Trans. Nonferrous Met. Soc. China 22(2012) s504-s511

Influence of asymmetric hot rolling on microstructure and rolling force with austenitic steel

Jie LIU, Rudolf KAWALLA

Institute of Metal Forming, University of Technology and Mining Freiberg, Freiberg 09599, Germany

Received 28 August 2012; accepted 25 October 2012

Abstract: In order to establish a new processing technique of producing steels with fine grain, asymmetric hot rolling and symmetric rolling were performed. The asymmetric condition was introduced by applying mismatched roll diameters. The diameter ratios between big and small rolls were 1.00, 1.05 and 1.11. The rolling temperatures were between 900 °C and 1100 °C. The thickness reduction of workpiece was set at 15%, 30% and 60%. The results showed that asymmetric rolling produced higher volume fraction of recrystallization grain and smaller average grain size at the center layer of rolled sample than symmetric rolling. The diameter ratio of 1.05 tended to generate the highest recrystallization level and the smallest average grain size. With high temperature and low thickness reduction value, the grain growth was obvious. The conventional dynamic recrystallization mechanism was prevailing, while accompanied by twinning. At low temperature of 900 °C, even at thickness reduction of 60%, symmetric rolling cannot initiate dynamic recrystallization as asymmetric rolling did. The asymmetric rolling force was smaller than that of symmetric rolling, except at 900 °C and thickness reduction of 60%. The rolling force also increased with descending temperature and climbing thickness reduction.

Key words: austenitic steel; asymmetric hot rolling; microstructure evolution; rolling force

1 Introduction

Asymmetric rolling had been revealed its ability of reducing rolling force since 1940s [1-11], in the process of rolling profile, such as, T-section steel [1,2]. Recently, this technique has been attracting more attention for its potential to improve microstructure, thus mechanical properties [9-23].

The concept of asymmetric rolling is derived from the conventional (symmetric) rolling, where not only the two rolls in a pair are designed to have the same diameter, angular velocity, surface quality, but also the flat workpiece should have symmetric geometry, surface condition to contact the roll pair at the same time. As a result, the neutral points related to top and bottom roll would be on the same vertical plane, as shown in Fig. 1(a). Meanwhile, the workpiece would flow through the roll gap with a symmetric feature, as shown in Fig. 1(c).

Asymmetric conditions could be generated when any of those symmetric features is changed. As demonstrated in Fig. 1(b), when the top roll is smaller than the bottom roll, the neutral points are no longer on the same vertical plane. With a small ratio between big and small rolls, the neutral point related to the small roll moves towards the entrance side, while the one related to big roll shifts towards the exit side of the roll gap. In the region between the two neutral points, friction stresses have opposite sense on both surfaces, which introduce a constant shear strain distribution through the thickness of workpiece [7,24-26]. This extra shear value can influence the microstructure evolution by increasing the total value of effective strain, also by changing the stress field of the plastic deformation. With the extra shear stress field, the deformation mode would change from single compression into combined mode of compression and shear [14,15], which could result in a whole different dynamic softening mechanism. Currently, the grain refinement and the generation of ideal texture component have been reported for various steels and alloys through asymmetric rolling. A grain refinement of 20% was claimed for C-Mn steel after asymmetric rolling with initial thickness of 9.9 mm [12]. For low carbon plate of 2 mm thickness, the grain size reduction reached 72.3% at 973 °C [12]. Small grain of ~2 μm was achieved for IF steel [16]. For pure iron [18] and magnesium alloys [19], asymmetric rolling was studied as new SPD process that was capable of mass production while small grains of 1.4-2 μm, and 0.2 μm were achieved, respectively. The ultra small grain size of 1-2 μm had been reported for pure aluminum [20-23].

Fig. 1 Schematic pictures

There are common features shared by the above mentioned grain refinement. The smaller grains were obtained by asymmetric warm and/or cold rolling. Due to the lower finishing temperature, the required reheating temperature was also relatively low, which means that the initial grain size for rolling was depressed. This contributed to the smaller final grain. Under this circumstance, the effect of asymmetric conditions on grain refinement could not be isolated and has not been clearly explained.

