文章编号:1004-0609(2011)11-2964-07

过渡层红土镍矿中的镁质矿中和沉矾浸出

王多冬1, 2, 赵中伟1, 陈爱良1, 霍广生1, 陈星宇1

(1. 中南大学 冶金科学与工程学院,长沙 410083;2. 金川集团有限公司,金昌 737100)

摘 要:采用沉矾浸出法将铁质矿浸出液对镁质矿进行沉矾浸出。结果表明:镁质矿酸浸过程中,在镁质矿粒度为106 ~150 μm、搅拌强度为150 r/min、终点pHe值为1.3、温度为 95 ℃的条件下,浸出镁质矿3 h,镍、镁、铁的浸出率分别为93.34%、78.28%、26.4%;在沉矾浸出过程中,在反应温度为95 ℃、搅拌强度为150 r/min、硫酸钠中的钠与形成黄钠铁矾中的钠的摩尔比x为1.3、镁质矿粒度为106 ~150 μm、反应终点pHe为1.3±0.2的条件下,沉矾浸出5 h,镍浸出率能达到92%,镁浸出率在74%以上,铁质矿浸出液除铁率达到87%以上,铁质矿浸出液中铁的浓度在15.87~42.16 g/L的范围内,对镁质矿的镍、镁浸出及铁质矿浸出液中Fe的浓度没有显著的不利影响,溶液中铁基本上控制在4 g/L以下。

关键词:过渡层;红土镍矿;镁质矿;镍的浸出率;黄钠铁矾沉淀

中图分类号: TF111.3 文献标志码:A

Leaching nickel and removing Fe from

garnierite of transition layer nickel laterite ores

WANG Duo-dong1, 2, ZHAO Zhong-wei1, CHEN Ai-liang1, HUO Guang-sheng1, CHEN Xing-yu1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Jinchuan Group Ltd. Co., Jinchang 737100, China)

Abstract: Garnierite was leached with pregnant solution of leaching limonitic by Na-jarosite precipitation. The results show that, during the process of leaching garnierite with acid, the leaching rates of Ni, Mg and Fe are 93.34%, 78.28% and 26.4% under the conditions of garnierite ore size between 106 μm and 150 μm, end pH of leaching 1.3, leaching time 3 h, temperature 95 ℃ and stirring rate 150 r/min. During the process of leaching garnierite with pregnant solution of leaching limonitic, the leaching recoveries of Ni and Mg are 92% and above 74%, respectively, when the molar ratio of Na of sodium sulfate added to that of Na-jarosite precipitation is 1.3. Fe removal efficiency is more than 87%. When Fe concentration is 15.87-42.16 g/L, there is little effect on leaching recoveries of Ni and Mg. Moreover, Fe concentration is almost less than 4 g/L.

Key words: transition layer; nickel laterite ores; garnierite, nickel leaching rate; Na-jarosite precipitation

世界镍产量中70%来自硫化镍矿,随着可经济利用的硫化镍矿的日益枯竭,占镍资源70% 的氧化镍矿的经济开发已成为当今镍冶金讨论的热点[1]。

红土镍矿从上到下分为铁帽、褐铁矿层、过渡层、腐植土层、基岩层,金属镍主要存在于褐铁矿层、过渡层、腐植土层中[2-4]。含镍红土矿很难选矿,无法通过选矿方法进行富集,基本上是针对某一种特定矿石的成分,采用不同的工艺直接冶炼处理原矿。一般的冶炼方法有火法与湿法两种工艺。

火法包括镍铁合金工艺和镍锍生产工艺[5-7]。镍生产大多采用工艺简单、易于控制的电炉熔炼生产含镍 20 %~30 %的镍铁合金, 镍的回收率达90%~95%,但钴不能回收。镍锍生产工艺是在镍铁合金工艺的基础上, 在电炉熔炼过程中,以黄铁矿(FeS2)、石膏(CaSO4·2H2O) 、硫磺和含硫的镍原料为硫化剂还原硫化熔炼,产出低镍锍,然后再通过转炉吹炼生产含镍79 %、硫 19.5 % 的高镍锍,全流程镍回收率约70 %。但电炉熔炼能耗高,污染严重,这对节能减排是十分不利的。

