文章编号:1004-0609(2010)05-0807-06

Mg-7Gd-4Y-1Nd-0.5Zr合金热轧过程中的组织与织构演变

唐昌平,张新明,邓运来,李 理,吴懿萍,刘 杰,贺 婷

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用金相显微镜、扫描电镜和X射线衍射仪,对Mg-7Gd-4Y-1Nd-0.5Zr合金铸锭在450 ℃条件下轧制变形过程中的微观组织和织构演变规律进行研究。结果表明:该合金在轧制过程中存在着两种织构组分:基面织构和棱柱面织构。随变形程度的增加,基面织构不断增强,棱柱面织构不断减弱。在450 ℃条件下轧制时,棱柱面滑移系启动协调晶粒的塑性变形形成棱柱面织构,形成的棱柱面织构组分在后续变形过程中通过 <

< >孪生及退火过程中孪生区域的静态再结晶而不断被削弱。

>孪生及退火过程中孪生区域的静态再结晶而不断被削弱。

关键词:滑移系;孪生;织构;再结晶

中图分类号:TG146.2; TG335.11 文献标志码:A

Microstructures and texture evolution of

Mg-7Gd-4Y-1Nd-0.5Zr alloy during hot rolling

TANG Chang-ping, ZHANG Xin-ming, DENG Yun-lai, LI Li, WU Yi-ping, LIU Jie, HE Ting

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The microstructure and texture evolution of Mg-7Gd-4Y-1Nd-0.5Zr alloy during hot rolling at 450 ℃ were investigated by means of OM, SEM and XRD. The results show that there exist two components of textures: basal texture and prismatic texture. The basal texture becomes stronger and stronger and the prismatic texture becomes weaker and weaker with increasing the strain. The prismatic texture is formed by the initiation of the prismatic slip system in the grains with particular orientations, the prismatic texture is weakened by  <

< > twinning and static recrystallization twinning-induced during annealing.

> twinning and static recrystallization twinning-induced during annealing.

Key words: slip system; twinning; texture; recrystallization

镁合金在室温下能够启动的滑移系少,晶粒间塑性变形协调能力差,但当变形温度升高后,镁合金中非基面滑移系被激活,从而使其塑性大幅度提高[1-2]。因此,镁合金的塑性变形通常都在高温下进行。通过轧制方式制备的镁合金板材,一般都具有很强的基面织构或倾向于集中在基面织构附近[3-5],通常不利于板材的二次成形。镁合金板材的织构形成取决于变形过程中基面滑移系的启动。在轧制压力作用下,基面逐渐平行于轧制板面,滑移方向平行于轧制方向,随轧制变形量的增大,基面织构不断增强[6]。

孪生是镁合金的另一种重要的塑性变形机制,能够协调晶粒间的变形,释放应力集中。JIANG等[7]的研究表明:试验合金的初始织构和加载方式对镁合金的孪生类型和加工硬化行为有重要的影响,当特定的加载方式作用于特定的初始织构使其沿平行于c轴方向产生拉伸应变时,易于发生 <

< >拉伸孪生;反之,若使其沿平行于c轴方向产生压缩应变时, 易于发生

>拉伸孪生;反之,若使其沿平行于c轴方向产生压缩应变时, 易于发生 <

< >压缩孪生。孪晶带内的晶体取向一般与未孪生部分的差别较大,且随孪生类型的不同而不同。

>压缩孪生。孪晶带内的晶体取向一般与未孪生部分的差别较大,且随孪生类型的不同而不同。

JIN等[8]对AZ31镁合金锭轧制过程中的微观组织及织构演变规律进行了研究,其结果表明,在轧制变形初期,铸锭中大量晶粒发生的 <

< >拉伸孪生对AZ31板材的塑性变形起到了重要的协调作用,而孪生诱发的动态再结晶是板材最终形成基面织构的关键。GOTTSTEIN等[9-10]也在相应的研究中观察到了孪生诱发的动态再结晶。

