文章编号:1004-0609(2008)08-1446-07

激光快速成形Rene88DT高温合金的热等静压处理

赵晓明,林 鑫,陈 静,黄卫东

(西北工业大学 凝固技术国家重点实验室,西安 710072)

摘 要:采用金相分析、扫描电镜分析、拉伸实验等方法研究热等静压(HIP)处理对激光快速成形Rene88DT粉末盘用高温合金裂纹和力学性能的影响。结果表明:成形件经1 160 ℃、2 h、200 MPa热等静压的高压、高温固溶处理后,热影响区裂纹得到明显的愈合修复,在原裂纹附近析出MC型碳化物;将HIP处理后的成形件进一步固溶时效热处理后,拉伸强度和塑性均明显提高,综合力学性能接近粉末冶金Rene88DT的标准。

关键词:Rene88DT高温合金;激光快速成形;热等静压;裂纹愈合;拉伸性能

中图分类号:TG 146.4 文献标识码 A

HIP treatment of superalloy Rene88DT prepared by laser rapid forming

ZHAO Xiao-ming, LIN Xin, CHEN Jing, HUANG Wei-dong

(State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The effects of hot isostatic pressing (HIP) on the cracks and tensile properties of laser rapid forming (LRF) superalloy Rene88DT were investigated by metallography, scanning election microscopy and tensile test. Due to the heat affected zone crack in the LRF Rene88DT superalloy, the mechanical properties are severely degraded. HIP treatment (1 160 ℃, 2 h, 200 MPa) is used to try to eliminate such defects. The results show that after HIP treatment, the cracks in the heat affected zone are obviously healed, while MC carbides precipitate along the healed crack area. Through further solution/aging treatment after LRF+HIP, the tensile properties of the Rene88DT samples can be improved considerably, and nearly reach that of the P/M Rene88DT standard.

Key words: superalloy Rene88DT; laser rapid forming; hot isostatic pressing(HIP); crack healing; tensile properties

涡轮盘是发动机重要的热端部件之一。超塑性等温锻造粉末冶金是这类高性能涡轮盘的主要制备技术。美国、俄罗斯、英国、法国等国家都已经在现役军用和民用飞机发动机中采用超塑性等温锻造的粉末高温合金涡轮盘,但限于技术和设备的成熟度,我国目前对这项技术仍处于研究阶段[1?2]。此外,近十年来迅速发展起来的激光快速成形技术能够实现高性能致密金属零件的快速无模近终形制造[3?6]。如果将激光快速成形技术应用于航空发动机高温难变形涡轮盘用高温合金的成形,将为高推比发动机中涡轮盘等关键零件的研制在成形方法上提供一种新的技术途径。

事实上,最早关于激光快速成形的研究就是针对高温合金涡轮盘的制备,1979年美国联合技术研究中心的SNOW等[7]通过调整镍基高温合金的成分,提高了合金在多层熔覆过程中的抗裂性,完成涡轮盘模拟件的无模制造,并提出合金的抗裂性将决定该合金能否进行激光成形。由于高温合金激光快速成形时存在较高的残余应力,以及高温合金本身的高合金化特征,成形过程中和后续的热处理过程都容易出现裂纹。而对于Al+Ti含量接近6%[8?10]的沉淀强化粉末盘用高温合金,激光成形零件时尤其容易开裂,裂纹的存在,严重影响合金激光快速成形后的力学性能[11?14]。而HIP技术已用于航空发动机中常用的铸造叶片和叶片长期使用后的缩孔和疏松等缺陷的消除,并且得到国内外广泛使用,可以使合金的力学性能及使用的可靠性得到明显的提升[15?17]。因此,本文作者采用HIP对激光快速成形粉末盘用Rene88DT高温合金裂纹线缺陷的消除进行尝试,考察经HIP高压、高温固溶处理后,激光快速成形Rene88DT裂纹的消除情况,以及HIP处理对激光快速成形件组织和性能的影响规律。

