Trans. Nonferrous Met. Soc. China 26(2016) 2609-2616

Properties and microstructure of Ti6Al4V by deformation accelerated low temperature plasma nitriding

Yu-dong FU1,2, Xiao-shuo ZHU1, Zi-feng LI1, Ke LENG1

1. College of Materials Science and Chemical Engineering, Harbin Engineering University, Harbin 150001, China;

2. Key Laboratory of Superlight Materials and Surface Technology of Ministry of Education, Harbin Engineering University, Harbin 150001, China

Received 2 July 2016; accepted 12 September 2016

Abstract: An integrated low-temperature nitriding process was carried out for Ti6Al4V to investigate its effect on microstructure and properties. The process was designed to enhance the nitriding kinetics in low-temperature (500 °C) nitriding by deformation, and to strengthen Ti6Al4V alloy by dispersion at the same time. Specimens of Ti6Al4V alloy were treated through the process of solid solution strengthening-cold deformation-nitriding at 500 °C. The white nitriding layer is formed after some time and then kept stable, changing little with the deformation degree and time. The effect of aging on substrate is significant. Surface hardness and substrate hardness increase with deformation increasing. The construction was investigated by XRD. The surface nitrides are TiN, Ti2N, Ti4N3-X and Ti3N1.29, and the nitrides in cross-section are Ti3N1.29 and TiN0.3. The wear tests of specimens after nitriding, aging and deformation were carried out, and the test data show that the nitrided pieces have the best wear resistance.

Key words: Ti6Al4V; low temperature nitriding; cold deformation; wear resistance

1 Introduction

The titanium and its alloys are widely used today in aerospace, medical health, desalination, energy and other fields because of their excellent comprehensive performance [1]. Ti6Al4V (TC4) alloy is a most widely- used titanium alloy. As an important titanium alloy, however, Ti6Al4V has a fatal weakness of poor wear resistance. A lot of work has been made to overcome this problem, and it has been shown that surface treatment with nitrogen can improve the wear resistance [2-5]. HOSSEINI and AHMADI [6] investigated the effects of plasma nitriding (PN) temperature and time on the structural and tribological characterisation of Ti6Al4V alloy. SCERRI et al [7] studied the corrosion resistance of triode plasma nitrided and oxynitrided Ti6Al4V in acidified aqueous chloride environments with untreated and the PVD TiN-coated alloy as benchmark. MORITA et al [8] developed a combination treatment composed of plasma nitriding, short-time duplex heat treatment, and fine-particle bombarding (FPB). The tensile strength was improved by 30% and fatigue strength was improved by 59% with combination treatment compared to hybrid surface treatment, composed of plasma nitriding and FPB. FAROKHZADEH et al [9] studied the impact of severe plastic deformation (SPD) to surface layer on plasma nitriding of Ti6Al4V alloy. AMANOV et al [10] treated Ti6Al4V and Ti by using an ultrasonic nanocrystalline surface modification (UNSM) technique to improve the fretting wear and friction characteristics. The results showed that the fretting wear and friction coefficient characteristics of the UNSM-treated specimens were improved compared to those of the untreated specimens.

So far, the normal temperature of nitriding TC4 alloy is from 600 to 900 °C [11-13]. High temperature improves the wear resistance, but hinders the T-S. FAROKHZADEH and EDRISY [14] reported that nitrided at 600 °C, Ti6Al4V specimen decreased 43% on ductility and lost 23% on fatigue. Nitriding at lower temperature is good for heat distortion and grain size growth, but decreases the diffusion speed. SHE et al [15] reported the same regular pattern on TA2 Ti.

Nitride compositions of Ti6Al4V plasma nitriding were investigated [16,17]. DA SILVA et al [17] reported that the composition of nitride of near face is influenced by treatment time, proportion of nitrogen, sample temperature and total pressure and got ε-Ti2N and δ-TiN at 500 °C in φ(N):φ(H)=3:2 atmosphere.

