature. The constitutive equation of AA6061 was assumed to conform to power-exponent function model with the influence of strain rate ignored and finally it was obtained, namely,

(1)

(1)

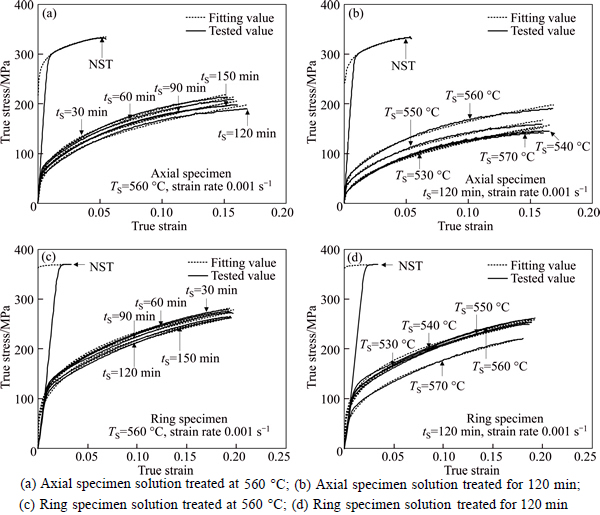

where σ is equivalent stress; ε is equivalent strain; K is strain strength coefficient; n is strain hardening index. The true stress-strain curves of AA6061 tube in different solution treatment processes were obtained by experiments, as shown in Fig. 3. T is solution temperature and t is holding time. Under the condition of no solution treatment (NST), the strength of AA6061 tube is very high.

In Fig. 3, the true stress-strain curves of the axial tensile test can be obtained directly and the true stress-strain curves of the hoop tensile test can be obtained indirectly through converting with the means provided in Ref. [11] for the fraction between D shaped blocks and ring specimen. Through comparing true stress-strain curves of AA6061 pre and post solution treatment, it is found that the strength decreases and the percentage elongation Agt at a maximum force increases after solution treatment.

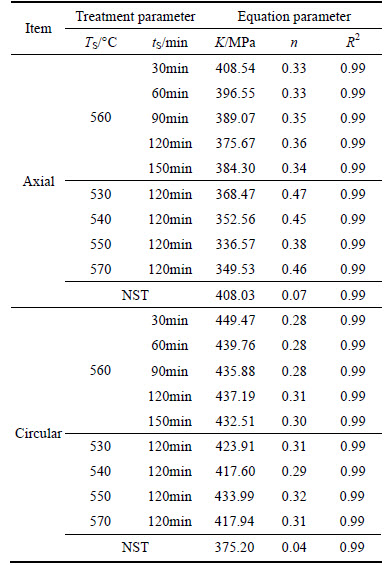

In true stress-strain curve, the interval from yield point to the peak point was selected as fitting range. Multiple linear regression statistics of the test data were conducted and constitutive equation parameters of this model were obtained, as shown in Table 2.

Although the significant changes of strength and elongation are shown in hoop tensile test, the uncertain test result still exists for the influence of friction. In this work, axial tensile test was analyzed only to find the effect of solution treatment process parameters on AA6061.

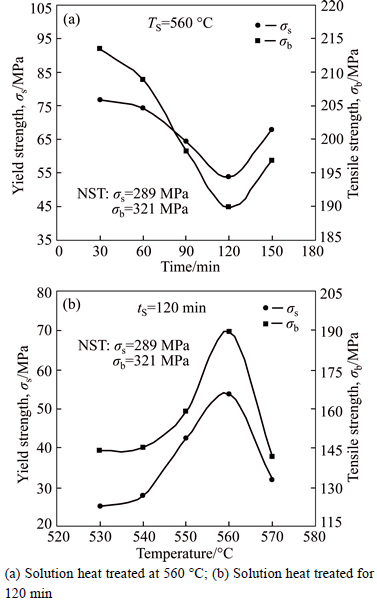

3.1.2 Effect of solution treatment on strength of AA6061

The strength curves of AA6061 extruded tube in different solution treatment processes are shown in Fig. 4. At a solution temperature of 560 °C, the strength of AA6061 goes up after dropping with solution time prolonging. The minimum value was obtained when holding time was 120 min, namely the yield strength was