湿法处理红土镍矿主要的工艺是浸出,目前主要有微生物浸出[8-9]、氨浸法[10]、高压酸浸法[11-15]、常压酸浸法[16]等。

一般来说,含硅镁低褐铁型红土矿常用氨浸或加压硫酸浸出工艺处理,而硅镁高、铁低的腐植土层常用火法还原熔炼工艺生产镍铁,也可以在工艺过程中加入黄铁矿或硫生产镍锍。

刘学等[8]利用黑曲菌产生的有机酸,在矿浆浓度为 2.5 %、温度为33 ℃、转速为120 r/min 时,对红土镍矿进行了浸出试验,镍、钴、铁浸出率分别为 73.5%、53.2%、47. 2%。目前,有机酸的循环利用尚未解决,微生物浸出也存在微生物培养成本高等问题。氨浸法全流程镍、钴回收率分别为 75%~80%、40%~50%,氨浸法只适合处理红土镍矿床上层的红土矿,不适合处理下层硅镁含量高的矿层,这就极大地限制了氨浸法的发展。

加压酸浸在 250~270 ℃、 4~5 MPa 的高温高压条件下,控制一定的pH 值等条件,使铁、铝和硅等杂质元素水解进入渣中, 镍、钴选择性进入溶液。镍 的浸出率达90%以上,而且能耗低,工艺逐渐成熟和完善,是近年来红土矿处理技术的发展方向,但是投资高,而且也只适合含镁很低(<3%)的褐铁矿层。高压、高温的操作条件也限制了其应用。而对于含镁、含铁均较高(>10%),而含镍较低(<2.0% )的那部分过渡层红土镍矿,现有的火法工艺与湿法工艺都不能经济地处理,需要开发新的、经济的处理工艺。

本文作者针对过渡层红土镍矿的特性,根据矿物粒度的不同,可分为铁质矿(铁高镁低)与镁质矿(镁高铁低)两部分,其中,铁质矿在常压、高温、高酸度下硫酸强化浸出后,浸出液余酸>40 g/L、Fe3+ 浓度>25 g/L、温度95 ℃。镁质矿含氧化镁20%~40%,含铁6%~12%。结合铁质矿浸出液酸浓度较高、镁质矿氧化镁较高的特点,以及Fe3+形成沉淀的条件,本文作者研究了硫酸直接浸出的镁质矿行为(以镁质矿作为铁质矿浸出液及黄钠铁矾除铁的中和剂),及利用铁质矿浸出液的余酸与铁沉淀成黄钠铁矾过程中释放出来的硫酸浸出镁质矿中镍和镁,开发一种低成本的常压硫酸浸出过渡层红土镍矿中镁质矿的新工艺。

1 实验

1.1 实验原料

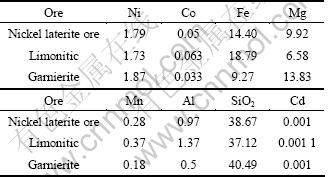

本实验所用原料为进口过渡层红土镍矿,经过洗矿分离成铁质矿、镁质矿两种,其典型成份如表1所列。实验用铁质矿浸出液由铁质矿加硫酸浸出所得,其浸出液的成分如表2所列,所用化学试剂为工业级浓硫酸、无水硫酸钠、10%石灰乳。

表1 红土镍矿成分

Table 1 Composition of nickel laterite ores(mass fraction, %)

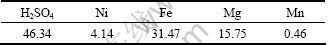

表2 铁质矿浸出液的成分

Table 2 Composition of pregnant solution of leaching limonitic (g/L)

1.2 实验方法

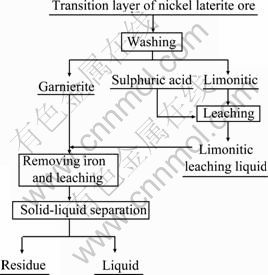

图1所示为过渡层红土镍矿浸出流程图。本研究分两部分:

1) 镁质矿常压硫酸浸出:将镁质矿磨成一定的粒度,用水配成浓度为30% 的矿浆,按一定比例加入98%的浓硫酸,在一定温度下,搅拌浸出一定时间后,过滤、洗涤。

2) 沉矾浸出:在镁质矿浸出条件的基础上,量取一定量的铁质矿浸出液,按照加入硫酸钠中的钠与形成黄钠铁矾中的钠的摩尔比(ΨNa)加入无水硫酸钠,然后按一定比例加入镁质矿矿浆,搅拌浸出一定时间后,过滤。

