文章编号:1004-0609(2017)-01-0187-11

含砷石膏渣还原分解行为及砷迁移规律

赵占冲1, 2,史谊峰3,祝 星1, 2,祁先进1, 2,王晓武3,尤开云4,王 华1, 2

(1. 昆明理工大学 省部共建复杂有色金属资源清洁利用国家重点实验室,昆明 650093;

2. 昆明理工大学 冶金与能源工程学院,昆明 650093;

3. 云南铜业股份有限公司,昆明 650102;

4. 云南铜业(集团)有限公司,昆明 650102)

摘 要:在分析石灰铁盐法含砷石膏渣的物相组成和浸出毒性基础上,开展石膏渣-煤粉的TG-DSC和固-固反应研究,探索石膏渣碳热还原分解行为及砷迁移规律。结果表明:石膏渣在1000 ℃时的质量损失率接近50%,石膏渣与煤粉质量比为40:1时能够有效促进热分解,具有较高的质量损失率;石膏渣-煤粉反应过程中,分解残渣出现CaSO4→CaS→CaO的物相转变,还原分解后期CaSO4→CaO/SO2转变较为彻底,挥发率为45.29%、减容率为65.83%,气体产物成分为SO2和CO2,挥发性烟尘主要成分为As2O3;分解残渣微观结构较为致密,砷浸出毒性为1.05mg/L低于《GB 5085.1-2007》限值,浸出率仅为原石膏渣的1/236,残留的63.38%砷被有效固化在分解残渣中。碳热还原分解实现石膏渣的无害化处置、硫资源利用和砷的富集。

关键词:含砷石膏渣;碳热还原分解;TG-DSC;浸出毒性

中图分类号:X75 文献标志码:A

目前,铜冶炼以火法熔炼为主,该过程产生大量含硫含砷烟气,在进入制酸工序之前通常会采用烟气洗涤的方式去除烟气中杂质成分,进而会产生大量酸性重金属废水(简称污酸),污酸经石灰-铁盐法 [1-2]处理后转化为达标的工业用水,同时也产生了大量的含砷及重金属石膏渣。据估计,年产10万t铜冶炼厂配套的石灰-铁盐法工艺年产石膏渣约1万t,由此,中国铜冶炼行业每年约产生50万t左右的石膏渣污泥。受制于处置技术和处理成本,在愈加严苛的环保法律法规条件下,此类石膏渣污泥仍无法有效处置或利用,冶炼企业通常将其暂存于“三防”渣库中。“三防”渣库用于堆存石膏渣,不仅维护成本较高,而且存在巨大的安全隐患,一旦发生地震、泥石流、山洪暴发等地质灾害,将对当地生态造成无可挽回的伤害[3-4]。开展石膏渣无害化处置或资源化利用具有十分重要的环境保护意义,关乎铜冶炼企业可持续发展与社会稳定。

国内外学者针对含砷固废的处置,主要包括水泥固化[5-6]、石灰/火山灰固化[7-8]、药剂固化[9]、塑性固化[10]、高温熔融固化[11]、高温还原分解[11]等方法。其中药剂固化是通过添加化学药剂使砷和重金属元素形成更稳定的化合物,从而降低其浸出、迁移的技术,化学试剂如镁、铁、钙等都可以作为砷固化和稳定化的有效试剂[12-13]。塑性固化是以塑性材料为固化剂配加适量的催化剂和骨料,在塑性材料的共聚作用下实现对有害元素的包裹并形成具有一定强度和稳定性的固化体,常用的塑性材料有沥青、石蜡、聚乙烯、聚丙烯等[14]。高温熔融处置法是借鉴垃圾焚烧飞灰的熔融处置方法,将含砷固废和一定量的添加剂混合后,在高温下达到熔融状态,然后迅速冷却降温形成玻璃固化体,利用降温过程中形成的致密玻璃体结构,完成对砷和其他重金属元素的固化。高温还原分解处置法是利用还原剂还原分解含重金属固体废弃物,有目的地提取有价成分,以达到二次资源化的目的,同时还原后熔渣可以实现对重金属元素的有效固化。上述几种处置方法中,水泥固化处置法由于操作简单,成本较低,原料极易获得,是最常用的无害化处置法,但是该处置方法存在体积增容比过大的问题,且该方法主要是通过废物和凝结剂之间的化学键合力、凝结剂对废物的物理包胶作用及凝结剂水合物对废物的吸附等共同作用固化有害物质元素,因此固化体的中长期稳定性和潜在风险尚待深入研究,仍有大量的理论和技术问题特别是耐久性需要解决[15]。而药剂固化处置法和塑性固化处置法由于成本较高,尚未得到大面积推广。研究结合铜冶炼厂产生的含砷石膏渣成分特点和铜冶炼工艺流程,提出碳热还原分解法处置该类废渣,可实现石膏渣无害化处置、砷及挥发性重金属回收和硫资源利用。此外,还可以含砷石膏渣代替石灰石在熔炼过程中造渣,以达到协同处置石膏渣目的。但此类含砷石膏渣高温碳热还原分解行为的相关研究未见报道,因此有必要开展含砷石膏渣碳热分解行为及砷迁移规律的研究。本文作者在分析含砷石膏渣物相组成与浸出毒性基础上,开展了含砷石膏渣污泥-煤粉的TG-DSC和固-固反应特性研究,探索了含砷石膏渣碳热分解行为及砷迁移规律,为含砷石膏渣的无害化处置与资源化利用提供科学依据。

1 实验

1.1 实验原料

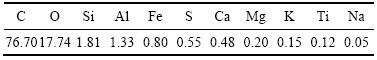

实验中的石膏渣取自西南地区某铜冶炼厂渣场,由该厂石灰-铁盐法污酸处理工艺产生的新鲜石膏渣含水量约为60%,经自然风干后含水量约为16%。煤粉取自云南某煤矿,元素分析和工业分析结果如表1和表2所示。

1.2 实验方法

采用日本理学max–3B X射线衍射仪分析物相组成,Cu靶Kα射线,管电压35kV,管电流20 mA,扫描速度10 (°)/min,扫描范围2θ=10°~90°。

