文章编号:1004-0609(2008)08-1432-08

Al-Zn-Mg-Cu-Cr合金厚板组织细化

林高用,杨 伟,孙利平,彭大暑

(中南大学 材料科学与工程学院 教育部有色金属材料科学与工程重点实验室,长沙 410083)

摘 要:提出一种细化Al-Zn-Mg-Cu-Cr合金厚板组织的“强化固溶→过时效→中温多向锻造→中温轧制→快速加热再结晶处理”的中间变形热处理(ITMT)技术原型,采用金相分析、能谱分析和透射电镜分析等方法,研究ITMT工艺过程中的组织演变规律和晶粒细化的机理,并讨论利用不连续再结晶控制晶粒大小所具备的条件。结果表明:采用ITMT工艺能够保证Al-Zn-Mg-Cu-Cr合金厚板的充分、均匀变形,在轧制变形量不超过80%的条件下,使厚度达6 mm以上的Al-Zn-Mg-Cu-Cr合金再结晶晶粒组织和第二相结构深度细化:短横向平均晶粒尺寸为8 μm,纵向及长横向平均晶粒尺寸为12 μm,第二相点状颗粒尺寸一般小于3 μm。ITMT工艺细化晶粒的机理主要是利用变形储能和第二相的有利影响,通过不连续再结晶实现组织细化。

关键词:Al-Zn-Mg-Cu-Cr合金;厚板;ITMT工艺;不连续再结晶;组织细化

中图分类号:TG 113; TG 146.1 文献标识码:A

Structures refinement of Al-Zn-Mg-Cu-Cr alloy thick plates

LIN Gao-yong, YANG Wei, SUN Li-ping, PENG Da-shu

(The Key Laboratory of Nonferrous Metals Materials Science and Engineering, Ministry of Education, School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: An intermediate thermal-mechanical treatment (ITMT), which includes reinforced solid solution, over-aging, heavy strain by combination of multi-directional forging and rolling at warm temperature and re-crystallization by fast heating was proposed and studied for structure refining of Al-Zn-Mg-Cu-Cr alloy thick plates. The structures evolution laws and the mechanism of grain refining with the above ITMT were studied by means of OM, EDS and TEM. Then the qualifications of controlling the grain size under discontinuous re-crystallization were discussed. The results show that ITMT process can make Al-Zn-Mg-Cu-Cr alloy thick plates deform sufficiently and equally, also make the structure of re-crystallization refine effectively, though the rolling reduction is not more than 80%. The average re-crystallization grain size is refined to around 8 μm in the short transverse direction and 12 μm in the vertical or long transverse direction. Most of the secondary particles are refined to less than 3 μm. The mechanism of grain refining for ITMT can be summarized as: the fine, homogenous and equal-axial grains are refined by discontinuous re-crystallization, making full use of the heavy strain energy formed by the severe plastic deformation and the feasible size and distribution of secondary particles formed chiefly in the over-aging.

Key words: Al-Zn-Mg-Cu-Cr alloy; thick plates; intermediate thermal-mechanical treatment (ITMT); discontinuous re-crystallization; structure refinement

组织细化是铝加工发展的新方向,通过细化组织,可使铝合金获得更为优异的综合性能[1]。近年来对铝合金晶粒细化的研究报道较多,但对于高性能铝合金厚板的制备,许多细化措施还很难获得实际应用。高性能铝合金厚板加工制备技术涉及多方面的基础理论问题,包括合金化理论、大塑性变形理论、强韧化理论、回复与再结晶理论等,国内外专门针对高性能铝合金厚板的加工制备技术已有相关研究报道,主要集中在熔炼与铸造、热处理技术及残余应力等方面[2?7],而对于厚板的塑性成型过程及组织细化处理的研究相对较少。由于铝合金厚板,尤其是超厚板(厚度大于50 mm),因技术装备限制,难以通过轧制实现充分变形,所以采用常规方法很难使合金的晶粒组织和第二相得到有效细化。本文作者针对一种典型的高强度Al-Zn-Mg-Cu-Cr合金,提出一种包括分段强化固溶和锻造后轧制复合强应变工序的中间变形热处理(ITMT)技术,实现了其晶粒和第二相的有效细化。