均采用络合滴定与原子吸收法将滤液及滤渣中镍、镁、铁进行分析。

其浸出率η及除铁效率ζ按下式计算:

η=

ζ=

式中:m0为镁质矿中含金属量,g;m为渣中含金属量,g;w0为铁质矿浸出液中铁浓度,%;w为沉矾浸出后溶液中铁浓度,%。

图1 过渡层红土镍矿浸出流程

Fig.1 Flowsheet of leaching transition layer nickel laterite ores

2 结果与讨论

2.1 镁质矿常压硫酸浸出

2.1.1 浸出终点pH值对镁质矿浸出的影响

在浸出温度95 ℃、搅拌强度150 r/min、镁质矿粒度范围75~106 μm,加入一定量的98%浓硫酸,浸出3 h的条件下,考察浸出终点pH值(pHe)对镁质矿浸出效果的影响,结果如图2所示。

图2 pHe对镁质矿浸出率的影响

Fig.2 Effect of pHe on leaching rate of garnierite

由图2可知:随着pHe的降低,矿浆中酸增加,H+ 浓度增加,金属氧化物和酸发生式(1)~(3)的反应机会增多,镍、铁、镁等物质的浸出率增加。pHe从3.55降低至1.9,镍的浸出率由17.2% 增加至48.25%,铁的浸出率由3.48% 增加至14.84%,镁的浸出率由19.43% 增加至37.11%。pHe降到1.9后,镍、铁、镁的浸出率随pHe 的降低迅速增加,pHe降到1.44时,镍、铁、镁的浸出率分别升高到95.04%、59.68%、78.85%。但是,pHe自1.44继续降低时,镍、铁、镁等浸出率的增加明显减缓,当pHe降低至0.39时,镍、铁、镁的浸出率分别增加到98.94%、84.21%、99.49%。

MgO+H2SO4=H2O+MgSO4 (1)

Fe2O3+3H2SO4=3H2O+Fe2(SO4)3 (2)

NiO+H2SO4=H2O+MgSO4 (3)

2.1.2 浸出时间对浸出的影响

在浸出温度为95 ℃,搅拌强度为150 r/min,镁质矿粒度范围为75~106 μm,pHe为1.3的条件下,研究浸出时间对浸出率的影响,结果如图3所示。

图3 浸出时间对镁质矿浸出率的影响

Fig.3 Effect of leaching time on leaching rate of garnierite

由图3可知,镁质矿在开始阶段浸出非常快,在反应初始的0.5 h内,镍的浸出率达到84.49%,随着反应时间的延长,浸出率逐步升高,1.5 h后,镍的浸出率就达到91.01%,浸出时间大于1.5 h后,浸出时间延长对镍、镁的浸出率均没有太大影响。镁的浸出与镍的相似,只是镁的浸出率低于镍。在0.5 h内,镁的浸出率达70.76%,1.5 h后升到74.76%。而铁的浸出率明显低于镍与镁, 0.5 h内只有30.67%,在1 h后达到最大值(47.38%)。然后,随着时间的延长,铁的浸出率开始下降,由1 h的47.38%下降至3 h的26.4%,可能是由于铁与溶液中的水合氢离子H3O+ 形成稳定的草黄铁矾沉淀。

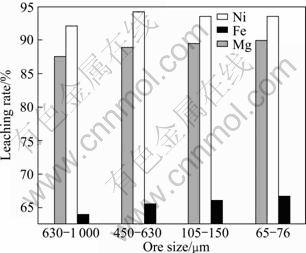

2.1.3 镁质矿粒度对浸出率的影响

在浸出温度为95 ℃、浸出时间为1.5 h、搅拌强度为150 r/min及pHe=1.3的条件下,镁质矿粒度对浸出率的影响如图4所示。

图4 镁质矿粒度对浸出率的影响

Fig.4 Effect of garnierite ore size on leaching rate

从图4可知,颗粒越细越有利于镍浸出。当粒度为630~1 000 μm时,镍、铁、镁的浸出率分别为92.03%、63.96%、87.58%;当粒度为450~630 μm时,镍浸出率达到最高,为94.14%;当粒度小于150 μm时,粒度对镍浸出率的影响不显著,镍、铁、镁的浸出率分别保持在93%、66%、89%左右。这是由于粒度小于150 μm后,溶液中的H+ 能通过颗粒与金属氧化物充分反应,故继续减少粒度不会对其浸出率带来影响。其粒度选105~150 μm为最佳。