>拉伸孪生对AZ31板材的塑性变形起到了重要的协调作用,而孪生诱发的动态再结晶是板材最终形成基面织构的关键。GOTTSTEIN等[9-10]也在相应的研究中观察到了孪生诱发的动态再结晶。

Mg-Gd-Y系合金具有优异的高温力学性能,在航空航天领域有着广阔的应用前景[11-13]。本文作者研究Mg-7Gd-4Y-1Nd-0.5Zr合金在450 ℃条件下轧制及 退火过程中的织构演变规律,并就棱柱面织构的形成机理及其在后续轧制及退火过程中的演变规律进行 探讨。

1 实验

试验合金所用原料如下:纯度(质量分数)为99.96%的Mg,而Gd、Y、Nd、Zr分别以Mg-Gd、Mg-Y、Mg-Nd、Mg-Zr中间合金的形式加入。将上述原料在由电阻炉加热的铁坩埚中熔炼,采用熔剂保护。熔体经熔炼、精炼并静置后,浇铸成尺寸为105 mm×55 mm×45 mm的方锭,合金的实际化学成分如表1所示。方锭均匀化处理后出炉水冷,然后用电火花线切割机将均匀化处理后的合金锭切成100 mm×50 mm×10 mm的方块,然后将其轧制成2 mm厚的薄板。轧制实验在轧辊直径为145 mm的二辊轧机上进行,轧制温度为450 ℃,道次变形量为8%,道次间保温时间为10 min。考虑到镁合金散热较快,出炉后的轧制过程中与轧辊接触温降大,在轧制前先将轧辊预热至200 ℃左右,取样时为避免温降的影响,选取轧制板材中部心层样品进行分析。

表1 试验合金的实际成分

Table 1 Chemical composition of experimental alloy (mass fraction, %)

金相组织的观察在XJP-6A型立式光学显微镜上进行,用于金相组织观察的试样采用体积分数为4%的硝酸酒精溶液进行腐蚀,腐蚀时间为20~30 s。织构测试在Brucker D8 Discovery上进行,织构分析采用Labtex 3.0软件,计算取向分布函数(ODF)时,晶体坐标系的选择以< >、<

>、< >和<0001>方向分别为X、Y和Z轴。

>和<0001>方向分别为X、Y和Z轴。

2 结果与分析

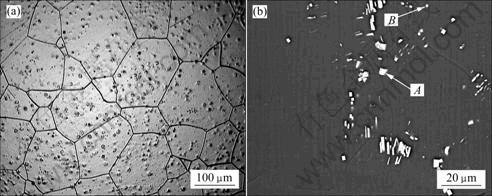

2.1 轧制前的显微组织

锭坯轧制前的显微组织如图1所示。从图1(a)可以看出:合金铸锭经均匀化处理后,晶粒较为粗大,呈近似等轴状,晶界平直清晰,晶界处的非平衡共晶组织已经基本溶入基体,但在晶界及晶内残留有黑色第二相粒子。图1(a)中的黑色第二相粒子在扫描电镜下的形貌呈方块状或球形(见图1(b)),能谱分析表明,方块状粒子为富稀土(Y、Gd、Nd)相(见表2),球形粒子为富Zr相(见表3)。富Zr相在合金凝固时形成,能作为形核核心以细化铸态合金晶粒[14]。

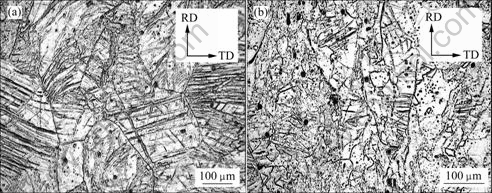

2.2 轧制态显微组织

图2(a)所示为实验合金在450 ℃条件下轧制变形至40%时板面的金相组织。从图2(a)可以看出,合金锭坯经前期的变形及道次间退火后,晶粒得到了一定程度的细化,晶粒尺寸由原来的200 μm左右细化到了大约100 μm,大多数晶粒沿轧制方向有一定程度的拉长,而在一些晶粒内,出现了大量的孪晶组织,这是因为这些晶粒塑性变形时处在不利于滑移的取向,只能通过孪生来协调变形。

