喷射成形70Si30Al合金在加热保温过程中显微组织的演变规律

魏衍广, 熊柏青, 张永安, 刘红伟, 朱宝宏, 王 锋

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室, 北京 100088)

摘 要: 利用喷射成形技术制备了70Si30Al合金新型电子封装材料, 研究了沉积态合金的显微组织及其随温度变化的规律。 结果表明: 沉积态70Si30Al合金显微组织细小, 初生硅相为不规则的块状, 均匀弥散分布, 初生硅相之间主要是过饱和α(Al)相和铝硅伪共晶相; 70Si30Al合金在620℃以下保温90min, 初生硅相没有明显长大, 但随着温度的升高出现球化现象, 过饱和α(Al)相没有显著变化, 铝硅伪共晶相在566~582℃之间熔化, 随着温度的升高, 熔化相增多并互相凝聚在一起; 合适的喷射成形70Si30Al合金热加工变形温度为560~590℃。

关键词: 70Si30Al合金; 封装材料; 喷射成形; 显微组织演变 中图分类号: TG132.1+1

文献标识码: A

Microstructure variation of spray formed 70Si30Al alloy during heating procedure

WEI Yan-guang, XIONG Bai-qing, ZHANG Yong-an, LIU Hong-wei,

ZHU Bao-hong, WANG Feng

(State Key Laboratory for Fabrication and Processing of Nonferrous Metals,

Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: A novel 70Si30Al alloy was prepared by spray forming process for electronic packaging material. Microstructure variation of as-deposited preforms during heating procedure was studied. The results show that the microstructure is fine and homogenous, the primary silicon phases distributing in the alloy evenly are fine and irregular, and most of the phases that disperse between the primary silicon phases are supersaturated α(Al) and Al-Si Pseudo-eutectic phases. When the alloy is held under 620℃ for 90min, the primary silicon phases do not increase obviously and have spheroidized phenomenon with temperature increasing. The supersaturated α(Al)phases do not change significantly during heating procedure. The Al-Si pseudo-eutectic phases remelt in the temperature range from 566℃ to 582℃, and the mass of remelting phases increase with temperature increasing and they conglomerate together. The range of hot deformation temperature of spray formed 70Si30Al alloy is from 560℃ to 590℃.

Key words: 70Si30Al alloy; packaging material; spray forming; microstructure variation

喷射成形硅铝合金(Al-50%Si~Al-70%Si)作为新一代电子封装材料具有卓越的性能[1-6]: 热膨胀系数(6.8×10-6~11×10-6/K)与芯片(GaAs或Si)的热膨胀系数匹配; 导热率高(120~149W/(m·K)), 能够把芯片工作时产生的热量及时地传导出去; 密度小(2.42~2.51g/cm3), 能够满足航空航天设备和移动计算/通讯设备轻量化的要求。 此外, 该材料具有足够的强度和刚度, 能够用传统工艺方法进行机械加工和涂镀。 因此, 硅铝合金电子封装材料近几年在国内外的研究开发十分活跃。 日本住友电气公司用传统的粉末冶金法生产Al-40%Si(质量分数)材料[7], 英国Osprey金属公司用喷射成形法生产出Si-Al系列合金[8, 9](Al- 27%Si、 Al- 42%Si、 Al- 50%Si、 Al- 60%Si、 Al- 70%S i), 现在已经批量生产, 在高频电路载波器、 信号放大器等方面获得了应用。 国内的一些单位采用喷射成形法或粉末冶金法制备出Si-Al合金(Al- 50%Si、 Al- 60%Si、 Al- 70%Si)[10-13]。

喷射成形制备70Si30Al合金, 组织均匀, 初生硅细小弥散, 但是, 由于喷射成形技术特点, 喷射成形70Si30Al合金的致密度在95%~98%之间[14], 因此在材料使用前必须通过热变形加工工艺使材料致密化。 本文作者对该材料在加热保温过程中显微组织的变化规律进行研究, 探索合理的热变形加工致密化工艺参数,以便更好地控制组织转变过程, 降低硅相的粗化速度, 最大限度地保留喷射成形硅铝合金的快速凝固组织。

1 实验

实验所用的原料选用工业纯铝和工业纯硅, 配制合金为(质量分数)70%Si和30%Al, 喷射成形实验是在北京有色金属研究总院和锦州市冶金技术研究所联合研制的高真空高温喷射成形设备中进行, 采用双层非限制式气流雾化喷嘴, 雾化气体为高纯氮气, 斜喷角为30°~40°, 偏心距为20~30mm, 接收距离为 500~700mm, 雾化气体压力在0.45~0.6MPa范围内变化, 导流管直径在3.8~4.5mm范围内变化。

