Parameter identification of inertially stabilized platforms using current command design

来源期刊:中南大学学报(英文版)2013年第2期

论文作者:LI Zhi-qiang(黎志强) 张智永 周擎坤 范大鹏

文章页码:342 - 353

Key words:parameter identification; current command design; multilevel coordinate search; inertially stabilized platforms

Abstract: Accurate parameter identification is essential when designing controllers for inertially stabilized platforms (ISPs). But traditional identification methods suffer from observation measurement noise and operating restrictions of ISPs. To address this issue, a novel identification method based on current command design and multilevel coordinate search (MCS) algorithm without any higher order measurement differentiations was proposed. The designed current commands were adopted to obtain parameter decoupled models with the platform operating under allowable conditions. MCS algorithm was employed to estimate the parameters based on parameter decoupled models. A comparison experiment between the proposed method and non-linear least square method was carried out and most of the relative errors of identified parameters obtained by the proposed method were below 10%. Simulation and experiment based on identified parameters were conducted. A velocity control structure was also developed with disturbance observer (DOB) for application in disturbance compensation control system of an ISP. Experimental results show that the control scheme based on the identified parameters with DOB has the best disturbance rejection performance. It reduces the peak to peak value (PPV) of velocity error integral to 0.8 mrad which is much smaller than the value (10 mrad) obtained by the single velocity controller without DOB. Compared with the control scheme based on sweep model with DOB compensation, the proposed control scheme improves the PPV of velocity error integral by 1.625 times.

J. Cent. South Univ. (2013) 20: 342–353

DOI: 10.1007/s11771-013-1494-y

LI Zhi-qiang(黎志强), ZHANG Zhi-yong(张智永), ZHOU Qing-kun(周擎坤), FAN Da-peng(范大鹏)

College of Mechatronics Engineering and Automation, National University of Defense Technology, Changsha 410073, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2013

Central South University Press and Springer-Verlag Berlin Heidelberg 2013

Abstract: Accurate parameter identification is essential when designing controllers for inertially stabilized platforms (ISPs). But traditional identification methods suffer from observation measurement noise and operating restrictions of ISPs. To address this issue, a novel identification method based on current command design and multilevel coordinate search (MCS) algorithm without any higher order measurement differentiations was proposed. The designed current commands were adopted to obtain parameter decoupled models with the platform operating under allowable conditions. MCS algorithm was employed to estimate the parameters based on parameter decoupled models. A comparison experiment between the proposed method and non-linear least square method was carried out and most of the relative errors of identified parameters obtained by the proposed method were below 10%. Simulation and experiment based on identified parameters were conducted. A velocity control structure was also developed with disturbance observer (DOB) for application in disturbance compensation control system of an ISP. Experimental results show that the control scheme based on the identified parameters with DOB has the best disturbance rejection performance. It reduces the peak to peak value (PPV) of velocity error integral to 0.8 mrad which is much smaller than the value (10 mrad) obtained by the single velocity controller without DOB. Compared with the control scheme based on sweep model with DOB compensation, the proposed control scheme improves the PPV of velocity error integral by 1.625 times.

Key words: parameter identification; current command design; multilevel coordinate search; inertially stabilized platforms

1 Introduction

Inertially stabilized platforms (ISPs) are commonly employed in vehicles, ships, aircrafts, and missiles for different missions, including reconnaissance, surveillance, missile guidance, and so on [1–3]. Precise parameter estimation is required in ISP control systems to achieve stable control of the line of sight of optical imaging sensors. Generally, parameter identification of a DC motor is accomplished based on traditional method using armature voltage, armature current, angular velocity, and even the angular acceleration and the derivative of the armature current without operation restrictions. The identification accuracy is susceptible to the noise presented in the measurements [4]. Angular velocity computations based on simple numerical differentiation from a low-resolution position sensor may be largely erroneous, especially in the low-velocity regions [5]. Furthermore, if angular acceleration calculation is performed, derivative calculation is inevitable, which makes the quantization error larger. In the present work, a novel method using only the armature voltage, armature current, and position signal for system parameter identification is presented. we focus attention on finite rotations because ISPs operate in finite rotations under normal status.

