Effect of heat treatment on microstructure and

tensile properties of A356 alloys

PENG Ji-hua1, TANG Xiao-long1, HE Jian-ting1, XU De-ying2

1. School of Materials Science and Engineering, South China University of Technology,Guangzhou 510640, China;

2. Institute of Nonferrous Metal, Guangzhou Jinbang Nonferrous Co. Ltd., Guangzhou 510340, China

Received 17 June 2010; accepted 15 August 2010

Abstract: Two heat treatments of A356 alloys with combined addition of rare earth and strontium were conducted. T6 treatment is a long time treatment (solution at 535 °C for 4 h + aging at 150 °C for 15 h). The other treatment is a short time treatment (solution at 550 °C for 2 h + aging at 170 °C for 2 h). The effects of heat treatment on microstructure and tensile properties of the Al-7%Si-0.3%Mg alloys were investigated by optical microscopy, scanning electronic microscopy and tension test. It is found that a 2 h solution at 550 °C is sufficient to make homogenization and saturation of magnesium and silicon in α(Al) phase, spheroid of eutectic Si phase. Followed by solution, a 2 h artificial aging at 170 °C is almost enough to produce hardening precipitates. Those samples treated with T6 achieve the maximum tensile strength and fracture elongation. With short time treatment (ST), samples can reach 90% of the maximum yield strength, 95% of the maximum strength, and 80% of the maximum elongation.

Key words: Al-Si casting alloys; heat treatment; tensile property; microstructural evolution

1 Introduction

The aging-hardenable cast aluminum alloys, such as A356, are being increasingly used in the automotive industry due to their relatively high specific strength and low cost, providing affordable improvements in fuel efficiency. Eutectic structure of A390 can be refined and its properties can be improved by optimized heat treatment [1]. T6 heat treatment is usually used to improve fracture toughness and yield strength. It is reported that those factors influencing the efficiency of heat treatment of Al-Si hypoeutectic alloys include not only the temperature and holding time [2], but also the as-cast microstructure [3-5] and alloying addition [6-8]. Some T6 treatment test method standards of A356 alloys are made in China, USA, and Japan, and they are well accepted. However, they need more than 4 h for solution at 540 °C, and more than 6 h for aging at 150 °C, thus cause substantial energy consumption and low production efficiency. It is beneficial to study a method to cut short the holding time of heat treatment.

The T6 heat treatment of Al-7Si-0.3 Mg alloy includes two steps: solution and artificial aging; the solution step is to achieve α(Al) saturated with Si and Mg and spheroidized Si in eutectic zone, while the artificial aging is to achieve strengthening phase Mg2Si. Recently, it is shown that the spheroidization time of Si is dependant on solution temperature and the original Si particle size [9-11]. A short solution treatment of 30 min at 540 or 550 °C is sufficient to achieve almost the same mechanical property level as that with a solution treatment time of 6 h [12]. From thermal diffusion calculation and test, it is suggested that the optimum solution soaking time at 540 °C is 2 h [13]. The maximum peak aging time was modeled in terms of aging temperature and activation energy [14-15]. According to this model, the peak yield strength of A356 alloy could be reached within 2-4 h when aging at 170 °C. However, few studies are on the effect of combined treatment with short solution and short aging.

In our previous study, it was found that the microstructure of A356 alloy could be optimized by the combination of Ti, B, Sr and RE, and the eutectic melting peak temperature was measured to be 574.4 °C by differential scanning calorimetry (DSC) [16]. In this study, using this alloy modified together with Sr and RE, the effect of different heat treatments on the microstructure and its mechanical properties were investigated.