表1 煤粉元素分析

Table 1 Chemical composition of coal sample (mass fraction, %)

表2 煤粉工业分析

Table 2 Proximate analysis of coal sample (mass fraction, %)

采用日本理学ZSX100e X射线荧光光谱仪分析元素组成,将粉末放入直径20 mm的塑环中,采用30 t/cm3压力压制成20 mm原片,放入仪器中进行全元素+半定量检测;温度20 ℃,湿度30%。

采用德国耐驰公司(NETZSCH)生产的STA449F3热分析仪对样品进行热重分析,样品质量10 mg,温度范围0~1450 ℃,升温速率10 ℃/min,高纯氩气(流量20 mL/min)作保护气体,高纯氮气(流量50 mL/min)作载流气体,坩埚为带孔盖的Al2O3坩埚。

样品中Cu、Pb、Zn、Cd等元素含量采用PS-1000电感耦合等离子发射光谱(ICP-AES,利曼·中国,检测条件:功率1.0 kW;冷却气17 L/min;雾化气流量0.252 MPa;辅助气0.2 L/min;泵速1.0 mL/min)。分析样品中Hg、Se、Sb、As元素含量采用AFS-9130原子荧光光度计(北京吉天仪器有限公司生产,检测条件:光电倍增管负高压:240~250 V;原子化气高度:8 mm;灯电流:A道55 mA,B道25 mA;载气流量:400 mL/min;屏蔽气流量:800 mL/min)重金属浸出毒性测定按照《危险废物鉴别标准-浸出毒性鉴别》(GB5085.3—2007)进行[16],浸出液采用 ICP或原子吸收光谱仪分析,所测数据与《危险废物鉴别标准》(GB 5085.1—2007)进行比较[17]。

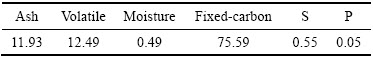

1.3 实验装置图

利用自建的一套常压小型固定床反应装置,对石膏渣-煤粉固-固反应进行研究,装置图如图1所示。采用MRU公司生产的红外烟气测量仪(MGA-5)分析气体产物CO、SO2和CO2的浓度,测量范围:SO2(0~5×10-3),CO(0~5×10-3),CO2(0~30%)。氮气购自昆明梅塞尔气体产品有限公司,纯度99.99%,采用合肥科晶公司生产的GSL-1700X管式电阻炉作为固定床加热升温装置,采用氮气作为石膏渣碳热还原热分解的保护性气氛,氮气流量控制在1 L/min。

图1 石灰-铁盐法石膏渣碳热分解装置图

Fig. 1 Schematic diagram of experimental flow chart

2 结果与讨论

2.1 含砷石膏渣物相组成与浸出毒性

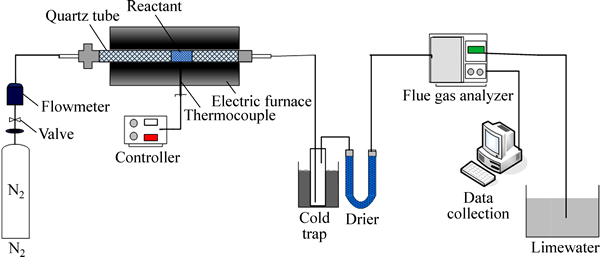

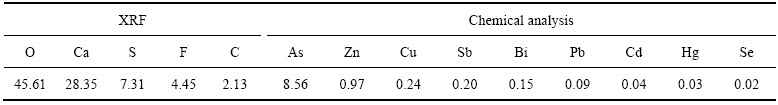

图2所示为西南某铜冶炼企业渣场露天堆存的黄色或灰白色粉状、块状含砷石膏渣。表3所列为经105 ℃干燥24 h后的石膏渣元素分析结果,除Ca、S和O主要元素外,还有As、Zn、Cu、Sb、Bi、Pb、Cd、Hg和Se等重金属元素,特别是砷含量达到8.56%。图3所示为干燥后石膏渣XRD图谱,其主要物相为硫酸钙及其水合物(CaSO4、CaSO4·0.5H2O和CaSO4·2H2O),源于石灰-铁盐法中电石渣(Ca(OH)2)和污酸中H2SO4之间的中和反应。XRD谱中还出现强度较弱的Ca(OH)2和Ca5F(AsO4)3特征衍射峰,分别源于过量未反应的残余电石渣和污酸中砷酸根离子与Ca(OH)2之间的沉淀反应。石膏渣中重金属元素则是由于污酸经过中和沉淀反应后,pH值调至碱性,重金属元素进而以氢氧化物的形式沉淀至石膏渣中[18]。XRD和XRF结果能够较好的吻合,石膏渣中砷含量较高,主要以较为稳定的砷酸盐或移动性较强的亚砷酸盐形态存在[19]。

图2 在渣场堆放的含砷石膏渣

Fig. 2 Arsenic bearing gypsum sludge in slag field

为确定含砷石膏渣危害性,取渣场中堆存的经自然风干的石膏渣,参照《GB5085.3-2007》测定浸出液中重金属浓度对其进行浸出毒性鉴别,结果如表4所列。由表4可知,石膏渣浸出液中As的浸出浓度达214.06 mg/L是《GB5085.3—2007》规定限值的42倍,砷元素的浸出浓度超标约1.5倍,Hg元素略微超标。由此可知,此含砷石膏渣属于危险废物,具有较高的浸出毒性。含砷石膏渣具有较高的砷浸出毒性,是由于污酸中砷以砷酸和亚砷酸形态存在,特别是亚砷酸具有很高的迁移性,部分砷元素以可溶性的弱酸态存在,导致浸出液毒性较高[19]。这些弱酸态的砷主要以非稳态的亚砷酸盐存在,在高温过程中会分解,而已经形成的砷酸盐在高温过程较为稳定,因此高温热分解过程能够大幅降低石膏渣的浸出毒性。

图3 含砷石膏渣的XRD谱

Fig. 3 XRD patterns of arsenic bearing gypsum sludge

表3 含砷石膏渣中元素分析结果

Table 3 Chemical composition of arsenic bearing gypsum sludge (mass fraction, %)

