Effects of heat-treatment on microstructure of

wrought magnesium alloy ZK60

MA Yan-long(麻彦龙)1, 2, PAN Fu-sheng(潘复生)2, ZUO Ru-lin(左汝林)2,

ZHANG Jin(张 津)1, YANG Ming-bo(杨明波)1

1. College of Materials Science and Engineering, Chongqing Institute of Technology, Chongqing 400050, China;

2. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China

Received 28 July 2006; accepted 15 September 2006

Abstract: The microstructure of the as-cast, as-solution-treated and as-aged wrought magnesium alloy ZK60 was studied. The results indicate that the microstructure of the as-cast ZK60 alloy is mainly composed of network eutectic (α-Mg+MgZn) and divorced eutectic MgZn, which semi-continuously distribute along the grain boundaries or in the interdendritic area and almost dissolve into the matrix after solid solution treatment. The Laves phase MgZn2 is not sensitive to the heat treatment and seems to form at the early stage of solidification and keeps its size and shape till the aging stage. It is believed that the occurrence of the Laves phase in the ZK60 alloy would possibly contribute to the defects. Many new phases, including MgZn phase which is different from that forms during eutectic reaction, precipitate after aging treatment.

Key words: wrought magnesium alloy; ZK60; microstructure; alloy phase; MgZn2; eutectic

1 Introduction

ZK60 alloy is one of the most typical high strength wrought magnesium alloys. However due to its poor deformability at ambient and elevated temperatures, great attention of researchers was drawn on the superplasticity of ZK60 alloy in the past ten years[1-5]. Correspondingly, the grain refinement technologies and the deformation mechanism were also studied in the same period[6-9]. However, it is almost a blank for studying the microstructure of ZK60 alloy under both cast and heat-treated state, which is in fact closely related to the deformation behavior of the alloy.

Although some primary researches on micro- structure were done in the last decade, no systematical study is focused on the microstructure of the cast ingot and aged alloys. ZHANG et al[10] studied the alloy phases and the microstructure in MB15 alloy (equal to ZK60 alloy), however they failed to report the morphologies of the alloy phases and their evolution during heat treatment. GU et al[11] studied the age hardening precipitation reactions in a ZK60 matrix composite reinforced with 12%(volume fraction) SiC whiskers; XU et al[12] studied the effect of precipitates on the mechanical properties of ZK60-Y alloy. Unfortunately, they carried out the researches on the foundation of ZK60-based alloy instead of pure ZK60 alloy. In addition, they only paid their attentions to the microstructure of the alloy in the age state and did not go deeply into the relationships of the microstructure between the original cast ingot and the alloy under heat treatment or plastic deformation.

In the present study, the microstructure of the as-cast, as-solution-treated and as-aged commercial ZK60 magnesium alloys is investigated. The specimen for solution treatment is sealed in a quartz glass tube, which is kept at vacuum of 10-3 with certain amount of argon. Solid solution treatment is 380 ℃, 12 h+510℃, 12 h. Aging process is 180 ℃, 8 h. The purpose of the study is to trail the structure transformation of the alloy from cast state to different heat treatment state and bridge the microstructure of the alloy before and after heat treatment. The results of the experiments will benefit for the microstructure control and optimization, and it will also provide theoretical reference for the determination of the technical parameters for plastic deformation such as rolling and forging.

2 Experimental

Semi-continuously cast ZK60 alloy ingot (the chemical composition (mass fraction, %): Zn 5.6, Zr 0.54, Fe≤0.003, Ni≤0.002, Mg balance) with a diameter of d129 mm was used in the experiments. The specimens were taken from the position 1/2 r away from the ingot center. The OLYMPUS optical microscope, AMRAY 1845 scanning electron microscope, TECANI 20 transmission electron microscope, STA 449C thermal analyzing instrument, and D/Max-1200 X-ray analyzing instrument were used in the experiments.

3 Results

3.1Microstructure of as-cast Alloy

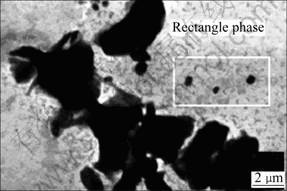

Observed under low magnification, it is found that the microstructure of the as-cast ZK60 magnesium alloy is mainly composed of the matrix and semi-continuously distributed black network. When the magnification is enlarged, it is quite clearly that semi-continuous network distributes along the grain boundaries with certain width. In some places the semi-continuous network is broken into pieces and stacks together. And on the side of some black structure there are some rectangle phases with dimension of 300 nm×500 nm. Combined the informa- tion from the DSC curves and Mg-Zn binary phase diagram[13], it could be deduced that the black structure must be the eutectics formed at eutectic temperature (about 340 ℃). The eutectic structure could be described as (α-Mg+MgZn+Mg7Zn3). Because the narrow scope of existence temperature of Mg7Zn3[14], the eutectic structure could be more simply described as (α-Mg+MgZn). When α-Mg and MgZn lose co- relationship and grow up by themselves, divorced eutectic MgZn forms. The rectangle phases around the eutectic are finally specified as MgZn2 (Figs.1 and 2).