喷射成形沉积坯件加热温度为: 420、 540、 580、 585、 590、 610、 620和630℃, 保温时间为90min, 水淬。 显微组织的观察在NEOPHOT-2型光学显微镜和CAMBRIDGE-2型扫描电镜上进行, DSC的测试在NETZSCH STA 409C上进行, 密度的测量采用排水法。

2 结果与讨论

2.1 喷射成形显微组织的分析

图1所示为喷射成形70Si30Al合金沉积态的显微组织。 由图可知, 喷射成形制备70Si30Al合金组织细小, 初生硅相为不规则的块状, 尺寸在20~40μm之间, 均匀弥散地分布在Al基体中, 材料中有小尺寸的疏松和孔洞, 沉积坯件不同部位的致密在96.2%~97.6%之间变化。

图1 70Si30Al合金沉积态的显微组织

Fig.1 Microstructure of as-deposited 70Si30Al alloy

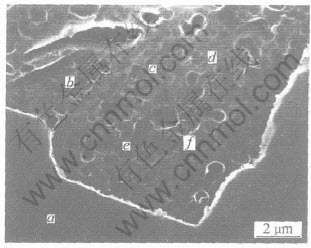

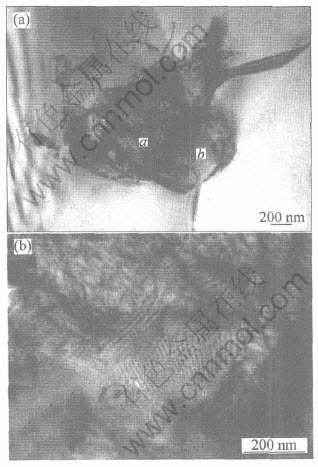

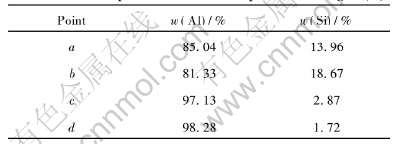

图2所示为70Si30Al合金沉积态的SEM照片。 对初生硅相和初生硅相之间的物质进行成分能谱分析, 得到各微小区域内的成分, 如表1所列。 由图2及其对应的各点成分可以判断, a点为初生硅相的过饱和固溶体。 由b点、 c点和e点以及d点和f点可知, 根据硅含量的不同可以把铝基体分为两类: 一类是硅含量较低的铝基体(Si含量在1.43%~5.77%之间), 根据铝硅合金相图[15]可知, 这种铝基体是α(Al)相和过饱和α(Al)相; 另一类是硅含量较高的铝基体(Si含量在12.57%~19.55%之间), 根据铝硅合金相图可知, 这种铝基体可能是铝硅伪共晶相和铝硅共晶相。 但是由于这两类铝基体非常细小, 在图2中无法把它们分辨清楚。

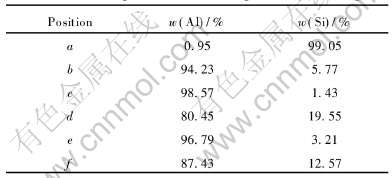

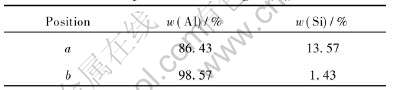

图3所示为喷射成形70Si30Al合金的TEM照片。 从图3(a)中可以清楚地分辨出α-Al相和共[CM(22]晶相, 二者的成分分析如表2所列。 由图3(a)可以

图2 70Si30Al合金沉积态的SEM照片

Fig.2 SEM photograph of as-deposited 70Si30Al alloy

表1 图2中6个点的成分

Table 1 Compositions of six positions in Fig.2

图3 喷射成形70Si30Al合金沉积态的TEM照片

Fig.3 TEM photographs of as-deposited 70Si30Al alloy

看出, 区域a为层片状的共晶组织, 区域b为α(Al)相。 图3(b)所示是区域a的放大图, 可以清楚地观察到共晶相为层片状组织。 因此可以确定, 铝基体分两类: 硅含量较低的过饱和α(Al)相和α(Al)相以及硅含量较高的铝硅伪共晶相和铝硅共晶相。