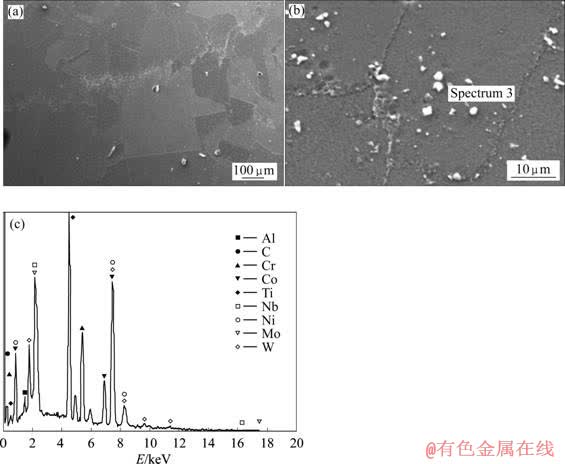

1 实验

成形试样是在西北工业大学凝固技术国家重点实验室建立的激光快速成形系统上制备的,这套系统包括RS850型CO2激光器、LPM?408型四坐标数控工作台、DPSF?1型送粉器和侧向送粉喷嘴。实验中基材选用1Cr18Ni9Ti不锈钢,尺寸为120 mm×50 mm×6 mm。成形用等离子旋转电极制备Rene88DT高温合金粉末粒度为15~45 μm,其名义化学成分见表1。实验前对粉末合金进行150 ℃真空烘干处理,以除去粉末中所吸附的水分,同时用砂纸将基材表面打磨后再用丙酮将沉积面清洗干净。激光成形工艺参数为:激光功率1.5~2.0 kW,光束扫描速度5~10 mm/s,光斑直径1~3 mm,送粉量8~12 g/min,保护气体流量4~8 L/min,搭接率10%~50%。

表1 Rene88DT粉末的名义化学成分

Table1 Chemical compositions of Rene88DT powder alloy (mass fraction, %)

将激光快速成形的试样进行1 160 ℃、2 h、200 MPa的热等静压工艺(为粉末冶金制备Rene88DT高温合金零件中常用工艺)HIP处理,然后采用1 160 ℃、2 h,空冷+760 ℃、28 h,空冷的热处理工艺进行固溶时效处理。拉伸实验在INSTRON11?96电子拉力实验机上完成。采用JSM?6460扫描电镜对裂纹进行EDS分析,采用HITACHI S?570对HIP处理前后的断口形貌进行了对比观察。利用Leica公司DM LM定量金相显微镜进行金相观察和分析。