Generally, the hot rolling process is inevitable chain for producing flat sheets and strips. A hot rolling process which can achieve rolling force reduction and microstructure improvement is of great power in saving energy and introducing high strength and good formability to the final products. The strictly defined hot rolling should be carried out with temperature above the dynamic recrystallization temperature, where the relative low temperature is not available for grain refinement. However, the effect of asymmetric condition could be still available. At present, the research on asymmetric hot rolling is very few, yet with positive results. One research on AISI304 austenitic steel showed that when it was hot rolled at 1000 °C with initial thickness of 14 mm and pass reduction of 50%, partial recrystallization reached the center layer of asymmetrically rolled samples. Concurrently, the same position of symmetric samples consisted of typical recovery microstructure. Moreover, the grain distributed more evenly along thickness direction in asymmetric samples [12].

In this work, systematic experiment was designed to reveal the possibility to produce flat product with less energy input and improved microstructure by asymmetric hot rolling.

2 Experimental

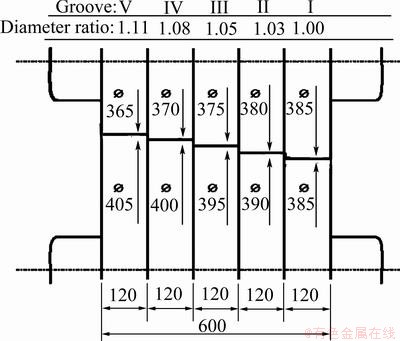

The received materials were continuous-cast with thickness of 30 mm. The rolling samples were cut out with length of 40 mm along the original rolling direction. The width was 60 mm. The nominal composition of the chosen austenitic steel is shown in Table 1. Asymmetric conditions were created by using a small top roll, as shown in Fig. 1(b) and Fig. 2. The diameter ratios between the big and small rolls were 1.00, 1.05 and 1.11. The values of 1.05 and 1.11 were chosen because they are not only available in the laboratory, but also are possible to be applied in actual industrial practice. With diameter ratio of 1.00, the symmetric rolling was carried out for comparison. The samples were pre-rolled to the thickness of 20 mm, length of about 40 mm and width of 64 mm. All samples were reheated at 1150 °C for 30 min, then cooled down to 1100 °C, 1000 °C and 900 °C for symmetric and asymmetric rolling. The thickness of samples was reduced by 15%, 30% and 60% in one pass. Water quench was used right after hot rolling to preserve the dynamic microstructure changing. The rolling force was automatically recorded during rolling.

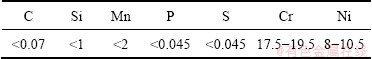

Table 1 Nominal composition of austenitic steel (mass fraction, %)

The starting microstructure was captured by water quenching a sample directly after reheating. The samples for microstructure observation were cut out in the middle of the workpiece. The optical micrographs were taken on the normal-rolling plane along the whole thickness. For hot rolled samples, only the microstructure of the centre layer would be presented and discussed in this paper.

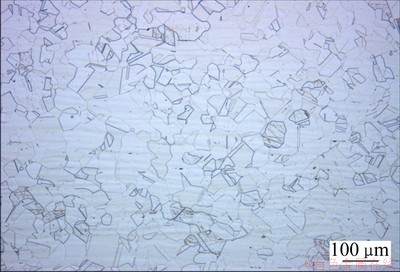

Figure 3 shows that the starting microstructure consisted of recrystallized grain and twins. Judging from the random direction of twinning boundaries, those were recrystallization twin grains. The analysis along the thickness direction showed that the starting microstructure was homogeneous with an average grain size of about 46 μm.

Fig. 2 Schematic picture of roll set (Unit: mm)