1 实验

厚板制备工艺流程如图1所示。该工艺流程包括如下3个主要部分:1) 开坯过程,采用多向热锻的方法;2) ITMT中间变形热处理(图1虚线框内部分),包括强化固溶、过时效处理、中温锻轧复合强应变处理和再结晶处理;3) 最终时效热处理,主要进行了峰值时效T6和过时效T73处理。本实验研究的重点是中间变形热处理(ITMT)过程中合金组织的演变规律以及组织细化的机理。

图1 Al-Zn-Mg-Cu-Cr合金厚板制备实验方案

Fig.1 Experimental schedule of fabricating Al-Zn-Mg-Cu-Cr alloy thick plates (ITMT routine is in dash line frame)

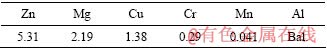

实验用材料为Al-Zn-Mg-Cu-Cr合金铸锭(已经过均匀化处理),取自国内某厂,合金主要元素含量如表1所列。

表1 实验用Al-Zn-Mg-Cu-Cr合金主要化学成分

Table 1 Main chemical composition of Al-Zn-Mg-Cu-Cr alloy in experiment (mass fraction, %)

实验中金相组织观察在POLYVAR?METII金相显微镜下进行;第二相颗粒观察和能谱分析在KYKY?2800扫描电子显微镜下进行;用H?800型透射电子显微镜进行微观组织的观察与分析。

2 结果与分析

7075一类的高强铝合金均由α固溶体及第二相质点组成,第二相质点按其生成机理可分为三类[8]:第一类是初生的金属间化合物,主要有FeCrAl7、FeAl3、Mg2Si、AlMnFeSi等含Fe、Si的化合物质点和S(CuMgAl2)相、T(Al2Mg3Zn3)相等,这些化合物在合金结晶时,直接从液相生成,故尺寸较大,在光学显微镜下呈块状,既而在塑性加工过程中被打碎,往往排列成串。根据合金的铸造及加工条件不同,其尺寸约为0.5~20 μm,这种相加热时不溶于基体,热处理很难使其变化,经常称为难熔相,这种第二相的存在,严重降低了合金的延展性和断裂韧性。第二类是含Cr的弥散E相质点Al12Mg2Cr和Al18Mg3Cr2。它们是在合金均匀化热处理、塑性加工前的加热以及固溶处理加热时,在高温下从固溶体中析出的,其尺寸约为0.05~0.5 μm。这些质点对合金再结晶和晶粒长大有明显的阻碍作用。第三类是时效强化质点。合金固溶处理加热时,它们溶入固溶体中,时效时从固溶体中析出,形状和尺寸变化较大,是影响合金组织与性能的重要因素。

2.1 第二相分析

实验用Al-Zn-Mg-Cu-Cr合金铸锭的金相组织及显微硬度测试如图2所示。从图2(a)可见,铸态Al-Zn-Mg-Cu-Cr合金的晶内和晶界均存在较多的粗大第二相,尤其是沿晶界处连续分布着大块共晶组织,这些难熔金属间化合物相主要有S(CuMgAl2)相、T(Al2Mg3Zn3)相和AlMnFeSi相等。图2(b)所示为Al- Zn-Mg-Cu-Cr合金铸态组织的显微硬度。在放大400倍显微镜下对测试点施加0.1 N的载荷,发现粗大难熔第二相的显微硬度达到HV238,明显高于基体的平均显微硬度HV169,而且在测试的过程中,可明显观察到粗大第二相在压头下破碎的现象,表明这种难熔相为脆硬相,它对合金的断裂韧性和塑性有严重影响。

图2 Al-Zn-Mg-Cu-Cr合金(已均匀化退火)的铸锭组织及显微硬度测试(OM)

Fig.2 Homogenized ingot structures and micro-hardness measurement of Al-Zn-Mg-Cu-Cr alloy (OM): (a) Ingot structures; (b) Micro-hardness measurement