2.1.4 温度对浸出率的影响

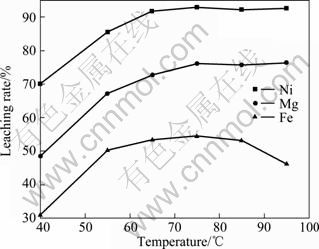

在粒度为106~150 μm、浸出时间为3 h、搅拌强度为150 r/min及pHe=1.3的条件下,温度对浸出的影响如图5所示。

图5 温度对镁质矿浸出率的影响

Fig.5 Effect of temperature on leaching rate of garnierite

由图5可知,温度越高,镍、镁的浸出率越高,越有利于浸出。温度较低时,镍、铁、镁的浸出率随着温度的升高显著升高,镍的浸出率由40 ℃时的70.05%升高到65 ℃时的91.72%,镁的浸出率由40 ℃时的48.54%升高到65 ℃时的72.74%,铁的浸出率40 ℃时的30.94% 升高到65 ℃时的53.38%。在65 ℃以上,温度对镍、镁浸出率的影响已经不明显。铁的浸出行为在温度较低阶段与镍、镁的浸出行为一致,但是,当温度达到85 ℃以上时,铁的浸出率开始下降,由53.16%降低到95 ℃时的46.15%,其原因是高温阶段,由于浸出率高,溶液的pH值升高,被浸出的三价铁离子具备了生成铁矾的条件,与溶液中的H3O+、SO42- 结合生成稳定的草黄铁矾沉淀。

2.2 沉矾浸出实验研究

根据镁质矿酸浸结果,在粒度为106~150 μm,浸出时间>1.5 h,温度>65 ℃,pHe<1.3的条件下,能够得到比较高的镍浸出率。铁的浸出率与镍和镁的不同,在温度较高、反应时间较长时,被浸出的铁会形成草黄铁矾沉淀,导致铁的浸出率降低。结合黄钠铁矾法除铁的性质[17-18],以镁质矿作为铁质矿浸出液的中和剂进行沉矾浸出,使铁沉淀的同时将镁质矿中的镍和镁浸出。

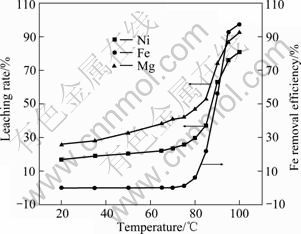

2.2.1 反应温度的影响

在搅拌强度150 r/min、反应时间 4 h、加入1.3倍理论量钠离子与10%黄钠铁矾晶种的条件下,往铁质矿浸出液中加入106~150 μm 的镁质矿粉末调整终点pHe值至1.3,反应温度对沉矾浸出的影响如图6所示。

由图6可知,温度对铁的沉淀与镁质矿的浸出均有显著的影响,在温度低于75 ℃的条件下,铁质矿浸出液中的铁几乎不沉淀。此后,随着温度的升高,铁质矿浸出液中的铁会发生式(4)反应,生成黄钠铁矾NaFe3(SO4)2(OH)6沉淀,铁的沉淀率迅速上升,到95 ℃时达到92.7%。镁质矿的浸出行为与铁的沉淀紧密相关,在较低的温度下,主要是铁质矿浸出液中的余酸与镁质矿发生的浸出反应,镍与镁的浸出率随着温度的升高缓慢升高,当温度升高到75 ℃以上后,随着铁的沉淀,释放出的硫酸参与镁质矿的浸出,镍与镁的浸出率随着铁的沉淀相应升高,95 ℃时的浸出率分别达到86.8%与76.08%。

3Fe2SO4+Na2SO4+12H2O→

2NaFe3(SO4)2(OH)6+6H2SO4 (4)