3 Results and discussion

3.1 Microstructure evolution

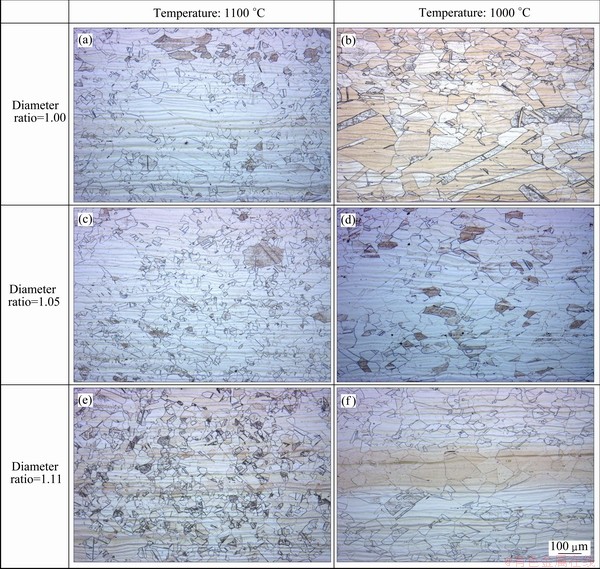

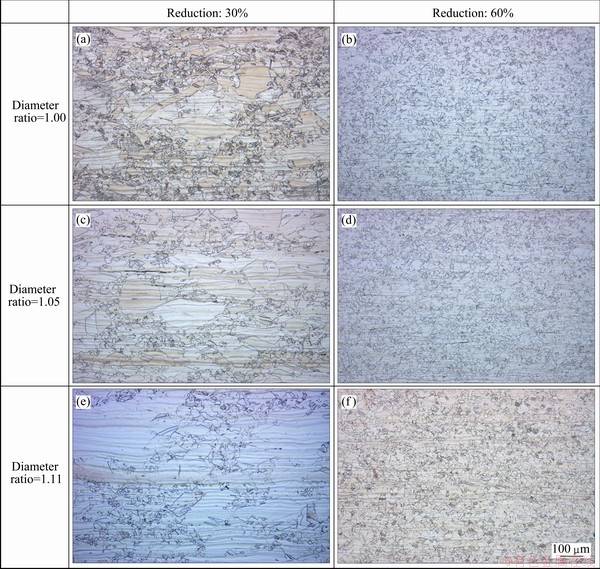

Figures 4-6 show that, compared to symmetric rolling, asymmetric hot rolling generated higher volume fraction of recrystallization grain and obtained smaller average grain size in the center layer. The diameter ratio of 1.05 tended to produce the highest recrystallization level and the smallest average grain size.

Fig. 3 Starting microstructure for asymmetric and symmetric hot rolling

Fig. 4 Microstructures after hot rolling at reduction of 15% (rolling direction: horizontal)

Figure 4 demonstrates that at the pass reduction of 15%, even though the volume fraction was low, the new grain appeared at 1100 °C for both symmetric and asymmetric rolling. The average grain size was around 67 μm, about 142% of the starting grain size. This can be explained by grain growth. During deformation, the energy transmitted by the external force into the material was stored as defect, for example, point and dislocation. Due to the localization of the plastic deformation, at some area the stored energy was high enough to initiate nucleation and stimulate the nuclei growing into a new recrystallization grain. At some other area, the stored energy might not be high enough or the rate of energy accumulation was lower than the rate of consumption (dynamic recovery), where the grain growth could be the possible approach to release the absorbed energy, so that the lattice could regain the equilibrium.

It can be seen in Fig. 4 that when the rolling temperature was 1000 °C, the grain growth was more obvious than that at 1100 °C. The twinning boundaries which located in the center line of the sample were almost parallel to each other and rotated to form an angle with the rolling direction. This feature indicated the occupation of dynamic recovery. The grain and twin grain growth were less remarkable in asymmetric rolling, which made the microstructure more homogeneous. Yet, the new grains were rare. In another word, at this low thickness reduction level, higher temperature of 1100 °C has more advantage to precede recrystallization than 1000 °C.

Fig. 5 Microstructures after hot rolling at reduction of 30% and 60% under temperature 1100 °C (rolling direction: horizontal)

Fig. 6 Microstructures after hot rolling at temperature 900 °C (rolling direction: horizontal)

Figure 5 demonstrates the results of the other two reduction levels at 1000 °C. It can be seen that the recrystallization level increased clearly with ascending thickness reduction. At the reduction of 30%, the microstructure was of average grain size less than starting value by 20%, and featured in “necklace” structure, which is a signature for conventional recrystallization (nucleation and growth). The symmetric rolling again showed higher percentage of large twinning grain inside huge deformed grain. At thickness reduction of 60%, the volume fraction of recrystallization grain reached even above 80%. The average grain sizes were about 24, 19 and 21 μm for diameter ratios of 1.00, 1.05 and 1.11, respectively. It indicated a grain refinement of 21% and 13% corresponding to diameter ratios of 1.05 and 1.11.