Many parameter estimation methods for DC motor systems can be employed. The most common application is the direct use of information on the input and output data. Many researchers have contributed efforts on such method, and various optimal algorithms were developed [6–9]. DUPUIS et al [6] presented a parameter identification method using multiobjective genetic algorithm to eliminate the specified weights for the different objectives and the experiments demonstrated the robustness of the technique. According to the obtained parametric models, DUB and JALOVECKY et al [7] and UDOMSUK et al [8] realized an accurate parameter estimation for motor system with Nelder-Mead simplex search method and adaptive Tabu search technique, respectively. All of them indirectly utilized the saturation effect of velocity under large command excitation; however, the velocity saturation effect is not allowed because of the restrictive conditions of ISPs. The less common approach is the estimation of the parameters using the least square (LS) algorithm based on the dynamic model of a DC motor [10–11]. Theoretically, the parameters can be estimated easily if all the responses and the input of the dynamic model are available. Nevertheless, estimating perfectly the angular velocity and angular acceleration in an actual system using a low-resolution position sensor is difficult, and the unknown signal noise contained in the armature current causes inaccuracy in the result of the derivative of the armature current estimation. SAAB and KAED–BEY [11] utilized a Kalman filter to estimate angular acceleration and derivative of the armature current. The third method is the estimation of the parameters based on empirical formula or special phenomenon occurring in a specific system. TAKANASHI et al [12] proposed a simple method based on empirical formulae for estimating the inertia and load torque as well as the winding resistance and back electromotive force (back-EMF) constant of a three-phase brushless DC motor, but the results were sensitive to acceleration signal error. BORSOTTO et al [13] proposed an approach for identifying static and Coulomb friction coefficients based on limit-cycle oscillation properties in the position loop of a mechanical system, but he had to design a special position controller to put the system in oscillation, which is not acceptable in ISPs. At last, an identification scheme based on the algebraic identification method was studied in the region of brushless DC motor [14–15]. The methodology can eliminate the disturbances and the effect of the initial conditions and filter out high frequency measurement noise, but also exhibits a drawback of the singularities in the solutions of the parameter estimates. To solve the singularity issue, GARRIDO and CONCHA [16] presented an on-line identification technique that combined a least squares algorithm and the parameterization by the Operational Calculus, which exploits the advantages of algebraic identification and does not exhibit the problem of singularity. Therefore, the above-mentioned approaches are suitable only for the specific motor systems without restrictions.

This work focused on applying only three measurements to identify the system parameters for ISPs operating in finite range. The main contributions are as follows: The parameter decoupled models were obtained by using the method of current command design (CCD). To overcome the problem of local minimizer for traditional optimal algorithms, the multilevel coordinate search (MCS) was employed to search the parameters in the obtained nonlinear parameter decoupled models. A parameter identification experiment for the simulator of ISPs was conducted. Based on the identified parameters, a special current closed-loop response under a large input reference was analyzed. A velocity feedback control experiment was conducted. The disturbance observers (DOB) based on different normal models were employed to verify the consistency between the normal model and the practical system. Comparative experiments between the single velocity controller without and with DOB were conducted on the simulator of ISPs.

2 System modeling

The system considered in this work is an industrial two-degree-of-freedom platform shown in Fig. 1. It consists of two main structural units, namely, azimuth and pitch gimbals, and the revolution axes of the gimbals, equipped with current-controlled DC torque motor, are orthogonal to each other. Therefore, the ISPs can be reduced into two single-axis systems for designing the controllers.

The system dynamic model of ISPs is given by

(1)

(1)

(2)

(2)

where t is the time variable; ia(t) is the armature current; R is the armature resistance; L is the armature inductance; ua(t) is the armature voltage; ε(t) is the back-EMF, and Ke is the back-EMF constant (V·s/rad).  is the angular velocity, J is the motor and load moments of inertia, B is the damping coefficient of the system, and Km is the motor torque constant (N·m/A).

is the angular velocity, J is the motor and load moments of inertia, B is the damping coefficient of the system, and Km is the motor torque constant (N·m/A).  denotes the resistance torque acting on the motor shaft.

denotes the resistance torque acting on the motor shaft.

Fig. 1 Schematic diagram of a two-degree-of-freedom platform.

Based on the power balance of a motor system, the following basic relationship is obtained [12]:

(3)

(3)

The Coulomb friction of an actual ISP is often asymmetric; therefore, the resistance torque is a nonlinear function characterized by the angular position and velocity under bi-directional low-velocity operating conditions.

(4)

(4)

where F+c denotes the Coulomb friction coefficient in the positive direction, F–c denotes the Coulomb friction coefficient in the negative direction, Fs represents the static friction coefficient, G(θ) is the lopsided moment, and  is the critical angular velocity.

is the critical angular velocity.

To develop the ISP controller, the parameters of Eqs.(1), (2), and (4), namely, R and L, Ke, J, B, F+c, F–c, and Fs should be estimated, and the restrictions that guarantee ISP operation in normal status are defined as follows:

(5)

(5)

where  is the maximum velocity of the system, and θlower and θupper represent the minimum and maximum angular positions of ISPs, respectively. Conventional estimation methods suffer from drawbacks, limited by these two restrictions. A novel identification method of CCD and MCS will be presented based on above system analysis.

is the maximum velocity of the system, and θlower and θupper represent the minimum and maximum angular positions of ISPs, respectively. Conventional estimation methods suffer from drawbacks, limited by these two restrictions. A novel identification method of CCD and MCS will be presented based on above system analysis.