图6 反应温度对沉矾浸出的影响

Fig.6 Effect of reaction temperature on Na-jarosite precipitation and leaching rate of Ni and Mg

2.2.2 pHe的影响

在95 ℃、反应时间4 h、搅拌强度150 r/min、加入10%黄钠铁矾晶种、1.3倍钠离子的条件下,以106~150 μm的镁质矿粉作为中和剂调节铁质矿浸出液反应终点pH值(pHe),考察终点pHe值对沉矾浸出的影响,其结果如图7所示。

图7 pHe值对镁质矿浸出率与铁质矿浸出液沉铁率的影响

Fig.7 Effect of pHe on Na-jarosite precipitation and leaching rate of garnierite

从图7可以看出,铁的沉淀率随着终点pH值(pHe)的升高而升高,在pHe=1.26时,铁沉淀为83.11%的;pHe=1.45时,铁沉淀率为91.85%,此后,铁沉淀率随pHe值的变化趋于平缓。镁质矿的浸出率与铁沉淀率正好相反,在低pHe值(1.26)时,有镍、镁有较高的浸出率(分别为91.32%、87.65%);随着pHe值的升高,浸出率迅速下降,当pHe值升到1.45时,镍和镁浸出率分别降低到88.03%与79.16%,此后降幅明显加快,当pHe值升到2.0时,镍和镁的浸出率分别降低到50.08%和36.88%。

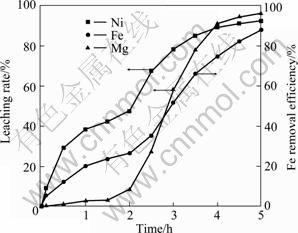

2.2.3 反应时间的影响

在温度95 ℃、搅拌强度150 r/min、1.3倍理论量钠离子的条件下,往铁质矿浸出液中加入106~150 μm 的镁质矿粉末调整终点pHe值至1.3,研究反应时间对铁质矿浸出液中铁的沉淀率与镁质矿浸出率的影响,其结果如图8所示。

图8 浸出时间对沉矾浸出的影响

Fig.8 Effect of leaching time on Na-jarosite precipitation and leaching rate of Ni and Mg

由图8可知,铁质矿浸出液中铁的沉淀率随着时间的延长而升高,在反应的初始阶段,铁的沉淀较慢,1.5~2 h后,铁迅速开始沉淀,在4 h时,沉淀率达到91.1%。镁质矿中镍与镁的浸出率随着时间的延长而升高,在反应的初始阶段,主要是铁质矿浸出液中的余酸参与浸出反应,在1 h内镍的浸出率达到38.36%,镁的浸出率达到20.08%。反应进行到2 h以后,由于铁开始沉淀,铁沉淀释放出来的酸参与反应,镍与镁的浸出率开始随着铁的沉淀率上升,到5 h后,随着铁沉淀率达到96.19%,镍与镁的浸出率也分别达到92.28%与87.83%。

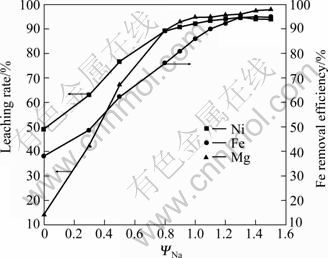

2.2.4 硫酸钠加入量的影响

在反应温度95 ℃、搅拌转速150 r/min、反应时间5 h、加入理论量10%的黄钠铁矾晶种,用106~150 μm的镁质矿粉调节铁质矿浸出液终点pHe值至1.28±0.2,硫酸钠加入量对沉矾浸出的影响如图9所示。

由图9可知,铁的沉淀率随着ΨNa增大而升高。当加入量达到理论用量的0.9倍时,铁的沉淀率达到92.86%;当达到1.2倍以上时,铁的沉淀率不再随钠加入量的变化而变化。当钠加入量较少时,部分铁不是以黄钠铁矾的形式沉淀,可能为部分铁与H3O+ 结合形成草黄铁矾沉淀。镁质矿的浸出伴随着铁的沉淀而变化。

