预时效对汽车用2000系铝合金板材性能的影响

王孟君1, 2,任 杰1,黄电源1,姜海涛1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 湖南大学 汽车车身先进设计制造国家重点实验室,湖南 长沙,410082 )

摘 要:通过单向拉伸实验、DSC热分析及TEM观察,研究预时效处理对汽车用2036铝合金板材的力学性能、成形性及显微组织的影响。研究结果表明:经180 ℃/20 min的预时效处理后,合金发生软化,合金的屈服强度先降低,之后逐渐回升。在预时效为10 min时达到最低值202.3 MPa,而此时伸长率和应变硬化指数达到最高,分别为25.5%和0.26,这能有效地改善汽车板材的冲压成形性能;在T4P的预时效初期,GP区发生溶解,形成少量的θ″相核心,抑制随后自然时效的硬化效果;增加预时效时间能使材料产生θ″强化相,而在烤漆过程中形成更多的θ″强化相;与汽车用6000系铝合金相比,2036铝合金的烤漆强化效果较低,冲压前的屈服强度较高,板材的成形难度加大。

关键词:2036铝合金;汽车板;预时效;性能;微观组织;烤漆硬化

中图分类号:TG146.2 文献标识码:A 文章编号:1672-7207(2008)04-0755-05

Effect of pre-aging on properties of 2000 series aluminum alloy for

automotive body sheets

WANG Meng-jun1, 2, REN Jie1, HUANG Dian-yuan1, JIANG Hai-tao1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of Advanced Design and Manufacture for Vehicle Body, Hunan University,

Changsha 410082, China)

Abstract: The effects of pre-aging treatment on the tensile properties, formability and microstructures of 2036 aluminum alloy for automobile body sheets were investigated using the tensile tests, DSC analysis and TEM observation. The results show that the alloy is softened, which is pre-aged at 180 ℃ within 20 min and then natural aging, namely T4P. However, the yield strength decreases first and then rises. The yield strength of the alloy after T4P(10 min) reaches the minimal value 202.3 MPa, but the elongation and strain hardening exponent arrive at the maximum, 25.5% and 0.26 respectively, which can improve its formability effectively. In the early stage of T4P, GP zones dissolve, and generate some θ″ nuclei, so the strengthening effect is restrained during the natural aging following the pre-aging, which causes the decrease of the strength. With the increment of pre-aging time, the θ″ phases are formed. The number of the θ″ phases grows, and the strength increases sharply during the paint-bake treatment. In contrast with the 6000 series aluminum alloy for automobile body sheets, the paint-bake strengthening ability of the 2036 alloy is low and its yield strength before the paint bake is accordingly high, which will add to the difficulty of forming the sheets.

Key words: 2036 aluminum alloy; automobile body sheets; pre-aging; property; microstructure; paint-bake hardenability

为降低汽车的燃油消耗,世界各国都在研究汽车的轻量化问题,而铝合金作为一种轻合金材料正在不断地应用于汽车的设计和开发中[1-2]。

作为汽车车身用铝合金板,不仅要求材料本身具有较高的强度,较强的冲压成形性、抗蚀性等,更要求材料在涂漆后的烘烤期间能产生一定的强化作 用[3-4]。2000系铝合金作为一种热处理可强化合 金,具有较好的时效强化功能,日本和欧美等国[2]都在研究和开发适合汽车车身板要求的新型2000系铝合金,如AA2008和AA2010铝合金。有研究表明[5],短时预时效能有效地改变热处理可强化合金的析出特性,对材料的综合性能产生较大的影响。贺自强等[6]研究了短时加热对2A50-T6铝合金显微组织的影响发现,短时加热温度较低时,铝合金的显微组织基本不变;温度较高时,在基体上可见细小弥散的第2相,且晶界粗糙,而沿晶界有粗大的第2相析出。在此,本文作者通过不同的短时预时效工艺,研究预时效对汽车用2000系铝合金板材的力学性能、成形性能及显微组织的影响,以便为开发强度和成形性能更优异的汽车用2000系铝合金板材提供理论依据。

1 实验材料与方法

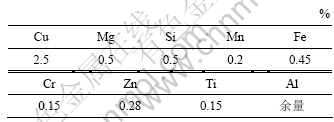

本实验采用厚度为1.2 mm的2036铝合金轧制板材,其化学成分如表1所示。此板材的生产工艺流程为:熔炼→铸造→锯切→铣面→均匀化(480 ℃,10 h)→热轧(5.0 mm)→中间退火(390 ℃,2 h)→冷轧(1.2 mm)。将冷轧后的试样在500 ℃保温1 h后水淬[7],然后,在180 ℃分别进行5,10,20和30 min的短时预时效,在室温停留10 d以进行自然时效(T4P态),最后,将试样在175 ℃保温30 min,以模拟汽车板材烤漆过程。