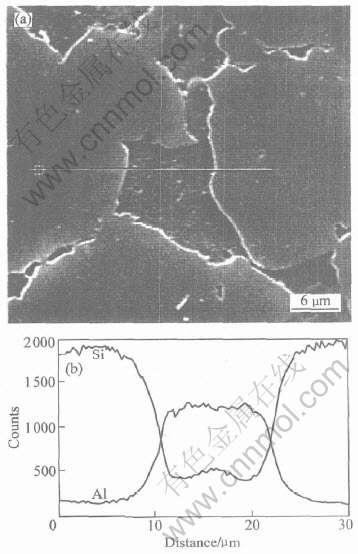

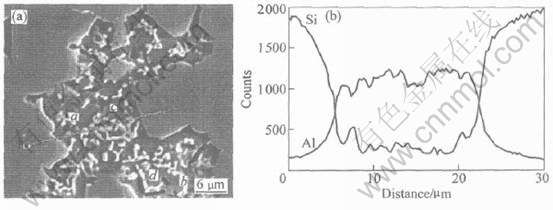

图4所示为70Si30Al合金线扫描图。 由图可见, 初生硅相与铝基体之间有一个厚度约为4~6μm界面层。 在界面层中, 当硅含量下降的同时, 铝含量上升, 反之亦然。 除了界面层, 铝基体内的硅含量和铝含量的变化基本保持稳定。

2.2 显微组织随温度变化的演变规律

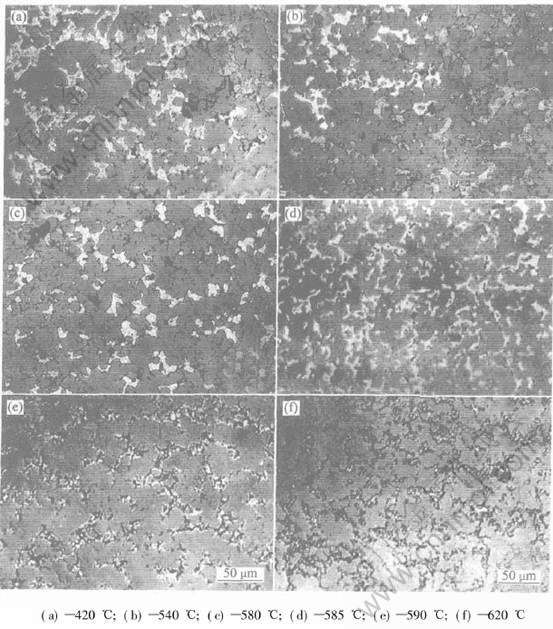

图5所示为70Si30Al合金分别在420、 540、580、 585、 590和620℃保温90min的显微组织。

表2 图3(a)中2个点的成分

Table 2 Compositions of two positions in Fig.3(a)

图4 70Si30Al合金沉积态的SEM照片

Fig.4 SEM photograph(a) and linear scanning graph (b) of as-deposited 70Si30Al alloy

由图可见, 70Si30Al合金在620℃及以下温度保温90min时, 初生硅相没有显著的长大现象, 但由于初生硅相边界处的能量较高, 在高温下原子活动剧烈, 扩散容易进行, 初生硅边界变得圆滑, 随着温度的升高, 初生硅相有球化现象。 在620℃保温90min时, 初生硅相球化现象比较显著, 如图5(f)所示。

图5 在不同温度保温90min后70Al30Si合金的显微组织

Fig.5 Microstructures of spray formed 70Si30Al alloy kept at different temperatures for 90min

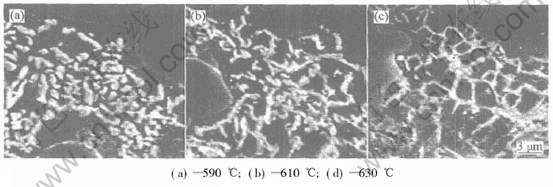

由图5可知, 70Si30Al合金在590℃保温90min时, 初生硅相之间的铝基体内有熔化相。 图6所示为70Si30Al合金分别在590、 610和630℃保温90min的SEM照片。 由图可见, 在590℃及以上温度保温90min时, 铝基体内有熔化相, 随着温度的升高, 熔化相增多, 而且熔化相之间开始互相连接, 在630℃时熔化相互相连接在一起, 在某些部位凝聚成团块状。

图7所示为70Si30Al合金在590℃保温90min的线扫描图。 表3所列为图7(a)所示铝基体内4个点的成分。 同图4比较, 初生硅相与铝基体之间的界面层厚度约为5~7μm, 界面层厚度的增加是由于两相间硅原子和铝原子的扩散造成的, 铝基体内的硅含量和铝含量的变化不再保持稳定, 有熔化相的部位硅含量升高。 由表中a点和b点可知, 熔化相中的Si含量在13.96%~18.67%之间, 熔化相为铝硅共晶相和铝硅伪共晶相; 由表中c点和d点可知, α(Al)相中Si含量在1.72%~2.97%之间, 未熔化相为α(Al)相和过饱和α(Al)相。