2 Experimental

Commercial pure aluminum and silicon were melted in a resistance furnace. The alloy was refined using Al5TiB master alloy, modified using Al-10Sr and Al-10RE master alloys. The chemical composition of this A356 alloy ingot (Table 1) was checked by reading spectrometer SPECTROLAB. Before casting, the hydrogen content of about 0.25 cm3 per 100 g in the melt was measured by ELH-III (made in China). Four bars of 50 mm×70 mm×120 mm were machined from the same ingot and heat-treated according to Table 2. Followed the solution, bars were quenched in hot water of 70 °C. Samples cut from the cast ingot and heat-treated bars were ground, polished and etched using 0.5% HF agent. Optical microscope Leica-430 and scanning electric microscope LEO 1530 VP with EDS (Inca 300) were used to examine the microstructure and fractograph. To quantify the eutectic Si morphology change of different heat treatments, an image analyzer Image-Pro Plus 6.0 was used, and each measurement included 800-1 200 particles.

Table 1 Chemical composition of A356 modified with Ti, Sr and RE (mass fraction, %)

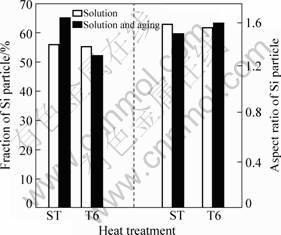

Table 2 Heat treatments in this study

Tensile specimens were machined from the heat treated bars. The tensile tests were performed using a screw driven Instron tensile testing machine in air at room temperature. The cross-head speed was 1 mm/min. The strain was measured by using an extensometer attached to the sample and with a measuring length of 50 mm. The 0.2% proof stress was used as the yield stress of alloys. Three samples were tested for each heat treatment to calculate the mean value.

3 Results and discussion

3.1 Microstructural characterization of as-cast alloy

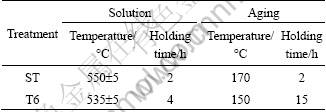

The microstructure of as-cast A356 alloy is shown in Fig. 1(a). It is shown that not only the primary α(Al) dendrite cell is refined, but also the eutectic silicon is modified well. By means of the image analysis, microstructure parameters of as-cast A356 alloy were analyzed statistically as follows: α(Al) dendrite cell size is 76.1 μm, silicon particle size is 2.2 μm×1.03 μm (length×width), and the ratio aspect of silicon is 2.13.

The distributions of RE (mish metal rare earth, more than 65% La among them), Ti, Mg, and Sr in the area shown in Fig. 1(b) are presented in Figs. 1(c)-(f) respectively. It is shown that the eutectic silicon particle is usually covered with Sr, which plays a key role in Si particle modification; Ti and RE present generally uniform distribution over the area observed, although a little segregation of RE is observed and shown by arrow in Fig. 1(d). It is suggested that because the refiner TiAl3 and TiB2 are covered with RE, the refining efficiency is improved significantly. In the as-cast alloy, some clusters of Mg probably indicate that coarser Mg2Si phases exist (arrow in Fig. 1(d))).

Ti solute can limit the growth of α(Al) primary dendrite because of its high growth restriction factor [17]. The impediment of formation of poisoning Ti-Si compound around TiAl3 [18] and promotion of Ti(Al1-xSix)3 film covering TiB2 [19] are very important in Al-Si alloy refining. For Al-Si alloys, the effect of RE on the refining efficiency of Ti and B can be contributed to the following causes [20]: preventing refiner phases from poisoning; retarding TiB2 phase to amass and sink; promoting the Ti(Al, Si)3 compound growth to cover the TiB2 phase. In this work, with suitable addition of Re and Sr, the microstructure of A356 alloy was optimized. Especially, eutectic Si is modified fully, which is beneficial to promote Si to spheroidize further during solution treatment.