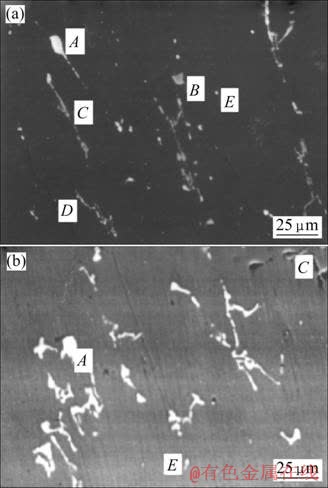

图3所示为固溶处理(466 ℃, 2 h, 14 ℃, h→ 480 ℃, 15 min)前后试样的暗场相扫描电镜照片。由图3(a)可见,强化固溶前,合金中单位面积的粗大块状相(A、B点)、长条状难熔相(C、D点)以及点状相(E点)均表现为数量较多,尺寸较小,且较为分散;而由图3(b)可见,经固溶处理后,尺寸较小的第二相粒子减少(E点),但粗大块状颗粒(A点)有所增加。图4所示为图3中典型粗大第二相颗粒(均为A点)的能谱分析结果。由图可见,这些粗大第二颗粒通常包含多种化学元素,应该是几种金属间化合物的聚合体,因此又硬又脆(见图2(b)),固溶处理前的粗大颗粒中基本上无含Cr相,而固溶处理后聚集块中出现了Cr元素,且Fe元素的含量剧增,表明固溶处理时有部分含Cr相和含Fe相在高温下析出,并与未完全溶解的S(CuMgAl2)相和T(Al2Mg3Zn3)相聚到一起。

图3 Al-Zn-Mg-Cu-Cr合金固溶处理前后粗大第二相颗粒SEM形貌

Fig.3 SEM images of coarse secondary particles in Al-Zn-Mg-Cu-Cr alloy: (a) Before solid solution; (b) After solid solution

图4 Al-Zn-Mg-Cu-Cr合金固溶处理前后粗大第二相颗粒能谱

Fig.4 Energy patterns of coarse particles in Al-Zn-Mg-Cu-Cr alloy (SEM): (a) Before solid solution; (b) After solid solution

2.2 组织演变

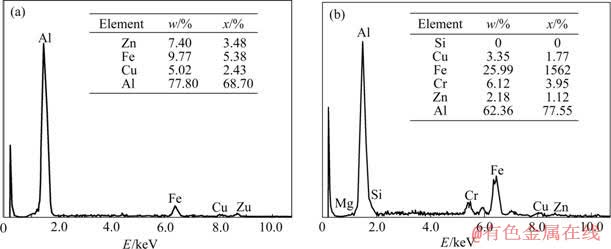

图5所示为经过多向锻造开坯的Al-Zn-Mg-Cu-Cr合金经ITMT工艺各阶段处理后的金相组织。从图5(a)可见,经固溶处理后,合金中的第二相已完成固溶,由于坯料进行了多向变形,所以再结晶组织比较均匀;与铸造组织(图2(a))相比,粗大难熔相在数量上有所降低,但颗粒尺寸反而增大(图3),可能是高温析出相与原有的难熔相聚合到一起而形成的粗大的第二相颗粒。图5(b)所示为合金过时效后的金相组织,与图5(a)相比,第二相颗粒尺寸没有明显区别,但过时效后大量沉淀相从过饱和固溶体中脱溶,晶粒内出现大量平衡态第二相质点,这些质点对合金再结晶和晶粒长大有明显的阻碍作用,后面将对这种组织进行高倍显微分析。从图5(c)可见,经锻轧复合强应变后,合金中的粗大第二相聚集块大部分被压碎,并在合金中均匀分布,在一些大颗粒附近和晶界交叉处可以看到少量新生的再结晶晶粒,但尚未长大;粗大颗粒的细化不仅可为再结晶提供更多的形核部位,更主要的是为了减小其对合金断裂韧性和延展性的有害影响,因为研究表明,材料受载时裂纹和空洞往往起源于这些粗大硬脆团;另外,强应变难以使某些硬质颗粒破碎,金属绕过其流动(如箭头所指部位),因此,在其周围形成高畸变能的剪切变形区,在随后的热处理过程中,这些变形区将极易成为再结晶的形核部位。从图5(d)可见,经再结晶处理后,合金已基本完成再结晶,获得均匀细小的等轴晶组织,且晶内弥散相绝大部分已固溶于基体,粗大难熔相颗粒在数量和尺寸上也有所减少。