53.7 MPa and the tensile strength was 189.9 MPa. At a holding time of 120 min, the strength of AA6061 increases first and then decreases with the elevating of solution temperature. The maximum value was obtained when solution temperature was 560 °C. The AA6061 extruded bar was solution heat treated for 50 min in Ref. [8]. The strength reaches the maximum value when solution temperature is 535 °C. WU et al [12] studied the solution treatment process of AA6061 sheet and found that the strength reaches the maximum value when it is solution heat treated at 555 °C for 45 min. The strength of AA6061 extruded tube shows strong sensitivity to solution temperature and holding time.

Fig. 3 Effect of solution treatment process parameters on true stress-strain curves of AA6061:

Through uniaxial tensile test, it is concluded that the strength of AA6061 tube is very high before solution treatment, namely the yield strength is 288.9 MPa and the tensile strength is 321.2 MPa. The yield strength and the tensile strength decrease by 90% and 60% respectively after solution treatment. The decrease of strength makes deformation resistance reduce and it is beneficial to decrease the requirement of forming equipment. The yield ratio of the origin tube is 0.899. However, it decreases to 0.174-0.359 after solution treatment. The smaller it is, the better the formability becomes. The plastic deformation process increases and the formability of AA6061 is improved with the prolongation of this process. The maximum value was obtained when holding time was 120 min, namely the yield strength was 53.7 MPa, and the tensile strength was 189.9 MPa.

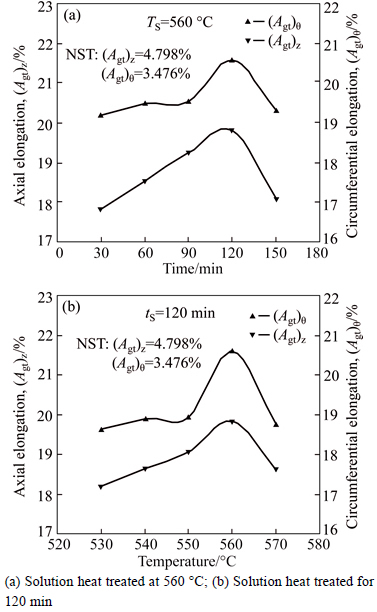

3.1.3 Effect of solution treatment on elongation of AA6061

The elongation is an important index which influences the material forming capability. YUAN et al [13, 14] studied the formability of AZ31B magnesium alloy tube in warm hydroforming and revealed that the impact on formability is elongation Agt at the maximum force rather than total elongation At at the maximum force. The fracture mode of AA6061 extruded tube in uniaxial tension test is brittle fracture, namely the Agt and the At are basically the same. Therefore, the Agt is analyzed only in this work.

The (Agt)θ is Agt on circle orientation and the (Agt)z is Agt on axial orientation. At room temperature, the Agt of the original tube is very low under the condition of strain rate 0.001 s-1, namely the (Agt)θ is 3.476% and the (Agt)z is 4.798%. Therefore, the alloy tube fractured easily in internal high pressure forming. The Agt of AA6061

Table 2 Constitutive equation parameters of different solution treatment processes

extruded tube increases significantly after solution treatment. The Agt curves of AA6061 under different solution treatment processes are shown in Fig. 5. The (Agt)θ is 20.6% and the (Agt)z is 19.8% when it is solution heat treated at 560 °C for 120 min. The (Agt)θ and the (Agt)z increase by 490% and 313%, respectively. The increase of Agt in AA6061 tube makes it possible to be formed with internal high pressure forming. At a solution temperature of 560 °C, the (Agt)θ and the (Agt)z of AA6061 increase first and then decrease with solution time prolonging. The maximum value was reached when holding time was 120 min. At a holding time of 120 min, the (Agt)θ and the (Agt)z of AA6061 increase first and then decrease with the elevating of solution temperature. The maximum value was reached when solution temperature was 560 °C. The results of experiment show that the plastic deformation capacity of AA6061 extruded tube nearly reaches the maximum value when it is solution heat treated at 560 °C for 120 min.