表4 含砷石膏渣的浸出毒性结果

Table 4 Leaching toxicity of arsenic bearing gypsum sludge

2.2 含砷石膏渣TG-DSC分析

2.2.1 含砷石膏渣直接热分解

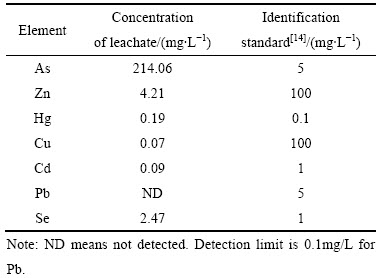

为了进一步探究含砷石膏渣碳热还原分解行为,开展了煤粉和石膏渣直接热分解TG-DSC分析,如图4所示。由图4(a)可知,煤粉热解是一个缓慢质量损失的过程,至1000 ℃时,质量损失约21%。TG曲线可分为3个质量损失阶段:第一阶段温度区间40~100 ℃,质量损失约2%,为干燥脱气段,主要析出H2O(包括化学结合水)、CO、CO2、H2S(少量)、甲酸(痕量)和烷基苯类(少量)等[20],在DSC曲线上很明显对应一个吸热峰,峰值点79 ℃;第二阶段100~500 ℃,TG曲线略微平滑,质量损失约4%,DSC曲线没有峰形出现,可能主要发生微弱的脱羧基反应,含羧基化合物的析出源于化学吸附表面配合物及羧基和酚羟基的分解[21];第三阶段500~1000 ℃,质量损失率明显加快,质量损失15%左右,DSC曲线上在701 ℃附近出现一个吸热峰,源于煤粉的活泼分解以及二次脱气,以解聚、分解和芳香部分缩聚反应为主,析出大量挥发物[22]。

图4 煤粉和含砷石膏渣直接热分解的TG-DSC曲线

Fig. 4 TG-DSC curves of coal powder (a) and arsenic bearing gypsum sludge (b)

如图4(b)所示,TG曲线表明石膏渣直接热分解是一个缓慢质量损失过程,在DSC曲线上出现3个明显的吸热峰,整个分解过程可分为4个阶段,可能发生的反应如下:

CaSO4·xH2O→CaSO4+xH2O(g) (1)

Me(OH)2→MeO+H2O(g) (2)

MeCO3→MeO+CO2(g) (3)

CaCO3→CaO+CO2(g) (4)

2FeAsO3→Fe2O3+As2O3(g) (5)

Ca3(AsO3)2→3CaO+As2O3(g) (6)

CaSO4→CaO+SO2+0.5O2(g) (7)

第一阶段温度区间40~200 ℃,质量损失8%左右,DSC曲线上对应第一个吸热峰,源于石膏渣物理水和结晶水的脱除,石膏渣结晶水脱除过程[23]为CaSO4·2H2O→CaSO4·0.5H2O→CaSO4(见式(1))。第二阶段温度区间200~600 ℃,质量损失约6%,DSC曲线上没有明显的峰形出现,可能源于少量重金属氢氧化物的分解(见式(2))。第三阶段温度区间600~700 ℃,质量损失4%左右,DSC曲线上对应第二个吸热峰,这可能是少量碳酸盐的分解导致的(见式(3))[24]。第四阶段温度区间700~1000 ℃,质量损失7%左右,DSC曲线上对应第三个吸热峰,主要由CaSO4的分解引起,同时伴随着CaCO3和少量亚砷酸盐(FeAsO3和Ca3(AsO3)2)的分解[25],石膏渣中含有的杂质可能会对硫酸钙的分解有一定的促进作用,见式(4)~(7)。

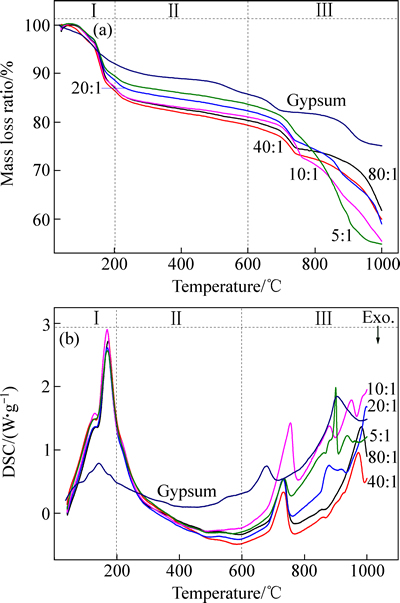

2.2.2 煤粉对含砷石膏渣分解的影响规律

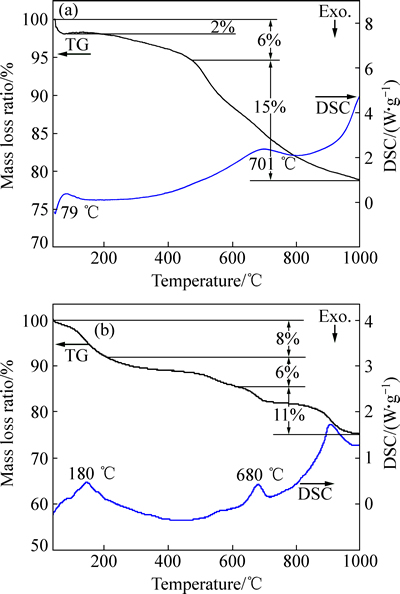

为了考察煤粉用量对含砷石膏渣还原分解过程的影响,开展了石膏渣/煤粉质量比分别是80/1、40/1、20/1、10/1、5/1的TG-DSC分析。如图5所示,掺入煤粉的TG曲线明显低于纯石膏渣的,这表明掺入少量的煤粉即可显著加快石膏渣分解速度,但不同煤粉比例的质量损失变化相对较小。由于煤粉直接分解的质量损失过程较为平缓,且煤粉在石膏渣中掺入量很小,可以忽略煤粉质量损失对石膏渣/煤粉TG曲线的影响。因此,可将石膏渣/煤粉质量损失速率的增大归结于煤粉对石膏渣分解过程的促进作用。石膏渣碳热还原分解可分为3个阶段,与磷石膏碳热还原分解较为相似,且石膏渣中存在的重金属及其氧化物可能在分解过程中起到了催化促进作用[26-27]。此外,煤粉热分解的脱气过程可促进在固体混合物中形成大量空隙,有利于石膏渣脱水和低温分解过程,而高温段煤粉可与包括重金属在内的氧化物反应,进而直接起到促进质量损失的作用。