3 System identification

3.1 Current command design

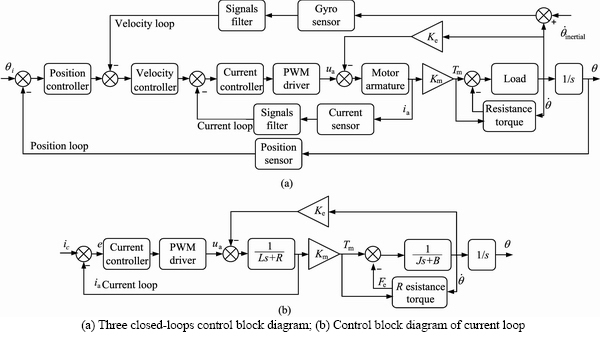

As shown in Fig. 2(a), the traditional three closed-loops control scheme, which includes the current, velocity, and position loops, is employed in the motor servo control [17].

The motor servo control with current control loop has two advantages [18]. 1) The motor output torque can be controlled accurately by the armature current of the motor. 2) The current control loop response is quicker than that of the velocity loop, and the armature voltage fluctuations caused by the back-EMF can be suppressed. Based on the aforementioned advantages, the current control loop is employed in the servo control of ISPs, and two main goals must be achieved in designing the current command signals. First, the platform movement should be within a restricted range, and second, the current command signal should be designed based on the characterization of the sub-models shown in Fig. 2 (b) to attenuate the effect among parameters.

Fig. 2 Control loop block diagram of ISP:

The platform response excited by the current commands can be divided into stationary and moving parts, as shown in Fig. 3, because of the influence of friction. When the driving torque is smaller than the breakaway torque, the platform remains in stationary state. Therefore, the electrical parameters of the system can be identified according to the ua(t) and ia(t) measurements. The mechanical parameters can be identified based on the relationship between the armature current ia(t) and the angular position θ(t) when the driving torque is larger than the breakaway torque.

The slope of amplitude-frequency characteristic in low-frequency region for the open-loop transfer function of the current control loop is 20 dB/(10a), as shown in Fig. 2 (b), and a proportional–integral (PI) controller is commonly chosen for current closed-loop control [19]. The output voltage of the driver is given by

(6)

(6)

(7)

(7)

Fig. 3 Identification signals and responses:

where kp and ki are the parameters of the PI controller and ic(t) is the input current command.

3.1.1 Stationary status

1) When ic(t) is a slope command that satisfies ic(t)= ka·t, where ka is a constant value, and driving torque Tm satisfies the inequality Tm = Km·ia(t) < Fs, a steady-state error Δ can be produced in the current response, i.e.,

(8)

(8)

Based on Eqs. (6) and (8), the armature voltage ua(t) is given by

(9)

(9)

where kpwm is the motor driver gain and parameters kp and ki are provided by the motor driver. The armature voltage ua(t) linearly changes with time, but no parameters to be identified are present in Eq. (9). Therefore, a formulation between ua(t) and the parameters to be identified has to be established.

As the platform remains in the stationary state,Eq. (1) can be rewritten as

(10)

(10)

From Eqs. (8) and (10), the following equation is obtained:

(11)

(11)

Equation (9) is coincident with Eq. (11). the motor parameters R and L can be estimated by fitting the ua(t) measurement into a line model. Compared with an inductive load, resistive load is the main component in Eq. (11). When noise exists in the current loop, the inductance parameter L is estimated inefficiently. A sine signal is used to increase the weighting of the inductive load for this problem.

2) When the input is ic(t)=ka·sin(ωt), and satisfies Tm=Km·ia(t)

(12)

(12)

where k′=-kα·ξ / 2; then, Eqs. (6) and (12) yield

(13)

(13)

where and

and

,

, and k'' can be estimated by fitting the ua(t) measurement without the parameters kp and ki of the PI controller.

and k'' can be estimated by fitting the ua(t) measurement without the parameters kp and ki of the PI controller.

According to Eq. (13), ua(t) is a sine signal. The solution of Eq. (10) can be described in the following form:

(14)

(14)

where ω is the frequency of the sine signal and ω = 100 rad/s. Inductance L can be estimated based on Eq. (14) using the sampling datum ia(t).

3.1.2 Moving status

Considering that the adverse effect caused by nonlinear friction is more serious than the effect caused by unbalanced moment, to reduce computation cost, the friction parameters are primarily being focused here based on the following assumptions:

1) The platform is adjusted subtly so that the unbalanced moment is negligible.

2) The friction distribution is uniform, i.e., the Coulomb friction coefficient is constant in the rotary direction.