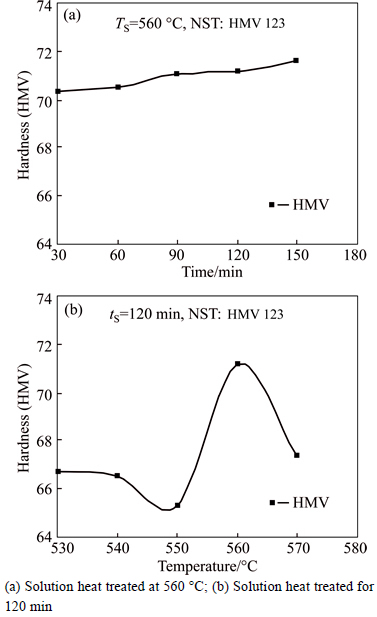

3.1.4 Effect of solution treatment on hardness of AA6061

Hardness is treated to evaluate the capacity of material resisting deform. The smaller the hardness is, the easier the plastic deformation occurs. The hardness of origin tube is as high as HMV 123. However, thehardness decreases by nearly 50% after solution treatment. The hardness curves of AA6061 extruded tube under different solution treatment conditions are shown in Fig. 6. The hardness changes slightly with solution treatment parameters changing. At a solution temperature of 560 ℃, the hardness of AA6061 increases slowly with solution time prolonging. At a holding time of 120 min, the hardness of AA6061 only fluctuates at the interval of HMV 65-71. Through Vickers microhardness test, it is concluded that the solution temperature and the holding time have no significant influence on the hardness of AA6061.

Fig. 4 Effect of solution treatment on strength of AA6061:

Fig. 5 Effect of solution treatment on Agt of AA6061:

Fig. 6 Effect of solution treatment on hardness of AA6061:

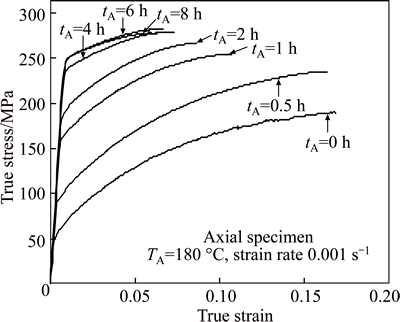

3.2 Effect of aging treatment process parameters on mechanical properties of AA6061

The axial tensile specimens were solution heat treated at 560 °C for 120 min followed by quenching in water at room temperature. Following the solution treatment, the specimens were artificially age hardened at 180 °C for a period of 0.5, 1, 2, 4, 6 and 8 h in a furnace and subsequently cooled in air. The true stress-strain curves of AA6061 under different aging treatment conditions are shown in Fig. 7. The strength increases and the Agt decreases with aging time extending, namely the mechanical properties of AA6061 tube is recovered to the state of NST.

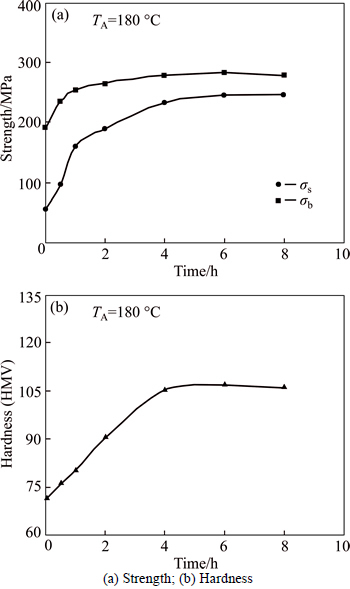

The strength and hardness curves of AA6061 under different aging treatment conditions are shown in Fig. 8. The yield strength and the tensile strength of AA6061 rise sharply at the early stage of aging treatment and reach the maximum value when aging time is 6 h, namely the yield strength is 247.1 MPa, and the tensile strength is 282.3 MPa. The strength of the tested alloy is almost invariant with the further increasing of aging time. The changing rule of hardness is the same as strength. The hardness of AA6061 increases constantly with aging time prolonging and it reaches the maximum value when the aging time is 6 h. DEMIR and  [15] studied the solution treatment of AA6061 ingot at 530 °C for 4 h followed by aging treatment at 180 °C and found that the hardness reaches the maximum value at an aging time of 11 h.