There is only a limited work done on low temperature plasma nitriding of Ti6Al4V alloy. RAJASEKARAN et al [18] carried out the PN treatment on Ti6Al4V at 500 °C and reported that plasma nitriding increased the plain and fretting fatigue lives due to improvement in surface hardness, surface residual stress, surface roughness and friction force. MUBARAK ALI et al [19] performed PN on Ti6Al4V at 520 °C. They investigated the influence of PN at low temperature on fretting wear in different environments and time periods.

We purposed a new integrated process of nitriding Ti6Al4V at low temperature. The process is solid solution strengthening-cold deformation-nitriding at low temperature. As existing researches reported, deformation can increase the nitrogen diffusion and improve the nitriding layer formation [20]. The process is designed to have an integrated effect. Nitriding generates a hard coating on the surface of the alloy, and makes precipitation occur in martensite phase to strengthen the inside at the same time. In this work, Ti6Al4V was nitrided at 500 °C and the investigation on properties and microstructure was carried out.

2 Experimental

2.1 Substrate material and surface treatments

The as-received Ti6Al4V used in this investigation is commercial product with chemical composition of Al 6.1%, V 4.0%, Fe 0.18%, C 0.03%, N 0.009%, H <0.0003%, O <0.16% and balance Ti (mass fraction). Samples with 6 mm thick were cut to dimensions of 50 mm × 60 mm. Microstructure was composed of annealing organization of α+β.

In solid solution process, the samples were heated and then quenched by water. After solid solution, the specimens were deformed on an industrial cold rolling mill with two rolls. The rolled specimens were ground through 400, 600, 800 grade sandpaper and washed by ultrasonic washer before being placed inside the nitriding chamber. The plasma nitriding was performed at 500 °C in a pulsed plasma furnace. The environment was φ(N):φ(H)=1:1 and the voltage was 650 V. In order to study the effect of deformation and nitriding time on microstructure, factorial experiments with two facts of deformation degree and nitriding time were carried out. Deformation levels were 0%, 10%, 30% and 50%, and nitriding time levels were 4, 8, 16 and 22 h. An aging experiment was carried out as benchmark. It was a factorial experiment with two facts of deformation degree and heating time. The deformation levels are as same as that in nitriding and heating time is as same as nitriding time in nitriding experiment.

2.2 Characterization

Microstructure was observed under a OLYMPUS- PM3 microscope and a JEOL JSM-6480A SEM. Nital of microscope sample was mixture of HF and HNO3. The volume ratio was HF:HNO3:H2O=1:3:6. The etching time was 4 s.

Knoop microindentation hardness measurements were taken by means of a HVS-1000 hardness testing machine on the surface and cross-section of both the nitrided and aged coupons. The machine was set at a load of 0.5 N and 15 s dwell time. Three measurements were taken on each test sample.

The phase constituents in the nitrided and aged coupons were studied by means of Panalytical X’Pert Pro XRD analyzer. The scan speed was 5 (°)/min and 2θ range was 20°-80°.

Wear test was conducted by a Pin-On-Disk-1-Auto testing machine with the grinding ball material of GCr15. The setting was applied at load of 5 N, wear speed of 200 r/min and wear time of 20 min. The wear tracks were observed by SEM .

3 Results and discussion

3.1 Impact of deformation to specimen surface

After nitriding process at 500 °C, the surface of specimens turns into golden color and as nitriding time increases, the color gets dark golden. This is due to the fact that TiN is a golden color compound. The SEM images of surface after 22 h nitriding are shown in Fig. 1. During nitriding period, particles grow on the surface and when deformation degree increases from 0% to 30%, the size of particles increases averagely, and then becomes sparse again with deformation degree increasing to 50%.

3.2 XRD results

The XRD patterns of surface after 22 h nitriding are shown in Fig. 2. The XRD patterns of surface of 30% deformed specimen after different nitriding time are shown in Fig. 3.