According to Eq. (2), the dynamic model of the platform can be rewritten as

(15)

(15)

If input ic(t) is a step signal and satisfies Tm= Km·ia(t)>Fs, then

where kβ is a constant. The solution of Eq. (15) is

(16)

(16)

Thus, the parameters can be estimated using position datum θ(t) under different amplitude input signals according to Eq. (16).

When the input signal is switched to zero, the back-EMF ε(t) is equal to the output of the driver to enable the armature current to track the current command signal; therefore, Eq. (1) is written as

(17)

(17)

In the area marked with rectangles in Fig. 3(d), for the friction effect, velocity  is reduced to zero in extremely short time so that ua(t) can be written approximately as a linear formula ua(t)=at+b. Parameters a and b can be estimated using ua(t); then, the solution of Eq. (17) is

is reduced to zero in extremely short time so that ua(t) can be written approximately as a linear formula ua(t)=at+b. Parameters a and b can be estimated using ua(t); then, the solution of Eq. (17) is

(18)

(18)

Parameter Ke can be estimated using the sampling position datum θ(t) according to Eq. (18).

3.2 Identification algorithm

To identify the nonlinear parameters that appear in the parameter decoupled models, several Matlab methods can be employed. However, the problem of such algorithms is that such methods are local minimizers, which are dependent of the initial conditions. Sometimes, the algorithms do not converge or deliver only mathematical solution to the problem, rather than a solution with physical meaning. Further, the optimization procedure is likely to get stuck before the global minimum is reached [21]. Hence, the MCS algorithm, as a global optimization algorithm, is chosen to solve the problem. The merits of the MCS algorithm are as follows [22]: 1) MCS is guaranteed to converge if the objective function is continuous in the neighbourhood of a global minimizer, and 2) MCS does not require an initial condition but only a range where the parameters should lie.

The objective function is defined as a quadratic function of the error by

(19)

(19)

where y is the measured information,  is the estimation of y with respect to the parameter decoupled models obtained in Section 3.1, x is a vector of the parameters to be identified, and u and v are n-dimensional vectors with components ui < vi, i = 1,···, n. Therefore, the target is to minimize the objective function f(τ) using the MCS algorithm. In the next section, the main MCS processes are introduced.

is the estimation of y with respect to the parameter decoupled models obtained in Section 3.1, x is a vector of the parameters to be identified, and u and v are n-dimensional vectors with components ui < vi, i = 1,···, n. Therefore, the target is to minimize the objective function f(τ) using the MCS algorithm. In the next section, the main MCS processes are introduced.

3.2.1 Initialization and sweeps

The procedure produces an initial set of boxes. The boxes are obtained by comparing the objective function value at the base points. The function value not only defines the size of the sub-box according to the golden selection ratio but also defines the level of the sub-box. The sweep function selects the box with the lowest function value among all boxes at the same level as a candidate for splitting.

3.2.2 Box splitting

According to the splitting information in the candidate history, the level of box s is compared with 2n(min nj + 1) (where nj is the number of the splitting times of coordinate j in the box history), and the box can be split based on one of the following rules:

Rule 1: Splitting by rank

When s > 2n(min nj + 1), this condition signifies that although the box has already reached a high level, at least one coordinate exists along which the box has not split very often. Therefore, the box should be split along with coordinate j, which processes the smallest nj and the highest variability rank. Obviously, this rule guarantees that all coordinates are split in a proper manner.

Rule 2: Splitting by expected gain

When s∈2n(min nj+1), the local separable quadratic model is obtained based on the completed local approximation of the objective function using quadratic interpolation, and the optimal splitting coordinate and the position of the split can be determined in the interval {ξ', ξ"},

(20)

(20)

(21)

(21)

3.2.3 Local search

When s=smax, the local search to accelerate convergence of the algorithm is determined to have progressed or not by checking whether the base point of the box is likely to be in the basin of attraction of a local minimizer already in the shopping basket. The local search algorithm used in the implementation of MCS essentially consists of building a local quadratic model using triple and coordinate searches.

Part 1: Triple search

The main idea of the triple search is that a quadratic model q(x) is used to approximate the objective function f based on  function values, and a promising search direction is obtained through the minimized q(x) in a suitable box and making a line search along this direction.

function values, and a promising search direction is obtained through the minimized q(x) in a suitable box and making a line search along this direction.

The quadratic model q(x) is defined as

(22)

(22)

where f is a function value at point x, g is the gradient approximation, G is the Hessian matrix approximation, and xbest is the current best point in the triple search. The objective of the triple search is to select elements g and G that satisfy q(x) = f(x) at  distinct points.

distinct points.

Part 2: Coordinate search

The coordinate search process is used to find the elements for the triple search based on a line search routine.