[15] studied the solution treatment of AA6061 ingot at 530 °C for 4 h followed by aging treatment at 180 °C and found that the hardness reaches the maximum value at an aging time of 11 h.

Fig. 7 True stress-strain curves 0f AA6061 tube under different aging treatment conditions

Fig. 8 Effect of aging treatment on strength and hardness of AA6061:

The effect of aging treatment on (Agt)z of AA6061 is shown in Fig. 9. The (Agt)z declines rapidly at the first hour, then decreases slowly, and finally it is tending towards stability with the extending of aging time, namely the (Agt)z is 5.6% when aging time is 6 h.

3.3 Effect of solution and aging treatment on microstructure of AA6061

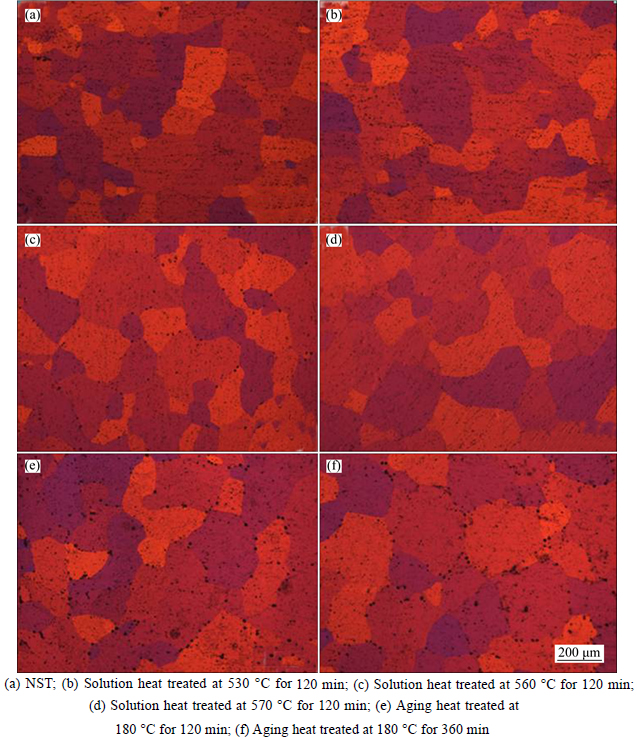

Figure 10 shows the microstructures of AA6061 in various conditions of treatment. The AA6061 tube is prepared by extrusion process. The microstructure of original tube is equiaxed grain rather than fibrous structure because recrystallization occurs in preparation process, as shown in Fig. 10(a). Through pitting holes obtained by corrosion of metallographic samples, it can be seen that the phase particles dissolved into the matrix is very few. The second coarse phases are not well

distributed with a part gathered in grain boundary and another part dispersed in grain inner. The microstructure of AA6061 tube changes a lot with solution temperature elevating. Figure 10(b) shows that plenty of second coarse phases are found in grain boundary and grain inner because the solution treatment of AA6061 was insufficient. Figure 10(c) shows that the remaining phase particles decrease significantly and the strengthening phase particles are almost dissolved into the matrix when solution temperature is 560 °C. AA6061 tube is recrystallized completely when solution temperature is 570 °C, as shown in Fig. 10(d). At this time, sub grain is not existent in microstructure. The metallographic samples were solution heat treated at 560 °C for 120 min followed by aging treatment at 180 °C. As they are aging heat treated at 180 °C for 120 min and 360 min, the grain sizes grow up a little and the second phase particles precipitate again in grain boundary with aging time prolonging, as shown in Figs. 10(e) and Fig. 10(e).