The nitrides on surface with different deformation degree and nitriding time are TiN, Ti2N, Ti4N3-X and Ti3N1.29. The nitride composition keeps stable with deformation degree and time varying. When deformation degree reaches 30%, it exhibits absence of the peak of Ti3N1.29(116), Ti4N3-X(1112), and new peak Ti2N(116) grows up in Fig. 2. This indicates that deformation texture is formed in samples and nitrides are oriented. MUBARAK ALI et al [19] nitrided Ti6Al4V at 520 °C in the environment of pure nitrogen and a mixture of nitrogen and hydrogen in the volume ratio of 3:1, and obtained TiN and Ti2N.

XRD patterns of near surface of cross-section after 22 h nitriding are shown in Fig. 4.

Nitrides such as Ti3N1.29 and TiN0.3 are found in the cross-section as well as a bit of AlTi3. And when the deformation degree is 30%, Ti3N1.29 disappears. This could be attributed to deformation texture.

Fig. 1 Morphologies of specimen surface with different deformation degrees after 22 h nitriding at 500 °C

Fig. 2 XRD patterns of surface after 22 h nitriding

Fig. 3 XRD patterns of surface with 30% deformation degree after nitriding

3.3 Mechanical properties

3.3.1 Microhardness analysis

After nitriding process, the hardness of specimen increases. The surface hardness of nitrided and deformed specimens is shown in Fig. 5. As can be seen, when the deformation is not big enough, hardness of nitrided specimen alters little. However, when deformation continues to increase, hardness of nitrided samples climbs. At 50% deformation, we get the highest microhardness which is HV 850, almost HV 500 higher than that of only deformed specimen. This increase of HV 500 is 80% higher than the increase of HV 280 of non-deformed specimen at 50% deformation.

The microhardness of surfaces on 30% deformed specimen after varying nitriding time is shown in Fig. 6. The hardness climbs when nitriding time increases at first, and reaches the highest point at 8 h. Then, hardness decreases by about HV 50 and keeps stable when time increases. It is attributed to nitride grain size growing up and the bombardment of plasma loosening the substrate. The hardness of 0% deformed specimen is HV 360 after solid solution strengthening (Fig. 5), and after 30% deformation and 4 h nitriding, the hardness reaches HV 630 (Fig. 6), increasing by 73%. RAJASEKARAN et al [18] nitrided Ti6Al4V at 500 °C for 6 h, and the hardness from unnitrided samples to nitrided ones was from HV0.2 330 to HV0.2 390, increasing by 9% [18].

Fig. 4 XRD patterns of cross-section for nitrided specimen

Fig. 5 Microhardness of specimen surfaces after 22 h nitriding and only deformed

3.3.2 Hardness gradient

The cross-section of specimen was divided into six parts from the surface to the center. The hardness of each part was tested and the hardness gradient profiles were made. The gradient as function of deformation degree and nitriding time is shown in Figs. 7 and 8, respectively. The surface hardness of 30% deformed specimen after aging (contrast experiment) is shown in Fig. 9. The deformation degrees in Figs. 8 and 9 are same.

Fig. 6 Microhardness of surfaces of 30% deformed samples after varying nitriding time

As shown in Fig. 7, when the deformation degree increases, the hardness increases at first, and when the deformation degree is more than 30%, it decreases a bit. The hardness of the center increases with the surface hardness. The deformation causes defects in substrate material and accelerates nitrogen diffusion kinetics. Nitrogen moves to inner part and strengthens the material. Nitrogen diffusion speed increases with the deformation degree increase at first, and reaches the peak at 30% deformation degree. When the deformation degree is increased beyond 30%, sever deformation causes dislocation cells, and the dislocation cells hinder the diffusion of nitrogen.