When rolled at 900 °C, the reduction levels of 15% and 30% were not enough to initiate dynamic recrystallization. The microstructure was the result of dynamic recovery. At the reduction of 30%, the average grain size under diameter ratio of 1.05 was also 67 μm, as shown in Fig. 6. However, there was no sign of recrystallization grain. Yet, the grain boundary started to serrate, which indicates that subgrain boundary was forming and tangling with the original grain boundary. If the deformation kept accumulating, and the new grain generated by the contact of opposite curve boundaries, then it was so called geometric recrystallization. Yet, at this stage, the reason for smaller grain under diameter ratio of 1.05 could be the result of continuous recrystallization mechanism. This mechanism is featured by the growth of misorientation angle between neighbored subgrains. New grain generated by the transformation of low angle sub-boundary to high angle sub-boundary. Since no nucleation is involved, it is classified as dynamic recovery. To sum up, it seems that even with dynamic recovery, asymmetric rolling was still able to achieve smaller average grain than symmetric rolling.

When the thickness reduction was up to 60%, the symmetric rolling was still not able to carry out dynamic recrystallization at 900 °C. Instead, the microstructure was composed of elongated grain along the rolling direction. While in asymmetric rolling, the new small grain appeared around the original boundaries of the elongated grain.

It can be concluded that asymmetric rolling has advantage in refining grain size and improving the homogeneity of microstructure at the tested temperature and deformation region for AISI304 austenitic steel.

3.2 Rolling force

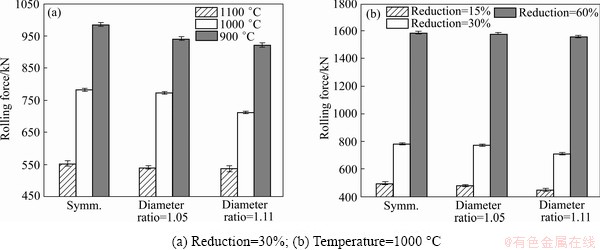

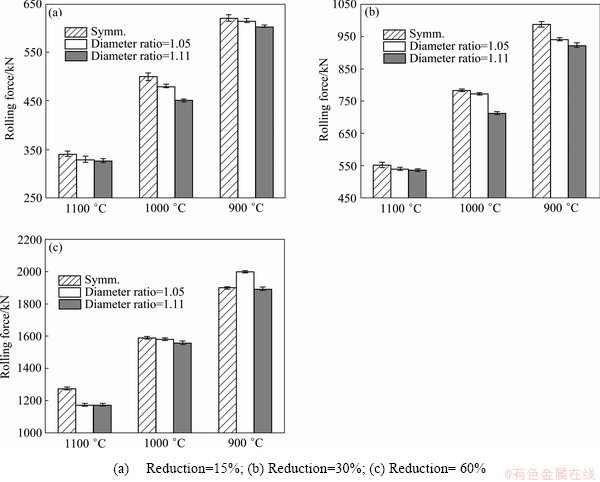

The results showed that the rolling force of asymmetric rolling decreased with increasing the rolling temperature and descending thickness reduction, just as in conventional symmetric rolling. Two examples are given in Fig. 7.

Figure 8 demonstrates that the required rolling force to perform asymmetric rolling was smaller than that for symmetric rolling, except at the lowest temperature of 900 °C and the highest pass reduction of 60%. Except for this condition, the rolling force decreased monotonously with increasing diameter ratio.

The highest rolling force reduction was up to 10%, obtained at 1000 °C, diameter ratio of 1.05 and reduction of 15% and 30%. The asymmetric rolling forces increased by 5% and 1% at 900 °C, at diameter ratio of 1.05 and 1.11, respectively. Three samples were rolled under each of those three conditions to confirm this result. And each time asymmetric rolling had higher rolling force. Microstructure changes are suspicious for this phenomenon. More analysis is needed for a reasonable explanation.

At present, the asymmetric rolling showed its ability to reduce rolling force by less than 10%, which was not as high as the number reported by the former researches. This result has to be interpreted by the combination of the current rolling parameters and the applied material.