图8所示为喷射成形70Si30Al合金和金属模铸造70Si30Al合金的差示扫描量热分析图(DSC)。 由图可知, 沉积态70Si30Al合金在566~582℃之间有吸热反应, 铸态70Si30Al合金在575~596℃之间有吸热反应。 由铝硅合金相图可知铝硅共晶相的熔点为576.5℃, 而金属模铸造得到的70Si30Al合金在575℃有熔化相出现, 可知熔化相是铝硅共晶相。 但是, 喷射成形70Si30Al合金在566℃时就开始有熔化相, 这说明材料内有铝硅伪共晶相的存在, 伪共晶相是非平衡结晶相, 畸变能较高, 使得材料处于不稳定的高能态, 当合金加热到566℃时, 热能和畸变能的总和足以使得铝硅伪共晶相熔化。

表3 图7(a)中4个点的成分

Table 3 Compositions of four points in Fig.7(a)

图6 70Si30Al合金的SEM照片

Fig.6 SEM photographs of 70Si30Al alloy at different temperatures

图7 70Si30Al合金在590℃的SEM照片(a)和线扫描图(b)

Fig.7 SEM photograph (a) and liner scanning graph (b) of 70Si30Al alloy at 590℃

图8 喷射成形70Si30Al合金和铸态70Si30Al合金的DSC曲线

Fig.8 DSC curves of spray formed 70Si30Al alloy (a) and molten 70Si30Al alloy (b)

综上所述, 初生硅相之间主要是过饱和α(Al)相与铝硅伪共晶相。 沉积坯的这些组织特点是由喷射成形70Si30Al合金复杂的凝固过程决定的。 在喷射成形70Si30Al合金过程中, 由于可控参数众多, 各个雾化液滴的冷却速率是不同的, 从而造成了凝固组织成分构成的不同, 但是, 喷射成形过程中快速凝固冷却特征决定了大部分凝固组织处于非平衡结晶状态, 因此, 初生硅相为过饱和固溶体, 铝基体主要是过饱和α(Al)相与铝硅伪共晶相。 在喷射成形70Si30Al合金凝固过程中, 在较高的冷却速率(102~104 K/s)下初生硅相首先开始凝固, 剩余液相中的Si很容易依附在已凝固的初生硅相上结晶, 形成“离异共晶”[16], 这时液相中硅的含量减少, 在较高的冷却速率下结晶成为过饱和α(Al)相与铝硅伪共晶相。

通过对70Si30Al合金在420~620℃之间保温90min后显微组织变化规律的研究, 可知材料在566℃时有熔化相出现, 随着温度的升高, 熔化相增多, 但是由于熔化相比较细小, 在光学显微镜下难以分辨清楚, 直到590℃时, 在显微镜下才能观察到熔化相的存在。 当选择加工温度对材料进行热加工变形时, 在尽可能保留喷射成形70Si30Al合金快速凝固组织的同时, 还应该选择较高的加工温度使材料得到充分的软化及变形, 达到较高的致密度, 遵循这两条原则, 热加工变形温度范围应为560~590℃。

3 结论

1) 利用喷射成形技术制备70Si30Al合金, 沉积态合金显微组织细小, 初生硅相为不规则块状, 均匀弥散分布在Al基体中, 材料中有孔洞和疏松, 沉积坯件不同部位的致密度在96.2%~97.6%之间。

2) 沉积态70Si30Al合金中初生硅相为过饱和固溶体, 铝基体主要为过饱和α(Al)相和铝硅伪共晶相。 在620℃以下保温90min, 过饱和初生硅相没有明显的长大现象, 但是随着温度升高, 初生硅相有球化现象; 过饱和α(Al)相没有显著的变化, 然而铝硅伪共晶在566℃时开始熔化, 随着温度的升高, 熔化相增多, 而且熔化相之间开始互相连接, 在较高的温度下熔化相在局部区域凝聚成团块状。

3) 喷射成形70Si30Al合金热加工变形温度范围可选择为560~590℃, 这样既能保留材料快速凝固组织, 又能使材料得到充分的软化及变形, 达到较高的致密度。

REFERENCES

[1]Sangha S P S, Jacobsom D M, Arun J A, et al. Novel aluminium-silicon alloys for electronics packaging[J]. Engineering Science and Education Journal, 1997, 11: 195-201.

[2]陈美英. 喷射成形新型轻量化电子封装材料Si-Al合金的研究[D]. 北京: 北京科技大学, 2003.