Fig. 7 Hardness gradient of specimen after 22 h nitriding

Fig. 8 Hardness gradient of 30% deformed specimen after nitriding

Fig. 9 Surface hardness of 30% deformed specimen with varying aging time

In Fig. 8, the hardness of the center (Part 1) increases as nitriding time increasing from 16 to 22 h. In Fig. 9, however, when aging time increases from 16 to 22 h, the hardness decreases. So, the hardness increase of 22 h nitrided specimen is not attributed to the aging effect but the nitrogen diffusion to the center of specimen.

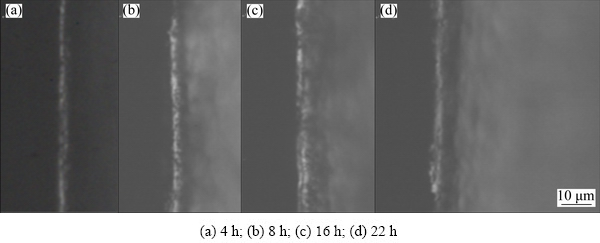

3.4 Microstructural analysis

The micrographs of nitriding layer with varying deformation degree after nitriding for 22 h, and of 30% deformed specimen with varying nitriding time are shown in Figs. 10 and 11, respectively. The thin white layer is the nitriding layer, which exhibits that the thicknesses of the layers are almost same in both conditions. This illustrates that neither deformation degree nor nitriding time affects the layer thickness. The layer is formed in the early period of nitriding and blocks the diffusion of nitrogen. So, nitrogen diffusion rate crossing the layer becomes the same with the nitrogen diffusion rate to specimen center, and the thickness keeps stable.

Fig. 10 Micrographes of nitriding layer after nitriding for 22 h at 500 °C

Fig. 11 Micrographs of nitriding layer of 30% deformed specimen with varying nitriding time

Fig. 12 Metallographs of nitriding layers after 22 h nitriding with varying deformation degree

Metallographs of nitriding layers after 22 h nitriding with varying deformation degree are shown in Fig. 12. The grain size decreases when the deformation degree increases. The β phase becomes small streak and particle when the deformation degree is 50%, different from β phase block at small deformation degree. This indicates that deformation can accelerate the aging speed and refine the microstructure.

3.5 Anti-wear performance

3.5.1 Anti-wear performance of nitrided specimen

The wear rate of 30% deformed specimen after varying nitriding time is shown in Fig. 13. As can be seen, the specimen after 8 h nitriding gets the best wear resistance and its wear rate decreases by 36% compared with that of non-nitrided specimen. This is constant with hardness results above. All nitrided specimens have smaller wear rate than non-nitrided one, which exhibits that nitriding process improves the wear resistance. Friction coefficient analysis result also supports this conclusion. The friction coefficient of 30% deformed specimen after varying time nitriding is shown in Fig. 14. As nitriding time increases, the friction coefficient decreases. But friction coefficient changes little with deformation degree changing. The wear scar morphology analysis indicates that the wear mechanism of non-nitrided specimen is adhesive wear and that of the 8 h nitrided specimen is abrasive wear.

Fig. 13 Wear rate of 30% deformed specimen with varying nitriding time

Fig. 14 Friction coefficient of 30% deformed specimen

3.5.2 Anti-wear effect of nitriding versus aging

Aging process can also decrease wear rate. The wear rate of specimen after 22 h nitriding and aging is shown in Fig. 15. After nitriding at 500 °C, the deformed specimen has less wear rate than undeformed one, but rates with varying deformation degree are close. When the deformation degree is 0%, the wear rate of aged specimen is lower than that of nitrided one. When the specimen is deformed, however, the wear rate of nitrided specimen is lower than that of aged one. The wear scar morphology indicates that the wear mechanism of nitrided specimen is abrasive wear and that of aged one is adhesive wear.