Fig. 7 Rolling force according to rolling temperature and thickness reduction

Fig. 8 Rolling force according to different diameter ratio

4 Conclusions

The asymmetric condition was introduced by mismatched roll diameters. The asymmetric diameter ratios of 1.05 and 1.11 were chosen, because they can also be realized in industry without major rebuilding of the current roll mill. The results showed that, compared to symmetric rolling, asymmetric rolling produced higher volume fraction of recrystallization grain and smaller grain at the center layer of rolled sample above 900 °C. The diameter ratio of 1.05 tended to be stronger in grain refinement and homogeneity improvement than diameter ratio of 1.11. At low thickness reduction of 15%, the high temperature of 1100 °C showed superiority in introducing new recrystallization grain to the other two temperatures. The “necklace” structure indicated that conventional dynamic recrystallization was the prevailing mechanism for AISI304 austenitic steel in symmetric and asymmetric rolling.

The rolling force of asymmetric hot rolling on 20 mm-thick austenitic steel decreased with increasing rolling temperature and descending reduction as in conventional symmetric rolling. It also had a clear trend to decrease with increasing diameter ratio, except at 900 °C and thickness reduction of 60%.

Acknowledgement

The acknowledgement is owed to ThyssenKrupp for the supply of the material.

References

[1] SIEBEL E. The theory of rolling process with separately driven rolls [J]. Archive for the Iron and Steel Industry (Archiv für Eisenhüttenwesen), 1941, 15(S): 125-128. (in German)

[2] JURETZEK G. Rolling force and moment with mismatched roll diameters [J]. Freibergerer Researchcorpus B, 1957, 16: 74-81. (in German)

[3] JOHNSON W, NEEDHAM G. Further experiments in asymmetrical rolling [J]. Int J Mech Sci, 1966, 8: 443-455.

[4] DEWHURST P, COLLINS I F, JOHNSON W. A theoretical and experimental investigation into asymmetrical hot rolling [J]. Int J Mech Sci, 1974, 16: 389-397.

[5] COLLINS I F, DEWHURST P. A slipline field analysis of asymmetrical hot rolling [J]. Int J Mech Sci, 1975, 17: 643-651.

[6] PAN D, SANSOME D H. An experimental study of the effect of roll-speed mismatch on the rolling load during the cold rolling of thin strip [J]. Journal of Mechanical Working Technology, 1982, 6: 361-377.

[7] HWANG Y M, TZOU G Y. An analytical approach to asymmetrical hot-sheet rolling considering the shear stress and internal moment at the roll gap [J]. Journal of Materials Processing Technology, 1995, 52: 399-424.

[8] VYDRINAND V N, AGEEV L M. A new technology for rolling sheet and strip [J]. Steel USSR, 1971, 1: 4-8.

[9] ROBERTSON D K, SANSOME D H. Further experimental data on rolling tin-plated strip in the S-mill [J]. Met Technol, July, 1977: 365-374.

[10] CAO L H, LIU Y M. Technical measure’s determination and its theoretical analysis of rolling thin strip by different diameter and different step process [J]. Shandong Metallurgy, 2001, 22(1): 37-39. (in Chinese)

[11] TIAN Y, GUO Y H, WANG Z D. Analysis of rolling pressure in asymmetrical rolling process by Slab method [J]. Journal of Iron and Steel Research, International, 2009, 16(4): 22-26, 38.

[12] SALVATORI I, TOLLENEER I, CHASSAGNE F, BUTLER J. Modification of textural distribution in hot-rolled stainless steels using asymmetric hot-rolling techniques [R]. Report of European Commission, Research Fund for Coal and Steel, 24207, 2005-2008: 1-195.

[13] NILSSON A, SALVATORI I, GOLDHAHN G, MALBRANCKE J. Using asymmetrical rolling for increased production and improved material properties [R]. Report of Research Programme of the Research Fund for Coal and Steel, RFSR-CT-2006-00011, 2006-2009.

[14] HERMAN G, BARCELO D, MUSIK C,  H, VANEL L, LANNOO G, SALVATORI I. Metallurgical impact of hot asymmetric rolling [R]. Report of European Commission, Research Fund for Coal and Steel, 23335, 2003-2006: 1-150.

H, VANEL L, LANNOO G, SALVATORI I. Metallurgical impact of hot asymmetric rolling [R]. Report of European Commission, Research Fund for Coal and Steel, 23335, 2003-2006: 1-150.