CHEN Mei-ying. Study on Spray-formed Novel and Lightweight Silicon-Aluminum Alloys Used for Electronics Packaging[D]. Beijing: University of Sciences and Technology Beijing, 2003.

[3]张济山. 新型喷射成形轻质、 高导热、 低膨胀Si-Al电子封装材料[J]. 材料导报, 2002, 16(1): 1-4.

ZHANG Ji-shan. Spray formed new type of light weighted Si-Al electronic packaging materials with low thermal expansion and high heat conducting[J]. Mat Rev, 2002, 16(1) : 1-4.

[4]张臣, 沈能钰. 电子封装材料现状与发展[J]. 新材料产业, 2003, 112(3): 5-11.

ZHANG Chen, SHEN Neng-yu. Present state and development of electronic packaging materials[J]. Industrial Forum of Advanced Materials, 2003, 112(3): 5-11.

[5]Jacobson D M, Sangha S P S. Future trends in materials for lightweight microwave packaging[J]. Microelectron Intl, 1998, 15(3): 17-21.

[6]Jacobson D M. Spray-forming silicon-aluminum[J]. Advanced Materials & Process, 2000, 3: 36-39.

[7]杨培勇, 郑子樵, 蔡杨, 等. Si-Al电子封装材料粉末冶金制备工艺研究[J]. 稀有金属, 2004, 28(1): 160-165.

YABG Pei-yong, ZHENG Zi-qiao, CAI Yang, et al. PM process of Si-Al electronic packaging materials[J]. Chinese Journal of Rare Metals, 2004, 28(1): 160-165.

[8]Jacobson D M, Sangha S P S. Novel low expansion packages for electronics[J]. The GEC Journal of Technology, 1997, 14(1): 48-52.

[9]Jacobson D M. Lightweight electronic packaging technology based on spray formed Si-Al[J]. Powder Metallurgy, 2000, 43(3): 200-202.

[10]Chien C W, Lee S L, Lin J C, et al. Effects of sip size and volume fraction on properties of Al/Sip composites[J]. Materials Letters, 2002, 52(4-5): 334-339.

[11]张永安, 刘红伟, 朱宝宏, 等. 新型 60Si40Al合金封装材料的喷射成形制备[J]. 中国有色金属学报, 2004, 14(1): 23-27.

ZHANG Yong-an, LIU Hong-wei, ZHU Bao-hong, et al. Novel 60Si40Al alloy packaging material by spray forming process[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 23-27.

[12]杨滨, 陈美英, 尧军平, 等. 新型电子封装Si-Al合金的基础研究[J]. 南昌航空工业学院学报(自然科学版), 2004, 18(1): 1-4.

YANG Bin, CHEN Mei-ying, YAO Jun-ping, et al. Fundamental study of new Si-Al electronic packaging materials[J]. Journal of Nanchang Institute of Aeronautical Technology(Natural Sciences), 2004, 18(1): 1-4.

[13]王晓峰, 赵九洲, 田冲. 喷射沉积制备新型电子封装材料70%Si-Al的研究[J]. 金属学报, 2005, 41(12): 1277-1279.

WANG Xiao-feng, ZHAO Jiu-zhou, TIAN Chong. Study of novel electronic packaging material 70%Si-Al prepared by the spray deposition[J]. Acta Metallurgica Sinica, 2005, 41(12): 1277-1279.

[14]魏衍广, 熊柏青, 张永安, 等. p/m比值对喷射成形70Si30Al合金沉积坯件的影响[J]. 中国有色金属学报, 2005, 15(11): 16603-1664.

WEI Yan-guang, XIONG Bai-qing, ZHANG Yong-an, et al. Effect of ratio of p/m on performs of spray formed 70Si30Al alloy[J].The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1660-1664.

[15]Mondolfo L F. 铝合金的组织与性能[M]. 王祝堂, 张振录, 郑旋, 等, 译. 北京: 冶金工业出版社, 1988.

Mondolfo L F. Microstructure and Performance of Aluminium Alloys[M]. WANG Zhu-tang, ZHANG Zhen-lu, ZHENG Xuan, et al, transl. Beijing: Metallurgical Industry Press, 1988.

[16]余永宁. 金属学原理[M]. 北京: 冶金工业出版社, 2003.

YU Yong-ning. Theorem of Metal[M]. Beijing: Metallurgical Industry Press, 2003.

(编辑何学锋)

基金项目: 国家重点基础研究发展规划资助项目(G20000672)

收稿日期: 2005-08-22; 修订日期: 2006-01-10

通讯作者: 张永安, 教授, 博士; 电话: 010-82241161-209; E-mail: zhangyongan@grinm.com