图5 不同煤粉掺入量下的含砷石膏渣TG和DSC曲线

Fig. 5 TG (a) and DSC (b) curves of decomposition at different mass fractions of gypsum sludge/coal

石膏渣与煤粉质量比为5/1和10/1时,TG曲线显示的质量损失率更大,可能是过量的煤粉除参与分解反应外,自身的热分解也会产生质量损失。第一阶段温度区间40~200 ℃为脱水过程,质量损失约15%,对应着DSC曲线上的吸热峰,煤粉掺量对石膏渣脱水的起始温度影响不大。第二阶段温度区间200~600 ℃,质量损失较为缓慢,质量损失约8%,可能是源于石膏渣中的金属氢氧化物分解以及煤粉脱羧基反应,石膏渣与煤粉质量比为40/1时具有较高的质量损失率;第三阶段温度区间600~1000 ℃,出现显著质量损失,质量损失约30%。以CaSO4为主要成分的磷石膏在700 ℃左右才开始快速分解[28],相比较而言石膏渣具有较低的CaSO4→CaO/SO2分解温度,进一步验证了重金属氧化物对分解反应的催化促进作用[26-27]。在该阶段,随着煤粉的增加,石膏渣的分解速率明显加快,发生的反应有:

2CaSO4+C=2CaO+CO2(g)+2SO2(g) (8)

CaSO4+4C=CaS+4CO(g) (9)

3CaSO4+CaS=4CaO+4SO2(g) (10)

CaSO4+3CaS=4CaO+4S (11)

CaS+2SO2=CaSO4+2S (12)

其中,式(8)是石膏渣碳热还原分解主反应,式(9)是分解的副反应,生成CaS,而反应(10)~(12)是CaS的消减反应。CaS作为石膏渣分解的副产物,煤粉的掺入量能够影响CaS的生成。大量研究结果表明[29-32]:1) 煤粉掺入量过高过低都不利于CaS的消除;2) 理论上C/S摩尔比为0.5(石膏渣与煤粉的质量比为60/1)最有利于脱硫,实际上考虑到石膏渣中大量杂质的存在,最佳的C/S摩尔比要高于0.5,但煤粉量过高容易导致结焦,在本次实验中石膏渣/煤粉质量比为20/1的时候就开始出现结焦现象了;3) 气体产物浓度CO2和SO2正相关,气体产物CO和副产物CaS正相关。据此,结合图4和图5的TG-DSC曲线,确定石膏渣与煤粉的最佳质量比为40/1,该条件下最有利于反应(8)的进行,这一结论也得到了后续实验结果的支持。

2.3 含砷石膏渣分解机理及砷迁移规律

2.3.1 含砷石膏渣碳热还原分解机理

为揭示含砷石膏渣碳热还原分解机理,利用如图1所示实验装置进行了石膏渣-煤粉固-固反应特性研究,对石膏渣/煤粉质量比为40/1的样品程序升温(10 ℃/min)和恒温分解过程气体产物、分解残渣和含砷烟尘进行了分析。

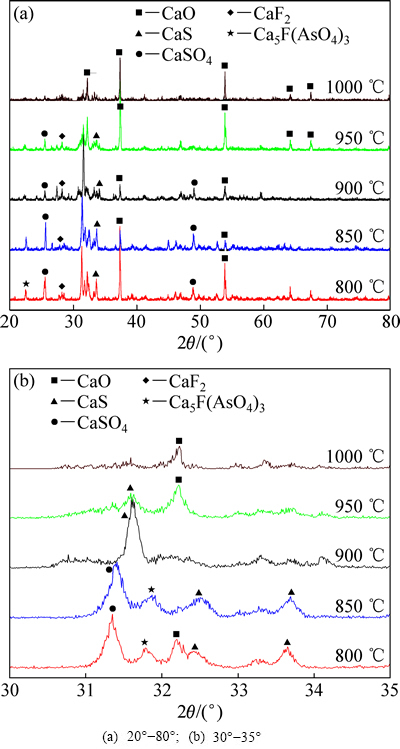

图6所示为800 ℃、850 ℃、900 ℃、1000 ℃恒温40 min的含砷石膏渣/煤粉反应残渣物相演变规律。如图6所示:800 ℃和850 ℃对应的石膏渣分解残渣除原有CaSO4、CaF2和Ca5F(AsO4)3物相外,还可以检测到CaO和CaS物相,这说明在该温度条件下已经发生了硫酸钙分解,涉及反应(8)和(9)。随温度的升高,主要物相CaSO4对应的特征衍射峰强度逐渐减弱直至消失,与之相对应的分解产物CaO的衍射峰逐渐增强(见图6(b)),且还可以观察到CaS作为中间产物,当温度升高到900 ℃时消失,这也说明发生了反应(10)。主要物相的转变也表明CaSO4→CaO/SO2转化反应进行得较为彻底。通过图6还可以看出,在800 ℃和850 ℃时出现的Ca5F(AsO4)3特征衍射峰随着温度的升高出现明显的弱化,这可能是由于该含氟砷酸盐分解成了更为稳定的砷酸钙或部分砷酸盐发生了碳热还原分解反应[26]。石膏渣碳热还原分解过程中物相演变规律是,CaSO4先分解生成了CaO和少量的CaS,继而随着温度的升高CaS通过反应(10)转变为CaO。与磷石膏或纯硫酸钙分解特性不同的是,石膏渣具有较低的分解温度。这可能是因为两个体系所含的杂质元素不一样,导致催化体系迥异,磷石膏中的杂质以P、F、Al、Fe、K、Na等[33]轻金属及其氧化物为主,而石膏渣中含有大量的As、Zn、Pb、Se、Hg、Fe等重金属元素及其化合物,而重金属元素及其化合物的存在也已被证实有利于降低硫酸钙的分解温度[26-27]。