表1 2036铝合金化学成分

Table 1 Chemical compositions of 2036 aluminum alloy %

试样的室温强度和应变硬化指数测定分别按照GB/T 6397―1986标准和GB/T 5027―1999标准在CSS-44100型电子万能试验机上进行,拉伸速度为2 mm/min。用DUPONT9900差热分析仪对时效态试样进行热分析实验。透射电镜实验是先用机械方法将厚度为1.2 mm的板材减薄成厚度为0.1 mm的薄片,然后,在MIT-Ⅱ型双喷减薄机上用30%硝酸甲醇溶液进行双喷减薄,采用液氮冷却至-20 ℃,最后,在H-800型电子显微镜上进行TEM组织观察。

2 实验结果

2.1 示差扫描量热仪(DSC)分析

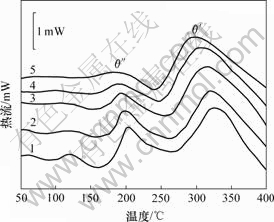

合金在固溶处理后,直接在室温停放10 d(T4态)以及在180 ℃分别进行5,10,20和30 min的短时预时效处理,再在室温停放10 d(T4P态)的DSC热分析结果如图1所示。从图1可以看出明显的θ″相和θ′相的析出峰,同时,随着预时效时间的增加,θ″相的析出峰越来越平直,并且峰值点逐渐向低温方向移动。

1—T4态; 2—5 min; 3—10 min; 4—20 min; 5—30 min

图1 预时效时间不同时T4P态的DSC曲线

Fig.1 DSC curves of alloy after T4P treatments for

different time

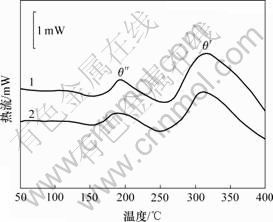

图2所示为合金预时效10 min的T4P态DSC分析曲线与预时效10 min的T4P态+175 ℃/30 min的模拟烤漆处理后的DSC分析曲线对比。从图2可以看出,经过T4P+模拟烤漆后的DSC曲线比T4P态的平直,θ″相和θ′相的析出峰也较多地向低温方向偏移。

1—T4P态(10 min); 2—T4P态(10 min)+175 ℃/30 min

图2 T4P态与T4P态+175 ℃/30 min的DSC曲线

Fig.2 DSC curves of alloy with T4P treatment and after T4P (10 min) and then isothermal aging at 175 ℃ for 30 min

2.2 合金短时预时效后的力学性能及成形性

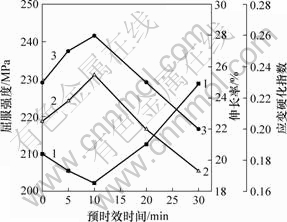

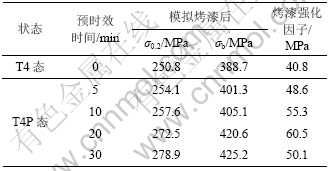

2036铝合金经过不同预时效时间处理后的T4P态屈服强度、伸长率和应变硬化指数变化如图3所示,而合金经过模拟烤漆处理后的屈服强度σ0.2、抗拉强度σb和烤漆强化因子(PBR)如表2所示。

1—屈服强度;2—伸长率;3—应变硬化指数

图3 不同预时效时间的T4P态合金屈服强度、伸长率和

应变硬化指数的变化曲线

Fig.3 Variable curves of yield strength, elongation and

strain hardening exponent with T4P treatment for

different pre-aging time

表2 模拟烤漆后合金的力学性能和烤漆强化因子

Table 2 Mechanical properties and PBR values of alloy after paint-bake treatment for different pre-aging time

由图3可知,2036合金的屈服强度随着预时效时间的延长,先降低后升高,而伸长率和应变硬化指数则先升高后降低。当预时效时间为10 min时,合金的屈服强度下降到最低值202.3 MPa,而伸长率和应变硬化指数分别达到最大值,分别为25.5%和0.26;当预时效超过10 min时, 合金屈服强度逐渐升高,而伸长率和应变硬化指数下降;当预时效时间达到20 min时,合金的屈服强度才略高于T4态的屈服强度。而2036合金经过模拟烤漆后,材料的屈服强度和抗拉强度大幅度提高,烤漆强化因子在预时效20 min时达到最大(如表2所示)。