3.2.4 Shopping basket

To avoid the unnecessary local minimizer, one of the functions of this procedure is to check whether the results of the box splitting are the basin of attraction of a local minimizer already in the shopping basket. To ensure search efficiency, the results of the local search are checked to determine whether a new point is really found.

4 Test case: experimental setup of isps simulator

4.1 Experimental setup

As shown in Fig. 4, a DC torque motor is axially assembled on one side of the assembly, and a magnetic brake is fixed on the other side. The motor–brake pair is aligned coaxially so that the sensors have a one-degree-of-freedom rotation around the axis. The high-resolution encoder RON285-18000-01-03 from Heidenhain (18 000 signal periods/revolution ×256 decoding; approximately 22-bit resolution) is assembled in the middle. The encoder provides the position signal and enables construction of an 18-bit low-resolution encoder following the method used in Ref. [23]. A torque sensor 9349A from Kistler and an inertial plate are mounted on the test apparatus. All sensors are connected to the dSPACE1103 RS422 and the ADC systems with real-time interface, thereby enabling precise data acquisition. The control signal produced by the dSPACE1103 DAC system can be realized by the motor driver ADS50/5 from Maxon.

Fig. 4 Experimental setup

Current closed-loop control is executed by the current loop controller designed in ADS50/5. The system operates in a given range by two limited blocks and a stop mounted on the inertial plate and on the base, respectively. The experimental system runs on a dSPACE1103 real-time operating system based on Matlab / Simulink at 1 000 Hz sampling rate.

4.2 Identification experiment

To investigate the validity of the proposed method, a parameter identification experiment is conducted on the ISPs simulator. For illustration purposes, the parameter values are provided in Table 1.

To ensure suitable excitation of the ISP simulator, static friction should be estimated first. A simple method is by using a small ramp current command to excite the system. When the simulator begins to rotate, the torque sensor data at the moment are considered as static friction. The current command can then be designed adequately based on these data.

Table 1 Parameter values of test apparatus

A comparison of the identification performance of the MCS method and the nonlinear LS (NLS) algorithm are shown in Figs. 5 and 6, respectively. Two kinds of parameter decoupled models, namely, Eqs. (11) and (14), are used in the test.

Equation (11) is simplified as y(t)=at+b, whereas Eq. (14) is simplified as y(t)=ae–bt+(c–d)t+e. Both algorithms have the same search space, and all initial values of the NLS parameters are set to zero.

Case 1. As shown in Fig. 5, the linear parameters are identified by MCS and NLS. Several local minima are obtained by the MCS algorithm; however, the algorithm does not get stuck until the global minimum is achieved (denoted by an asterisk), as shown in Fig. 5(a). On the other hand, the NLS algorithm obtains the optimal value (denoted by an asterisk) with the decrease in the identification error, as shown in Fig. 5(b). The parameters obtained by MCS is equal to the ones identified by NLS, as shown in Figs. 5(c) and (d).

Case 2. The nonlinear parameters are identified by MCS and NLS in Fig. 6. In this case, MCS spends more iteration times in searching for the global minimum, which fluctuated seriously compared with the linear case, as shown in Fig. 6(a). The NLS identification error decreases fast in the first several iterations, and the local minimum is found at the last iteration, as shown in Fig. 6(b). However, the parameters identified by both methods are totally different.

To verify the parameter identification accuracy, the fitted curves of the parameters identified by MCS and NLS are shown in Figs. 6(c) and (d). Obviously, the curve fitted with parameters estimated by NLS is not coincident with the measured position response. As the initial values are not properly provided, the NLS algorithm may either get stuck at a local minimum or deliver a mathematical solution for the problem, instead of a solution with physical meaning.

Fig. 5 Comparison of identification performances of MCS and NLS in a linear case:

Fig. 6 Comparison of identification performances for MCS and NLS in a nonlinear case:

As shown in Fig. 6(c), the efficiency of the parameter decoupled model obtained by CCD and the accuracy of the MCS identified parameters are validated by the remarkable consistency between the fitted curve and the practical response data.

Furthermore, in Case 1, the armature resistance is calculated based on the corresponding coefficient relationship in Eq. (11). Similarly, the armature inductance and the back-EMF coefficient can be estimated. In Case 2, under two different position responses in the same direction, the other physical parameters can be estimated by MCS. To improve the identification precision that suffers from stochastic factors (e.g., noise), the identified parameters have to be averaged. Table 2 shows the averaged experimental results from 30 groups of data.