图6 不同温度下含砷石膏渣/煤粉分解残渣的XRD谱

Fig. 6 XRD patterns of arsenic bearing gypsum sludge/ coal reacted residue at different temperatures

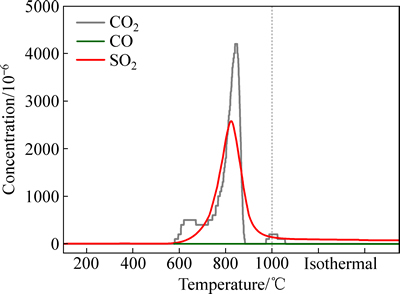

图7所示为含砷石膏渣/煤粉碳热还原过程中气体产物的浓度-温度曲线。如图7所示,当温度升高至600 ℃时,含砷石膏渣/煤粉固-固反应气体产物中CO2浓度曲线上出现一个小肩峰,这可能由少量碳酸盐在该温度下分解导致的[25],发生式(3)。随着温度继续升高,CO2浓度开始快速升高,继而下降,在1000 ℃出现第二个小肩峰,可能是由煤粉还原金属氧化物所释放的CO2导致的[34],见式(13)。伴随着CO2从600 ℃开始释放,气体产物中SO2开始出现并且浓度快速上升,至800 ℃时达到峰值,至1000 ℃时SO2浓度降至较低水平。800 ℃附近产生的CO2和SO2主要源于反应(8),其中部分CO2还可能源自于CaCO3的分解。SO2浓度变化曲线与CO2的十分相似且相一致,且整个升温和恒温过程中CO的浓度一直处于较低的水平。结合2.2.2中石膏渣的TG-DSC分析,可知温度升高至600 ℃,CaSO4就开始快速分解,发生反应(8),升温至1000 ℃时CaSO4分解基本完全。这说明CaSO4→CaO/SO2转化过程较为彻底,有利于石膏渣中硫资源利用。图7中显示的气体产物变化曲线和2.2部分的TG-DSC结果十分吻合。

2MeO+C=Me+CO2(g) (13)

式中:Me代表金属。

图7 含砷石膏渣/煤粉反应气体产物的浓度-温度曲线

Fig. 7 Concentration-temperature curves of evolved gas in reductive decomposition of arsenic bearing gypsum sludge/coal

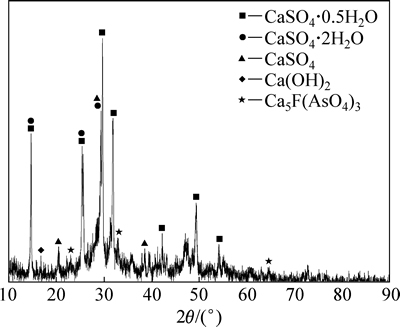

图8所示为含砷石膏渣/煤粉碳热还原过程中收集到的烟尘。收集到的烟尘主要成分为As2O3和CaSO4,除此之外还有来自于反应器材料表面上的物相Ca2Mg(Si2O7)。部分衍射峰由于含量较低无法识别,可能源自于含砷石膏渣中挥发性重金属元素形成的化合物。含砷石膏渣中砷化合物热分解生成As2O3烟尘[25, 35-36],少量石膏渣也随烟气进入烟尘中,进而在烟尘中出现CaSO4。碳热还原分解处置含砷石膏渣,可在降低石膏渣含砷量和毒性的同时富集砷和其他重金属元素,挥发性烟尘也存在潜在利用价值。

2.3.2 含砷石膏渣分解过程中砷的迁移规律

图8 含砷石膏渣还原分解挥发物烟尘的XRD谱

Fig. 8 XRD patterns of dust in reductive decomposition of arsenic bearing gypsum sludge/coal

含砷石膏渣/煤粉在1000 ℃还原分解,石膏渣挥发率为45.29%,减容率为65.83%。砷在石膏渣中主要以弱酸态F1和可还原态F2存在,稳定性最差、环境危害性大[19],结合亚砷酸盐和砷酸盐溶解度和稳定性可知,石膏渣中除XRD物相中显示存在的Ca5F(AsO4)3(砷酸盐)外还存在亚砷酸盐。碳热还原分解过程中,当温度上升至600 ℃左右时亚砷酸盐开始分解,当温度升高900 ℃时出现了明显的砷酸盐分解,还原性气氛下亚砷酸盐和砷酸盐会加速分解致使在分解残渣中砷的含量急剧下降,砷的脱除率达到36.62%,发生的主要反应如下所示(以钙盐为例)。

Ca3(AsO3)2=3CaO+As2O3(g) (14)

2Ca5F(AsO4)3+3C=CaF2+9CaO+3As2O3(g)+3CO2(g) (15)

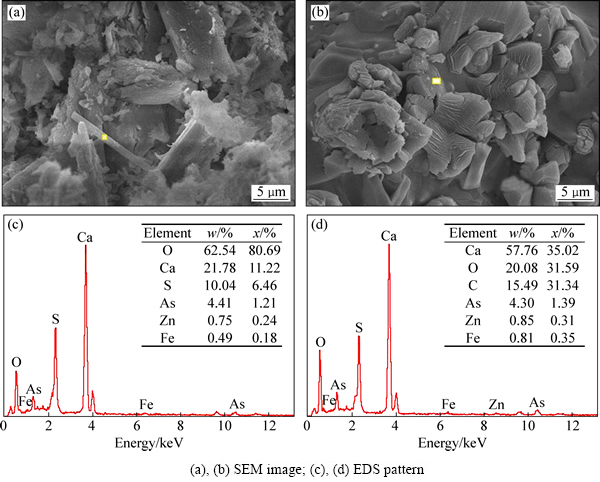

通过碳热还原高温分解反应,几乎全部亚砷酸盐和部分砷酸盐被分解,砷以烟尘形式释放出来(见图8),分解残渣中砷主要以较为稳定的砷酸盐存在。此外,在高温煅烧过程中,未分解的砷酸盐晶型趋于完整、晶化程度提高,进而提高了其中砷的稳定性。如图9所示,在石膏渣和分解残渣中都可检测到As元素。石膏渣微观结构较为蓬松,存在块状和柱状晶体及附着在晶体上的杂质,分解残渣微观形貌十分密实,晶化程度高。其密实的微观结构和较高的晶化程度有利于提高砷的稳定性,降低砷及其化合物的移动性。