3.2 Microstructural evolution during heat treatment

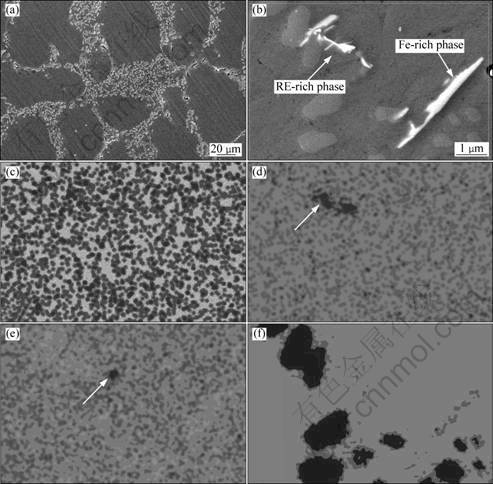

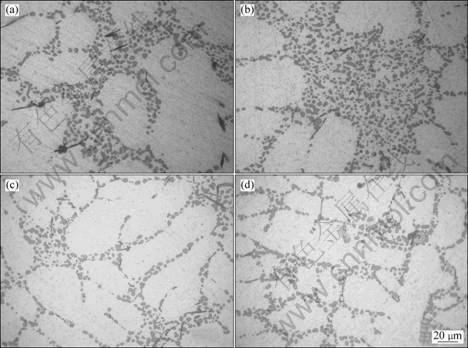

The microstructures of A356 alloys treated with solution at 550 °C for 2 h and ST treatment are presented in Figs. 2(a) and (b) respectively, while those treated with solution at 535 °C for 4 h and T6 treatment are presented in Figs. 2(c) and (d), respectively. From Fig. 1 and Fig. 2, after different heat treatments, the primary α(Al) has been to some extent and the eutectic silicon has been spheroidized further. Both ST and T6 treatments produce almost the same microstructure. The eutectic Si particle distribution and statistical mean aspect ratio of eutectic Si particle are shown in Fig. 3. After only solution at 535 °C for 4 h and 550 °C for 2 h, the mean aspect ratios of Si are 1.57 and 1.54 respectively. After being treated by ST and T6, those aspect ratios of Si do not vary greatly, and they are 1.49 and 1.48, respectively. After solution or solution + aging in this study, the friction of eutectic Si particles with aspect ratio of 1.5 is 50%.

Fig. 1 SEM images (a, b), and EDS mapping from (b) for Ti (c), La (d), Mg (e) and Sr (f) in as-cast alloy

Fig. 2 Microstructure of A356 alloy with different heat treatments: (a) Solution at 550 °C for 2 h; (b) ST treatment; (c) Solution at 535 °C for 4 h; (d) T6 treatment

Fig. 3 Statistic analysis of eutectic Si in A356 alloy with different heat treatments

The eutectic melting onset temperature of Al-7Si-Mg was reported to be more than 560 °C [16, 19]. 550 °C is below the liquid +solid phase zone. During solution, two steps occur simultaneously, i.e., the formation of Al solution saturated with Si and Mg, and spheroidization of fibrous Si particle. The following model predicts that disintegration and spheroidization of eutectic silicon corals are finished at 540 °C after a few minutes (τmax) [9]:

(1)

(1)

where f denotes the atomic diameter of silicon; γ symbolizes the interfacial energy of the Al/Si interface; ρ is the original radius of fibrous Si; Ds is the inter-diffusion coefficient of Si in Al; and T is the solution temperature. When the Ds variation at different temperatures is taken into account, it is plausible to suggest that τmax at 550 °C is less than τmax at 540 °C. From Fig. 2(a), it is actually proved that spheroidization of eutectic Si particle could be finished within 2 h when solution at 550 °C.

In a selected area of A356 alloy treated with only solution at 550 °C for 2 h (Fig. 4(a)), the distribution of element Mg is presented in Fig. 4(b). Because there is no cluster of Mg in Fig. 4(b), it means a complete dissolution of Si, Mg into Al dendrite during this solution. From the microstructure of A356 alloy treated with T6 (Fig. 5(a)), the distribution of Mg is shown in Fig. 5(b).