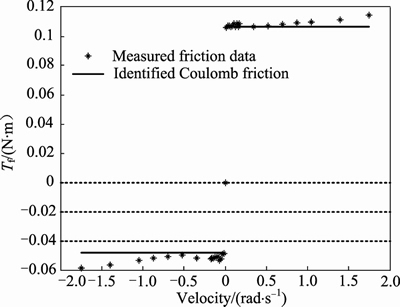

The identified Coulomb friction is equal to the friction measured by the torque sensor, as shown in Fig. 7, and the Coulomb friction in the actual system is asymmetric. Moreover, conclusion can be made that the viscosity friction coefficient is approximately 0.005 N·m/(rad×s–1), smaller than the identified damping coefficient B of the experimental system, although B is regarded conventionally as the viscosity friction coefficient.

To verify the effectiveness of the identified parameters on the characterization of the system behaviour under large current command, experiment and simulation of the current closed-loop control are conducted. As shown in Fig. 8, the simulated current response based on the identified parameters is very close to the measured one; thus, conclusion can be drawn that the proposed method is reliable and effective based on the excited condition of a small current command. The current command is tracked well by the actual current in the first 0.1 s; then, the actual current decreases gradually until it is steady with a nonzero constant value after 0.4 s. The reason of the phenomena in the current closed loop could be the saturation effect of velocity. And the steady-state current value is dependent on the saturation limit of the driver and the back-EMF and the resistance torque.

4.3 Comparison of control characteristics

High-precision motion control is based on accurate model parameters. A disturbance compensation scheme based on disturbance observer (DOB) [24–25] is used to evaluate the consistency between the identified model and the actual plant.

Velocity control is a basic pattern of ISPs. As shown in Fig. 9, a velocity feedback control system is developed based on nominal model Gn(s).

where  is the reference input signal, Gcv(s) is the velocity controller, Gp(s) denotes the actual plant model, and Gn(s) is the nominal model. Gdt(s) is a tracking differentiator, designed according to the method used in Ref. [26] to estimate the angular velocity.

is the reference input signal, Gcv(s) is the velocity controller, Gp(s) denotes the actual plant model, and Gn(s) is the nominal model. Gdt(s) is a tracking differentiator, designed according to the method used in Ref. [26] to estimate the angular velocity.

is a filter employed in DOB [27–28]. Considering the angular velocity noise, the Q(s) bandwidth is set at 52 Hz, i.e., τ = 0.005. Ff denotes the disturbance torque.

is a filter employed in DOB [27–28]. Considering the angular velocity noise, the Q(s) bandwidth is set at 52 Hz, i.e., τ = 0.005. Ff denotes the disturbance torque.

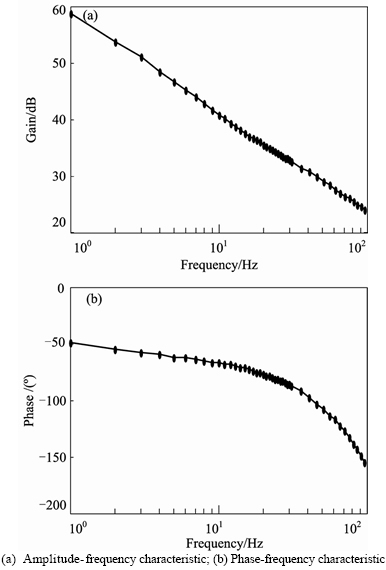

According to the frequency response of the simulator shown in Fig. 10, a nominal model Gns(s) of the simulator can be obtained.

(23)

(23)

Model Gni(s) is the other nominal model of the simulator obtained by the proposed method, i.e.,

(24)

(24)

whereas the corresponding velocity loop controllers [29] are developed as

(25)

(25)

(26)

(26)

where Gcvs(s) is the controller based on the model Gns(s) and Gcvi(s) is the controller based on the model Gni(s).

Table 2 Identified parameter values

Fig. 7 Comparison of measured friction data with identified Coulomb friction

Fig. 8 Comparison of armature current responses for measured and simulated data

Fig. 9 Schematic of control system based on DOB

The velocity closed-loop responses based on the two nominal models with reference to input  are shown in Figs. 11 (a) and (b). The control scheme with DOB compensation shows better performance than the scheme with single-loop velocity control. Velocity hysteresis caused by friction torque can be compensated perfectly by DOB based on nominal model Gni(s) in the low-velocity region. This phenomenon can also be suppressed to some extent by DOB based on nominal model Gns(s); however, when the velocity is near the zero-velocity region, a peak generated by improper disturbance compensation appears. Similar phenomenon is revealed in detail in response to the velocity error integral. the velocity error integrals (E) of the controllers based on the two nominal models are shown in figs. 11(c) and (d). the peak-to-peak values (ppvs) of velocity error integrals for the nominal model Gni(s) with and without dob compensation are 0.8 and 10 mrad, respectively and the ppvs of velocity error integrals for the mode Gns(s) with and without dob compensation are 1.3 and 7 mrad, respectively. although the performance of the velocity controller based on Gni(s) is not better than the performance of the controller based on Gns(s), the velocity error integral of Gni(s) is smaller than the error of Gns(s) after applying dob compensation. meanwhile, the velocity error integral curve of the nominal model Gni(s) is smoother than the curve of Gns(s). therefore, the model Gni(s) appears to be more consistent with the actual system than the model Gns(s) in the comparison between both integral error curves with dob compensation.