Fig. 15 Wear rate of specimens after 22 h nitriding and aging

4 Conclusions

1) Ti6Al4V alloy was deformed and then nitrided at 500 °C. The surface nitrides are TiN, Ti2N, Ti4N3-X and Ti3N1.29, and the nitrides in cross-section are Ti3N1.29 and TiN0.3.

2) The substrates are aged and strengthened at 500 °C and the aging rate has positive correlation with deformation.

3) The surface microhardness has positive correlation with deformation degree. The hardness of the inner part has positive correlation with deformation degree when the deformation degree is less than 50%. As surface and substrate have been strengthened at same time in the process, the improvement of fatigue becomes promising.

4) After nitriding at 500 °C, the deformed specimen has better wear resistance than non-deformed and only aged one.

References

[1] ZHAO Yong-qing, CHEN Yong-nan, ZHANG Xue-min, ZENG Wei-dong, WANG Lei. Phase transformation and heat treatment of titanium alloys [M]. Changsha: Central South University Press, 2012. (in Chinese)

[2] BONELLO T, AVELAR-BATISTA WILSON J C, HOUSDEN J, GUTMANAS E Y, GOTMAN I, MATTHEWS A, LEYLAND A, CASSAR G. Evaluating the effects of PIRAC nitrogen-diffusion treatments on the mechanical performance of Ti-6Al-4V alloy [J]. Materials Science and Engineering A, 2014, 619: 300-311.

[3] CHEN Guo-qing, JIAO Yan, TIAN Tang-yong, ZHANG Xin-hua, LI Zhi-qiang, ZHOU Wen-long. Effect of wet shot peening on Ti-6Al-4V alloy treated by ceramic beads [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 690-696.

[4] LIU Xuan-yong, CHU P K, Ding Chuan-xian. Surface modification of titanium, titanium alloys, and related materials for biomedical applications [J]. Materials Science and Engineering R, 2004, 47(3): 49-131.

[5] WILSON J C AVELAR-BATISTA, BANFIELD S, HOUSDEN J, OLIVERO C, CHAPON P. On the response of Ti-6Al-4V and Ti-6Al-7Nb alloys to a Nitron-100 treatment [J]. Surface & Coatings Technology, 2014, 260: 335-346.

[6] HOSSEINI S R, AHMADI A. Evaluation of the effects of plasma nitriding temperature and time on the characterisation of Ti6Al4V alloy [J]. Vacuum, 2013, 87: 30-39.

[7] SCERRI A, BUHAGIAR J, BANFIELD S, WILSON J C AVELAR-BATISTA, HOUSDEN J, LEYLAND A, MATTHEWS A, CASSAR G. Corrosion behaviour of triode plasma diffusion treated and PVD TiN-coated Ti-6Al-4V in acidified aqueous chloride environments [J]. Surface & Coatings Technology, 2015, 280: 185-193.

[8] MORITA T, ASAKURA K, KAGAYA C J. Effect of combination treatment on wear resistance and strength of Ti-6Al-4V alloy [J]. Materials Science and Engineering A, 2014, 618: 438-446.

[9] FAROKHZADEH K, QIAN J, EDRISY A. Effect of SPD surface layer on plasma nitriding of Ti-6Al-4V alloy [J]. Materials Science and Engineering A, 2014, 589: 199-208.

[10] AMANOV A, CHO I S, KIM D E, PYUM Y S. Fretting wear and friction reduction of CP titanium and Ti-6Al-4V alloy by ultrasonic nanocrystalline surface modification [J]. Surface & Coatings Technology, 2012, 207: 135-142.

[11] KIM T S, PARK Y G, WEY M Y. Characterization of Ti-6Al-4V alloy modified by plasma carburizing process [J]. Materials Science and Engineering A, 2003, 361: 255-282.

[12] YANG Jun-sheng. Improving Ti-6Al-4V alloy’s friction and wear properties by complex processing technology [D]. Xi’an: Chang’an University, 2010. (in Chinese)

[13]  T, FLESZAR A. Properties of surface layers on titanium alloy produced by thermo-chemical treatments under glow discharge conditions [J]. Surface & Coatings Technology, 1997, 96(2): 205-209.