图9 含砷石膏渣与分解残渣的SEM像及EDS谱

Fig. 9 SEM images and EDS spectrums before (a), (c) and after (b), (d) reaction of reductive decomposition for arsenic bearing sludge

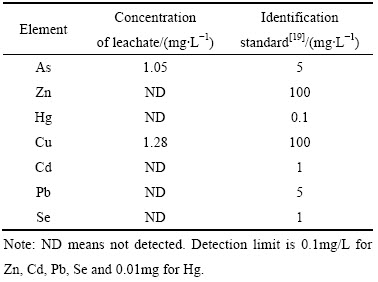

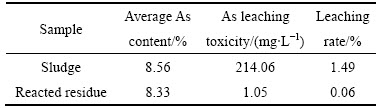

表5所列为分解残渣浸出毒性结果,除As和Cu外其他重金属元素未检出,且所有元素浸出毒性值都低于《GB 5085.1—2007》中规定的限值,实现了彻底的无害化处置。分解残渣中As浸出毒性从原始石膏渣的214.06 mg/L降低至1.05 mg/L,低于5 mg/L的国标限制值。表6中比较了石膏渣和分解残渣含砷量、浸出毒性和浸出率,结果发现分解残渣中砷含量略有降低,但相对应的浸出毒性却大幅下降,且浸出率仅为原始石膏渣的1/236。这说明分解残渣中砷的稳定性较高,砷移动性降低,能够较好地固化在分解残渣中。

表5 含砷石膏渣/煤粉还原分解残渣的毒性浸出结果

Table 5 Leaching toxicity of reacted residue from arsenic bearing sludge/coal reaction

表6 石膏渣和分解残含砷量、浸出毒性和浸出率比较

Table 6 Arsenic content, leaching toxicity and leaching rate of sludge/coal residue

3 结论

1) 石膏渣主要成分为CaSO4及其水合物,含有As、Zn、Cu、Sb、Bi、Pb、Cd、Hg和Se等重金属元素,As含量8.56%,As和Se浸出毒性分别为214.06 mg/L和2.47 mg/L,超过《GB 5085.1—2007》中规定的5 mg/L和1 mg/L限值,Hg元素略微超标,属危险废弃物。

2) 石膏渣热分解过程伴随着游离水和结晶水的脱除、氢氧化物、碳酸盐、亚砷酸盐分解和CaSO4分解,1000 ℃时的质量损失率接近50%,石膏渣与煤粉质量比为40:1时能够有效促进热分解,具有较高的质量损失率,还原分解过程分为3个阶段:40~200 ℃结晶水的脱除、200~600 ℃金属氢氧化物分解、600~1000 ℃硫酸钙及少量碳酸钙与砷酸盐分解。

3) 分解过程中出现了CaSO4→CaS→CaO物相转变,CaS为反应中间产物,随着温度的升高CaSO4→CaO/SO2转变反应进行得较为彻底,由于重金属氧化物的催化促进作用,该转变反应温度较同类石膏物料分解温度低,石膏渣挥发率为45.29%、减容率为65.83%,分解过程中气体产物中SO2含量较高,挥发性烟尘主要成分为As2O3。

4) 分解残渣微观结构较为致密,砷的脱除率达到36.62%,砷浸出毒性为1.05 mg/L低于《GB 5085.1—2007》限值,浸出率仅为原石膏渣的1/236,残留的63.38%砷被有效固化在分解残渣中。碳热还原分解实现了石膏渣的无害化处置、硫资源利用、砷的富集。

REFERENCES

[1] 倪 冲, 赵燕鹏, 阮福辉, 卢 娜, 杜冬云. 氨浸法从含砷石灰铁盐渣中回收铜的动力学[J]. 中国有色金属学报, 2013, 23(6): 1769-1774.

NI Chong, ZHAO Yan-peng, RUAN Fu-hui, LU Na, DU Dong-yun. Kinetics of copper recovery from as-contained solid waste by ammonia leaching method[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1769-1774.

[2] MIN X B, LIAO Y P, CHAI L Y, YANG Z X, XIONG S, LIU L, LI Q Z. Removal and stabilization of arsenic from anode slime by forming crystal scorodite[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1298-1306.

[3] CHEN J, WANG S X, ZHANG S, YANG X J, HUANG Z J, WANG C, WEI Q Y, ZHANG G L, XIAO J, JIANG F Z, CHANG J, XIANG X, WANG J. Arsenic pollution and its treatment in Yangzonghai lake in China: In situ remediation[J]. Ecotoxicology and Environmental Safety, 2015, 122: 178-185.

[4] CHAI L Y, WU J X, WU Y J, TANG C B, YANG W H. Environmental risk assessment on the slag and the iron-rich produced from reducing-matting smelting of lead-bearing wastes and iron-rich wastes[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3429-3435.

[5] YANG B, ZHANG G L, DENG W, MA J. Review of arsenic pollution and treatment progress in nonferrous metallurgy industry[J]. Advanced Materials Research, 2013, 634: 3239-3243.

[6] 李辕成, 祝 星, 祁先进, 王 华, 史谊峰, 王晓武, 廖天鹏, 胡建杭. 铜冶炼污泥固化剂优选试验研究[J]. 安全与环境学报, 2013, 13(6): 85-90.

LI Yuan-cheng, ZHU Xing, QI Xian-jin, WANG Hua, SHI Yi-feng, WANG Xiao-wu, LIAO Tian-peng, HU Jian-hang. Optimization research of the treating agents for solidifying the sludge in a copper metallurgical plant[J]. Journal of Safety and Environment, 2013, 13(6): 85-90.