图9 ΨNa对沉矾浸出的影响

Fig.9 Effect of ΨNa on Na-jarosite precipitation and leaching rate of Ni and Mg

2.3 验证实验

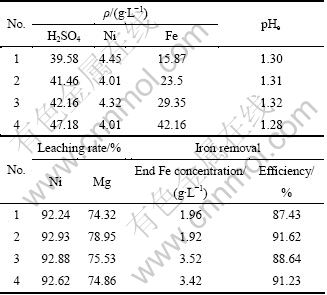

条件实验研究表明,反应时间>4 h、 温度>95 ℃、钠离子>理论量1.2倍、pH值1.26~1.45是较好的沉矾浸出条件。在反应温度96 ℃、反应时间5 h、搅拌强度150 r/min、加入10%黄钠铁矾晶种、ΨNa=1.3倍理论量的条件下,将粒度为106~150 μm的镁质矿加入至铁质矿浸出液中,调节反应终点pHe值至1.3±0.2,进行沉矾浸出的验证实验,其结果如表3所列。

表3 沉矾浸出验证试验结果

Table 3 Verification of experimental results of neutral leaching garnierite and Na-jarosite precipitating

表3结果表明,验证试验结果与单因素实验结果基本吻合,镍浸出率能达到92%以上,镁浸出率为74%~79%;铁质矿浸出液的铁浓度在15.87~42.16 g/L的范围内,对沉矾浸出没有显著的不利影响,沉矾浸出后,铁质矿浸出液除铁率达到87%以上,溶液中铁基本上控制在4 g/L以下。

3 结论

1) 在镁质矿粒度为106~150 μm、浸出时间为1.5 h,搅拌强度为150 r/min、终点pH值为1.3、温度为 95 ℃的条件下,浸出镁质矿3 h,镍、镁、铁的浸出率分别为93.34%、78.28%、26.4%。

2) 沉矾浸出实验研究表明,反应时间>4 h、温度>95 ℃、钠离子>理论量1.2倍、pH值1.26~1.45是较好的沉矾浸出条件,既可使铁质矿浸出液中的铁有较高的沉淀率,又可以使镁质矿中的镍有相对较高的浸出率,实现节约硫酸的消耗、降低成本的目的。

3) 沉矾浸出验证试验表明,在反应温度95 ℃、反应时间5 h、搅拌强度150 r/min、加入10%黄钠铁矾晶种、钠离子用量为理论量的1.3倍条件下,用粒度106~150 μm的镁质矿调节铁质矿浸出液终点值pHe 1.28~1.44,铁质矿浸出液中铁的沉淀率达到87.43%~91.62%,镁质矿镍的浸出率达到87.24%~92.62%,而且铁质矿浸出液的铁浓度在15.87~42.16 g/L的范围内,对沉矾浸出没有显著的不利影响。

REFERENCES

[1] 蒋继波, 王吉坤. 红土镍矿湿法冶金工艺研究进展[J]. 湿法冶金, 2009, 28(1): 3-11.

JIANG Ji-bo, WANG Ji-kun. Review on progresses for hydrometallurgy of laterite-nickel ore[J]. Hydrometallurgy, 2009, 28(1): 3-11.

[2] SUDOL S. The thunder from everything you wanted to know about nickel laterites but were afraid to ask[J]. Can Min, 2005, 126(5): 8-12.

[3] 李小明, 唐 琳, 刘仕良. 红土镍矿处理工艺探讨[J]. 铁合金, 2007(4): 24-28.

LI Xiao-ming, TANG Lin, LIU Shi-liang. Technology of treating nickel bearing laterite[J]. Ferro Alloys, 2007(4): 24-28.

[4] LOVEDAY B K. The use of oxygen in high pressure acid leaching of nickel laterites[J]. Minerals Engineering, 2008, 21(7): 533-538.

[5] 张友平, 周渝生, 李肇毅. 红土矿资源特点和火法冶金工艺分析[J]. 铁合金, 2007(6): 18- 21, 40.

ZHANG You-ping, ZHOU Yu-sheng, LI Zhao-yi. Characteristic of nickel laterites source and pyrometallurgy technology[J]. Ferro Alloys, 2007(6): 18-21, 40.

[6] 李建华, 程 威, 肖志海. 红土镍矿处理工艺综述[J]. 湿法冶金, 2004(4): 191-194.