[15] WAUTHIER A, REGLE H, FORMIGONI J, HERMAN G. The effects of asymmetrical cold rolling on kinetics, grain size and texture in IF steels [J]. Materials Characterization, 2009, 60: 90-95.

[16] CHIKUSHI I, KOZAKI M, KURAHSHI R, TAKAHASHI M, ADACHI A, TAKAOKA S. Ultrafine grained steel production at the new Nakayama hot strip mill [J]. AISE Steel Technology, June, 2002: 42-48.

[17] ZHANG Z G, YAO X S, ZHU X B, ZHOU L, WANG F. Effect of speed ratio in cross shear rolling on texture of non-orientated low silicon steel [J]. Materials for Mechanical Engineering, 2007, 31: 8-10, 40.

[18] DING Y, JIANG J H, SHAN A D. Microstructures and mechanical properties of commercial purity iron processed by asymmetric rolling [J]. Materials Science and Engineering A, 2009, 509: 76-80.

[19] BEAUSIR B, BISWAS S, KIM D I, TOTH L S, SUWAS S. Analysis of microstructure and texture evolution in pure magnesium during symmetric and asymmetric rolling [J]. Acta Materialia, 2009, 57: 5061-5077.

[20] CUI Q, OHORI K. Grain refinement of high purity aluminium by asymmetric rolling [J]. Materials Science and Technology, 2000, 16: 1095-1101.

[21] JIN H, LLOYD D J. Effect of a duplex grain size on the tensile ductility of an ultra-fine grained Al-Mg alloy, AA5754, produced by asymmetric rolling and annealing [J]. Scripta Materialia, 2004, 50: 1319-1323.

[22] ZUO F Q, JIANG J H, SHAN A D. Shear deformation and grain refinement in pure Al by asymmetric rolling [J]. Transactions of Nonferrous Metal Society of China, 2008, 18: 774-777.

[23] JIANG J H, DING Y, ZUO F Q, SHAN A D. Mechanical properties and microstructures of ultrafine-grained pure aluminum by asymmetric rolling [J]. Scripta Materialia, 2009, 60: 905-908.

[24] ROUMINA R, SINCLAIR C W. Deformation geometry and through-thickness strain gradients in asymmetric rolling [J]. Metallurgical and Materials Transactions A, 2008, 39: 2495-2503.

[25] LU J S, HARRER O K, SCHWENZFEIER W, FISCHER F D. Analysis of the bending of the rolling material in asymmetrical sheet rolling [J]. International Journal of Mechanical Sciences, 2000, 42: 49-61.

[26] TZOU G Y, HUANG M N. Study on minimum thickness for asymmetrical hot-and-cold PV rolling of sheet considering constant shear friction [J]. Journal of Materials Processing Technology, 2001, 119: 229-233.

异步轧制对奥氏体钢组织和性能的影响

Jie LIU, Rudolf KAWALLA

Institute of Metal Forming, University of Technology and Mining Freiberg, Freiberg 09599, Germany

摘 要:分别采用异步轧制和同步轧制工艺制备具有细晶组织的钢材。异步轧制通过采用不同直径的轧辊来实现,轧辊直径比分别为1.00、1.05和1.11,轧制温度在900~1100 °C,轧制变形量为15%、30%和60%。结果表明,与同步轧制相比,异步轧制能够在轧制件中间层获得高体积分数的再结晶晶粒和更小的晶粒尺寸。在轧辊直径比为1.05时能够得到最高的再结晶程度和最小的晶粒尺寸。在较高的温度和低的变形量条件下,晶粒明显长大,其机制为传统的动态再结晶,伴随有孪晶发生。在900 °C下,即使变形量达到60%,异步轧制也不能导致动态再结晶发生,而同步轧制却可以。除了在900 °C和变形量为60%以外,异步轧制的压力要比同步轧制的小。轧制压力随着轧制温度的降低和变形量的升高而增加。

关键词:奥氏体钢;异步轧制;组织演变;轧制力

(Edited by YUAN Sai-qian)

Corresponding author: Jie LIU; Tel: +49-3731-392945; E-mail: Jie.Liu@imf.tu-freiberg.de

DOI: 10.1016/S1003-6326(12)61753-1