[7]  N, BRIONES-GALLARDO R, RAMOS-LEAL J A, AVALOS-BORJAC M,

N, BRIONES-GALLARDO R, RAMOS-LEAL J A, AVALOS-BORJAC M,  A D, RAZO-FLORESA E, VILLALOBOSD M. Arsenic mobility controlled by solid calcium arsenates: A case study in Mexico showcasing a potentially widespread environmental problem[J]. Environmental Pollution, 2013, 176: 114-122.

A D, RAZO-FLORESA E, VILLALOBOSD M. Arsenic mobility controlled by solid calcium arsenates: A case study in Mexico showcasing a potentially widespread environmental problem[J]. Environmental Pollution, 2013, 176: 114-122.

[8] NEUPANE G, DONAHOE R J. Calcium-phosphate treatment of contaminated soil for arsenic immobilization[J]. Applied Geochemistry, 2013, 28: 145-154.

[9]  ETTLER V. Chemical stabilization of metals and arsenic in contaminated soils using oxides-a review[J]. Environmental Pollution, 2013, 172: 9-22.

ETTLER V. Chemical stabilization of metals and arsenic in contaminated soils using oxides-a review[J]. Environmental Pollution, 2013, 172: 9-22.

[10] SINGH R, SINGH S, PARIHAR P, SINGH V P, PRASAD, S M. Arsenic contamination, consequences and remediation techniques: A review[J]. Ecotoxicology and Environmental Safety, 2015, 112: 247-270.

[11] 廖天鹏. 铜冶炼污泥资源化利用基础研究[D]. 昆明: 昆明理工大学, 2014.

LIAO Tian-peng. Basic research on resource utilization copper smelting sludge[D]. Kunming: Kunming University of Science and Technology, 2014.

[12] HU L F, FENG H J, WU Y Y, LONG Y Y, WANG J, SHEN D S. A comparative study on stabilization of available as in highly contaminated hazardous solid waste[J]. Journal of Hazardous Materials, 2010, 174(1): 194-201.

[13] KUMPIENE J, LAGERKVIST A, MAURICE C. Stabilization of As, Cr, Cu, Pb and Zn in soil using amendments–A review[J]. Waste Management, 2008, 28(1): 215-225.

[14] LEE J, PANDEY B D. Bio-processing of solid wastes and secondary resources for metal extraction-A review[J]. Waste Management, 2012, 32(1): 3-18.

[15] CLANCY T M, SNYDER K V, REDDY R, LANZIROTTIB A, AMROSEC S E, RASKINA L, HAYESA K F. Evaluating the cement stabilization of arsenic-bearing iron wastes from drinking water treatment[J]. Journal of Hazardous Materials, 2015, 300: 522-529.

[16] GB5085.3—2007. 固体废物浸出毒性浸出方法: 水平振荡法[S].

GB5085.3—2007. Test method for leaching toxicity of solid wastes: Horizontal vibration extraction procedure[S].

[17] GB5085.1—2007. 危险废物鉴别标准: 浸出毒性鉴别[S].

GB5085.1—2007. Identification standards for hazardous wastes: Identification for leaching toxicity[S].

[18] 廖天鹏, 祝 星, 祁先进, 王 华, 史谊峰, 李辕成, 胡建杭. 铜冶炼污泥形成机理及其特性[J]. 化工进展, 2013, 32(9): 2246-2252.

LIAO Tian-peng, ZHU Xing, Qi Xian-jin, WANG Hua, SHI Yi-feng, LI Yuan-cheng, HU Jian-hang. Formation mechanism and characteristics of sludge in copper metallurgy plant[J]. Chemical Industry and Engineering Progress, 2013, 32(9): 2246-2252.

[19] 廖天鹏, 祝 星, 祁先进, 王 华, 史谊峰, 刘春侠. 铜污泥中重金属形态分布及浸出毒性分析[J]. 化工进展, 2014, 3: 762-768.

LIAO Tian-peng, ZHU Xing, Qi Xian-jin, WANG Hua, SHI Yi-feng, LIU Chun-xia. Chemical speciation of heavy metals and leaching toxicity analysis of sludge in copper metallurgy plant[J]. Chemical Industry and Engineering Progress, 2014, 3: 762-768.

[20] WANG X, YANG D J, ZHU S H, PENG J H, DUAN X H. Thermodynamics and kinetics of carbothermal reduction of zinc ferrite by microwave heating[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3808-3815.

[21] 高新勇, 金 晶, 张 号, 董 振, 曾武勇, 孟 磊, 高文静. 市政污泥与烟煤的混合热解特性实验研究[J]. 煤炭转化, 2014, 37(1): 83-87.

GAO Xin-yong, JIN Jing, ZHANG Hao, DONG Zhen, ZENG Wu-yong, MENG Lei, GAO Wen-jing. Preparation and adsorption properties of coal-based formed activated carbon[J]. Coal Conversion, 2014, 37(1): 83-87.

[22] DOU L, HE X, HU H E, HE J, FAN J. Spatial structure evolution of overlying strata and inducing mechanism of rockburst in coal mine[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 1255-1261.

[23] YU Q L, BROUWERS H J H. Thermal properties and microstructure of gypsum board and its dehydration products: a theoretical and experimental investigation[J]. Fire and Materials, 2012, 36(7): 575-589.

[24] 张衡中. 碳酸盐分解温度的变化规律[J]. 有色金属, 2008, 46(3): 58-60.

ZHANG Heng-zhong. Regularity of decomposition temperature of carbonates[J]. Nonferrous Metals, 2008, 46(3): 58-60.

[25] 吴宏伟, 段铭诚. 砷铁渣中砷酸铁的热力学分析及热分解试验[J]. 云南化工, 2015, 42(3): 17-20.

WU Hong-wei, DUAN Ming-cheng. Thermodynamic analysis and thermal decomposition experiments of arsenic slag iron arsenate[J]. Yunnan Chemical Technology, 2015, 42(3): 17-20.