Fig. 4 SEM image (a) and EDS mapping (b) of Mg distribution in alloy after only solution at 550 °C for 2 h

Fig. 5 SEM image (a) and EDS mapping of Mg (b) in alloy after heat treatment with T6

For A357 alloy with dendrite size of 240 μm, uniform diffusion and saturation of Mg in Al could be finished at 540 °C within 2 h [13]. In this study, the cell size of primary α(Al) is less than 100 μm. It is reasonable that those solutions treated at 535 °C for 4 h and 550 °C for 2 h, can achieve α(Al) solid solution saturated with Mg and Si because diffusion route is short, even at a higher solution temperature.

During aging, Si and Mg2Si phase precipitation happened in the saturated solid solution of α(Al) according to the sequence in the Al-Mg-Si alloys with excess Si [21]. The needle shaped Mg2Si precipitation was observed to be about 0.5 μm in length and less than 50 nm in width, and the silicon precipitates were mainly distributed in α(Al) dendrites and few of them could be observed in the eutectic region [22]. Because of the small size, these precipitations could not be observed by SEM in this study. However, it is plausible to suggest that the distribution of Mg in dendrite Al cell zone and eutectic zone is uniform (Fig. 4(b) and 5(b)). According to the study by ROMETSCH and SCHAFFER [15], the time to reach peak yield is 2-4 h and 12-14 h at 170 °C and 150 °C, respectively. From 150 to 190 °C of aging temperature, the peak hardness varies between HB110 and HB120. Hence, it is believed that aging at 170 °C for 2 h produces almost the same precipitation hardening as aging at 150 °C for 15 h.

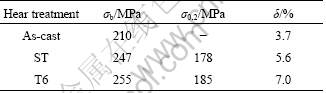

3.3 Tensile properties of A356 alloys

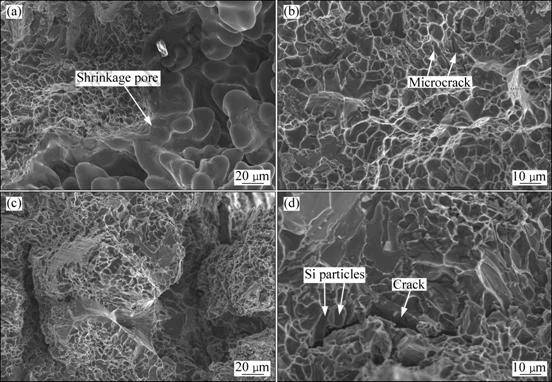

The tensile mechanical properties of A356 alloys are given in Table 3. Due to the microstructure optimization of A356 alloy by means of combination of refining and modification, tensile strength and fracture elongation can reach about 210 MPa and 3.7% respectively. Using T6 treatment in this study, strength and elongation can be improved significantly. For those samples with T6 treatment, the tensile strength and ductility present the maximum values. 90% of the maximum yield strength, 95% of the maximum ultimate strength, and 80% of the maximum elongation can be reached for samples treated by ST treatment. However, T6 treatment spends about 19 h, while ST treatment takes only about 4 h. Fractographs of samples treated with T6 are presented in Fig. 6. The dimple size is almost similar with different heat treatments, indicating that the size and spacing of eutectic silicon particle vary little with different heat treatments. Shrinkage pore, microcrack inside the silicon particle and crack linkage between eutectic silicon particles were observed on the fracture surfaces.

Table 3 Tensile properties of A356 alloys with different heat treatments

Fig. 6 Fractographs of samples with different heat treatments: (a), (b) T6; (c), (d) ST

It is well known that shrinkage pores have a great effect on the tensile strength and ductility of A356 alloys. In-situ SEM fracture of A356 alloy indicates the fracture sequence as follows [4]: micro-crack initiation inside silicon particle; formation of slipping band in the Al dendrite; linkage between the macro-crack and micro-crack, and the growth of crack. During tensile strain, inhomogeneous deformation in the microstructure induces internal stresses in the eutectic silicon and Fe-bearing intermetallic particles. Although the full modification of eutectic Si particle was reached in this study, those samples treated with T6 treatment do not perform as well as expected. The main reason is probably due to the higher gas content (0.25 cm3 per 100 g Al). Our next step is to develop a new means to purify the Al-SI alloys to further improve their mechanical properties.

