Application research of centrifugal investment cast TiAl component used for advanced aircraft engine

来源期刊:中国有色金属学报(英文版)2002年第4期

论文作者:李俊涛 李世琼 张继 马万青 邹敦叙 仲增墉

文章页码:625 - 628

Key words:TiAl alloy; mechanical properties; microstructure; investment cast; components

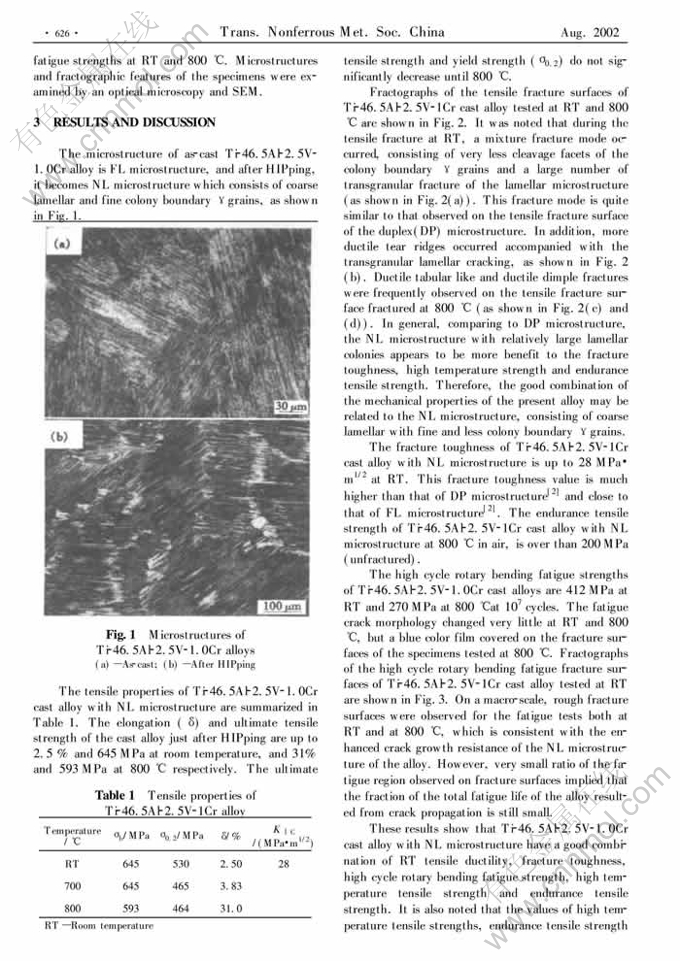

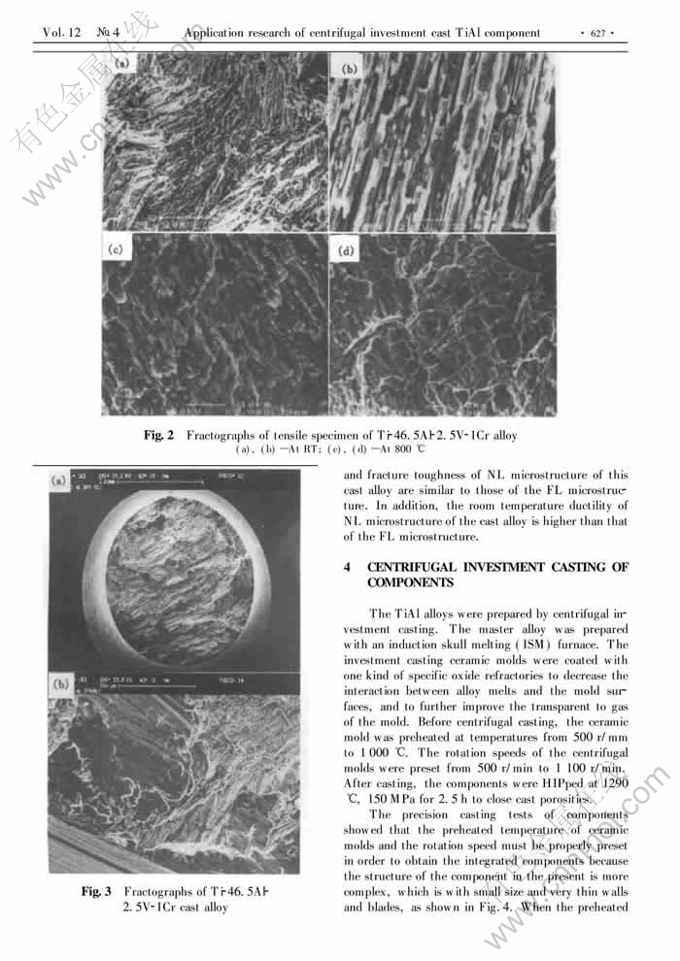

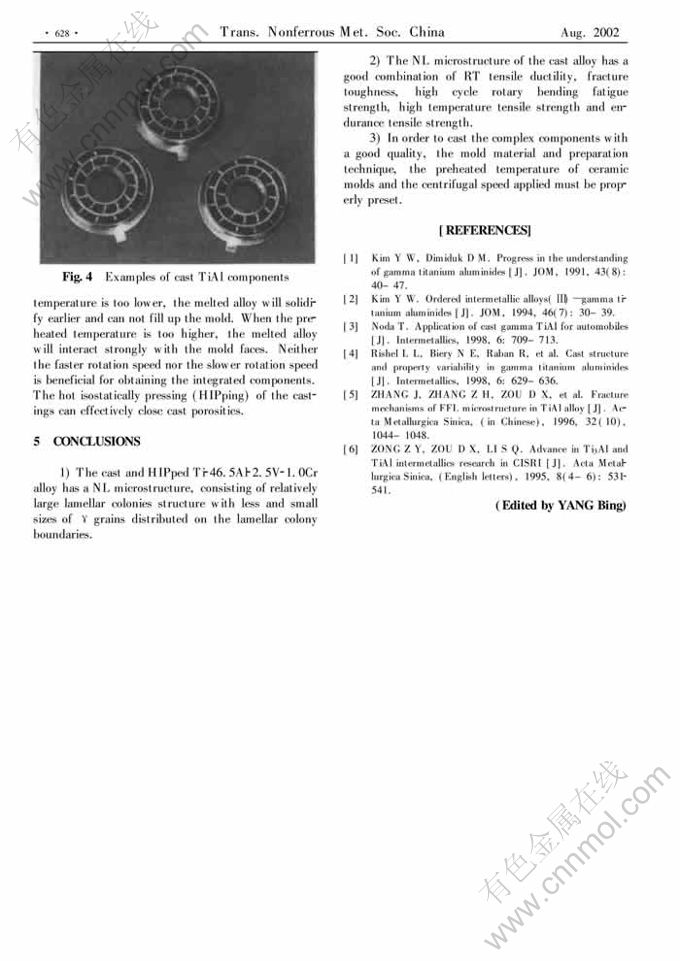

Abstract: A more complex structural component with small size and very thin walls and blades used for advanced aircraft engine was fabricated well by induction skull melting and centrifugal investment casting with a proper ceramic mold. The tensile elongation and ultimate strength of the hotisostatically pressed (HIPped) Ti-46.5Al-2.5V-1Cr (mole fraction, %) ca sting alloy s are up to 2.5% and 645MPa at room temperature, and 31% and 593MPa a t 800℃. The fracture roughness at room temperature is up to 28MPa·m1/2. The endurance tensile strength at 800℃ for 150h, is higher than 200MPa. The high cycle rotary bending fatigue strengths for 1×107 cycles at room temperature and 800℃ a re 412MPa and 270MPa, respectively.