are shown in Figs. 11 (a) and (b). The control scheme with DOB compensation shows better performance than the scheme with single-loop velocity control. Velocity hysteresis caused by friction torque can be compensated perfectly by DOB based on nominal model Gni(s) in the low-velocity region. This phenomenon can also be suppressed to some extent by DOB based on nominal model Gns(s); however, when the velocity is near the zero-velocity region, a peak generated by improper disturbance compensation appears. Similar phenomenon is revealed in detail in response to the velocity error integral. the velocity error integrals (E) of the controllers based on the two nominal models are shown in figs. 11(c) and (d). the peak-to-peak values (ppvs) of velocity error integrals for the nominal model Gni(s) with and without dob compensation are 0.8 and 10 mrad, respectively and the ppvs of velocity error integrals for the mode Gns(s) with and without dob compensation are 1.3 and 7 mrad, respectively. although the performance of the velocity controller based on Gni(s) is not better than the performance of the controller based on Gns(s), the velocity error integral of Gni(s) is smaller than the error of Gns(s) after applying dob compensation. meanwhile, the velocity error integral curve of the nominal model Gni(s) is smoother than the curve of Gns(s). therefore, the model Gni(s) appears to be more consistent with the actual system than the model Gns(s) in the comparison between both integral error curves with dob compensation.

Fig. 10 Frequency response of simulator:

Fig. 11 Comparison of velocity tracking performances without DOB compensation and with DOB compensation:

5 Conclusions

1) The proposed method is realized by intrinsic control loop and measurements of ISPs without requiring other sensors, thus reducing extra sensor requirements for identification realization.

2) The parameter decoupled models are obtained using CCD.

3) The system parameters, such as armature resistance, armature inductance, back-EMF constant, damping coefficient, moment of inertia, and Coulomb friction coefficient, can be estimated using only three measurements and most of the relative errors of identified parameters are below 10%.

4) Designed servo controller for the simulator by using the identified model obtained by proposed method with DOB technique can achieve superior disturbance rejection performance over the single velocity controller and the controller based on the model obtained by sweep method with DOB control strategies. The PPV of velocity error integral of the control scheme based on the identified model with DOB is 0.8 mrad which is much smaller than the value (10 mrad) obtained by the controller without DOB. Compared with the control scheme based on sweep model with DOB compensation, the proposed control scheme improves the PPV of velocity error integral by 1.625 times.

5) The drawback of the current work is that the static friction coefficient did not estimate and the friction considered in this work was simple as a static friction model which could not characterize frictional behaviour in ISPs. If a new dynamic friction model that can depict frictional behaviour well in all frictional regimes is developed, the performance of control system can be improved further. This research will be conducted in the future.

Acknowledgment

The authors would like to thank Dr. W. Huyer for his guidance on multilevel coordinate search algorithm.

References

[1] HILKERT J M. Inertially stabilized platform technology [J]. IEEE Control Systems Magazine, 2008, 28(1): 26–46.

[2] Michael K M. Inertially stabilized Platform for optical imaging systems [J]. IEEE Control Systems Magazine, 2008, 28(1): 47–64.

[3] FAN Da-peng, ZHANG Zhi-yong, FAN Shi-xun, LI Yan. Research of basic principles of E-O stabilization and tracking devices [J]. Optics and Precision Engineering, 2006, 14(4): 673–680. (in Chinese)

[4] LIU Hong-cai. System identification and parameter Estimation [M]. Beijing: Metallurgical Industry Press, 1996, 88–90.(in Chinese)

[5] Su Y X, Zheng C H, Mueller P C, Duan B Y. A simple improved velocity estimation for low-speed regions based on position measurement only. IEEE Trans., Control Systems Technology, 2006, 14: 937–942.

[6] Dupuis A, Ghribi M, Kaddouri A. Multiobjective genetic estimation of DC motor parameters and load torque [C] // IEEE International Conference on Industrial Technology. Hammamet: IEEE, 2004: 1511–1514.

[7] Dub M, Jalovecky R. DC motor experimental parameter identification using the Nelder-Mead simplex method [C] // Power Electronics and Motion Control Conference (EPE/PEMC). Ohrid: IEEE, 2010, S4–9–S4–11.

[8] Udomsuk S, Areerak K L, Areerak K N, SRIKAEW A. Parameters identification of separately excited DC motor using adaptive tabu search technique [C] // Advances in Energy Engineering (ICAEE). Beijing: IEEE, 2010, 48–51.