图5 ITMT工艺各阶段处理后Al-Zn-Mg-Cu-Cr合金的金相组织

Fig.5 Optical structures of Al-Zn-Mg-Cu-Cr alloy after each stage of ITMT: (a) After solid solution; (b) After over-aging; (c) After multi-directional forging and rolling (ε = 2.1); (d) After re-crystallization (holding for 10 min at 482 ℃)

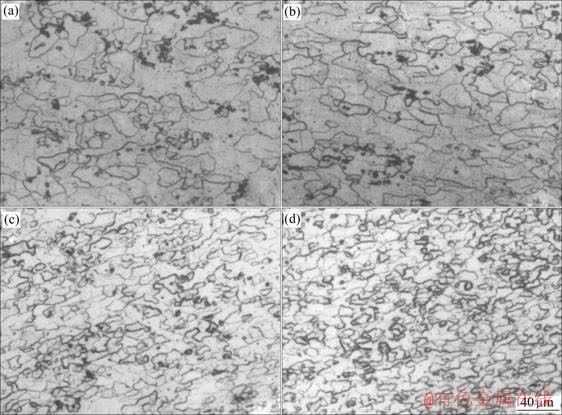

图6所示为获得不同变形程度的7075铝合金厚板试样(厚度为6~24 mm)横截面再结晶晶粒的变化情况。由图可见,在同样的再结晶处理条件下,随着变形程度的增加,再结晶后的晶粒尺寸和第二相颗粒逐渐变细。图6(a)所示为轧制前的锻坯板的再结晶组织,因中温锻造使其真应变达到2.1,已积累了较高的变形储能,所以即使未进行轧制变形,热处理后再结晶晶粒仍得到较好的细化,粗大第二相也得到较为严重的破碎和均匀分布。定量金相分析表明,其平均晶粒直径为35 μm,第二相颗粒大小一般在10 μm以下,且均为球状;对锻坯进行20%的中温轧制,合金又积累了部分变形储能,因此再结晶的平均晶粒尺寸被细化到约28 μm,如图6(b)所示;当轧制变形率达到60%,真应变累积到3.0的时候,平均再结晶晶粒被细化到12 μm,第二相颗粒被细化到5 μm以下,如图6(c)所示;继续轧制到压下率达80%,合金的真应变累积到3.7,再结晶的平均晶粒尺寸被细化到约8 μm,第二相颗粒被细化到3 μm以下,如图6(d)所示。实验还表明,图7所示的组织非常稳定,继续延长再结晶保温时间到30 min,晶粒尺寸变化很小。这主要是ITMT工艺为合金准备了最优化的第二相搭配,细小的第二相粒子钉扎住晶界,因此,晶粒难以长大。后面将对此进行详细分析。

图6 Al-Zn-Mg-Cu-Cr合金在不同变形程度下的再结晶组织

Fig.6 Re-crystallized structures of Al-Zn-Mg-Cu-Cr alloy after different deformations (OM): (a) ε=2.1; (b) ε=2.3; (c) ε=3.0; (d) ε=3.7