2 结果与讨论

2.1 HIP处理对激光快速成形Rene88DT显微组织的影响

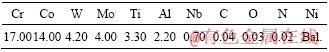

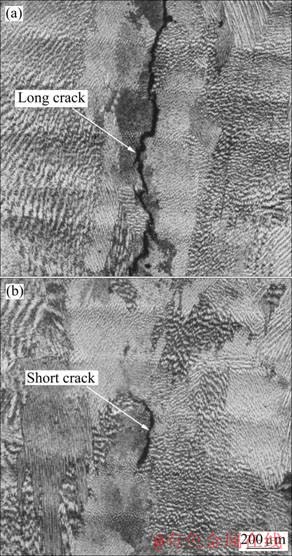

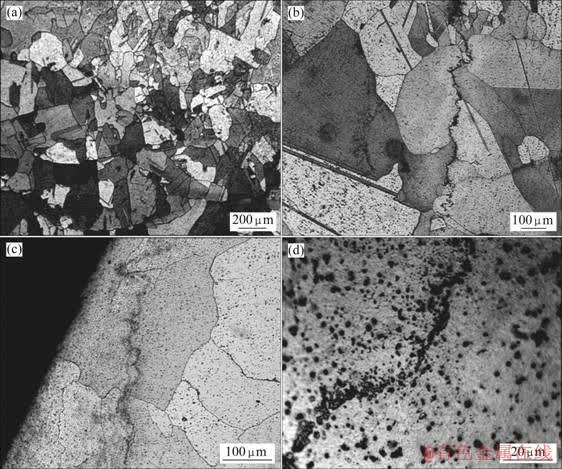

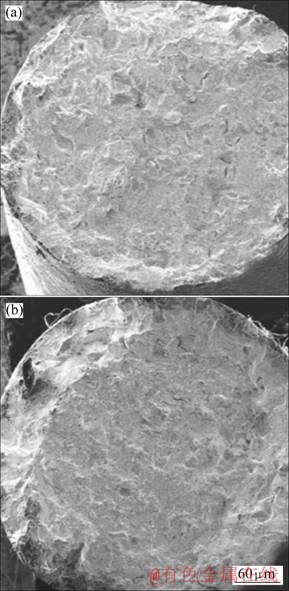

对于Al+Ti含量接近6%的沉淀强化粉末盘用Rene88DT高温合金,激光成形时非常容易开裂(见图1(a)), 尽管通过工艺参数的优化与控制,成形过程中不会产生大尺寸裂纹,但100~300 ?m小尺寸裂纹(见图1(b))的防止与消除仍是亟待解决的难题[13],它严重影响合金激光快速成形后的力学性能,尤其是对塑性影响很大。为了考察HIP处理对Rene88DT激光成形试样中裂纹的愈合修复作用,将带有图1中两种典型裂纹的Rene88DT激光成形试样进行HIP处理。经HIP处理后,激光快速成形Rene88DT高温合金试样在光学显微镜下原位观察并没有发现100~300 ?m的小尺寸裂纹(图2(a)), 这说明小尺寸裂纹得到有效消除。图2(b)和(c)所示分别为试样中部和底部的原位大尺寸裂纹愈合的情况,可以看到,成形制备过程中产生的3~10 mm的大尺寸裂纹也得以愈合。不过,裂纹愈合处存在大量析出物。图3(a)和图3(b)所示分别为裂纹愈合线及愈合线局部的SEM像。EDS分析结果显示,大尺寸裂纹愈合后留下的析出物中C、Ti、Nb元素含量较高(见图3(c)),为MC型碳化物。也就是说,图3(a)显示的实际上是裂纹愈合后析出的碳化物迹线。可以看到,碳化物基本沿原裂纹附近分布。由前期对Rene88DT激光快速成形试样开裂机理的分析[13]可知,Rene88DT激光快速成形试样中的裂纹主要是激光快速熔凝条件下晶界处生成的γ/γ′低熔共晶发生液化形成晶间液膜,在随沉积过程进行而逐渐增大的残余拉伸应力的作用下被拉开,形成的液化裂纹。HIP处理温度为1 160 ℃,在γ′溶解温度附近。HIP处理相当于一次高压下的高温固溶或均匀化处理,采用的200 MPa高压首先将裂纹自由面基本压合后、再经高温固溶扩散,使得原裂纹愈合,这一过程类似于扩散焊。实际上,Rene88DT合金虽然是一种高合金化的高温合金,但合金总的溶质浓度低于γ/γ?共晶成分,高温长时间保温裂纹曲面压合处g/g′低熔共晶膜处于热力学不稳定状态,在高温下发生γ?+γ→MC+γ转变,形成了高温下热力学更稳定状态的次生MC,从而在裂纹愈合处留下了MC型碳化物。同时,试样经HIP处理后,再结晶现象明显(图2(a)),这一方面由于HIP高温长时间固溶后使得激光成形后残余应力的消除,另一方面由于HIP温度选在1 160 ℃,即γ′完全固溶温度(1 130 ℃)以上, 失去了小尺寸γ′相对晶界的迁移的阻碍作用,有利于再结晶。

图1 激光快速成形后Rene88DT的裂纹

Fig.1 Crack of laser rapid forming Rene88DT before HIP treated: (a) Long crack; (b) Short crack

图2 HIP处理后的激光快速成形Rene88DT的显微组织

Fig.2 Microstructures of laser rapid forming Rene88DT after HIP treated: (a) Recrystallized microstructure; (b) Long crack healed in central section of sample; (c) Long crack healed in edge section of sample; (d) Magnification of precipates trace along healed crack area

图3 大尺寸裂纹愈合后的析出物迹线SEM像及EDS分析结果

Fig.3 SEM image of precipates trace along healed crack area (a) and EDS results (b), (c)