T, FLESZAR A. Properties of surface layers on titanium alloy produced by thermo-chemical treatments under glow discharge conditions [J]. Surface & Coatings Technology, 1997, 96(2): 205-209.

[14] FAROKHZADEH K, EDRISY A. Fatigue improvement in low temperature plasma nitrided Ti-6Al-4V alloy [J]. Materials Science and Engineering A, 2014, 620: 435-444.

[15] SHE Ding-shun, YUE Wen, FU Zhi-qiang, LIU Jian-jun. Effects of nitriding temperature on microstructures and vacuum tribological properties of plasma-nitrided titanium [J]. Surface & Coatings Technology, 2015, 264: 32-40.

[16] MORGIEL J,  T. New estimate of phase sequence in diffusive layer formed on plasma nitrided Ti-6Al-4V alloy [J]. Surface & Coatings Technology, 2014, 259: 473-482.

T. New estimate of phase sequence in diffusive layer formed on plasma nitrided Ti-6Al-4V alloy [J]. Surface & Coatings Technology, 2014, 259: 473-482.

[17] DA SILVA S L R, KERBER L O, AMARAL L, SANTOS C A D. X-ray diffraction measurements of plasma-nitrided Ti-6Al-4V [J]. Surface & Coatings Technology, 1999, 116: 342-346.

[18] RAJASEKARAN B, RAMAN S G S. Plain fatigue and fretting fatigue behaviour of plasma nitrided Ti-6Al-4V [J]. Materials Letters, 2008, 62: 2473-2475.

[19] MUBARAK ALI M, RAMAN S GANESH SUNDARA, PATHAK S D, GNANAMOOTHY R. Influence of plasma nitriding on fretting wear behaviour of Ti-6Al-4V [J]. Tribology International, 2010, 43: 152-160.

[20] DA SILVA S L R, KERBER L O, AMARAL L, SANTOS C A D. X-ray diffraction measurements of plasma-nitrided Ti-6Al-4V [J]. Surface & Coatings Technology, 1999, 116: 342-346.

冷变形促渗低温等离子渗氮对Ti6Al4V合金力学性能和显微组织的影响

傅宇东1,2,朱小硕1,李子峰1,冷 科1

1. 哈尔滨工程大学 材料科学与化学工程学院,哈尔滨 150001;

2. 哈尔滨工程大学 超轻材料与表面技术教育部重点实验室,哈尔滨 150001

摘 要:针对Ti6Al4V合金低温渗氮的问题,设计了一种渗氮工艺,研究了该工艺对Ti6Al4V合金组织和力学性能的影响。通过变形增强渗氮动力,使渗氮可以在较低温度(500 °C)下实现,氮化与Ti6Al4V合金基体的弥散强化同时进行。实验过程为固溶强化→室温下冷轧变形→500 °C低温渗氮。结果表明,在渗氮一段时间后,试样表面形成了白亮的氮化层并且趋于稳定,变形量和变形时间对氮化层的影响不明显。试样基体组织时效效果明显,表面硬度与基体组织硬度随变形量增加而增加。经XRD物相分析,试样表面生成的氮化物为TiN、Ti2N、Ti4N3-X和Ti3N1.29,横截面氮化物为Ti3N1.29和TiN0.3。对经过变形、渗氮和时效等工艺的试样进行摩擦磨损实验,渗氮试样的耐磨性最好。

关键词:Ti6Al4V;低温渗氮;冷变形;耐磨性

(Edited by Sai-qian YUAN)

Foundation item: Projects (51275105, 51375106) supported by the National Natural Science Foundation of China

Corresponding author: Yu-dong FU; Tel: +86-15204692272; E-mail: fuyudong@hrbeu.edu.cn

DOI: 10.1016/S1003-6326(16)64387-X