Fig.1 Morphology of rectangle phase in as-cast ZK60 alloy

Fig.2 SAD pattern of rectangle phase in Fig.1

3.2 Microstructure of as-solution-treated alloy

Leave-like structure is found in the solution-treated specimen that is subjected to nitric-acid-alcohol solution. The relatively detailed studies were carried out on the leave-like structure and found it was caused by incomplete diffusion of zinc and zirconium in the alloy [15-16]. Using the transmission electron microscope, detailed alloy phases are detected. Along the grain boundaries there are rectangle phases similar to that in as-cast specimen. They are also specified as MgZn2 phases(Figs.3 and 4).

Fig.3 Morphology of rectangle phase in solution-treated alloy

Fig.4 SAD pattern of rectangle phase shown in Fig.3

3.3 Microstructure of as-aged alloy

As expected, many alloy phases precipitate after aging treatment. Besides, leave-like structure appeared in the solution-treated alloy can still be seen in some areas in the aged alloy, and twin crystals are clearly detected inside the grains. One typical segregation alloy phase is a kind of 500 nm long acicular phase. The specified SAD pattern tells that the phase has a structure of MgZn (Figs.5 and 6). However, instead of forming during eutectic reaction, the above-mentioned MgZn phase forms during aging stage and is recorded as (MgZn) Ⅱ to differ from MgZn which forms during eutectic reaction. The rectangle phases are once more specified as MgZn2 (Figs.7 and 8). According to the shape, size and distribution, it is deduced that MgZn2 phases found in aged alloy are the same ones in the as-cast and as-solution treated specimens, which keep unchanged during heat treatment.

Fig.5 Morphology of acicular phase in as-aged alloy

Fig.6 SAD pattern of acicular phase in Fig.5

Fig.7 Morphology of rectangle phase in as-aged alloy

Fig.8 SAD pattern of rectangle phase in Fig.7

4 Discussion

4.1 Eutectics in as-cast ZK60 magnesium alloy

Zn content of ZK60 alloy is around 5.6% (mass fraction), which is quite close to Zn content at eutectic point (6.2%). Therefore, because of the fast cooling rate during semi-continuously casting, the major structure in ZK60 should be sub-eutectics and the solid solution. However due to alloy allotment coefficient KZn<1[17], Zn element will prefer to concentrate in the vicinity of the gain boundaries. Over concentration of Zn will break the general growing law of eutectic in which the growth of α-Mg is the precondition of MgZn and vice versa. Consequently, α-Mg and MgZn will grow up separately and lead to the formation of divorced eutectic. These may be the reason why there is little typical eutectics but much divorced eutectics in the cast alloy. As for the Mg7Zn3 phase, there is little chance for its existence in the author’s point of view. Even if Mg7Zn3 phase forms somewhere, it is only stable in a temperature range of 10 ℃ according to Ref.[14]. Such a narrow temperature range might be ignored during fast cooling. However as reported by WEI et al[18], Mg7Zn3 phase may form in Mg-Zn binary system in which Zn content is increased.

4.2 Formation of MgZn2 phase and possible influence on alloy properties

The Laves phase MgZn2 was first found in 1930 by LAVES according to Ref.[13]. JHA et al[19], through thermodynamic calculation and computer simulation, proved that the MgZn2 phase was the most possible alloy phase formed in the liquid Mg-Zn binary alloys. In the present paper, similar MgZn2 phases are found not only in the as-cast specimen, but also in the as-solution- treated and as-aged specimens. This provides good reasons that the MgZn2 phase forms at the early stage of solidification and keeps stable during the heat treatment process. So far no similar result has been reported except the present paper. ZHANG et al[10] declared that they found MgZn2 phase in ZK60 magnesium alloy by X-ray technology; unfortunately they failed to describe its specific configuration and distribution. However similar MgZn2 phases are quite widely reported in the Mg-Zn binary alloys[20-21]. Because the MgZn2 phase in ZK60 alloy has quite sharp edges and is very stable, it would possibly break the continuity of the matrix and severely affect the deformation behavior. Eliminating or rspheroidizing the MgZn2 phase will undoubtedly have profound meaning to overcome deformation defects in ZK60 magnesium alloy.

5 Conclusions

1) The microstructure of the as-cast ZK60 magnesium alloy is mainly composed of the eutectics and divorced eutectics in form of semi-continuous network, distributing along the grain boundaries or in the interdendritic area. The eutectic could be basically described as (α-Mg+MgZn), and MgZn for divorced eutectic.

2) The Laves phase MgZn2 is found not only in the as-cast specimens, but also in the as-solution-treated and as-aged specimens. The Laves phase MgZn2 has no concrete orientation to the matrix and distributes in the vicinity of eutectics or divorced eutectics in form of rectangle with dimension of 300 nm×500 nm. As it is not sensitive to heat treatment, it is believed that the stable MgZn2 phase inherited from cast alloy is possibly harmful to the plastic deformation of ZK60 alloy.