图2(b)所示为合金锭坯变形至80%时的金相显微组织。从图2(b)可以看到,合金的晶粒尺寸进一步细化,在局部区域有少量细小的再结晶晶粒,如图2(b)中箭头所指,说明合金在轧制或道次间退火过程中发生了再结晶。同样,在该合金中也能观察到大量的孪晶组织,出现了再结晶晶粒与孪晶共存的状态。

2.3 轧制过程中的织构演变规律

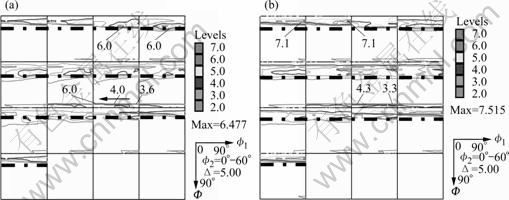

在450 ℃条件下变形40%及80%时样品的取向分布函数(ODF)图分别如图3(a)和(b)所示。从图3可以看出,合金经变形后出现了强的基面织构(图3中点划线以上部分),但是,进一步分析450 ℃变形40%样品的ODF图(见图3(a))表明,在φ2=30?、φ=80?~90?、φ1=0?~90?处存在较强的织构组分,亦即在变形40%的样品内除存在镁合金中常见的基面织构外,还出现了较强的棱柱面织构组分,即使变形量达80%时(见图3(b)),棱柱面织构也仍然存在,只是其取向密度较变形40%时的低一些。

图1 合金锭经均匀化处理后的显微组织

Fig.1 Microstructures of homogenized alloy ingot: (a) OM image; (b) SEM image

图2 实验合金在450 ℃条件下轧制至40%及80%时的金相组织

Fig.2 OM images of alloy plates hot rolled by strain of 40% (a) and 80% (b) at 450 ℃

表2 图1(b)中点A的EDS结果

Table 2 EDS result of point A shown in Fig.1(b)

表3 图1(b)中点B的EDS结果

Table 3 EDS result of point B shown in Fig.1(b)

根据文献[15],随着变形温度的升高,镁单晶棱柱面滑移系与基面滑移系的临界剪切应力(CRSS)均减小,但棱柱面滑移系的临界剪切应力减小得更快,在300 ℃以上时,两者基本趋于一致。因此,可以认为,Mg-7Gd-4Y-1Nd-0.5Zr合金在450 ℃条件下变形时,基面滑移系和棱柱面滑移系的临界剪切应力已基本趋于一致,在上述温度条件下进行轧制时,晶粒内基面滑移系和棱柱面滑移系均容易启动。当对无初始织构的铸锭进行变形时,总存在一部分特定取向的晶粒,其棱柱面滑移系的施密特因子大于基面滑移系的施密特因子。这些晶粒在轧制压力的作用下变形以棱柱面滑移为主,其结果是使棱柱面逐渐转向平行于板面,于是便出现了图3(a)所示的棱柱面织构组分。