2.2 HIP处理对激光快速成形Rene88DT拉伸性能的影响

表2所列出为HIP处理前、后激光快速成形Rene88DT拉伸性能测试结果。需要说明的是,HIP处理前、后的试样都分别进行一次固溶时效(1 165 ℃固溶2 h空冷+760 ℃时效28 h空冷)热处理,该工艺为目前对激光快速成形Rene88DT较优化的热处理工艺[14]。可以看出,经过HIP处理后,激光成形Rene88DT高温合金的室温拉伸强度和塑性都有明显的提升。抗拉强度较直接热处理态提高了50~200 MPa,而伸长率提高了近1倍,断面收缩率提高3%。综合力学性能已接近粉末冶金(P/M)Rene88DT标准。可见激光快速成形Rene88DT零件的裂纹对成形件的力学性能具有较大的影响,HIP处理对裂纹进行修复愈合后导致强度和塑性产生明显的回复和提升。另外,经HIP处理后发生的再结晶也是塑性提升的重要因素。由表2还可以看到,直接热处理态试样的抗拉强度有100 MPa的波动,塑性有2%~3%的波动。而经HIP处理后抗拉强度的波动程度缩小到40 MPa,同时,塑性也减小到只有0.5%~1.0%的波动。这主要是因为HIP处理本身是一个材料致密化和均匀化的过程,减小了不同成形试样之间的差异。这样,经HIP处理后,激光成形件力学性能的稳定性和可靠性也得到提高。不过,从表2还可见,经HIP处理后成形件的强度与粉末冶金试样的标准还有少量差距。这一方面可能是由于现有的热处理工艺还不是适合于激光快速成形Rene88DT合金的最优热处理工艺;另一方面,由上文对HIP处理后的成形件组织分析可知,原裂纹愈合后留下一条碳化物迹线,导致原裂纹附近组织与基体组织在裂纹修复愈合后不能保持一致。因此,需要进一步适当的热处理工艺调整使之扩散均匀,从而与基体组织一致达到等强的效果。

表2 HIP处理前后激光快速成形Rene88DT高温合金的室温拉伸性能

Table 2 Tensile properties of laser rapid forming Rene88DT at room temperature before and after HIP treated