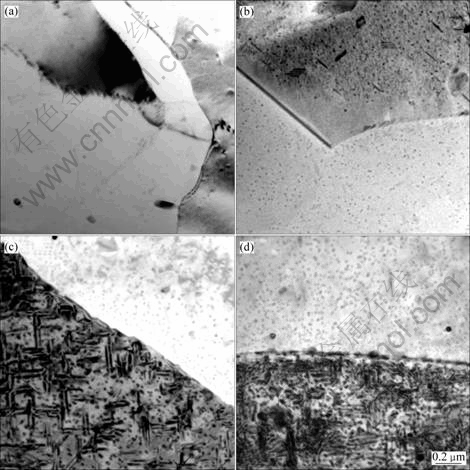

2.3 合金短时预时效后的显微组织

图4所示为T4态和不同预时效时间的T4P态显微组织照片。与T4态相比,预时效5 min的T4P态的合金有粒子析出,产生一定量的θ″相核心。而预时效20 min的T4P态合金则出现明显的θ″强化相,但数量不多。当合金经20 min的预时效T4P+模拟烤漆(175 ℃,30 min)处理后,θ″相的数量迅速增长,如图4(d)所示。

(a) T4态;(b) 180 ℃,5 min;(c) 180℃,20 min;(d) 180 ℃,20 min+模拟烤漆(175 ℃,30 min)

图4 不同预时效时间后合金的显微组织

Fig.4 Microstructures of alloy after different pre-aping time

3 分析与讨论

3.1 预时效对板材力学性能和成形性的影响

2036铝合金属于Al-Cu-Mg系列,其中Cu含量大于2%(质量分数),Mg含量小于0.8%,因此,合金中主要是α(Al)+θ两相共晶体,其沉淀相的析出顺序为:α(过饱和固溶体)→GP区→θ″→θ′→θ(Al2Cu),其中GP区和θ″相与基体完全共格,θ′平衡相与基体半共格,这3种相在合金中起主要强化作用,而θ相与基体非共格,其强化作用小[8-10]。所以,在预时效过程中,材料性能的变化主要取决于GP区、θ″相和θ′相的析出情况。

DSC作为研究热处理可强化铝合金时效析出行为的一种方法,与材料的微观分析手段相结合,就能对合金GP区、θ″相、θ′相和θ相的析出和溶解进行动态研究和分析[8, 11]。由图1和图3可以看出,预时效造成部分GP区溶解,成为形成θ″相核心的有利位置,且GP区的溶解比θ″相核心的形成速度快,而形成的θ″相核心造成了过饱和固溶体中溶质分布不均匀, 增加了合金内部的高密度位错组织,同时,降低了基体中非θ″相核心处溶质的过饱和度。高密度的位错组织对淬火空位容易产生吸附,使合金的淬火空位浓度降 低[12]。而GP区一般被认为是通过合金内部的过剩空位扩散形成的[13-15],因此,预时效造成的空位相对贫乏使得在随后的自然时效过程中GP区的形成受到抑制,从而降低自然时效的硬化功能,合金的屈服强度比T4态的低,而伸长率和应变硬化指数比T4态的高,其抗局部颈缩失稳能力增强,合金变形更加均匀,合金的成形极限提高。

对于T4P态的合金,随着预时效时间的延长,合金内的θ″相核心的形成速度加快,并且θ″相核心逐渐长大,开始生成一定量的θ″强化相,从而,材料强度上升。

3.2 预时效对板材烤漆性能的影响

对比板材烤漆前与烤漆后的DSC曲线可以发现(如图2所示),在175 ℃/30 min烤漆后的θ″相的放热峰比烤漆前的平直,并向左偏移,这表明在预时效阶段产生的θ″相核心在随后的自然时效过程中逐渐地发生聚合长大,从而在烤漆过程中更快地形成θ″强化相,如图4(c)和4(d)所示,所以,合金在烤漆后强度大幅度上升(如表2所示),产生烤漆强化效应。

对于材料的烤漆强化效应,本文引入一个烤漆强化因子(PBR)[16],即烤漆后的材料屈服强度减去烤漆前的屈服强度。从表2可以看到,2036合金在经短时预时效处理后的PBR并不高,只有60 MPa左右。有资料表明[13, 16],汽车用6000系铝合金的PBR可以达到110 MPa,并且6000系铝合金烤漆前的屈服强度较2000系的低,因此,2000系铝合金在烤漆前的冲压成形过程中将需要更大的载荷,成形难度进一步增大。

4 结 论

a. 2036铝合金在预时效10 min的T4P态屈服强度达到最低值202.3 MPa,而伸长率和应变硬化指数达到最高,分别为25.5%和0.26,其性能比T4态的优,能有效地改善汽车板材的冲压成形性能。

b. 短时预时效加速了GP区溶解,形成θ″相核心,抑制随后自然时效的硬化效果,使得强度下降。增加预时效时间使合金产生一定量的θ″强化相,强度有所提高;在随后的模拟烤漆过程中,形成更多的θ″强化相,材料强度又进一步上升。

c. 与汽车用6000系铝合金相比,2036铝合金的烤漆强化效果较低,冲压成形前的屈服强度较高,板材成形难度加大。

参考文献:

[1] Miller W S, Zhuang L, Bottema J. Recent development in aluminium alloys for the automotive industry[J]. Materials Science and Engineering A, 2000, 280(3): 37-49.