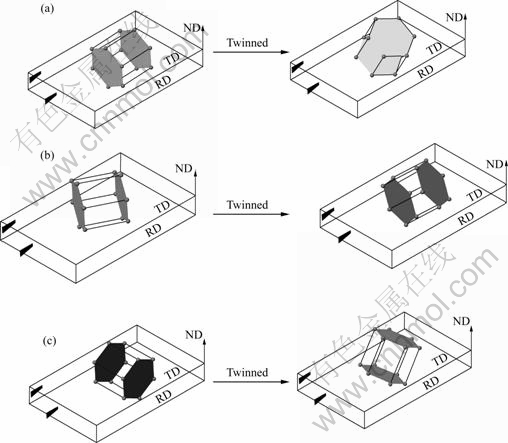

变形过程中出现上述棱柱面织构组分(见图3(a))后,对这些取向的晶粒而言,棱柱面滑移系和基面滑移系均不易启动,而更容易通过锥面滑移或 <

< >孪生[7]来协调变形。变形80%的显微组织中存在大量孪生组织,说明在后续的变形过程中,在轧制压力的作用下,大量具有上述取向的晶粒发生了

>孪生[7]来协调变形。变形80%的显微组织中存在大量孪生组织,说明在后续的变形过程中,在轧制压力的作用下,大量具有上述取向的晶粒发生了 <

< >拉伸孪生,拉伸孪生出现后,孪晶带内的晶体取向较未切变区的晶体取向转动大约86.3?。因此,孪晶带内的取向便转变为基面基本平行于轧制板面的取向,如图4所示。由于位错容易在孪晶界塞积,变形储能较高,在之后的道次间退火过程中,孪晶处易于发生再结晶形核,产生具有基面平行于轧制板面取向的再结晶晶粒。出现基面取向的再结晶晶粒后,其织构取向的改变对轧制压力将不再敏感,将基本维持基面取向[8],因此,随着再结晶体积分数的增长,基面织构不断增强,棱柱面织构逐渐减弱。

>拉伸孪生,拉伸孪生出现后,孪晶带内的晶体取向较未切变区的晶体取向转动大约86.3?。因此,孪晶带内的取向便转变为基面基本平行于轧制板面的取向,如图4所示。由于位错容易在孪晶界塞积,变形储能较高,在之后的道次间退火过程中,孪晶处易于发生再结晶形核,产生具有基面平行于轧制板面取向的再结晶晶粒。出现基面取向的再结晶晶粒后,其织构取向的改变对轧制压力将不再敏感,将基本维持基面取向[8],因此,随着再结晶体积分数的增长,基面织构不断增强,棱柱面织构逐渐减弱。

图3 实验合金在450 ℃条件下轧制至不同变形量时的ODF图

Fig.3 ODF images of alloy plates hot rolled by strains of 40% (a) and 80% (b) at 450 ℃

图4 轧制过程中不同取向晶粒发生拉伸孪生后孪晶带晶体取向变化示意图

Fig.4 Schematic diagrams of orientation transition in twining bands: (a) Axis c parallel to rolling direction; (b) 0-90? angle between axis c and rolling direction; (c) Axis c perpendicular to rolling direction

2.4 退火过程中的组织与织构演变

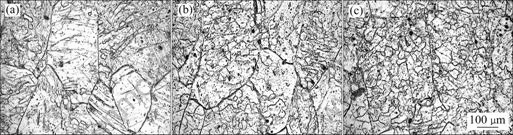

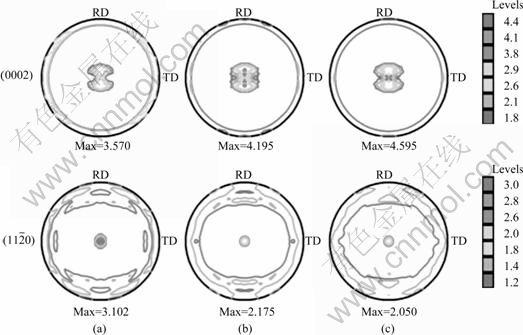

为了验证上述对基面织构形成机理的分析,对450 ℃条件下变形40%的样品在温度为450 ℃的盐浴中进行退火实验,退火时间分别选取为1、3和5 min,退火后的金相显微组织如图5所示。从图5可以看到:退火时间为1 min时(见图5(a)),还基本保留了变形组织的形貌,说明至少还未发生明显的再结晶。随着退火时间的延长,在孪晶区域出现了再结晶形核(见图5(b)),随后再结晶晶粒逐渐增多并吞噬孪晶及孪晶周围的基体(见图5(c))。不同退火时间后对应的(0002)极图和 极图如图6所示,从图6可以看出,随着退火时间的延长,(0002)极图的最大极密度不断增强,