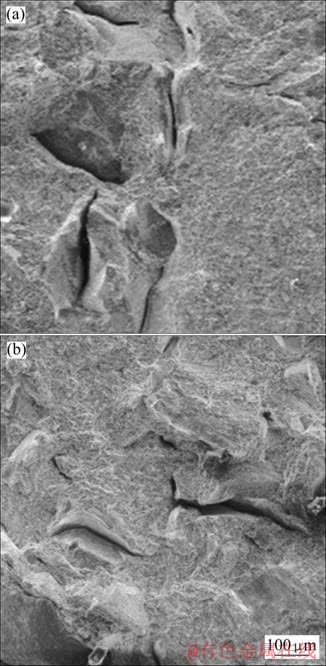

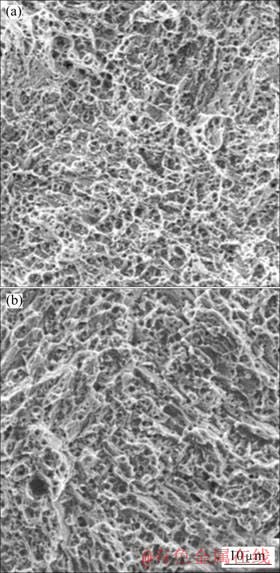

2.3 HIP对激光快速成形Rene88DT断口特征的影响

图4所示为未经HIP处理和HIP处理后激光快速成形Rene88DT拉伸试样的断口形貌。HIP处理前后断裂均起源于试样边缘,由图4(a)可见,HIP处理前的棒状拉伸试样断口没有出现明显的颈缩现象,断口比较平整。在断口表面上沿某一方向发现多处沿晶二次裂纹,如图5(a)所示,这也是造成成形件伸长率较低的原因。试样断口边缘剪切唇区较小,并且可以观察到大量短而弯曲的撕裂棱,这些撕裂棱主要是由单独微裂纹相互连接而形成的。而经HIP处理后(见图4(b)),试样端口附近发生了颈缩现象,剪切唇区约占断口面积的1/3。断口上可见的二次裂纹的明显减少,图5(b)所示为拉伸时出现的沿晶二次裂纹。说明经HIP处理后成形试样件中的大部分裂纹得到修复愈合。激光快速成形Rene88DT的平均密度为8.24 g/cm3,HIP处理后试样的平均密度为8.30 g/cm3,经HIP处理后,完全密实、致密度可由合金的理论密度(8.30 g/cm3)的99.3%提高到100%。提高近0.7%。试样更加均匀致密,这些因素的综合作用使拉伸试样的塑性得以提高。另一方面由上面的裂纹经HIP愈合后原位组织分析可知,即使裂纹修复愈合后,裂纹原位处析出的晶界 碳化物也是薄弱环节,经拉伸后也会出现开裂现象,这可能是断口上出现二次裂纹的原因。图6所示为高倍下断面中部区的韧窝形貌,HIP前后均为等轴韧窝形貌,为拉伸应力作用下,g′沉淀相从基体中脱落所致。

图4 HIP处理前后激光快速成形Rene88DT的断口形貌

Fig.4 Fracture surfaces of LRF Rene88DT before (a) and after (b) HIP treated

图5 HIP处理前后激光快速成形Rene88DT的二次裂纹 高倍放大像

Fig.5 High magnification of second crack in fracture surface of LRF Rene88DT before (a) and after (b) HIP treated

图6 HIP处理前后激光快速成形Rene88DT的高倍韧窝 形貌

Fig.6 High magnification of dimples in fracture surface of LRF Rene88DT before (a) and after (b) HIP treated

3 结论

1) 激光快速成形Rene88DT高温合金经HIP处理后大尺寸裂纹得以愈合,小尺寸裂纹得到有效的消除。裂纹愈合处存在MC型碳化物迹线。试样经HIP处理后发生了明显的再结晶现象。

2) 经HIP处理后,激光快速成形Rene88DT合金内裂纹修复愈合和再结晶使得成形件强度和塑性产生了较为明显的回复和提升。综合力学性能已接近粉末冶金(P/M)Rene88DT标准。同时,经HIP处理后,激光成形件力学性能的稳定性和可靠性也得到了提高。

3) 经HIP处理后,试样端口附近发生颈缩现象,断口上剪切唇区增大。可见的二次裂纹明显减少,使得拉伸试样的塑性得以提高。

REFERENCES

[1] 曹凤兰, 卿 华, 古远兴, 吴长波, 周 全. FGH96粉末高温合金亚尺寸轮盘研制及试验验证[J]. 燃气涡轮试验与研究, 2007, 20(3): 15?17.

CAO Feng-lan, QING Hua, GU Yuan-xing, WU Chang-bo, ZHOU Quan. Research and experiment on FGH96 P/M superalloy sub-scale disk[J]. Gas Turbine Experiment and Research, 2007, 20(3): 15?17.

[2] 王淑云, 李惠曲, 杨洪涛. 粉末高温合金超塑性等温锻造技术研究[J]. 航空材料学报, 2007, 27(5): 30?33.

WANG Shu-yun, LI Hui-qu, YANG Hong-tao. Superplastic isothermal forging technology of P/M superalloy[J]. Journal of Aeronautical Materials, 2007, 27(5): 30?33

[3] KEICHER D M, SMUGERESKY J E, ROMERO J A, GRIFFITH M L, HARWELL L D. Using the laser engineered net shaping (LENS) process to produce complex components from a CAD Solid model[J]. Proc of SPIE, 1997, 2293: 91?97.

[4] 冯莉萍, 黄卫东, 林 鑫, 杨海欧. FGH95合金激光成形定向凝固显微组织与性能[J]. 中国有色金属学报, 2003, 13(1): 182?187.

FENG Li-ping, HUANG Wei-dong, Lin Xin, YANG Hai-ou. FGH95 superalloy laser metal forming directional solidification [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 182?187.