[26] YAN B, MA L P, MA J, YAN X D. Mechanism analysis of Ca, S transformation in phosphogypsum decomposition with Fe catalyst[J]. Industrial & Engineering Chemistry Research, 2014, 53(18): 7648-7654.

[27] YAN B, MA L P, XIE L G, MA J. Reaction mechanism for iron catalyst in the process of phosphogypsum decomposition[J]. Industrial & Engineering Chemistry Research, 2013, 52(49): 17383-17389.

[28] ZHENG D, LU H, SUN X, LIU X D, HAN W Q, WANG L J. Reaction mechanism of reductive decomposition of FGD gypsum with anthracite[J]. Thermochimica Acta, 2013, 559: 23-31.

[29] YANG C Q, XIA J P. Study on the carbon-thermal reaction mechanism of potassium feldspar and phosphogypsum[C]. Advanced Materials Research, 2015, 1073/1076: 308-313.

[30] YAN X D, MA L P, ZHU B, ZHENG D L, LIAN Y. Reaction mechanism process analysis with phosphogypsum decomposition in multi-atmosphere control[J]. Industrial & Engineering Chemistry Research, 2014, 53(50): 19453-19459.

[31] LI C X, ZHONG H, WANG S, XUE J R, WANG H B. Reaction process and mechanism analysis for CaS generation in the process of reductive decomposition of CaSO3 with coal[J]. Journal of the Taiwan Institute of Chemical Engineers, 2015, 50: 173-181.

[32] YAN Z Q, WANG Z A, WANG X F, LIU H, QIU J R. Kinetic model for calcium sulfate decomposition at high temperature[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3490-3497.

[33] 资泽城, 马丽萍, 马 俊, 陈建涛, 周 龙, 张 杭. 杂质对磷石膏碳粉还原分解的影响研究[J]. 硅酸盐通报, 2014, 33(11): 2772-2777.

ZI Ze-cheng, MA Li-ping, MA Jun, CHEN Jian-tao, ZHOU Long, ZHANG Hang. Effect of impurities on the reductive decomposition of phosphor-gypsum by powdered carbon[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(11): 2772-2777.

[34] 周俊虎, 温正城, 王智化, 杨卫娟, 刘建忠, 岑可法. 用煤粉来再燃脱硝中金属氧化物催化作用的实验研究[J]. 高校化学工程学报, 2008, 22(1): 55-59.

ZHOU Jun-hu, WEN Zheng-cheng, WANG Zhi-hua, YANG Wei-juan, LIU Jian-zhong, CEN Ke-fa. Catalysis of metal oxide for NOx reduction via reburning with pulverized moal[J]. Journal of Chemical Engineering of Chinese Universities, 2008, 22(1): 55-59.

[35] FROST R L, WEIER M L, MARTENS W, KLOPROGGE T, DING Z. Thermal decomposition of the vivianite arsenates-implications for soil remediation[J]. Thermochimica Acta, 2003, 403(2): 237-249.

[36] HELSEN L, van BULCK E, van BAEL M K, VANHOYLAND G, MULLENS G. Thermal behaviour of arsenic oxides (As2O5 and As2O3) and the influence of reducing agents (glucose and activated carbon)[J]. Thermochimica Acta, 2004, 414(2): 145-153.

Reductive decomposition behavior of arsenic bearing gypsum sludge with coal and arsenic migration rule

ZHAO Zhan-chong1, 2, SHI Yi-feng3, ZHU Xing1, 2, QI Xian-jin1, 2, WANG Xiao-wu3, YOU Kai-yun4, WANG Hua1, 2

(1. State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization,

Kunming University of Science and Technology, Kunming 650093, China;

2. Faculty of Metallurgical and Energy Engineering,

Kunming University of Science and Technology, Kunming 650093, China;

3. Yunnan Copper Co., Ltd., Kunming 650102, China;

4. Yunnan Copper (Group) Co., Ltd., Kunming 650102, China)

Abstract: On the basis of chemical composition, phase, leaching toxicity and thermal stability of arsenic bearing gypsum sludge obtained in lime/ferrous sulfate precipitation process, the reductive decomposition characteristics and arsenic migration rule were investigated by TG-DSC and solid-solid reaction between arsenic bearing gypsum sludge and coal. The results show that mass loss ratio of 50% is obtained when temperature reaches to 1000 ℃. A sludge/coal mass ratio of 40:1 can effectively promote the thermal decomposition and lead to a higher mass loss rate. The CaSO4→CaS→CaO phase transformation occurs during the reductive decomposition process of gypsum sludge/coal. The transformation of CaSO4→CaO/SO2 proceeds completely and a volatilization rate of 45.29% and a volume reduction rate of 65.83% are obtained in the final stage. The evolved gas is consistent with SO2 and CO2 while As2O3 is the main phase of dust. The reacted residue is characterized with dense structure. The arsenic concentration in leaching toxicity test of the reacted residue is 1.05 mg/L which is lower than limit in GB 5085.1—2007. It is found that 63.38% of total arsenic remained in the reacted residue but with a low arsenic leaching rate (1/236 of arsenic leaching rate in gypsum sludge). The reductive decomposition of arsenic bearing gypsum sludge realizes the harmless disposal, sulphur utilization and arsenic enrichment.

Key words: arsenic bearing gypsum sludge; reductive decomposition; TG-DSC; leaching toxicity

Foundation item: Project(2012KJZD01) supported by Science and Technology Development Foundation of Aluminum Limited Corporation of China; Project(TNA-M-007) supported by Climate Technology Needs Assessment of the Chinese Nonferrous Metallurgy Sector

Received date: 2015-11-25; Accepted date: 2016-04-07

Corresponding author: ZHU Xing; Tel: +86-871-65153405; E-mail: zhuxing2010@hotmail.com

(编辑 王 超)

基金项目:中国铝业公司科技发展基金项目(2012KJZD01);中国有色冶金行业应对气候变化技术需求评估项目(TNA- M-007)

收稿日期:2015-11-25;修订日期:2016-04-07

通信作者:祝 星, 副教授,博士;电话:0871-65153405;E-mail: zhuxing2010@hotmail.com