LI Jian-hua, CHENG wei, XIAO Zhi-hai. Technology summarize of treating nickel laterites[J]. Hydrometallurgy, 2004(4): 191-194.

[7] ROORDA H J, HERMANS J M A. Energy constrains in the extraction of nickel from oxides ores[J]. Energy Metals, 1981, 34(3): 882-887.

[8] 刘 学, 温建康, 阮仁满. 真菌衍生有机酸浸出低品位氧化镍矿[J]. 稀有金属, 2006, 13(4): 490-493.

LIU Xue, WEN Jian-kang, RUAN Ren-man. Leaching of nickel and cobalt from low-grade lateritic nickel ores using organic acids produced by fungus aspergillus niger[J]. Chinese Journal of Rate Metals, 2006, 13(4): 490-493.

[9] SIMATE G S, NDLOVU S. Bacterial leaching of nickel laterites using chemolithotrophic microorganisms: Identifying influential factors using statistical design of experiments[J]. Int J Miner Process, 2008, 88(1): 31-36.

[10] 尹 飞, 阮书锋, 江陪海, 王成彦, 陈永强. 低品位红土镍矿还原焙砂氨浸试验研究[J]. 矿冶, 2007, 16(3): 39-32.

YIN Fei, RUAN Shu-feng, JIANG Pei-hai, WANG Cheng-yan, CHEN Yong-qiang. Experimental study on roasted ore of poor nickeliferous laterite ore with ammonia leaching technology[J]. Mining & Metallurgy, 2007, 16(3): 39-32, 4.

[11] WHITTINGTON B I, JOHNSON J A, QUAN L P. Pressure acid leaching of arid-region nickel laterite ore. Part Ⅱ: Effect of ore type[J]. Hydrometallurgy, 2003, 70(13): 47-62.

[12] JOHNSON J A, CASHMORE B C, HOCKRIDGE R J. Optimization of nickel extraction from laterite ores by high pressure acid leaching with addition of sodium sulphate[J]. Minerals Engineering, 2005, 18(13/14): 1297-1303.

[13] WHITTINGTON B I, JOHNSON J A. Pressure acid leaching of arid-region nickel laterite ore. Part Ⅲ: Effect of process water on nickel losses in the residue[J]. Hydrometallurgy, 2005, 78(3/4): 256-263.

[14] WHITTINGTON B I, MUIR D. Pressure acid leaching of nickel laterites: A review[J]. Mineral Processing and Extractive Metallurgy, 2000(21): 527-600.

[15] RUBISOV D H, KROWINKEL J M , PAPANGELAKIS V G. Sulphuric acid pressure leaching of laterites-universal kinetics of nickel dissolution for limonites and limonitic saprolitic blends[J]. Hydrometallurgy, 2000, 58(1): 1-11.

[16] KUMAR R, DAS S, RAY R K, BISWAS A K. Leaching of pure and cobalt bearing goethites in sulphurous acid: Kinetics and mechanisms [J]. Hydrometallurgy, 1993, 32(1/2): 39-59.

[17] 陈 松, 安 然, 李继洲, 刘志宏, 张多默. 镍精矿氯气浸出液净化除铁工艺[J]. 中南工业大学学报: 自然科学版, 2000, 31(5): 419-421.

CHANG Song, AN Ran, LI Ji-zhou, LIU Zhi-hong, ZHANG Dou-mo. The process for removal of iron from chlorine leaching solution of nickel concentrate[J]. Cent South Univ Technol: Natural Science, 2000, 31(5): 419-421.

[18] 郭学益,张多默,赵统来,刘志宏,葛荣德,陈慧光。氯化物中黄钠铁矾除铁的热力学和动力学[J]. 中南工业大学学报: 自然科学版, 1997, 28(1): 30-33.

GUO Xue-yi, ZHANG Duo-mo, CHO Tong-lai, LIU Zhi-hong, GE Rong-de, CHEN Hui-guang. The thermodynamics and kinetics of sodium jarosite formation in chloride solution[J]. J Cent South Univ Technol: Natural Science, 1997, 28(1): 30-33.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2007CB613603)

收稿日期:2010-08-25;修订日期:2010-11-22

通信作者:赵中伟,教授,博士;电话:0731-88830476;E-mail: zhaozw@csu.edu.cn