[5] ZHONG Min-lin, YANG Lin, LIU Wen-jin. Laser rapid manufacturing of special pattern Inco 718 nickel based alloy component[J]. Proc of SPIE, 2005, 5629: 59?66.

[6] HUANG Wei-dong, YANG Hai-ou, CHEN Jing, LIN Xin. Laser rapid forming of titanium component[J]. Rare Metal Materials and Engineering, 2006(Suppl.): 54?57.

[7] SNOW D B, BREINAN E M, KEAR B H. Rapid solidification processing of superalloy using high power lasers[C]// Superalloys, Proceedings Fourth International Symposium. Baton Rouge, LA: Alaitors Publishing Div, 1980: 189?203.

[8] OJO O A, RICHARDS N L, CHATURVEDI M C. Liquid film migration of constitutionally liquated γ? in weld heat affected zone (HAZ) of Inconel 738LC superalloy[J]. Scripta Materialia, 2004, 51: 141?146.

[9] OJO O A, CHATURVEDI M C. On the role of liquated γ? precipitates in weld heat affected zone microfissuring of a nickel-based superalloy[J]. Materials Science and Engineering A, 2005, 403: 77–86.

[10] ZHONG Min-lin, SUN Hong-qing, LIU Wen-jin, ZHU Xiao-feng, HE Jin-jiang. Boundary liquation and interface cracking characterization in laser deposition of inconel 738 on directionally Solidified Ni-based Superalloy[J]. Scripta Materialla, 2005, 53: 159?164.

[11] 杨海欧, 陈 静, 李延民, 冯莉萍, 林 鑫, 黄卫东. Rene95高温合金激光快速成形试样的力学性能[J]. 稀有金属材料与工程, 2003, 32(4): 276?279.

YANG Hai-ou, CHEN Jing, LI Yan-min, FENG Li-ping, LIN Xin, HUANG Wei-dong. The mechanics properties of the Rene95 samples produced by the laser rapid forming process[J]. Rare Metal Materials and Engineering, 2003, 32(4): 276?279.

[12] ZHANG Y Z, SHI L K. Research on laser direct metal deposition[J]. Proc of SPIE, 2003, 4831: 487?492.

[13] 赵晓明, 陈 静, 何 飞, 谭 华, 黄卫东. 激光快速成形Rene88DT高温合金开裂机理研究[J]. 稀有金属材料与工程, 2007, 36(2): 216?220.

ZHAO Xiao-ming, CHEN Jing, HE Fei, TAN Hua, HUANG Wei-dong, The cracking mechanism of Rene88DT superalloy by laser rapid forming[J]. Rare Metal Materials and Engineering, 2007, 36(2): 216?220.

[14] 赵晓明, 陈 静, 何 飞, 林 鑫, 黄卫东. 激光快速成形Rene?88DT高温合金的时效强化研究[J]. 稀有金属材料与工程, 2007, 36(12): 2208?2211.

ZHAO Xiao-ming, CHEN Jing, HE Fei, LIN Xin, HUANG Wei-dong. Study on the age-harding mechanism of Rene88DT superalloy by laser rapid forming[J]. Rare Metal Materials and Engineering, 2007, 36(12): 2208?2211.

[15] BAILEY P G, SCHWEIKERT W H. HIP densification of castings[C]// Superalloys 1976. Warrendale(PA): TMS, 1976: 451?462.

[16] STEVENS R A, FLEWITT P E J. Hot isostatic pressing to remove porosity & creep damage[J]. Materials & Design, 1982, 3(3): 461?469.

[17] 呼 和. 镍基高温合金的热等静压处理[J]. 金属学报, 2002, 38(11): 1199?1202.

HU He. Hot isostatic pressing treatment of cast Ni-base superalloy[J]. Acta Metall Sin, 2002, 38 (11): 1199?1202.

基金项目:国家自然科学基金重点资助项目(50331010);新世纪优秀人才支持计划资助项目

收稿日期:2007-07-13;修订日期:2008-07-01

通讯作者:赵晓明,博士研究生;电话:029-88492884;E-mail: zxm@mail.nwpu.edu.cn

(编辑 陈爱华)