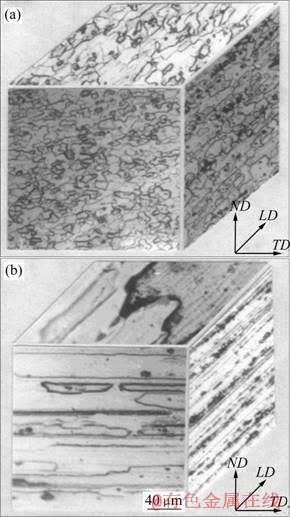

图7所示为采用该ITMT工艺方案制备的厚度为在同样的再结晶热处理条件下,8 mm的Al-Zn-Mg- Cu-Cr合金厚板和取自工业生产的厚度为25 mm的热轧板的金相组织比较。由图可以清楚地看到,两种制备方案对Al-Zn-Mg-Cu-Cr合金组织的影响:采用本设计的包含强化固溶处理、过时效、中温锻轧复合强应变处理和再结晶处理的中间形变热处理(ITMT)工艺方案,合金再结晶组织均匀细小,第二相粒子也得到有效细化。定量金相分析表明,轧板短横向的平均晶粒尺寸为8 μm,纵向和长横向的平均晶粒尺寸为12 μm,第二相点状颗粒直径一般都小于3 μm (见图7(a));而经工业生产的热轧板,热处理后再结晶组织非常粗大,不同方向的组织相差极大,且粗大难熔相也未得到有效细化和均匀布展(见图7(b))。

图7 Al-Zn-Mg-Cu-Cr合金厚板再结晶组织对比

Fig.7 Comparison of re-crystallized structures of Al-Zn-Mg- Cu-Cr alloy thick plates (OM): (a) Prepared by ITMT process; (b) Fabricated by industrial hot rolling

2.2 组织细化机理

许多研究发现[10?16],不同尺寸的第二相质点对再结晶过程有不同的影响。弥散的大质点通过增加再结晶晶粒形核部位的密度而加快再结晶速度;透射电镜观察表明,形变时在大质点周围形成的强烈形变区,是再结晶时新晶粒优先形核的部位。弥散的小质点通过对晶界或亚晶界的迁移施加阻力而减慢再结晶速度,从而限制再结晶晶粒的长大。透射电镜观察表明,形变时在大质点周围形成的强烈形变区,是再结晶时新晶粒优先形核的部位。形变前的强化固溶和过时效处理使合金内形成弥散分布的第二相质点,既有尺寸大于1 μm的大颗粒,又有尺寸小于0.5 μm的小质点;随后的中温锻轧复合强应变过程中,使粗大难熔相被有效碎化和均匀分布,进一步提高了大质点的密度,同时也使大质点附近形成高位错密度的畸变区,再结晶处理时,大量的这种高能畸变区优先被激活,成为再结晶核心;高密度的小尺寸质点阻碍了再结晶晶粒的长大,从而获得均匀细小且稳定的等轴再结晶晶粒组织。

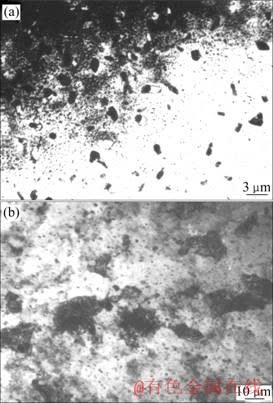

图8所示为强化固溶处理后Al-Zn-Mg-Cu-Cr合金的透射电镜像。由图8(a)可见,固溶处理后合金内的沉淀相均已溶入基体,但仍弥散分布着一些难溶第 二相质点。这些质点是由合金中的Cr和Mn形成 的[8, 10?11 ],尺寸在50~200 nm。本实验未对这些质点进行鉴别。固溶处理组织中还可观察到一些亚晶团,甚至还有残存的位错源。当固溶温度继续升高时,基体中将析出更多的弥散质点,有些聚集成雪花状的团块(图8(b))。这些高温析出的第二相主要是含Cr相[8]。

图8 不同固溶处理后Al-Zn-Mg-Cu-Cr合金固溶态的显微组织

Fig.8 Microstructures of Al-Zn-Mg-Cu-Cr alloy after different solid solution (TEM) solution process as: (a) 466 ℃, 2 h+14 ℃, h→ 480 ℃, 15 min; (b) 466 ℃, 2 h+14 ℃, h→480 ℃+5 ℃, h→496 ℃, 5 min