Fig. 9 Effect of aging treatment on (Agt)z of AA6061

Fig. 10 Effect of solution and aging treatment on microstructure of tested alloy:

In profile preparation process of AA6061 extruded tube, plenty of crystal defects like vacancy and dislocation are generated. As high deformation energy is stored in crystal defects, the strength increases and the elongation decreases, making the mechanical properties can not meet the subsequent processing requirements. Recrystallized grains grow further after solution treatment and the grain sizes become more uniform. Second phase particles are dissolved into matrix by solution treatment, the dissolved phase is Mg2Si and the undissolved phase is iron-rich phases. The dissolved quantity of Mg2Si firstly increases and then decreases, and it reaches the maximum value when solution temperature is 560 °C. Phase particle future reduces with the dissolved quantity of Mg2Si increase. The amounts of solute atoms in matrix gradually increase with the second coarse phases dissolved. In the process of solution treatment, the atoms with higher energy remove to equilibrium positions with lower energy because they have sufficient energy and function time. As a result, the inner stress of AA6061 tube reduces, the stored energy releases gradually and the dislocation density decreases simultaneously. However, the solution structure is conserved by rapid cooling, making mechanical properties of AA6061 tube changed. The elongation increases, the strength and the hardness decrease dramatically. As a result, the formability of AA6061 is improved [16, 17]. After aging treatment, the dispersive hardening phases precipitate at grain boundary. The precipitation hardening of AA6061 makes the strength and hardedss rise and the elongation decrease. Compared with the microstructure after solution treatment, the globular precipitates are obviously growing at grain boundary after aging treatment. At the beginning of aging, supersaturated solid solution dissolves and silicon atoms gather at some crystal faces, making solute atoms segregation zone (GP zone) form. GP zone maintains coherent relation with the matrix. These polymers constitute the coherent strain region which makes deformation resistance improve. Therefore, the strength and the hardness of AA6061 increase. With aging time prolonging, the atoms segregation zone continues increasing and it maintains coherent relation with the matrix. Coherent distortion becomes more serious for GP zone growing and the obstacle to dislocation motion further enhances. Therefore, the strengthening effect of aging treatment increases and the AA6061 tube achieves the maximum strengthening stage [18].

4 Process test

Granule medium internal high pressure forming is a technology which uses granule medium instead of rigid punch (or elastomer, liquid) to achieve the tube forming. Based on the properties of granule medium, such as high pressure resistance and filling well, the forming technology has some advantages, such as sealing easily and loading easily, which provides a convenient forming method for high strength aluminum alloy tube parts [19, 20].

In this work, granule medium internal high pressure forming technology is applied to form the tubes with different cross sections. The principle and moulds of granule medium internal high pressure forming are shown in Fig. 11. The experimental material is AA6061 extruded tube with 2 mm in thickness, 100 mm in diameter and 100 mm in length. The parts are formed with three cavities, namely no cavity, stepped shaft cavity and hexagonal cavity.

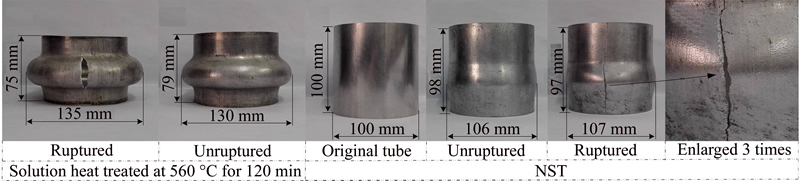

The forming limit of AA6061 tube changes greatly pre and post solution treatment, as shown in Fig. 12. The convex ring tube was formed with no cavity. The height

of bulging area is 30 mm. The tube can not be formed by this technology before solution treatment and it fractures easily when the maximum diameter of free bulging is 107 mm. The crack is perpendicular to circle orientation of tube and the fracture mode is brittle fracture. As it is solution heat treated at 560 °C for 120 min, the forming limit increases significantly. The maximum diameter of free bulging is 130 mm and the MER is 30%.

Fig. 11 Principle and moulds of granule medium internal high pressure forming technology

Fig. 12 Different parts formed by free bulging

Following the free bulging, the tube was artificially aging hardened at 180 °C for 360 min. The hardness of free bulging area was tested and its hardness is HMV 109. The hardness of the original tube is HMV 123. Due to the double effects of work hardening and precipitation strengthening, the hardness of the tube is close to the original value.