3) There might be more than one type of segregation phases in the as-aged specimen, among which MgZn phase precipitated from the solution is already determined. However more of segregation phases with different size, distribution and magnitude still need to be deeply researched.

References

[1] ROBERTO B F, TERENCE G L. The development of superplastic ductilities and microstructural homogeneity in magnesium ZK60 alloy processed by ECAP [J]. Mater Sci Eng A, 2006, 430(1/2): 151- 156.

[2] LAPOVOK R, THOMSON P F, COTTAM R, ESTRIN Y. Processing routes leading to superplastic behaviour of magnesium alloy ZK60 [J]. Mater Sci Eng A, 2005, 410/411(25): 390-393.

[3] CHUVIL’DEEV V N, NIEH T G, GRYAZONY M Y, KOPYOLY V I, SYSOEV A N. Superplasticity and internal friction in micro- crystalline AZ91 and ZK60 magnesium alloys processed by equal-channel angular pressing [J]. J of Alloys and Compounds, 2004, 378(1-2): 253-257.

[4] GALIYEV A, KAIBYSHEV R. Superplasticity in a magnesium alloy subjected to isothermal rolling [J]. Scripta Mater, 2004, 51(2): 89- 93.

[5] YAN F, WU K, WU G L, LEE B L, ZHAO M. Superplastic deforma- tion behavior of a 19.7vol% β-SiCw/ZK60 composite [J]. Materials Letters, 2003, 57(13/14): 1992-1996.

[6] AGNEW S R, MEHROTRA P, LILLO T M, STOICA G M, LIAW P K. Texture evolution of five wrought magnesium alloys during route A equal channel angular extrusion: Experiments and simulations [J]. Acta Mater, 2005, 53(11): 3135-3146.

[7] HIROYUKI W, TOSHIJI M, KOICHI I, KRNJI H. Low temperature superplasticity of a fine-grained ZK60 magnesium alloy processed by equal-channel-angular extrusion [J]. Scripta Mater, 2002, 46(12): 851-856.

[8] BUSSIBA B, ARTZY A, SHTECHMAN A, IFERGAN S, KUPIEC M. Grain refinement of AZ31 and ZK60 Mg alloys—towards superplasticity studies [J]. Mater Sci Eng A, 2001, 302: 56-62.

[9] MA C, LIU M, WU G U, DING W J, ZHU Y P. Tensile properties of extruded ZK60-RE alloys [J]. Mater Sci Eng A, 2003, 349(1/2): 207-212.

[10] ZHANG S Q. Phase constitutions and morporlogies of Mg-Zn-Zr alloy (MB15) [J]. Acta Metall Sin, 1989, 5(6): A346-A351.

[11] GU M Y, WU Z G, JIN Y P, KOCAK M. Effects of reinforcements on the aging response of a ZK60-based hybrid composite [J]. Mater Sci Eng A, 1999, 272(2): 257-263.

[12] XU D K, LIU L, XU Y B, HAN E H. The effect of precipitates on the mechanical properties of ZK60-Y alloy [J]. Mater Sci Eng A, 2006, 420(1/2): 322-332.

[13] LIU A S. Binary Alloy Phase Diagrams [M]. Beijing: Metallurgical Industry Press, 2004: 105.

[14] CLARK J B, ZABFYR L, MOSER Z. Binary Alloy Phase Diagrams [M]. Ohio: American Society for Metals, 1986: 1563-1566.

[15] DING P D, PAN F S, ZHANG D F, PENG J, ZUO R L. Researches on as-cast microstructure and segregation of ZK60 alloys used for large extruded profiles [A]. UK-China Advanced Materials Symposium [C]. 2005: 96-110.

[16] PENG J, ZHANG D F, YANG C M, DING P D. Homogenizing researchers on ZK60 magnesium alloy ingot [J]. Materials Engineering, 2004, 8: 32-53.

[17] FAN C H, CHEN G, YAN H G, CHEN Z H. Effect of rare earth on magnesium and magnesium alloy [J]. Materials Review, 2005, 19(7): 61-63, 68.

[18] WEI L Y, DUNLOP G L, WESTENGEN H. The intergranular microstructure of cast Mg-Zn and Mg-Zn-Rare earth alloys [J]. Metallurgical and Materials Transaction A, 1995, 26: 1947-1955.

[19] JHA N, MISHRA A K. Thermodynamic and surface properties of liquid Mg-Zn alloys [J]. J of Alloys and Compounds, 2001, 329: 224-229.

[20] GU M Y. The interfacial reaction and microstructure in a ZK60-based hybrid composite [J]. Journal of Materials Science, 2000, 35: 2499-2505.

[21] MAENG D Y, KIM T S. Microstructure and strength of rapidly solidified and extruded Mg-Zn alloys [J]. Scripta Mater, 2000, 43: 385-389.

(Edited by YANG Bing)

Foundation item: Project(AA331050) supported by the Hi-tech Research and Development Program of China; Project(AA4003) supported by the Chongqing Science and Technology Commission, China

Corresponding author: MA Yan-long; Tel: +86-23-68668958; E-mail: mayanlong@cqit.edu.cn