极图如图6所示,从图6可以看出,随着退火时间的延长,(0002)极图的最大极密度不断增强, 极图的最大极密度不断减弱,说明轧制变形过程中产生的棱柱面织构组分在退火过程中不断转变为基面织构。每一道次变形及退火时均重复上述过程,导致基面织构随着变形量的增加而不断增强,棱柱面织构不断在变形过程中形成,在道次间的退火过程中减弱。

极图的最大极密度不断减弱,说明轧制变形过程中产生的棱柱面织构组分在退火过程中不断转变为基面织构。每一道次变形及退火时均重复上述过程,导致基面织构随着变形量的增加而不断增强,棱柱面织构不断在变形过程中形成,在道次间的退火过程中减弱。

另外,仔细分析可以发现,沿图3(a)中箭头所指方向,取向密度逐渐增强,这是因为当φ2=30?、φ=90?而φ1从90?向0?变化的过程中,所描述的晶体取向是由 平行于轧制板面、c轴平行于轧向向

平行于轧制板面、c轴平行于轧向向 平行于轧制板面、c轴垂直于轧向变化。轧制变形的应力状态可近似为平面应力状态,沿轧制方向受拉应力较强,因此,在轧制压力的作用下,

平行于轧制板面、c轴垂直于轧向变化。轧制变形的应力状态可近似为平面应力状态,沿轧制方向受拉应力较强,因此,在轧制压力的作用下, 面平行于板面且c轴平行于轧向的晶粒更容易发生拉伸孪 生[7],从而诱发再结晶而更快地转变为基面织构。c轴垂直于轧向的晶粒由于沿c轴方向所受拉应力较弱,应变较小,发生孪生的几率也更低,转变为基面织构的速度就慢。因此,在总变形量一定的条件下,更多地保留了

面平行于板面且c轴平行于轧向的晶粒更容易发生拉伸孪 生[7],从而诱发再结晶而更快地转变为基面织构。c轴垂直于轧向的晶粒由于沿c轴方向所受拉应力较弱,应变较小,发生孪生的几率也更低,转变为基面织构的速度就慢。因此,在总变形量一定的条件下,更多地保留了 面平行于板面、c轴垂直于轧向的织构组分。

面平行于板面、c轴垂直于轧向的织构组分。

图5 450 ℃条件下变形40%的样品在450 ℃盐浴中退火不同时间的金相组织

Fig.5 OM images of samples hot rolled by strain of 40% and then annealed at 450 ℃ for different time in salt bath furnace: (a) 1 min; (b) 3 min; (c) 5 min

图6 变形40%的样品在450 ℃盐浴中退火不同时间的(0002)极图和 极图

极图

Fig.6 (0002) and  pole figures of samples rolled by strain of 40% and then annealed at 450 ℃ for different times in salt bath furnace: (a) 1 min; (b) 3 min; (c) 5 min

pole figures of samples rolled by strain of 40% and then annealed at 450 ℃ for different times in salt bath furnace: (a) 1 min; (b) 3 min; (c) 5 min

3 结论

1) Mg-7Gd-4Y-1Nd-0.5Zr合金在450 ℃条件下轧制变形至80%时的织构组分包括基面织构和 棱柱面织构。

棱柱面织构。

2) 450 ℃轧制时棱柱面滑移系启动协调晶粒的塑性变形形成棱柱面织构。

3) 部分晶粒在变形过程中先形成具有棱柱面织构取向的晶粒,随后通过孪生及在孪生区域发生的静态再结晶逐渐转变为基面织构。

REFERENCES

[1] ASM International. Magnesium and magnesium alloy[M]. OH: Metal Park, 1999.