[2] 王孟君, 黄电源, 姜海涛. 汽车用铝合金的研究进展[J]. 金属热处理, 2006, 31(9): 35-39.

WANG Meng-jun, HUANG Dian-yuan, JIANG Hai-tao. Research progress of aluminium alloys for the automotive industry[J]. Heat Treatment of Metals, 2006, 31(9): 35-39.

[3] 曾 渝, 尹志民. 超高强铝合金的研究现状及发展趋势[J]. 中南工业大学学报: 自然科学版, 2002, 33(6): 592-596.

ZENG Yu, YIN Zhi-min. Present research and developing trends of ultra high strength aluminum alloys[J]. Journal of Central South University of Technology: Natural Science, 2002, 33(6): 592-596.

[4] 田荣璋, 王祝堂. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000: 186-221.

TIAN Rong-zhang, WANG Zhu-tang. Aluminium alloy and their treating handbook[M]. Changsha: Central South University Press, 2000: 186-221.

[5] 李松瑞, 周善初. 金属热处理[M]. 长沙: 中南大学出版社, 2003: 228.

LI Song-rui, ZHOU Shan-chu. Metal heat treatment[M]. Changsha: Central South University Press, 2003: 228.

[6] 贺自强, 王新林. 短时加热对2A50铝合金显微组织和性能的影响[J]. 金属热处理, 2004, 29(12): 10-13.

HE Zi-qiang, WANG Xin-lin. Effects of short time heating on microstructure and properties of 2A50 aluminum alloy[J]. Heat Treatment of Metals, 2004, 29(12): 10-13.

[7] 曾苏民. 影响铝合金固溶保温时间的多因素相关规律[J]. 中国有色金属学报, 1999, 9(1): 79-86.

ZENG Su-min. Disciplines of multiple factors affect in solution treating of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 79-86.

[8] 李 伟, 龙剑平, 沈保罗, 等. Al-3.5Cu和Mullite/Al-3.5Cu复合材料的时效析出行为[J]. 金属热处理, 2001, 26(10): 9-11.

LI Wei, LONG Jian-ping, SHEN Bao-luo, et al. Age- precipitation behavior of Al-3.5Cu alloy and Mullite/Al-3.5Cu composite[J]. Heat Treatment of Metals, 2001, 26(10): 9-11.

[9] Abis S, Mengucci P. A study of ageing in an AlCuMgZn foundry alloy[J]. Materials Science and Engineering A, 1996, 214(1/2): 153-160.

[10] 刘 瑛, 张新明. 预变形量对2519铝合金抗晶间腐蚀性能的影响[J]. 中国有色金属学报, 2006, 16(9): 1545-1550.

LIU Ying, ZHANG Xin-ming. Effect of degree of predeformation on corrosion resistance of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1545-1550.

[11] Zhen L, Kang S B. DSC analyses of the precipitation behavior of two Al-Mg-Si alloys naturally aged for different times[J]. Mater Lett, 1998, 37(6): 349-353.

[12] Nagai Y, Murayama M. Role of vacancy-solute complex in the initial rapid age hardening in Al-Cu-Mg alloy[J]. Acta Mater, 2001, 49(5): 913-920.

[13] Burger G B, Gupta A K. Microstructural control of aluminum sheet used in automotive application[J]. Materials Characterization, 1995, 35(1): 23-29.

[14] Wolverton C. Crystal structure and stability of complex precipitate phases in Al-Cu-Mg-(Si) and Al-Zn-Mg[J]. Acta Mater, 2001, 49(16): 3129-3142.

[15] Ovono D, Guillot I. Determination of the activation energy in a cast aluminium alloy by TEM and DSC[J]. Journal of Alloys and Compounds, 2007, 432(1/2): 241-246.

[16] Birol Y. Pre-aging to improve bake hardening in a twin-roll cast Al-Mg-Si alloy[J]. Materials Science and Engineering A, 2005, 391(1/2): 175-180.

收稿日期:2007-06-27;修回日期:2007-09-01

基金项目:汽车车身先进设计制造国家重点实验室开放基金资助项目(2005-12)

通信作者:王孟君(1965-),男,湖南长沙人,博士,教授,从事有色金属成形理论和技术的研究;电话:0731-8836408;E-mail: wmj1965@yahoo.com.cn