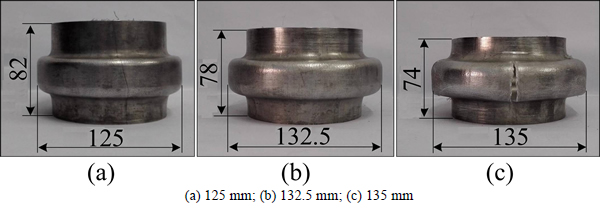

The stepped shaft tube and hexagonal tube were also formed with stepped shaft cavity and hexagonal cavity after they were solution heat treated at 560 °C for 120 min and the forming effects are all good, as shown in Figs. 13 and 14.

In the forming process of the stepped shaft tube, the maximum bulging diameter is 132.5 mm and it is fractured when the maximum bulging diameter is 135 mm. In the forming process of hexagonal tube, a good die fittingness of tube and a high accuracy of its inner diameter can be obtained.

Fig. 13 Stepped shaft tube obtained with different bulging diameters:

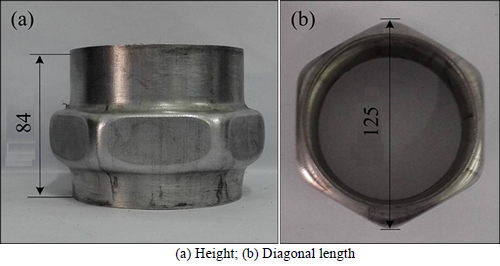

Fig. 14 Hexagonal tube obtained in test (Unit: mm):

5 Conclusions

1) After solution treatment, the (Agt)z and (Agt)θ of AA6061 increase by 4 times, but the strength and hardness decrease significantly. The formability of AA6061 tube is improved obviously with reasonable solution treatment.

2) The strength and hardness of AA6061 extruded tube can rise to the initial state after being artificially age hardened at 180 °C for 360 min. It can be explained by a diffusion assisted mechanism which causes an increase in the density of GP zones, distortion of lattice planes and hindering of dislocation movement by the impurity atoms. The strengthening effect can also be as a result of interference with the motion of dislocation, due to the formation of precipitates.

3) The technological process of AA6061 alloy tube, including solution treatment, granule medium internal high pressure forming and aging treatment, is applied to trial-produce typical tubes. The MER is increased by 25.5% and the material properties can reach to the performance index of raw material.

References

[1] ZHENG Y S, TANG G Y, KUANG J, ZHENG X P. Effect of electropulse on solid solution treatment of 6061 aluminum alloy [J]. Journal of Alloys and Compounds, 2014, 615: 849-853.

[2] PAN Dao-zhao, WANG Zhi-xiu, LI Hai, ZHENG Zi-qiao. Effects of two-step ageing treatment on tensile properties and intergranular corrosion of 6061 aluminum alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 435-441. (in Chinese)

[3] EI-MENSHAWY K, EI-SAYED A W A, EI-BEDAWY M E, AHMED H A, EI-RAGHY S M. Effect of aging time at low aging temperatures on the corrosion of aluminum alloy 6061 [J]. Corrosion Science, 2012, 54: 167-173.

[4] MAISONNETTE D, SUERY M, NELIAS D, CHAUDET P, EPICIER T. Effects of heat treatments on the microstructure and mechanical properties of a 6061 aluminium alloy [J]. Materials Science and Engineering A, 2011, 528(6): 2718-2724.

[5] KIM W J, KIM W Y, KIM H K. Hot-air forming of Al-Mg-Cr alloy and prediction of failure based on Zener-Holloman parameter [J]. Matals and Materials International, 2010, 16(6): 895-903.

[6] HE Zhu-bin, FAN Xiao-bo, SHAO Fei, ZHENG Kai-lun, WANG Zhi-biao, YUAN Shi-jiang. Formability and microstructure of AA6061 Al alloy tube for hot metal gas forming at elevated temperature [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(Suppl 2): s364-s369.

[7] SEYEDKASHI S M H, NAEINI H M, MOON Y H. Feasibility study on optimized process conditions in warm tube hydrofoming [J]. Journal of Mechanical Science and Technology, 2014, 28(7): 2845-2852.