图9(a)所示为强化固溶处理后的Al-Zn-Mg-Cu-Cr合金再经400 ℃,8 h过时效处理的显微组织。由图可见,过时效处理后,合金中形成一定密度的尺寸约 1 μm的大颗粒,基体中还弥散分布着50~200 nm的小质点。大尺寸平衡相质点主要是含Al、Zn、Mg的T相和含Al、Fe、Si的杂质相,小尺寸的质点除了固溶后的未溶相外,还有过时效析出的E相、η相(MgZn2)等[8, 10?11]。这些第二相的存在,为再结晶细化晶粒准备了条件。图9(b)所示为较均匀的热塑性变形组织,放大倍数较低,在比较大的范围内观察到弥散分布的第二相质点和位错密集的胞状组织。随着变形的深入,大尺寸的质点将与位错发生越来越复杂的反应,在其周围将形成畸变能越来越高的变形区。

图9 Al-Zn-Mg-Cu-Cr合金过时效和强应变组织

Fig.9 Over-aging and heavy-deformed structures of Al-Zn- Mg-Cu-Cr alloy (TEM): (a) Over-aging structures; (b) Heavy- strain structures

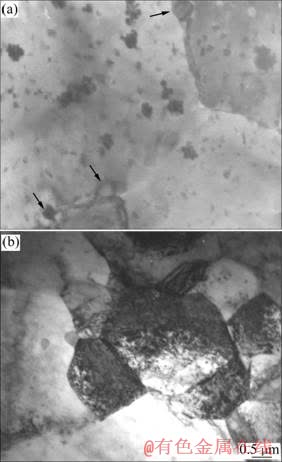

图10所示为变形组织中的形状为球形、直径约1 μm的大质点和其附近高位错密度的畸变区。这些区域在再结晶快速加热过程中,将被优先激活,成为再结晶核心。变形程度越大,这种畸变区域越多,再结晶形核率越高,晶粒越细小。

图10 第二相大质点周围的畸变区

Fig.10 Distortion area round bigger particles (TEM): (a) Secondary particle round high dislocation density zone; (b) Secondary particle in dislocation tangle

图11所示为经大变形后的试样,在再结晶进行到1 min和3 min时取出后观察的高倍组织。图11(a)显示了新生的低位错密度的再结晶新晶粒正在向高位错密度区扩展的状态,但晶界受到较小的第二相质点的阻碍,从而使新晶粒的长大受到限制。图11(b)所示为一个晶界未受到小质点钉扎的再结晶新晶粒正在吞并变形区而长大,而其晶体内残留有少量位错。

图11 Al-Zn-Mg-Cu-Cr合金再结晶的初始阶段(TEM)

Fig.11 Early stage of re-crystallization in Al-Zn-Mg-Cu-Cr alloy (TEM): (a) Holding at 482 ℃ for 1 min; (b) Holding at 482 ℃ for 3 min

图12所示为Al-Zn-Mg-Cu-Cr合金的完全再结晶组织。图12(a)显示了第二相质点对晶界的阻碍作用(箭头所指处),正是因为合金中存在这种高密度的第二相质点对晶界的钉扎,才使得晶粒尺寸得到有效控制。如果失去第二相对晶界的阻碍作用,即使因形核率高而获得细小再结晶组织,这种组织也将是不稳定的,延长再结晶时间,晶粒尺寸必将增大。可见,在变形前进行强化固溶和过时效等预处理,使合金内形成合理的第二相分布,对获得细小稳定的再结晶组织是至关重要的。来自实际生产的铝合金材料经常无法获得细晶组织,其根本原因是缺乏对晶粒长大的有效控制。

图12 Al-Zn-Mg-Cu-Cr合金的完全再结晶组织

Fig.12 Re-crystallized structures of Al-Zn-Mg-Cu-Cr alloy (TEM): (a) Grain boundary nailed by secondary particles; (b) Sub-grains in re-crystallized structures

此外,在同样状态下,还可观察到再结晶组织内仍残留一些亚晶组织,如图12(b)所示,这种亚晶粒在变形前的强化固溶态组织中也可观察到(图8(a))。这些亚晶粒尺寸约为1~3 μm,通常较为稳定。但在再结晶和固溶状态下,合金中一般只存在少量的这种亚晶组织,因此,不能以这些亚晶尺寸作为晶粒细化程度的表征。

REFERENCES

[1] 航空航天材料咨询研究组. 航空航天材料咨询报告[M]. 北京: 国防工业出版社, 1999.