4 Conclusions

1) The solution at 535 °C for 4 h and the solution at 550 °C for 2 h can reach full spheroidization of Si particle, over saturation of Si and Mg in α(Al). The heat treatments of T6 and ST produce almost the same microstructure of A356 alloy.

2) After both T6 and ST treatments, the aspect ratio of eutectic Si particle will be reduced from 2.13 to less than 1.6, and the friction of eutectic Si particles with aspect ratio of 1.5 is 50%.

3) The T6 treatment can make the maximum strength and fracture elongation for A356 alloy. After ST treatment, 90% of the maximum yield strength, 95% of the maximum ultimate strength, and 80% of the maximum elongation can be achieved.

References

[1] WAN Li, LUO Ji-rong, LAN Guo-dong, LIANG Qiong-hua. Mechanical properties and microstructures of squeezed and cast hypereutectic A390 alloy [J]. Journal of Huazhong University of Science and Technology: Natural Science Edition, 2008, 36(8): 92-95. (in Chinese)

[2] RAINCON E, LOPEZ H F, CINEROS H. Temperature effects on the tensile properties of cast and heat treated aluminum alloy A319 [J]. Mater Sci Eng A, 2009, 519(1-2): 128-140.

[3] MANDAL A, CHAKRABORTY M, MURTY B S. Ageing behaviour of A356 alloy reinforced with in-situ formed TiB2 particles [J]. Mater Sci Eng A, 2008, 489(1-2): 220-226.

[4] LEE K, KWON Y N, LEE S. Effects of eutectic silicon particles on tensile properties and fracture toughness of A356 aluminum alloys fabricated by low-pressure-casting, casting-forging, and squeeze- casting processes [J]. J Alloys Compounds, 2008, 461(1-2): 532-541.

[5] VENCL A, BOBIC I, MISKOVIC Z. Effect of thixocasting and heat treatment on the tribological properties of hypoeutectic Al-Si alloy [J]. Wear, 2008, 264 (7-8): 616-623.

[6] BIROL Y. Response to artificial ageing of dendritic and globular Al-7Si-Mg alloys [J]. J. Alloys Compounds, 2009, 484(1): 164-167.

[7] TOKAJI K. Notch fatigue behaviour in a Sb-modified permanent-mold cast A356-T6 aluminium alloy [J]. Mater Sci Eng A, 2005, 396(1-2): 333-340.

[8] KLIAUGA A M, VIEIRA E A, FERRANTE M. The influence of impurity level and tin addition on the ageing heat treatment of the 356 class alloy [J]. Mater Sci Eng A, 2008, 480(1-2): 5-16.

[9] OGRIS E, WAHLEN A, LUCHINGER H, UGGOWITZER P J.On the silicon spheroidization in Al-Si alloys [J]. J Light Metals, 2002, 2(4): 263-269.

[10] SJOLANDER E, SEIFEDDINE S. Optimisation of solution treatment of cast Al-Si-Cu alloys [J]. Mater Design, 2010, 31(s1): s44-s49.

[11] LIU Bin-yi, XUE Ya-jun. Morphology transformation of eutectic Si in Al-Si alloy during solid solution treatment [J]. Special Casting & Nonferrous Alloys, 2006, 26 (12): 802-805. (in Chinese)

[12] ZHANG D L, ZHENG L H, STJOHN D H. Effect of a short solution treatment time on microstructure and mechanical properties of modified Al-7wt.%Si-0.3wt.%Mg alloy [J]. J Light Metals, 2002, 2(1): 27-36.