[8] XIANG Sheng-qian, ZHOU Chun-rong, GUO Jia-lin, YIN Zhi-min, SHANG Bao-chuan. Effect of solid solution-aging treatment on microstructure and properties of 6061 aluminum alloy extruded rods [J]. Light Alloy Fabrication Technology, 2011, 39(4): 31-35. (in Chinese)

[9] SHANG Bao-chuan, YIN Zhi-min, ZHOU Xiang, HUANG Zhi-qi. Effect of solution and aging treatment on microstructure and properties of hot extruded 6082 aluminum alloy bars [J]. Transactions of Materials and Heat Treatment, 2011, 32(1): 77-81. (in Chinese)

[10] ZHOU Yu-jing, CHENG Xiu-quan, XIA Qin-xiang. Influence of heat treatment on spinning process and properties for 6061 aluminum alloy tube [J]. Forging & Stamping Technology, 2011, 36(3): 54-57. (in Chinese)

[11] HE Zhu-bin, YUAN Shi-jian, CHA Wei-wei, LIANG Ying-chun. Force and deformation analysis of tube ring specimen during hoop tension test [J]. Acta Metallurgica Sinica, 2008, 44(4): 423-427. (in Chinese)

[12] WU Yue. CHEN Wen-lin, LI Wei, MA Yong. Effects of solution treatment on microstructure and properties of Al-0.9Mg-0.6Si-0.7Cu alloy [J]. Transactions of Materials and Heat Treatment, 2014, 35(12): 56-61. (in Chinese)

[13] YUAN Shi-jian, TANG Ze-jun, WANG Xiao-song, MIAO Qi-bin. Formability of warm hydroforming of AZ31B magnesium alloy tube [J]. Materials Science & Technology, 2009, 17(5): 657-665. (in Chinese)

[14] LIU Gang, TANG Ze-jun, HE Zhu-bin, YUAN Shi-jian. Warm hydroforming of magnesium alloy tube with large expansion radio [J]. Transactions of Nonferrous Matals Society of China, 2010, 20(11): 2071-2075.

[15] DEMIR H,  S. The effects of aging on machinability of 6061 aluminium alloy [J]. Materials & Design, 2009, 30(5): 1480-1483.

S. The effects of aging on machinability of 6061 aluminium alloy [J]. Materials & Design, 2009, 30(5): 1480-1483.

[16] MIRZAKHANI B, MANSOURINEJAD M. Tensile properties of AA6061 in different designated precipitation hardening and cold working [J]. Procedia Engineering, 2011, 10: 136-140.

[17] MANSOURINEJAD M, MIRZAKHANI B. Influence of sequence of cold working and aging treatment on mechanical behaviour of 6061 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2072-2079.

[18] FARSHIDI M H, KAZEMINEZHAD M, MIYAMOTO H. Severe plastic deformation of 6061 aluminum alloy tube with pre and post heat treatments [J]. Materials Science and Engineering A, 2013, 563: 60-67.

[19] DONG Guo-jiang, ZHAO Chang-cai, YA Yuan-yuan, ZHAO Jian-pei. Discrete element and finite element coupling simulation and experiment of hot granule medium pressure forming [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(12): 4089-4101.

[20] KUMAR M, SOTIROV N, CHIMANI C M. Investigations on warm forming of AW-7020-T6 alloy sheet [J]. Journal of Materials Processing Technology, 2014, 214(8): 1769-1776.

(Edited by YANG Hua)

Cite this article as: BI Jiang, ZHAO Chang-cai, BI Meng-meng, DU Bing, CHEN Xiao-hua, DONG Guo-jiang. Heat treatment and granule medium internal high pressure forming of AA6061 tube [J]. Journal of Central South University, 2017, 24(5): 1040-1049. DOI: 10.1007/s11771-017-3507-8.

Foundation item: Project(51305386) supported by the National Natural Science Foundation of China; Project(E2013203093) supported by the Natural Science Foundation of Hebei Province, China

Received date: 2016-01-30; Accepted date: 2016-05-04

Corresponding author: DONG Guo-jiang, PhD; Tel/Fax: +86-335-8074682; E-mail: dgj@ysu.edu.cn