Consultation group for aerospace and vehicle materials. Consultation report of aerospace and vehicle materials[M]. Beijing: National Defensive Industry Press, 1999.

[2] SAINFORT P, SIGLI C, RAYNAUD G M, GOMIERO P. Structure and property control of aerospace alloys[J]. Materials Science Forum, 1996, 242: 25?32.

[3] STARKE E A, STALEY J T. Application of modern aluminum alloys to aircraft[J]. Prog Aerospace Sci, 1996, 32: 131?172

[4] 曾苏民. 影响铝合金固溶保温时间的多因素相关规律[J]. 中国有色金属学报, 1999, 9(1): 79?86.

ZENG Su-min. Disciplines of multiple factors affecting solution treating of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 79?86.

[5] ZHANG Hui, LIN Gao-yong, PENG Da-shu. Manufacturing of aluminum alloy ultra-thick plates by multidirectional forging and subsquent rolling[J]. Trans Nonferrous Met Soc China, 2002, 12(2): 218?231.

[6] LIN Gao-yong, ZHANG Hui, PENG Da-shu. Influences of processing routine on mechanical properties and structures of 7075 aluminum alloy thick-plates[J]. Trans Nonferrous Met Soc China, 2003, 13(4): 809?813.

[7] 林高用, 彭大暑, 戴圣明, 韩红阳, 张 辉. 强化固溶处理对7075铝合金组织的影响[J]. 金属热处理, 2002, 27(11): 29?32.

LIN Gao-yong, PENG Da-shu, DAI Sheng-ming, HAN Hong-yang, ZHANG Hui. Influence of strengthened solution on microstructures of 7075 aluminum alloy[J]. Heat Treatment of Metals, 2002, 27(11): 29?32.

[8] 刘伯操. 五种新型铝合金材料手册[M]. 北京: 航空工业出版社, 1994.

LIU Bo-cao. Dictionary of five new aluminum alloy[M]. Beijing: Aviation Industry Press, 1994.

[9] 陈康华, 刘允中, 刘卫红. 7075和2024铝合金的固溶组织与力学性能[J]. 中国有色金属学报, 2000, 10(6): 819?822.

CHEN Kang-hua, LIU Run-zhong, LIU Wei-hong. Microstructure and mechanical properties of enhanced solution treated 7075 and 2024 aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 819?822.

[10] WERT J A, PATON N E, HAMILTON C H, MAHONEY M W. Grain refinement of 7075 aluminum alloy with thermo- mechanical processing[J]. Metal Trans, 1981, 12: 1267?1276.

[11] WERT J A. Thermo-mechanical processing of heat-treatable aluminum alloys for grain size control[C]// CHIA E H, MC QUEEN H J. Micro-structure control in aluminum alloys. New York: Metall Soc Inc, 1985: 67?94.

[12] MC QUEEN H J. Experimental foundation for thermo- mechanical treatment (TMT) of aluminum alloys[J]. J Metals, 1980, 2: 17?26.

[13] HORNBOGEN E. Design of heterogeneous micro-structures by re-crystallization[C]// JEFFEE R I, WILCOX B A. Fundamental aspects of structural alloy design. New York: Plenum Press, 1977: 389?409.

[14] ALDEN T H. Processing and properties of super-plastic alloys[C]// JEFFEE R I, WILCOX B A. Fundamental aspects of structural alloy design. New York: Plenum Press, 1977: 411?430.

[15] WERT J A. Grain refinement and grain size control[C]// PATON N E, HAMILTON C H. Super-plastic forming of structural alloys. Warrendale: The Metallurgical Society of AIME, 1982: 69?83.

[16] LLOYD D J. The influence of particles and deformation structure on re-crystallization[C]// CHIA E H, MC QUEEN H J. Microstructural Control in Aluminum Alloys. New York: Metall Soc Inc, 1985: 45?66.

基金项目:国家重点基础研究发展计划资助项目(G1999064908)

收稿日期:2007-11-30;修订日期:2008-03-18

通讯作者:林高用,教授,博士;电话:0731-8830266;E-mail: gylin6609@yahoo.com.cn

(编辑 陈爱华)