[2] POLMEAR I J. Magnesium alloys and application[J]. Materials Science and Technology, 1994, 10(1): 1-14.

[3] AGNEW S R, YOO M H, TOM C N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y[J]. Acta Materialia, 2001, 49(20): 4277-4289.

[4] P?REZ-PRADO M T, DEL VALLE J A, RUANO O A. Effect of sheet thickness on the microstructural evolution of an Mg AZ61 alloy during large strain hot rolling[J]. Scripta Materialia, 2004, 50(5): 667-671.

[5] WANG Y N, HUANG J C. Texture analysis in hexagonal materials[J]. Materials Chemistry and Physics, 2003, 81(1): 11-26.

[6] P?REZ-PRADO M T, del VALLE J A, CONTRERAS J M, RUANO O A. Microstructural evolution during large strain hot rolling of an AM60 Mg alloy[J]. Scripta Materialia, 2004, 50(5): 661-665.

[7] JIANG L, JONAS J J, MISHRA R K, LUO A A, SACHDEV A K, GODET S. Twinning and texture development in two Mg alloys subjected to loading along three different strain paths[J]. Acta Materialia, 2007, 55(11): 3899-3910.

[8] JIN Q L, SHIM S Y, LIM S G. Correlation of microstructural evolution and formation of basal texture in a coarse grained Mg-Al alloy during hot rolling[J]. Scripta Materialia, 2006, 55(9): 843-846.

[9] AL-SAMMAN T, GOTTSTEIN G. Dynamic recrystallization during high temperature deformation of magnesium[J]. Mater Sci Eng A, 2008, 490(1/2): 411-420.

[10] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

[11] 彭卓凯, 张新明, 陈健美, 肖 阳, 蒋 浩, 邓桢桢. Mn, Zr 对 Mg-Gd-Y 合金组织与力学性能的影响[J]. 中国有色金属学报, 2005, 15(6): 917-922.

PENG Zhuo-kai, ZHANG Xin-ming, CHEN Jian-mei, XIAO Yang, JIANG Hao, DENG Zhen-zhen. Effects of Mn, Zr on microstructure and properties of Mg-Gd-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 917-922.

[12] 肖 阳, 张新明, 陈健美, 蒋 浩, 邓桢桢. 高强耐热 Mg-9Gd-4Y-0.6Zr 合金的性能[J]. 中南大学学报: 自然科学版, 2006, 37(5): 850-855.

XIAO Yang, ZHANG Xin-ming, CHEN Jian-mei, JIANG Hao, DENG Zhen-zhen. Performance of Mg-9Gd-4Y-0.6Zr alloy with high strength and heat resistance[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 850-855.

[13] 张新明, 肖 阳, 陈健美, 蒋 浩. 挤压温度对 Mg-9Gd-4Y-0.6Zr 合金组织与力学性能的影响[J]. 中国有色金属学报, 2006, 16(3): 518-523.

ZHANG Xin-ming, XIAO Yang, CHEN Jian-mei, JIANG Hao. Influence of extrusion temperature on microstructures and mechanical properties of Mg-9Gd-4Y-0.6Zr alloy[J]. The Chinese Journal of Nonferrous Metal, 16(3): 518-523.

[14] PENG Z K, ZHANG X M, CHEN J M, XIAO Y, JIANG H. Grain refining mechanism in Mg-9Gd-4Y alloys by zirconium[J]. Materials Science and Technology, 2005, 21(6): 722-726.

[15] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 51.

CHEN Zhen-hua. Wrought magnesium alloy[M]. Beijing: Chemical Industry Press, 2005: 51.

(编辑 何学锋)

基金项目:国防预研基金资助项目(51312010505);军品配套研制项目(JPPT-115-2-949)

收稿日期:2009-09-13;修订日期:2009-12-20

通信作者:张新明,教授, 博士;电话:0731-88830265;E-mail: tcpswnu@163.com