[13] YU Z, ZHANG H , SUN B, SHAO G. Optimization of soaking time for T6 treatment of aluminium alloy [J]. Heat Treatment, 2009, 24(5): 17-20. (in Chinese)

[14] ESTEY C M, COCKCROFT S L, MAIJER D M, HERMESMANN C. Constitutive behavior of A356 during the quenching operation [J]. Mater Sci Eng A, 2004, 383(2): 245-251.

[15] ROMETSCH P A, SCHAFFER G B. An age hardening model for Al-7Si-Mg casting alloys [J]. Mater Sci Eng A, 2002, 325(1-2): 424-434.

[16] TANG Xiao-long, PENG Ji-hua, HUANG Fang-liang, XU De-ying, DU Ri-sheng. Effect of mishmetal RE on microstructures of A356 alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2112-2117. (in Chinese)

[17] EASTON M A, STJHON D H. A Model of grain refinement incorporation alloy constitution and potency of heterogeneous nucleant particles [J]. Acta Mater, 2001, 49(10): 1867-1878.

[18] QIU D, TAYLOR J A, ZHANG M X, KELLY P M. A mechanism for the poisoning effect of silicon on the grain refinement of Al-Si alloys [J]. Acta Mater, 2007, 55(4): 1447-1456.

[19] JUNG H, MANGELINK-NOEL N, BERGMAN C, BILLIA B. Determination of the average nucleation undercooling of primary Al-phase on refining particles from Al-5.0wt% Ti-1.0wt% B in Al-based alloys using DSC [J]. J Alloys Compounds, 2009, 477(1-2): 622-627.

[20] LAN Ye-feng, GUO Peng, ZHANG Ji-jun. The effect of rare earth on the refining property of the Al-Ti-B-RE intermediate alloy [J]. Foundry Technology, 2005, 26(9): 774-778. (in Chinese)

[21] EDWARDS G A, STILLER K, DUNLOP G L, COUPER M J. The precipitation sequence in Al-Mg-Si alloys [J]. Acta Mater, 1998, 46(11): 3893-3904.

[22] RAN G, ZHOU J E, WANG Q G. Precipitates and tensile fracture mechanism in a sand cast A356 aluminum alloy [J]. J Mater Process Technol, 2008, 207(1): 46-52.

热处理对A356铝合金组织结构和力学性能的影响

彭继华1,唐小龙1,何健亭1,许德英2

1. 华南理工大学 材料科学与工程学院,广州 510640;

2. 广州金邦有色合金有限公司 有色金属研究所,广州 510340

摘 要:用两种不同的热处理制度对稀土和锶综合细化变质的A356合金进行处理,一种是长时间标准处理制度T6(535 °C固溶4 h+150 °C时效15 h),另一种是短时间的热处理制度ST(550 °C固溶2 h+170 °C时效2 h)。采用光学显微镜、扫描电镜及室温拉伸实验等手段分析热处理制度对A356合金微观组织和拉伸力学性能的影响。结果表明:在550 °C下固溶2 h可以获得Mg、Si过饱和且分布均匀的α(Al)固溶体,并使共晶硅相球化;再经170 °C人工时效2 h后,可以达到传统T6处理的时效析出效果。拉伸实验结果表明,A356铝合金经传统T6处理得到了最高的拉伸强度和断裂伸长率;通过ST短时热处理后,其拉伸强度、屈服强度及伸长率分别可以达到T6处理时的90%,95%和80%。

关键词:Al-Si合金;热处理;拉伸性能;微观组织演变

(Edited by LI Xiang-qun)

Foundation item: Project (2008B80703001) supported by Guangdong Provincial Department of Science and Technology, China; Project (09A45031160) supported by Guangzhou Science and Technology Commission, China; Project (ZC2009015) supported by Zengcheng Science and Technology Bureau, China

Corresponding author: PENG Ji-hua; Tel/Fax: +86-20-87113747; E-mail: jhpeng@scut.edu.cn

DOI: 10.1016/S1003-6326(11)60955-2