[9] Wei Wu. DC motor identification using speed step responses [C] // American Control Conference (ACC). Baltimore: IEEE, 2010: 1937–1941

[10] Ramakrishnan R, Islam R, Islam M, Sebastian T. Real time estimation of parameters for controlling and monitoring permanent magnet synchronous motors [C] // IEEE International Electric Machines and Drives Conference. Miami: IEEE, 2009: 1194–1199.

[11] Saab S S, Kaed-Bey R A. Parameter identification of a DC motor: an experimental approach [C] // IEEE International Conference on Electronics, Circuits and Systems. Malta: IEEE, 2001: 981–984.

[12] Takahashi H, Kenjo T, Takeuchi H. A real-time estimation method of brushless DC servomotor parameters [C] // Power Conversion Conference. Nagaoka: IEEE, 1997: 73–678.

[13] Bastien B, Emmanuel G, Dominique B, EMMANEUL D. An identification method for static and coulomb friction coefficients [J]. International Journal of Control, Automation, and Systems, 2009, 7(2): 305–310.

[14] Cortes-Romero J A, Luviano-Juarez A, Alvarez-Salas R. Fast identification and control of an uncertain Brushless DC motor using algebraic methods [C] // Power Electronics Congress (CIEP). San Luis Potosi: IEEE, 2010: 9–14.

[15] Luviano-Juarez A, Cortes-Romero J, Sira-Ramirez H. Algebraic identification and control of an uncertain DC motor using the delta operator approach [C] // Electrical Engineering Computing Science and Automatic Control (CCE), Tuxtla Gutierrez:IEEE, 2010: 82–487.

[16] Garrido R, Concha A. Combining Algebraic Identification and a Least Squares method for DC servomechanism identification [C] // Electrical Engineering Computing Science and Automatic Control (CCE). Tuxtla Gutierrez, IEEE, 2010: 8–33.

[17] PANG Xin-liang. A study on key technology of digital control of airborne electro-optical stabilization platform system [D]. Changsha: National University of Defense Technology, 2007. (in Chinese)

[18] CHEN Bo-shi. Electric drive automatic control system-motion control system [M]. Beijing: Mechanical Industry Press, 2003: 52–59. (in Chinese)

[19] HU Hao-jun. Line-of-sight stabilization of acquisition, tracking and pointing system on moving bed [D]. Changsha: National University of Defense Technology, 2005. (in Chinese)

[20] WEN Xi-sheng, CHEN Xun, XU Yong-cheng, et al. Modeling and dynamic analysis of mechanical system [M]. Beijing: Science Press, 2004: 9–70. (in Chinese)

[21] da Silva A R Parameters identification and failure detection applied to space robotic manipulators [D]. Sao José dos Campos: Instituto Nacional De Pesquisas Espaciais, 2002.

[22] Huyer W, eumaier Arnold. Global optimization by multilevel coordinate search [J]. Journal of Global Optimization, 1999, 14(4): 31–355.

[23] Lemkin M, Yang P H, Huang A C. Velocity estimation from widely spaced encoder pulses [C] // Proceedings of American Control Conference. Seattle: IEEE, 1995: 998–1002.

[24] Takaji U, Yoichi H. Robust speed control of DC servomotors using modern two degrees-of-freedom controller design [J]. IEEE Transactions on Industrial Electronics. 1991, 38(5): 363–368.

[25] FAN Shi-xun, FAN Da-peng, HONG Hua-jie, ZHANG Zhi-yong. Robust tracking control for micro machine tools with load uncertainties [J]. Journal of Central South University, 2012 19: 117-127.

[26] WU Li-qiang, LIN Hao, HAN Jin-qing. Study of tracking differentiator on filtering [J]. Journal of System Simulation, 2004, 16(4): 651–653. (in Chinese)

[27] SADHU S, GHOSHAL T K. Sight line rate estimation in missile seeker using disturbance observer-based technique [J]. IEEE Transactions on Control Systems Technology, 2011, 19(2), 449–454.

[28] LEE Seung-hi, KANG Hyun-jae, CHUNG Chung-choo. Robust fast seek control of a servo track writer using a state space disturbance observer [J]. IEEE Transactions on Control Systems Technology, 2012, 20(2): 346–355

[29] ZHANG Zhi-yong, FAN Da-peng, FAN Shi-xun. Servo system design for E-O stabilization and tracking devices [J]. Optics and Precision Engineering, 2006, 14(4): 681–688. (in Chinese)

(Edited by HE Yun-bin)

Foundation item: Project(50805144) supported by the National Natural Science Foundation of China

Received date: 2012–03–13; Accepted date: 2012–07–15

Corresponding author: LI Zhi-qiang, PhD candidate; Tel: +86–731–84574934; E-mail: lizhiqiang2002@gmail.com